Meso-porous silicon-copper compound electrode material, and preparation method and application thereof

An electrode material and mesoporous silicon technology, applied in the field of mesoporous silicon-copper composite electrode materials and their preparation, can solve the problems of poor high-rate discharge capability and poor conductivity of porous silicon, and achieve a small capacity loss rate and offset internal Stress, the effect of suppressing pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

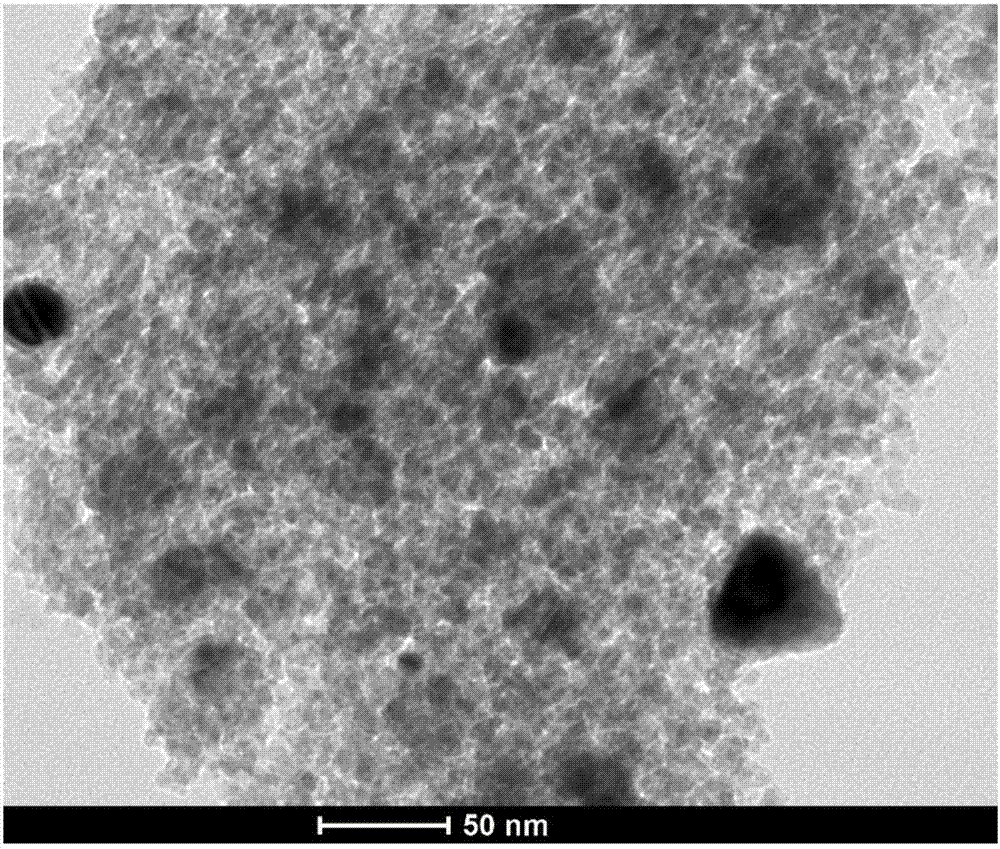

[0018] The present invention also provides the preparation method of the mesoporous silicon-copper composite electrode material, comprising: performing magnesia thermal reduction reaction on the mixture of magnesium powder and mesoporous silicon dioxide; performing impregnation-hydrogen reduction on the mesoporous silicon, A mesoporous silicon-copper composite was prepared.

[0019] The temperature of the magnesium thermal reaction is 400-700°C, can be 400-600°C, 600-700°C, etc., the holding time is 0-20h, and the heating rate is 0.5-10°C / min. The holding time is 0h, and the reaction temperature is 400-600°C by-product Mg 2 Si content is relatively high, the mass percentage is about 10%, as the temperature increases, the by-product Mg 2 Si content decreased gradually, when the reaction temperature was 650℃, Mg 2 Si content is about 4.2%, when it rises to 700°C, Mg 2 Si content is less than 1%. The by-product Mg can be reduced by increasing the holding time 2 Si content. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com