Mesoporous silicon-tin composite electrode material and preparation method thereof, and application thereof

An electrode material, mesoporous silicon technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor high-rate discharge capability, capacity fading, poor conductivity of porous silicon, etc., and achieve high-rate discharge capability and high reversible capacity , good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a mesoporous silicon-tin composite electrode material is as follows:

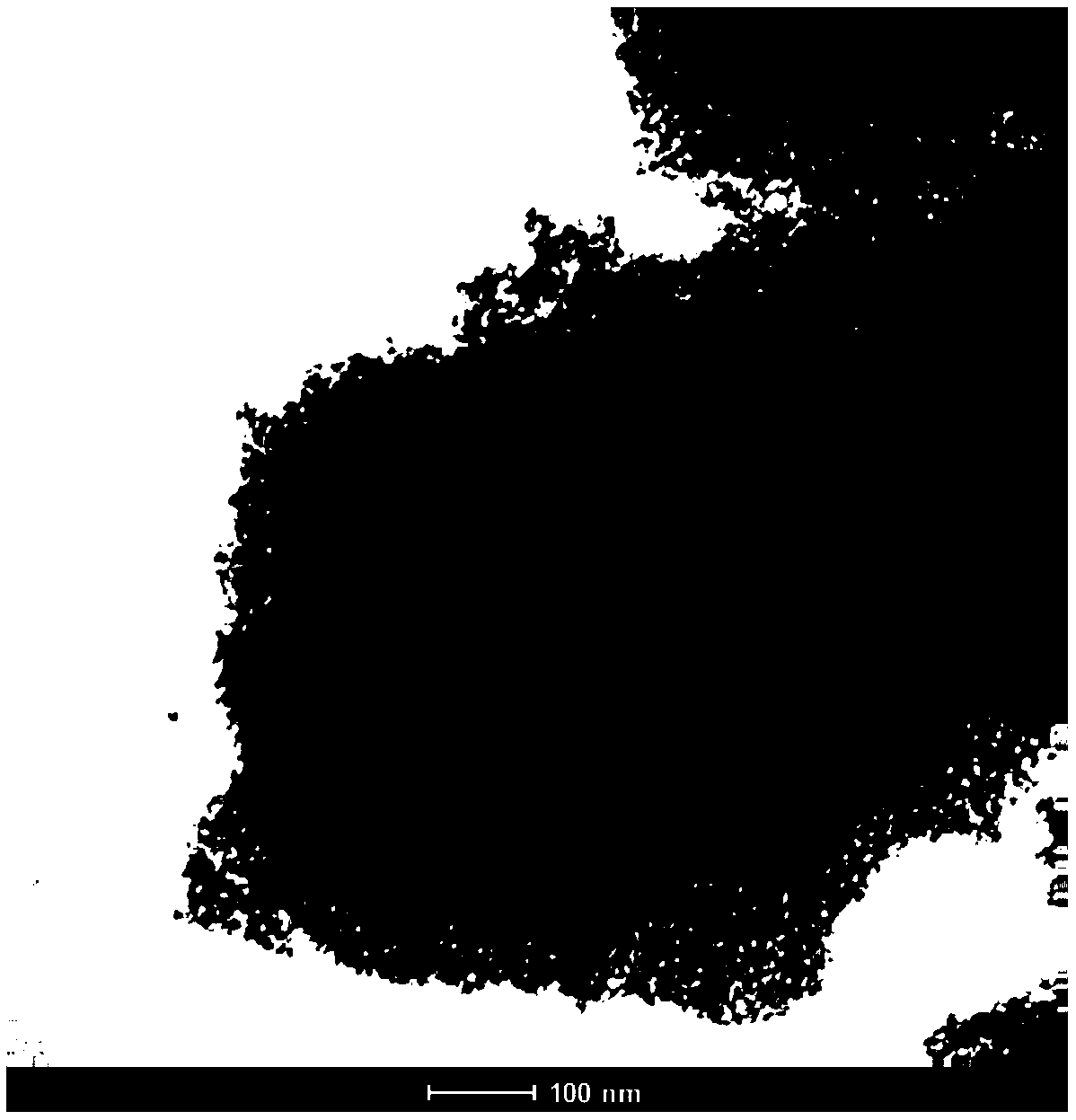

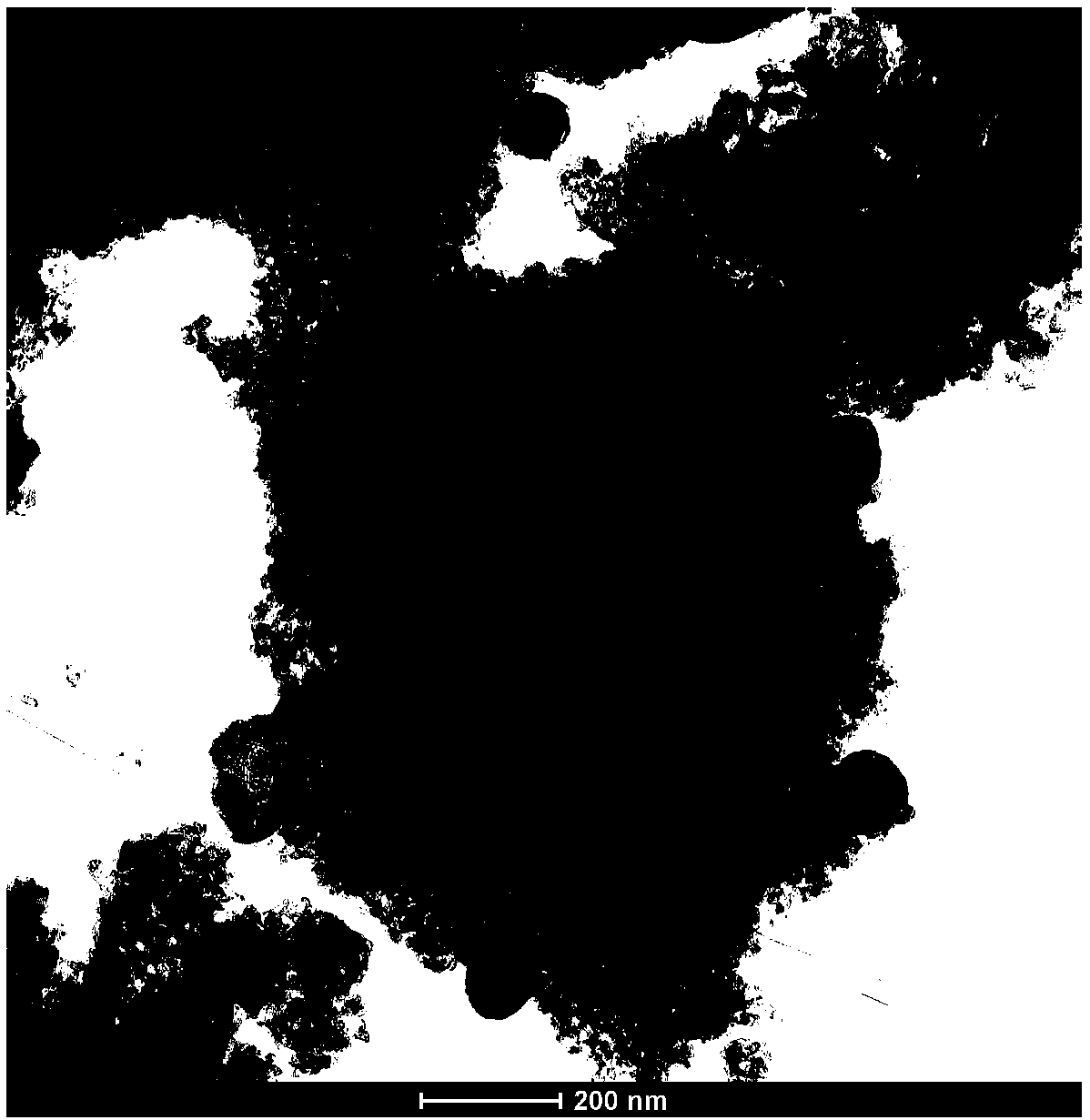

[0039] Grind and mix the magnesium powder with a particle size of 325 mesh and the mesoporous silica powder at a mass ratio of 1:1, and take 0.5 g of the mixed powder. Put the powder mixture into a quartz boat, put it into a tube furnace, and raise the temperature to 700°C at a rate of 1°C / min under an argon atmosphere, keep it warm for 5 hours, and cool down with the furnace. Take out the sample in the tube furnace, wash it with 1M HCl solution and 10% HF solution respectively, and the obtained material is the mesoporous silicon material (see figure 1 , figure 2 ).

[0040] The volume ratio of ethanol: deionized water is 1:3 to prepare the mixed solution, then add SnCl 4 ·6H 2 O solid, made into 100g / L concentration of SnCl 4 solution. Pour an appropriate amount of mesoporous silicon (30-50mg added) into 10ml SnCl 4solution, ultrasonic vibration for 60min. After suct...

Embodiment 2

[0047] The charging and discharging performance of the sample in Example 1 was tested on Xinwei charging and discharging equipment. The electrochemical test was carried out in a 2032-type coin cell system, and the electrolyte was 1M LiPF 6 Dissolve in EC / DEC (ethylene carbonate / diethyl carbonate, volume ratio 1:1) solution with 2% VC (vinylene carbonate) added, and the counter electrode is metal lithium sheet. Connect the above-mentioned button battery to Xinwei equipment, and conduct a rate charge and discharge test at room temperature. The specific process is to first discharge to the cut-off potential of 0.01V at a current density of 200mA / g (vs.Li / Li + ), after standing for 2min, then charged to the cut-off potential of 3.0V (vs.Li / Li + ), loop ten times. After that, the current density is changed to 500, 1000, 2000mA / g, and finally returned to 200mA / g. The current density of each level is cycled ten times to obtain the rate performance (see Image 6 ). Sn-Si composit...

Embodiment 3

[0049] The electrochemical impedance spectrum of the sample was tested by the CHI604E electrochemical comprehensive tester of Shanghai Chenhua Instrument Co., Ltd., and the test frequency was from 100kHz to 1Hz to obtain the AC impedance spectrum (see Figure 7 ). The charge transfer resistance of mesoporous silicon is 835.6Ω, and that of mesoporous silicon-tin composite is 117.68Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com