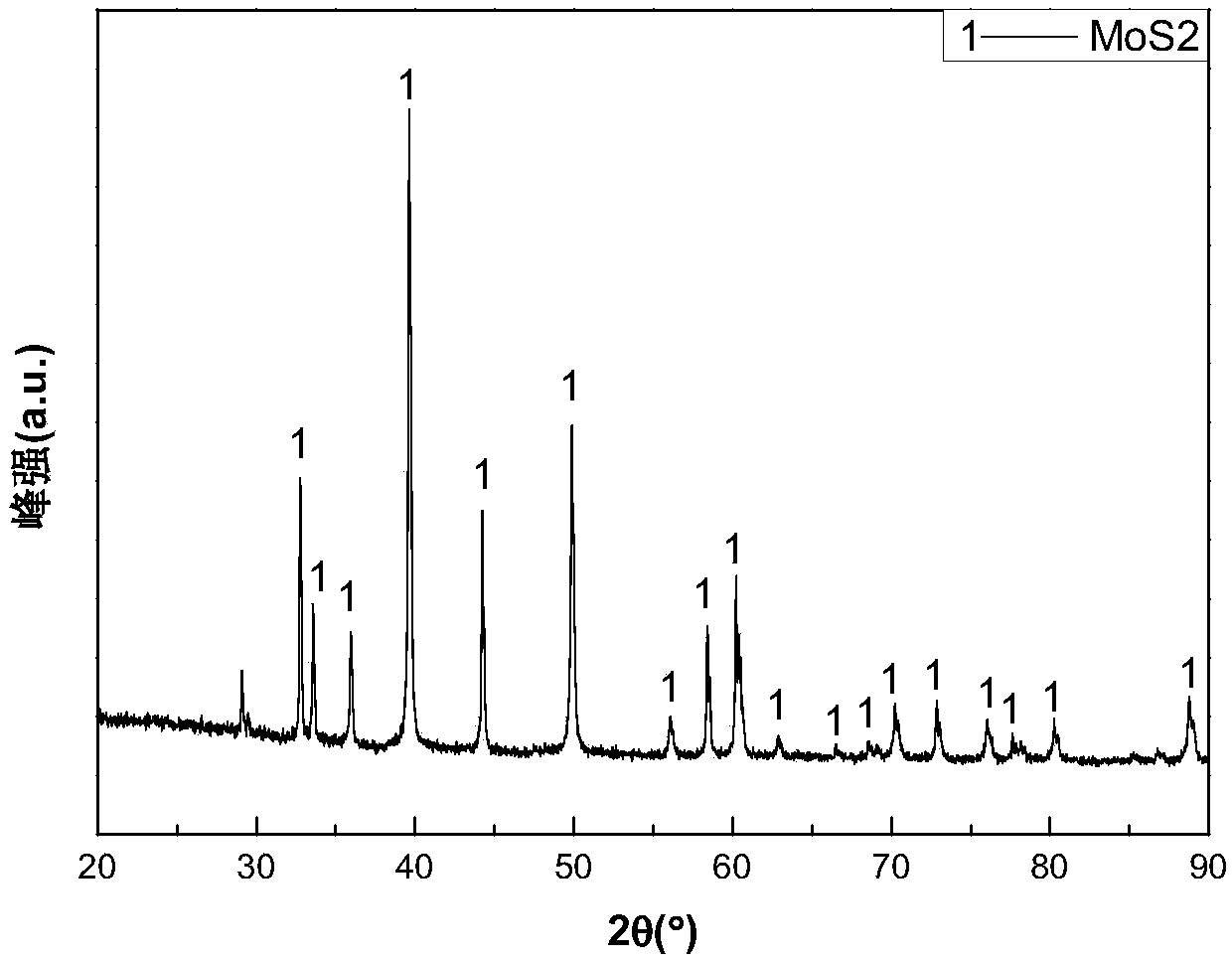

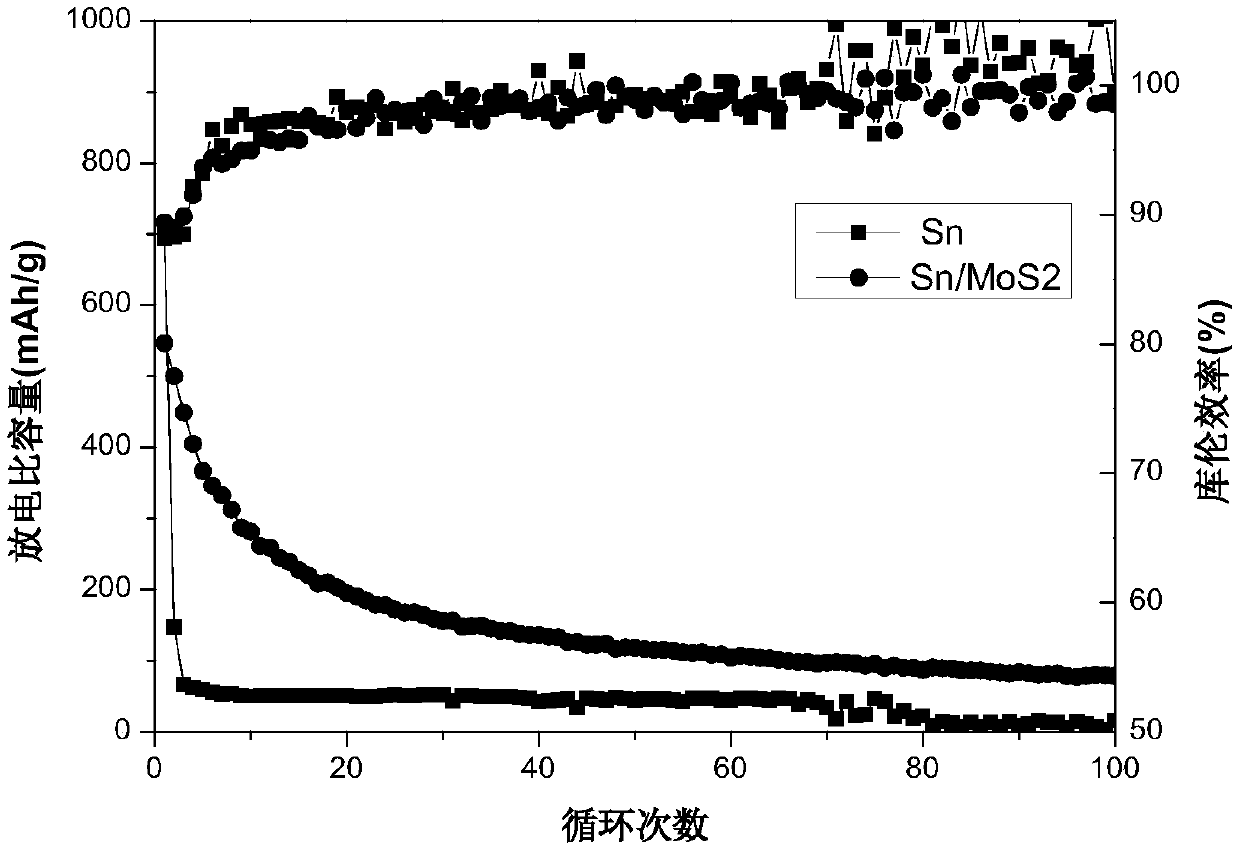

Nanometer tin-molybdenum disulfide compound negative electrode material as well as preparation method and application thereof

A technology of molybdenum disulfide and negative electrode material, applied in the direction of negative electrode, active material electrode, battery electrode, etc., to achieve the effect of good cycle stability, high rate discharge capacity and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

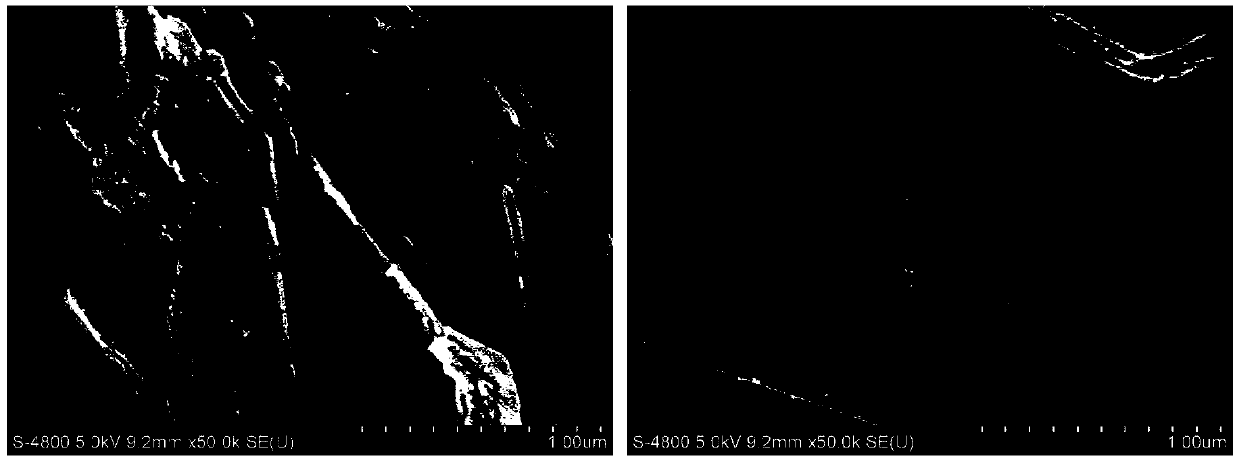

[0025] 1, the preparation method of tin-molybdenum disulfide compound is as follows:

[0026] The volume ratio of ethanol: deionized water is 1:3 to prepare the mixed solution, then add SnCl 4 -5H 2 O solid, made into SnCl with a concentration of 100g / L 4 -5H 2 O solution. Pour 30 mg molybdenum disulfide into SnCl 4 -5H 2 O solution, ultrasonic vibration for 30min, the total concentration of molybdenum disulfide in the total system is 30g / L. Then put it into a vacuum drying oven after suction filtration, and dry it at 100°C for 1 to 10 hours to obtain SnCl 4 Impregnated molybdenum disulfide composite.

[0027] The resulting SnCl 4 The impregnated molybdenum disulfide composite was put into a tubular calciner for hydrogen reduction, and the temperature was raised to 350°C at 5°C / min, and kept for 1 hour. During the hydrogen reduction process, 20 sccm of H was introduced throughout the process. 2 And 10sccm of Ar mixed gas, cooled to room temperature with the furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com