Magnesite or magnesium oxysulfate waste recovery system

A magnesium oxysulfide waste and recycling system technology, applied in packaging, loading/unloading, large containers, etc., can solve the problems of unfavorable material dispersion uniformity, uneven performance of magnesite or magnesium oxysulfide sheet products, etc., to prevent separation. Layers, reduce material drop, scientific and reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

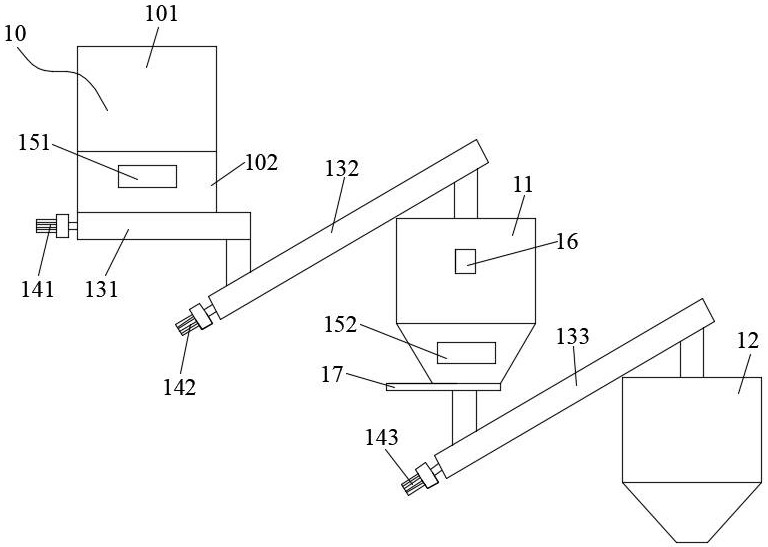

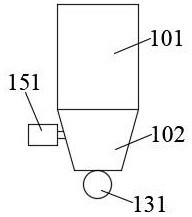

[0025] like Figure 1-5 As shown, a magnesite waste recycling system, the recycling system includes a transfer hoisting device, a storage bin 10, a weighing bin 11, a mixer 12 and an automatic electronic control system;

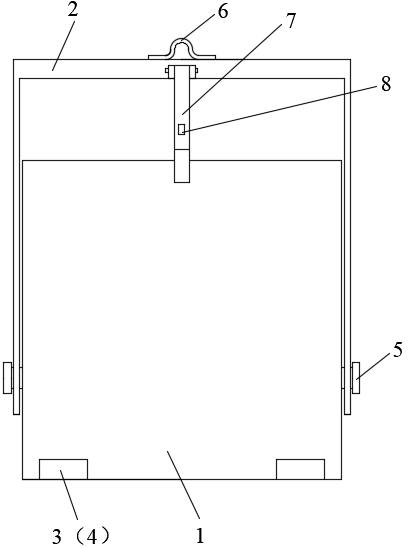

[0026] The transfer hoisting device includes a cylindrical cylinder 1 (both height and diameter are 1200mm) and an inverted U-shaped gantry 2; the cylinder 1 is closed at the bottom and open at the top, and the inner cavity of the cylinder 1 fits the bottom wall at the left and right intervals, front and rear. Two inverted U-shaped grooves 3 parallel to each other are welded to each other, the front and rear ends of the inverted U-shaped groove 3 are welded and fixed with the front and rear side walls of the cylinder body 1, and the front and rear side walls of the cylinder body 1 are provided with two inverted U-shaped grooves. The grooves 3 correspond to the gaps 4 one-to-one. A pair of hoisting shafts 5 are symmetrically welded and fixed on the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com