Piercing connecting conductor and device for connecting or tapping insulated wire thereof

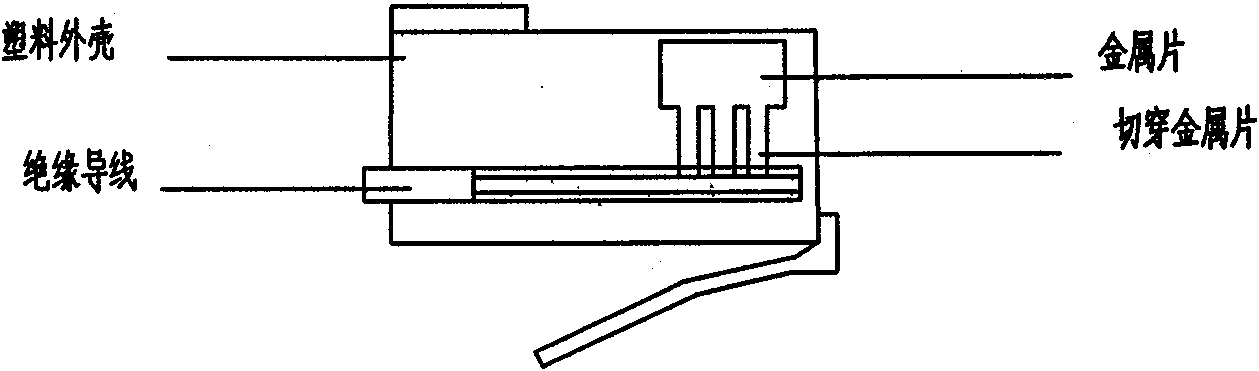

A technology for connecting conductors and insulated wires, which is applied in the directions of needle tip/slotted plate contacts, clamping/spring connections, and tightening/insulating connectors used to penetrate insulated wires/cable core wires. The sawtooth structure of the contact structure has problems such as large resistance, small metal sheet carrying current, which is not conducive to cutting through the insulating layer, etc., to achieve the effect of saving labor and material costs, easy insulation connection and tap work, and reducing the incidence of line faults and electric shock accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

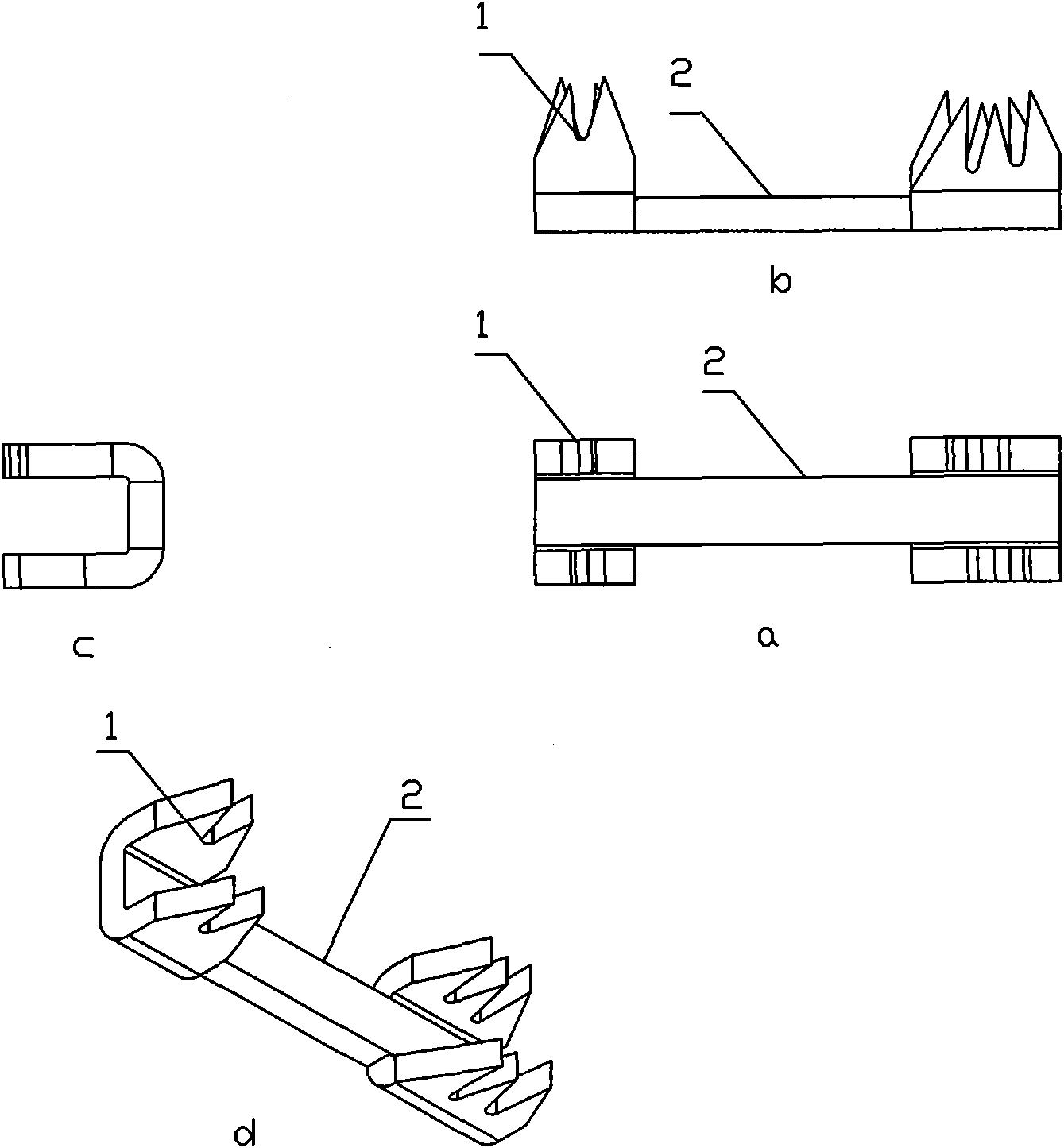

[0039] Such as figure 2 As shown, a piercing connection conductor is provided, wherein the views a, b, c, d are respectively the main view, top view, side view and perspective view, which include the connection conductor 2, and a V-shaped and A W-shaped two piercing contacts 1, the same two piercing contacts are arranged in two parallel rows along the connecting conductor, and a U-shape is formed between the two rows (see view c), of course, more than two rows can also be arranged , such as three rows, four rows, etc.; the piercing contact 1 and the connecting conductor 2 are made of conductive materials, and the connecting conductor 2 and the piercing contact 1 are electrically connected, and the piercing contact 1 can pierce through the Insulation layer of insulated wires to realize the connection or tap of insulated wires.

[0040] As another example, it can be seen from view b that the two rows of piercing contacts are asymmetrical and staggered, so that the staggered ar...

Embodiment 2

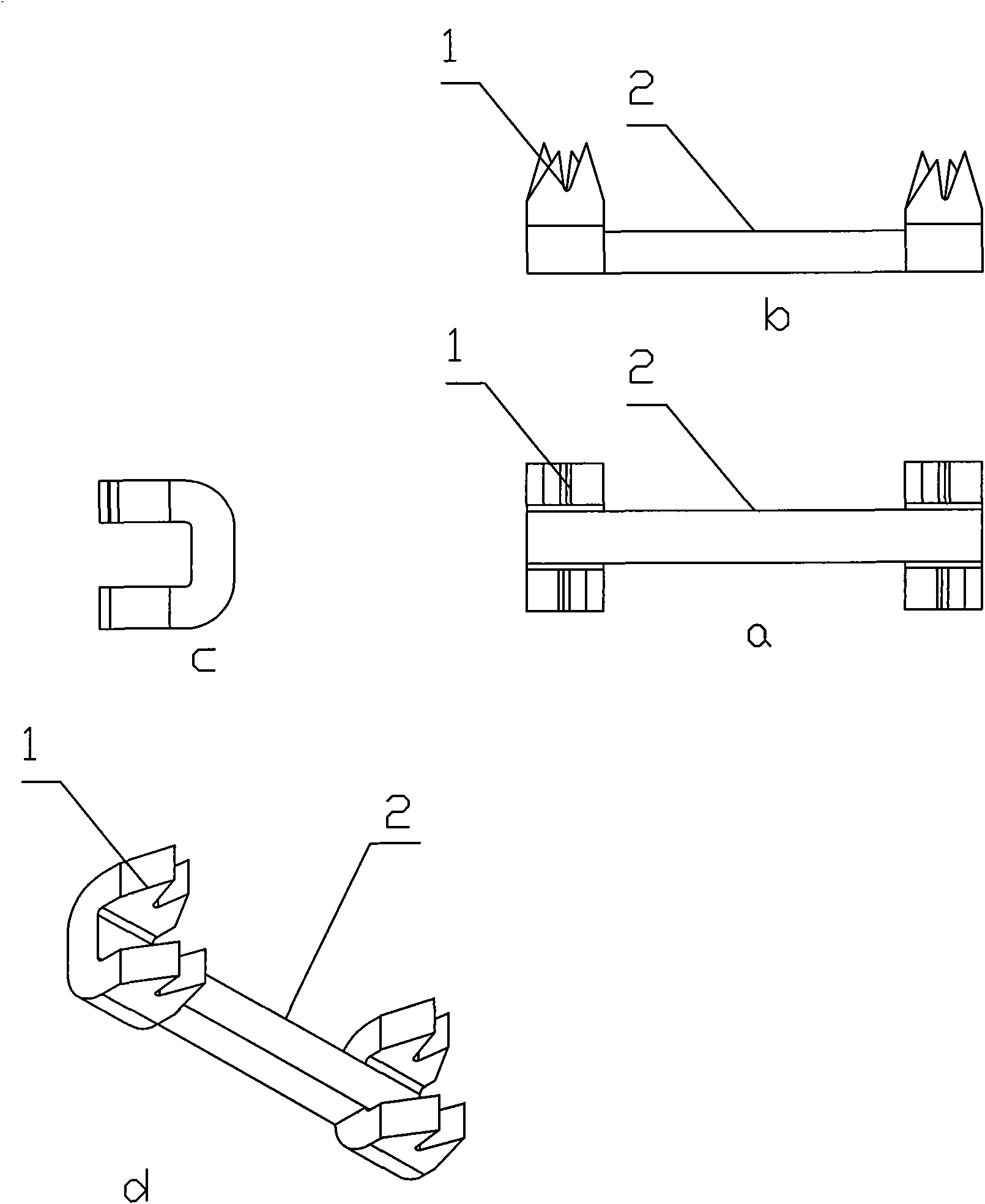

[0042] Such as image 3 As shown, a piercing connection conductor is provided, wherein the views a, b, c, d are respectively the main view, top view, side view and perspective view, and the difference from embodiment 1 is that in the piercing connection conductor of this embodiment , the piercing contacts at both ends are V-shaped.

Embodiment 3

[0044] Such as Figure 4 As shown, a piercing connection conductor is provided, wherein the views a, b, c, d are respectively the main view, top view, side view and perspective view, and the difference from embodiment 1 is that in the piercing connection conductor of this embodiment , the piercing contacts at both ends are W-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com