Optical, infrared and radar multispectral camouflage canopy and manufacture method thereof

A multi-spectrum and infrared technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve problems such as poor camouflage effect, narrow camouflage spectrum band, and deterioration of camouflage performance, and achieve scientific and reasonable structural design and comprehensive performance. Excellent and advanced technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

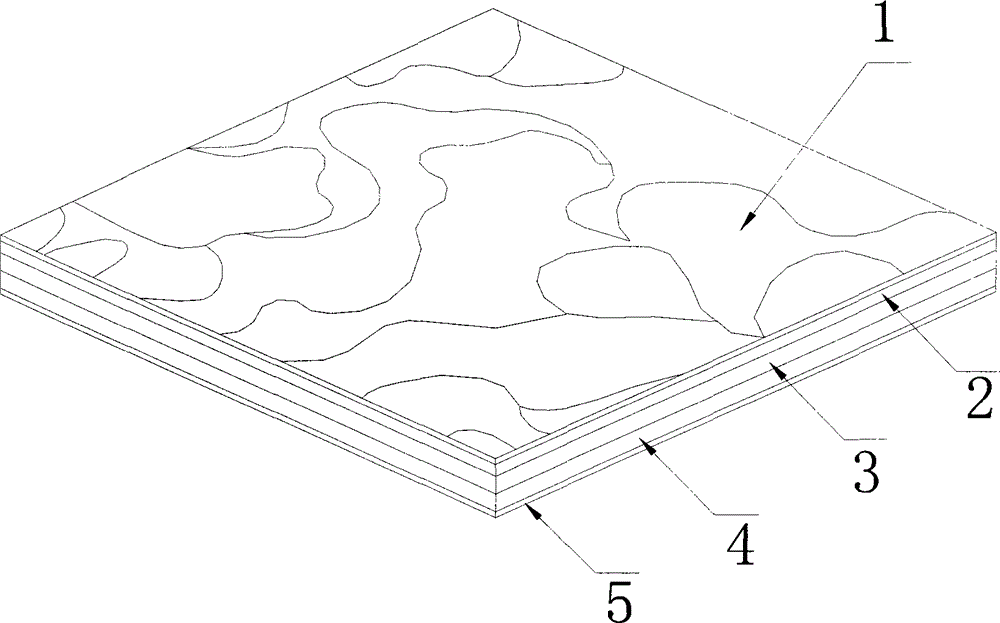

[0035] Such as figure 1 As shown, the optical, infrared, and radar multi-spectrum camouflage tarpaulins involved in the present invention sequentially include a camouflage layer 1, a radar wave forward scattering layer 2, a radar wave absorbing layer 3, a fabric base layer 4, and a reflective layer 5 from outside to inside. Five functional layers.

[0036] The base layer of the fabric is made of 1000D, 20×20 polyester filament woven fabric, and the upper and lower surfaces of the woven fabric are uniformly coated with a PVC paste resin coating with a thickness of 0.15mm by a scraping process, and the PVC paste resin is coated. The physical and chemical properties of the materials are shown in Table 1.

[0037] Table 1: Physical and chemical indicators of materials coated with PVC paste resin

[0038]

[0039] For the lower surface of the fabric base layer, use acetone and ethanol mixed solvent (1:1 volume ratio) to carry out chemical degreasing; after natural drying, use ...

Embodiment 2

[0047] In this embodiment, using the same manufacturing process and materials, after the camouflage layer, the radar wave forward scattering layer, the radar wave absorbing layer, and the fabric base layer after electroless copper plating are all prepared, the above-mentioned functional layers are sequentially assembled by sewing technology. , and stitched together in a pattern of warp and weft interweaving with a stitch spacing of 1 meter to prepare such figure 1 The optical, infrared, radar multi-spectral camouflage tarpaulin with multi-layer composite structure is shown.

Embodiment 3

[0049] In this embodiment, the metal reflective layer is prepared by vacuum aluminum plating instead of the chemical copper plating process. The vacuum aluminum plating equipment used is the SBD1200-10III vacuum aluminum plating machine developed by Wuxi Jinchi Automation Equipment Co., Ltd., and the thickness of the aluminum coating is 50um. The remaining steps are completely in accordance with the operation in Example 1. Finally, the 5550 type two-component polyurethane adhesive produced by Dongfang Chemical Co., Ltd. is selected to bond the above functional layers into one body in order to prepare the following: figure 1 The optical, infrared, radar multi-spectral camouflage tarpaulin with multi-layer composite structure is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com