A kind of PVC sole and preparation technology thereof

A technology of emulsified asphalt and reinforcing filler, which is applied in the field of plastic products, can solve the problems of PVC sole bending strength and fracture toughness limitation, increase of PVC sole defects, easy cracks and other problems, achieve good improvement effect, improve bending strength and fracture toughness , increase the binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

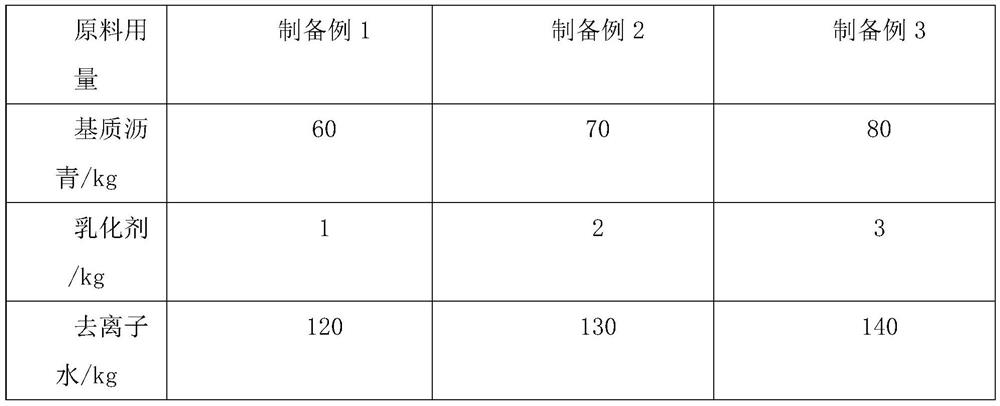

[0040] Preparation example of emulsified asphalt

[0041] As shown in Table 1, the main difference of Preparation Examples 1-3 is that the ratio of raw materials is different, wherein the emulsifier is selected from coconut oil-based imidazoline produced by Shanghai Chuxing Chemical Co., Ltd.; the base asphalt is selected from Shandong Kunda Road Material Co., Ltd. The 90# asphalt; the deionized water is selected from the industrial deionized water produced by Suzhou Aiying Environmental Protection Technology Co., Ltd.

preparation example 2

[0044] Emulsified asphalt is prepared according to the following steps:

[0045] (1) Pulverize the base asphalt and heat it to 120°C for later use;

[0046] (2) Mix emulsifier with deionized water, and heat to 70°C to obtain emulsifier solution, set aside;

[0047] (3) Mix and stir base asphalt and emulsifier solution, and obtain emulsified asphalt after cooling.

[0048] Table 1

[0049]

preparation example 4

[0051] The difference between this preparation example and preparation example 2 is that the emulsifier is selected from the alkylphenol polyoxyethylene ether produced by Taixing Hengyuan Chemical Factory.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com