Combined rectangular oil cylinder

A combined structure and oil cylinder technology, which is applied in the direction of cylinders, engine components, mechanical equipment, etc., to achieve the effects of easy processing, strong resistance to deformation under force, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The combined structural rectangular oil cylinder will be specifically described below in conjunction with the embodiments.

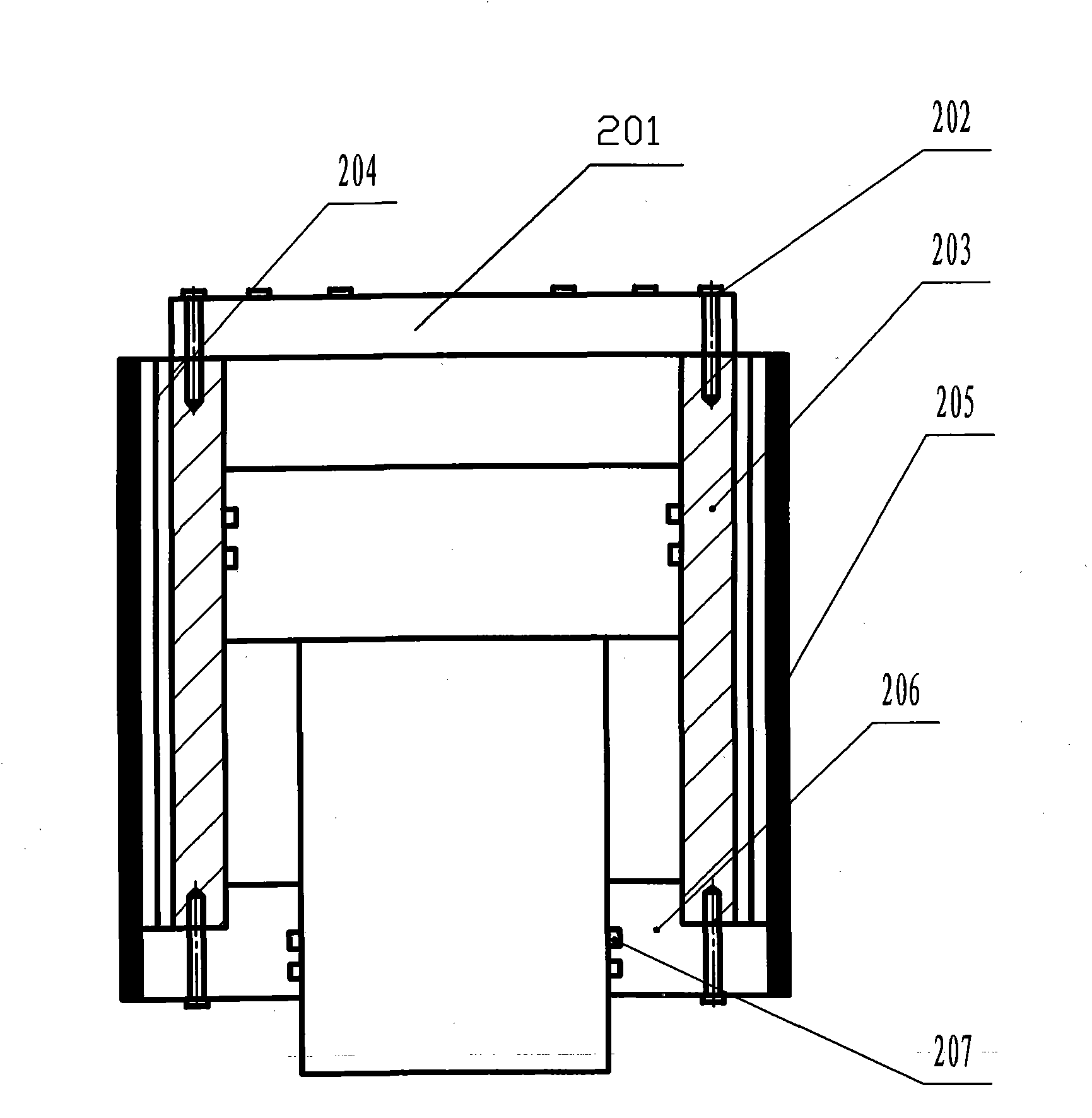

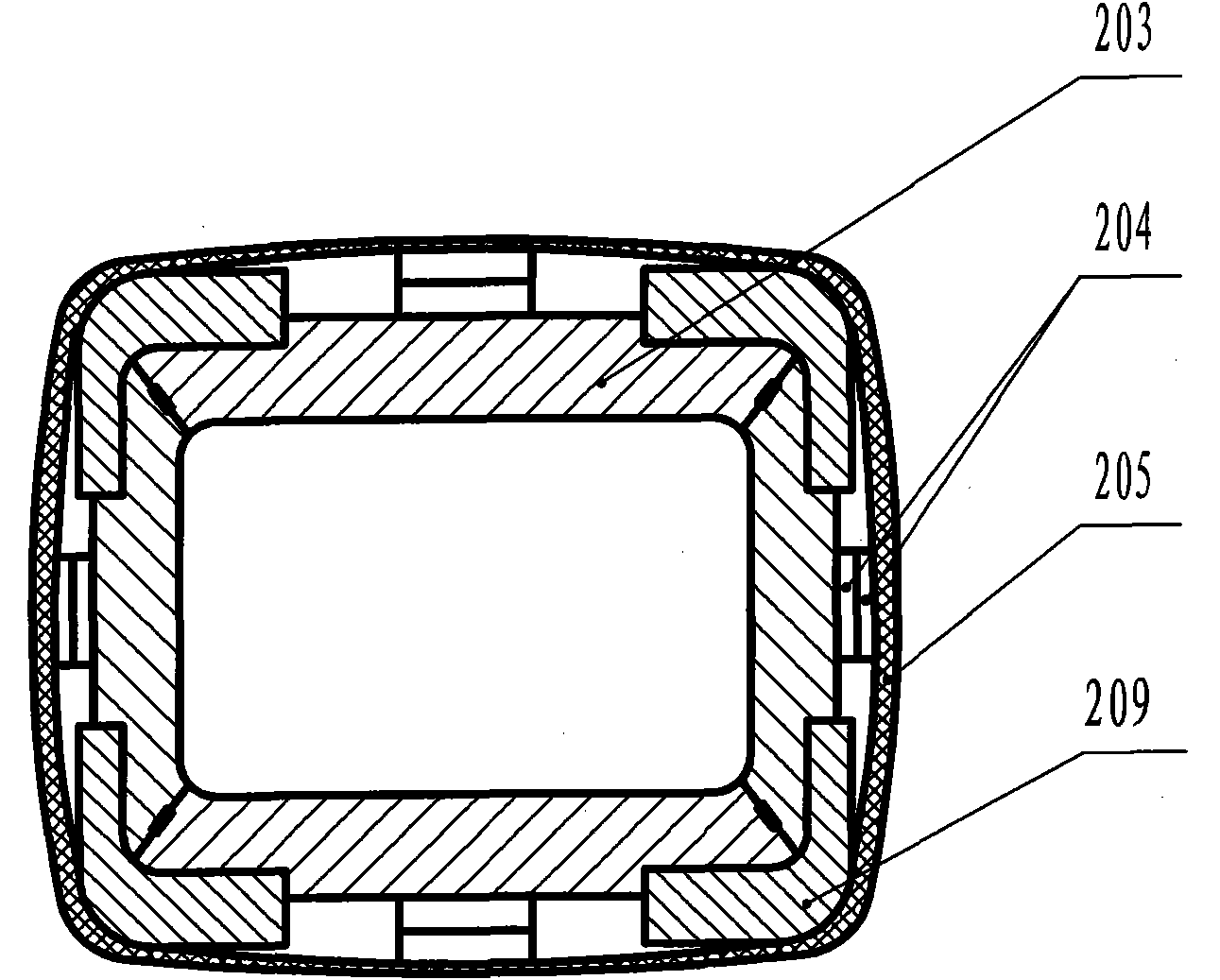

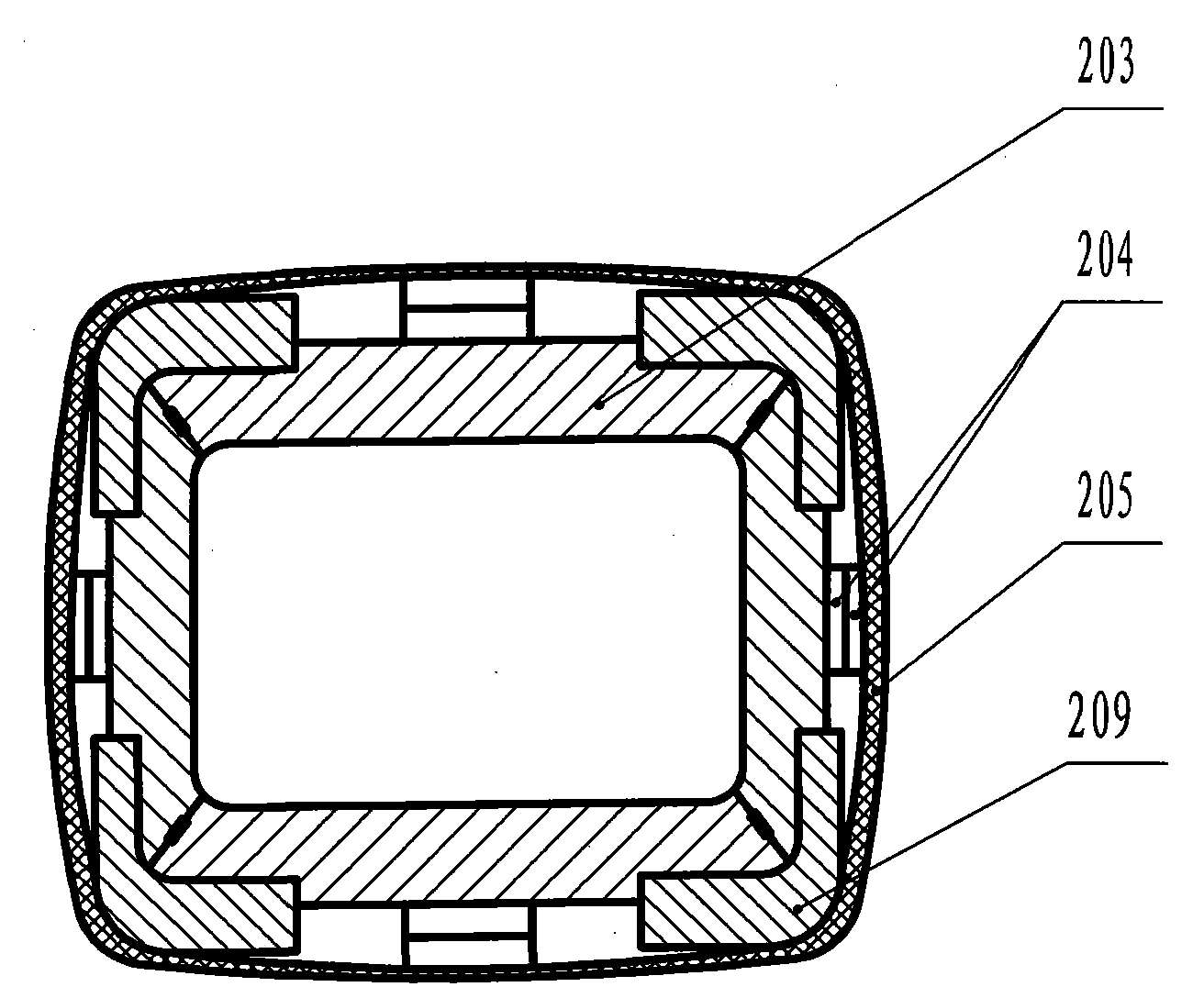

[0015] Such as figure 1 and figure 2 As shown, the shape of the oil cylinder block is rectangular, and the oil cylinder block is composed of a plurality of cylinder parts. The cylinder parts are four cylinder wall structural blocks 203 and four blocks in the longitudinal direction of the oil cylinder block. Composed of corner fixing blocks 209, the four corners of two adjacent cylinder wall structure blocks 203 are obliquely matched at 45 degrees, and the middle is sealed; the outside of the four corners is fixed by four corner fixing blocks 209; the steel wire winding layer 205 wraps around the corners The upper fixing block 209 is tightly wound, and the wedging block group 204 is wedged between the winding layer and the cylinder wall structure block 203 to further tighten the steel wire rope to achieve a greater pre-tightening force. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com