Thin type secondary battery and preparation method therefor

A secondary battery, thin technology, used in secondary battery manufacturing, batteries, small flat batteries/batteries, etc., can solve problems such as increased cost and waste of active materials, and achieves cost saving, convenient processing, and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

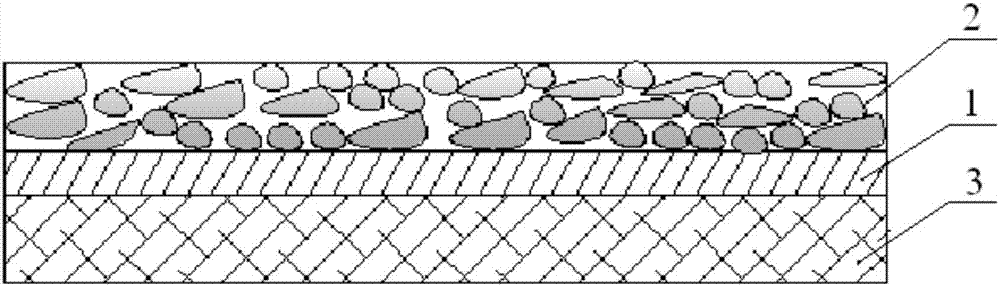

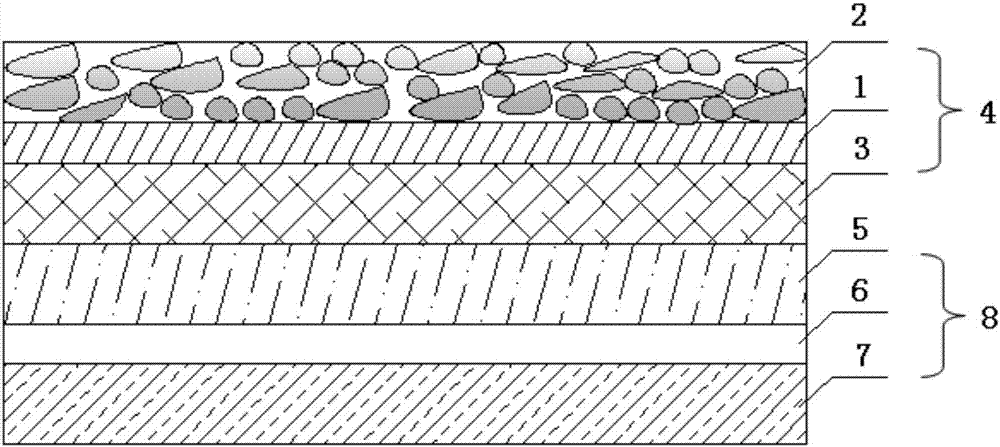

[0057] A thin secondary battery, comprising at least one positive pole piece and at least one negative pole piece, the positive pole piece and the negative pole piece are arranged at intervals in sequence, and each pole piece includes a metal current collector, such as figure 1 and 2 As shown, the metal current collector 1 in the outermost pole piece 4 is provided with an active material layer 2 on one side facing other pole pieces, and a polymer material layer 3 is provided on the other side; when the number of pole pieces is greater than or equal to 3, the middle pole piece Active material layers 2 are provided on both sides of the metal current collector.

[0058] Only one side of the outermost pole piece of a thin secondary battery needs to be provided with an active material layer. By providing a polymer material layer on the side of the metal current collector that does not need to be provided with an active material layer, it can offset or partially offset the damage ca...

Embodiment 2

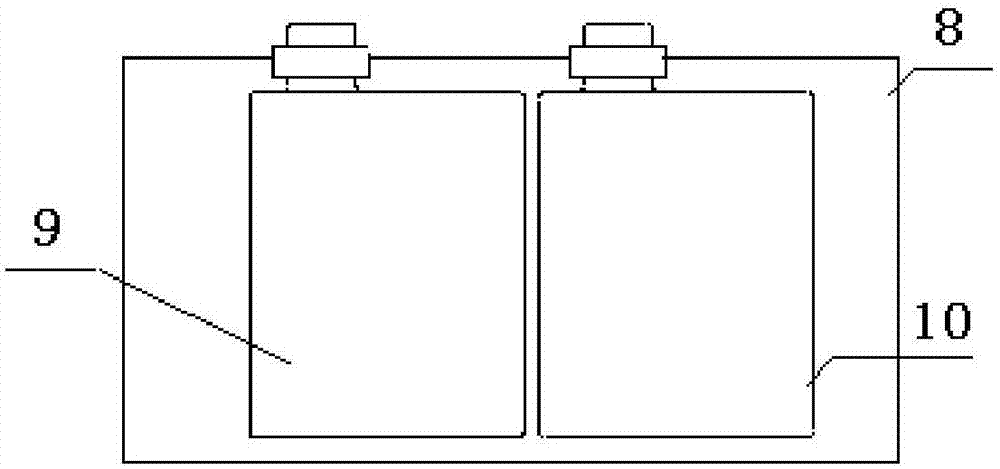

[0073] Such as image 3 As shown, this embodiment discloses a method for preparing a thin secondary battery, including:

[0074] The positive electrode sheet 9 is obtained, the positive electrode sheet includes a positive electrode current collector, one side of the positive electrode current collector is provided with a positive electrode active material layer, and the other side is provided with a hot melt adhesive polymer material layer, the structure of the positive electrode sheet 9 in this embodiment is the same as The structure of the outermost pole plate in Embodiment 1 is the same. In this embodiment, the specific steps for preparing the positive electrode sheet are: the positive electrode active material lithium cobaltate, the binder polyvinylidene fluoride (PVDF) and the conductive agent conductive carbon black are mass ratio (94 ~ 98): (1 ~ 3): (1~3) Mix evenly with the solvent N-methylpyrrolidone, stir at a high speed to obtain a uniformly dispersed positive elec...

Embodiment 3

[0085] Such as Figure 4 and 5 As shown, this embodiment discloses a method for preparing a thin secondary battery, including:

[0086]The positive electrode sheet is prepared, and the positive electrode sheet includes a positive electrode current collector. One side of the positive electrode current collector is provided with a positive electrode active material layer, and the other side is provided with a hot melt adhesive polymer material layer. In this embodiment, the specific steps for preparing the positive electrode sheet The steps of preparing the positive pole piece are the same as in Example 2, except that in this embodiment, the thickness of the positive pole piece 4 is 90 μm, the width is 42.2 mm, and the height is 25 mm.

[0087] Negative electrode sheet 10 is obtained, the negative electrode sheet includes a negative electrode current collector, and both sides of the negative electrode current collector are provided with a negative electrode active material laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com