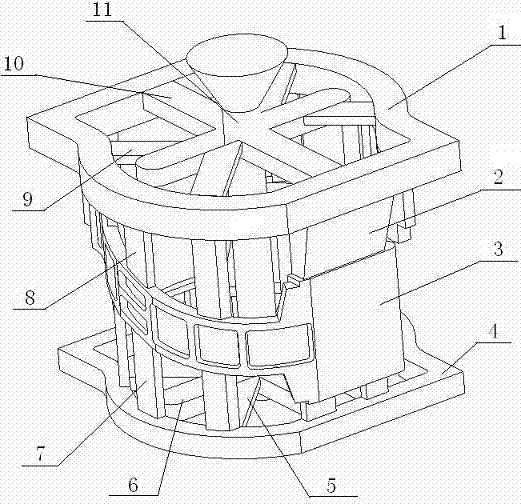

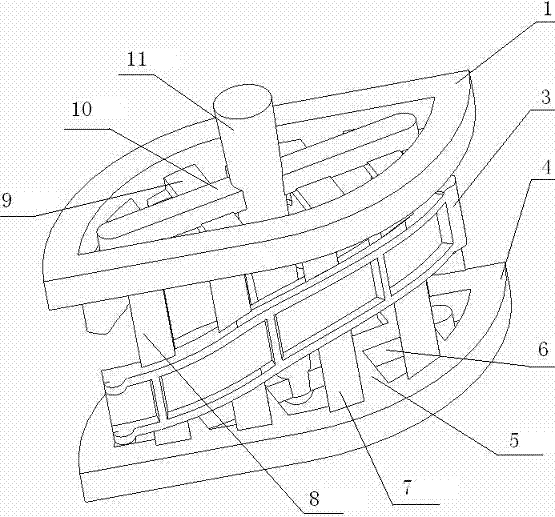

Space curve type casting anti-deformation box cage structure and machining method

A technology of space curves and processing methods, applied in metal processing equipment, casting molds, cores, etc., can solve the problem that the dimensional accuracy of castings cannot meet the processing and use requirements, and achieve the elimination of deformation defects, reduce production costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take solving the height and radial deformation of the lower guide rail as an example.

[0047] According to the casting structure of the lower guide rail and the actual deformation in production practice, the improvement measures are formulated as follows:

[0048] First: Change the casting method and control the number of deformations.

[0049] Using the resin sand casting process instead of the investment casting process, the resin sand will not be deformed during the molding process, which can effectively reduce the three deformation processes in the mold making stage. Resin sand adopts natural silica sand, SiO 2 The content is required to be above 98%, the angle coefficient should be less than 1.3, and the particle size should be 50-100 mesh.

[0050] Second: Design the anti-deformation box cage structure with space curve type castings to offset the internal stress caused by casting shrinkage and control the deformation during the pouring process and heat treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com