Silicon-carbon composite anode material, preparation method thereof and lithium ion battery

A negative electrode material, silicon-carbon composite technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems affecting battery cycle life, increase side reactions, etc., to improve cycle performance, Effect of reduced volume expansion and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

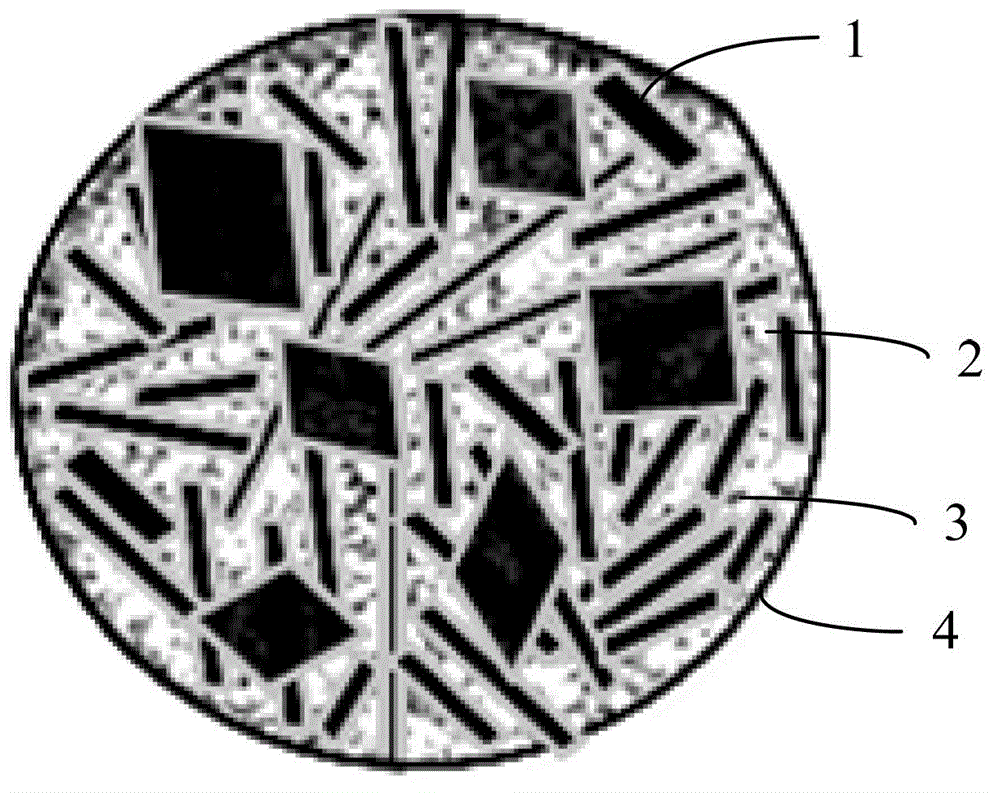

Image

Examples

preparation example Construction

[0045] In the second aspect, an embodiment of the present invention provides a method for preparing a silicon-carbon composite negative electrode material, including:

[0046] (1) Dissolving the nitrogen-containing aromatic compound in an organic solvent and preparing a solution with a mass fraction of 1% to 10%; the nitrogen-containing aromatic compound is pyrene diimide, metal-free phthalocyanine or aminopyrene;

[0047] (2) Add silicon nanomaterials to the solution obtained above, the silicon nanomaterials are silicon nanosheets or silicon nanobelts with a length and width of 50-5000nm and a thickness of 10-500nm, stir evenly and ultrasonicate for 5-15 minutes , drying the solvent at 80-100° C. to obtain nitrogen-coated silicon nanomaterials;

[0048] (3) Dissolving the nitrogen-containing organic carbon source in a solvent to prepare a solution with a mass fraction of 1% to 10%; the nitrogen-containing organic carbon source is a polymer containing -CN and / or -CON groups; ...

Embodiment 1

[0066] A method for preparing a silicon-carbon composite negative electrode material, comprising:

[0067] (1) Weigh 7.7g of pyreneimide and place it in a 500mL beaker, add 250mL of acetone, and stir for 30 minutes to obtain a pyreneimide solution with a mass fraction of 3.0%;

[0068] (2) Weigh 5g of silicon nanosheets with a thickness of 20nm, a width of 50nm, and a length of about 500nm, and add them to the above solution, stir at 5000r / min for 20 minutes, then use an ultrasonic cell disruptor to sonicate for 10 minutes, and then place the obtained solution in a rotating Evaporate the solvent in an evaporator, and then place it in an oven and dry it at 80°C for 8 hours to remove the residual solvent and obtain a nitrogen-coated silicon nanomaterial;

[0069] (3) Dissolve 3.0g of polyacrylamide completely in 100g of deionized water, then add 12g of nitrogen-coated silicon nanomaterials, 2.2g of carbon nanotubes, and 20g of artificial graphite powder with a particle size of 3...

Embodiment 2

[0075] A method for preparing a silicon-carbon composite negative electrode material, comprising:

[0076] (1) Weigh 3.8g of metal-free phthalocyanine into a 500mL beaker, add 250mL of acetone, and stir for 30 minutes to obtain a metal-free phthalocyanine solution with a mass fraction of 1.5%;

[0077] (2) Weigh 5g of silicon nanosheets with a thickness of 30nm, a width of 40nm, and a length of about 1000nm, add them to the above solution, stir at 5000r / min for 20 minutes, then use an ultrasonic cell disruptor to sonicate for 10 minutes, and then place the obtained solution in Evaporate the solvent in a rotary evaporator, and then place it in an oven and dry it at 90°C for 10 hours to remove the residual solvent and obtain a nitrogen-coated silicon nanomaterial;

[0078] (3) Dissolve 3.0g of polyacrylamide completely in 100g of deionized water, then add 12g of nitrogen-coated silicon nanomaterials, 2.2g of carbon nanotubes, and 20g of natural graphite powder with a particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com