Welding method of tetrahedron giant column in steel structure

A welding method and tetrahedral technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as difficult to guarantee welding quality, splicing, high difficulty in welding, deformation of tetrahedral giant columns, etc., to achieve shrinking The effect of temperature difference, avoiding delayed cracking of weld seam, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

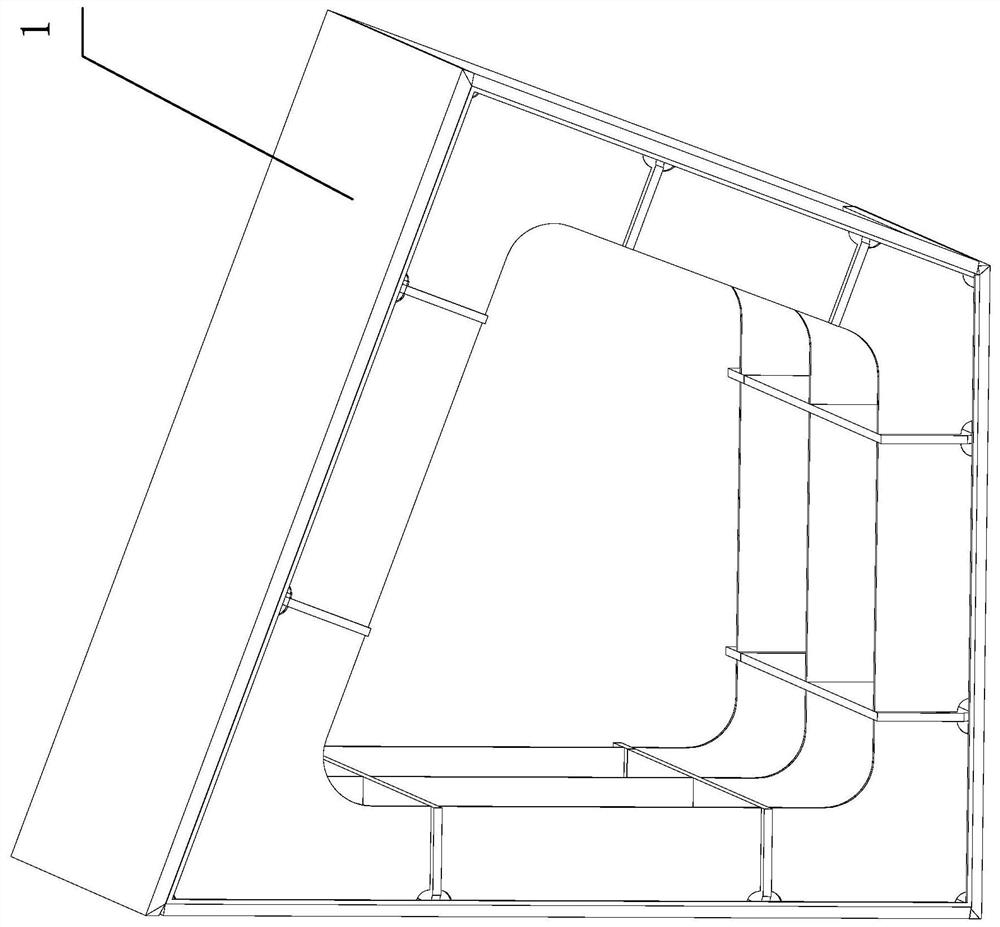

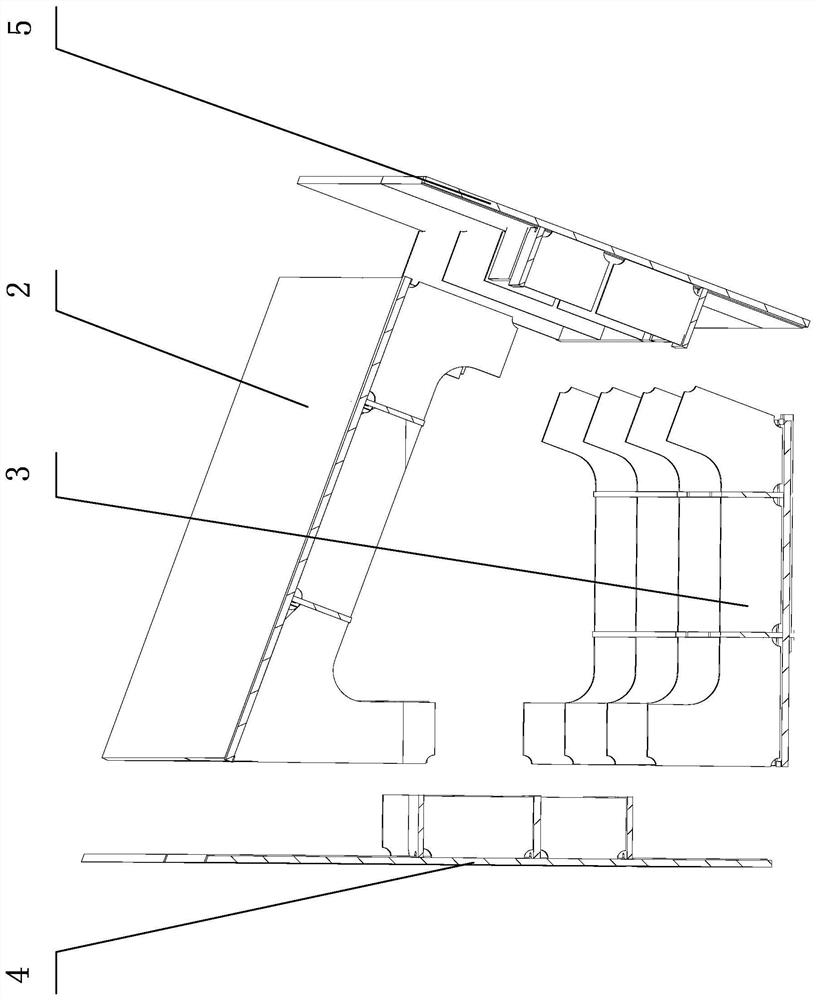

[0036] Taking the giant column of the peripheral frame of a construction project, that is, the giant column of tetrahedron 1 (length of the four-sided plate: 3250mm × 2050mm × 2353mm × 3038mm, plate thickness 45mm ~ 60mm) as an example and in conjunction with the embodiment shown in the accompanying drawings, the technical solution of the present invention will be described. Further explanation.

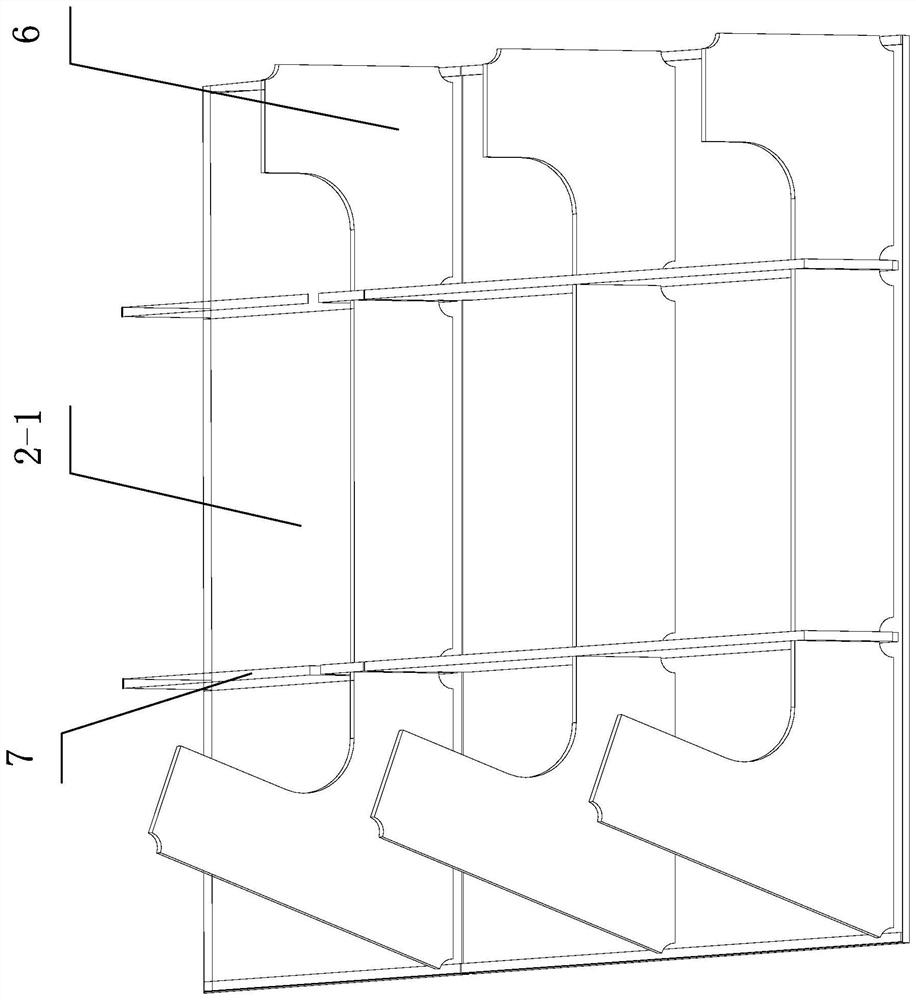

[0037] The steel structure tetrahedron giant column welding method of the present invention is to assemble and weld the front part 2, the rear part 3, the left part 4 and the right part 5 that constitute the tetrahedron giant column 1, and the front part 2 includes The front main board 2-1 (3250mm long) and the grid-shaped rib wall (consisting of interlaced longitudinal rib boards 6 and transverse rib boards 7) fully welded on the inner side, and the rear parts 3 include the rear main board 3-1 (2353mm long ) and a grid-shaped rib wall (consisting of interlaced longitudinal ribs 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com