Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

A self-compacting concrete, anti-freeze-thaw technology, applied in the field of concrete, can solve the problems of cracks and fine lines in concrete, poor anti-freeze and thaw effect, etc., to reduce chloride ion channels, offset expansion stress, and improve compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

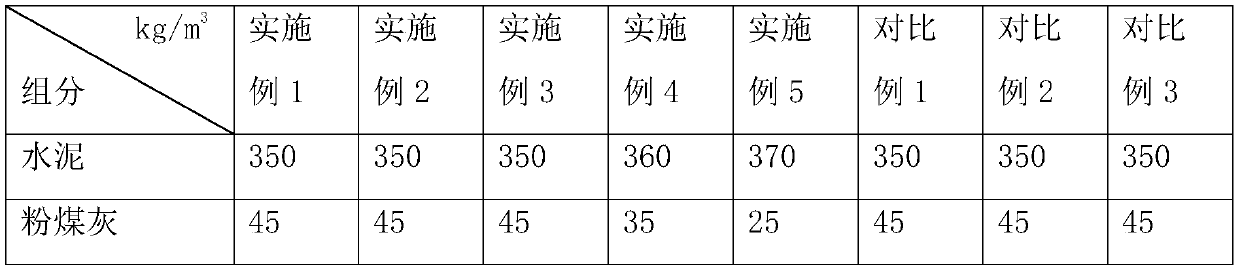

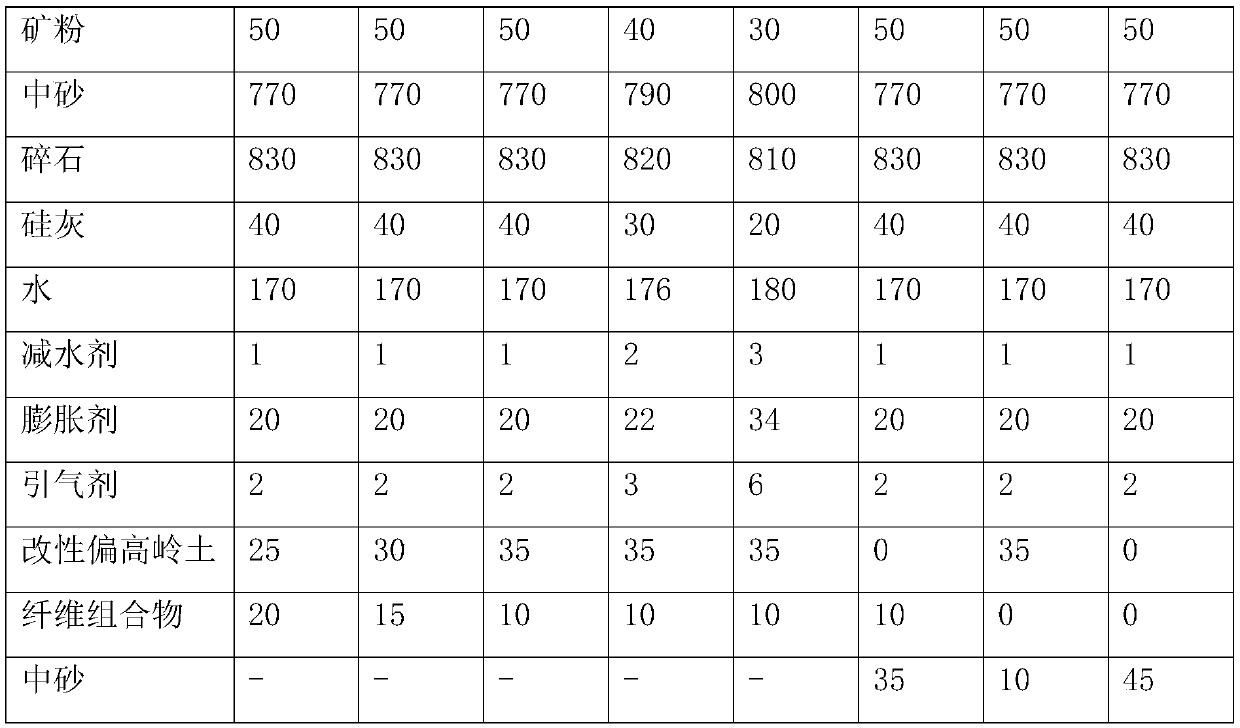

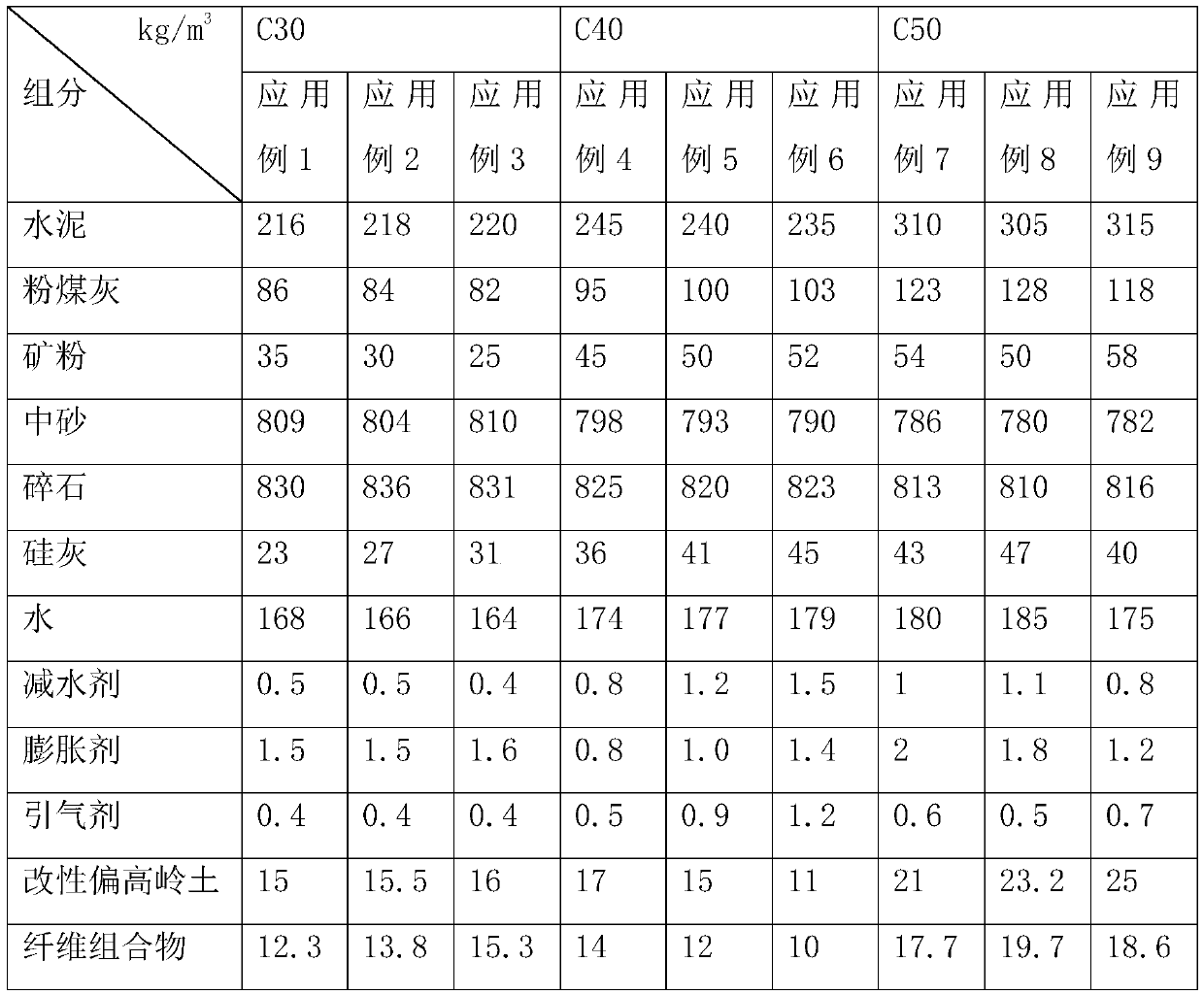

Examples

preparation example 1-3

[0039] Sodium dodecylbenzene sulfonate is selected from the model of LAS-P70 sodium dodecylbenzene sulfonate sold by Guangzhou Zhixin Trading Co., Ltd. in Preparation Example 1-3, and the silane coupling agent is selected from Dewar Chemical Industry ( The model sold by Shanghai) Co., Ltd. is KH-550 type silane coupling agent, and the epoxy resin emulsion is selected from the epoxy resin emulsion of QG-627 sold by Wuxi Qianguanghua Raw Material Co., Ltd.

preparation example 1

[0040] Preparation example 1: (1) mix perchloric acid and glacial acetic acid with a volume ratio of 3:1.5 to make a mixed solution, place 1kg metakaolin in the mixed solution, soak for 5min, the concentration of perchloric acid is 70%, The concentration of glacial acetic acid is 95%;

[0041] (2) place the metakaolin processed in step (1) in 5kg epoxy resin emulsion again, add 0.5kg sodium dodecylbenzenesulfonate and 0.8kg silane coupling agent successively, stir under the condition of 1500r / min 10min.

preparation example 2

[0042] Preparation example 2: (1) mix perchloric acid and glacial acetic acid that volume ratio is 3.5:1.8, make mixed solution, 2kg metakaolin is placed in mixed solution, soak 8min, the concentration of perchloric acid is 71%, The concentration of glacial acetic acid is 96%;

[0043] (2) place the metakaolin processed in step (1) in 8kg epoxy resin emulsion again, add 0.6kg sodium dodecylbenzenesulfonate and 1.0kg silane coupling agent successively, stir under the condition of 1800r / min 15min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com