Automatic egg breaking and eggshell, egg white and egg yoke separating machine

A technology for egg yolk and egg breaking, which is applied in protein food ingredients, protein ingredients of eggs, food science, etc., and can solve the problem that broken egg yolks cannot be removed and peeled off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

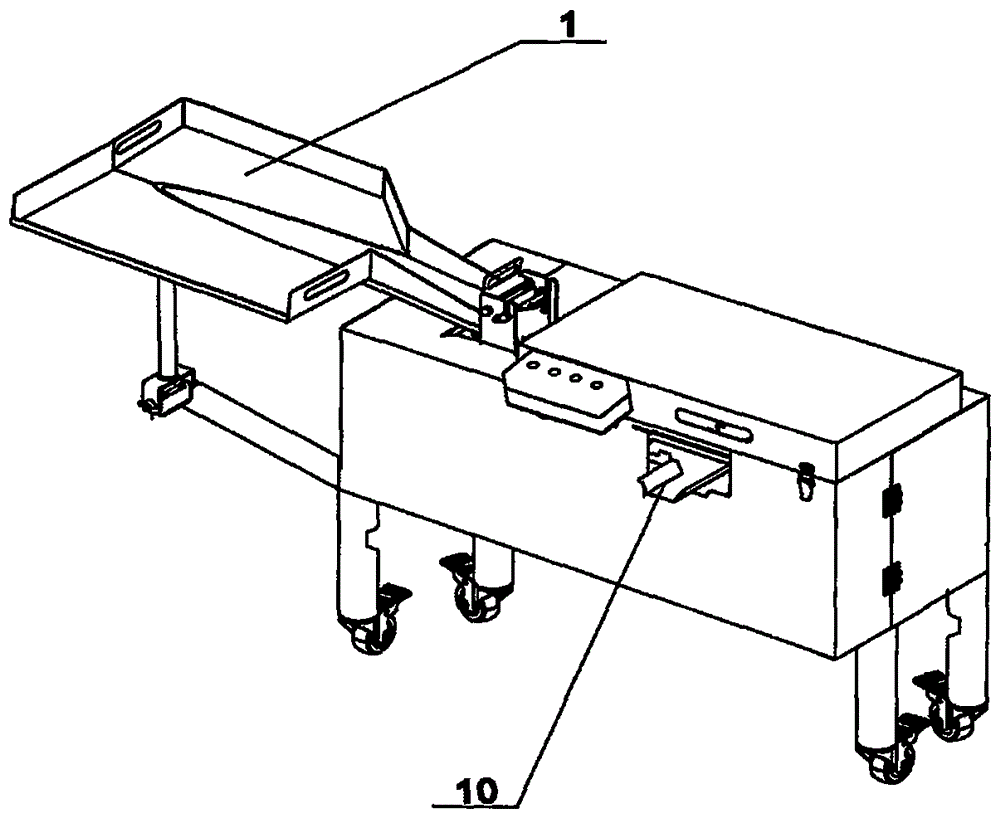

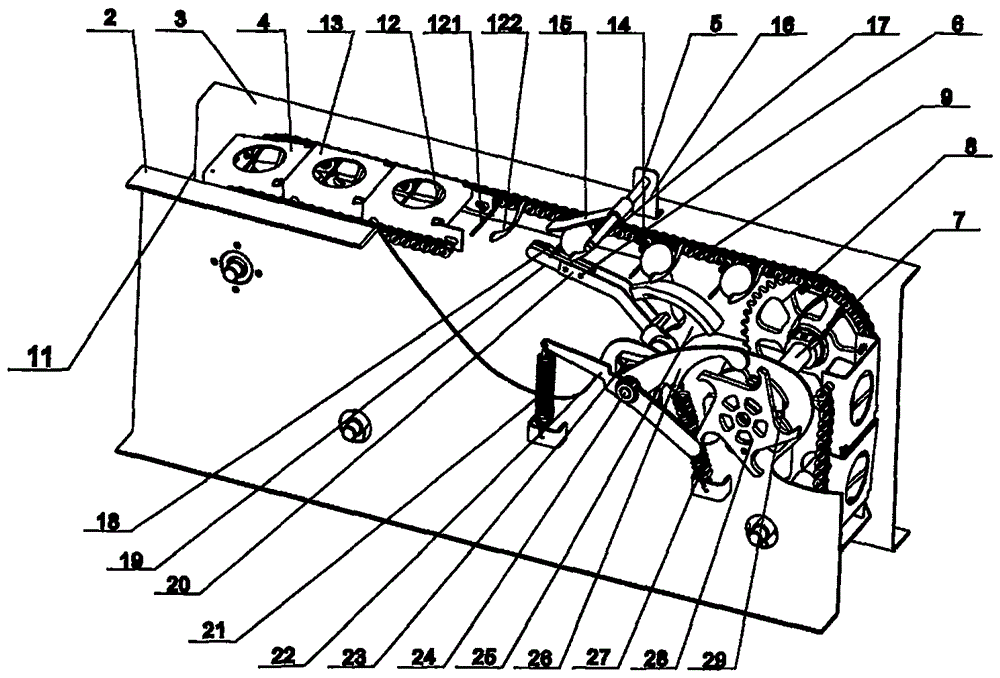

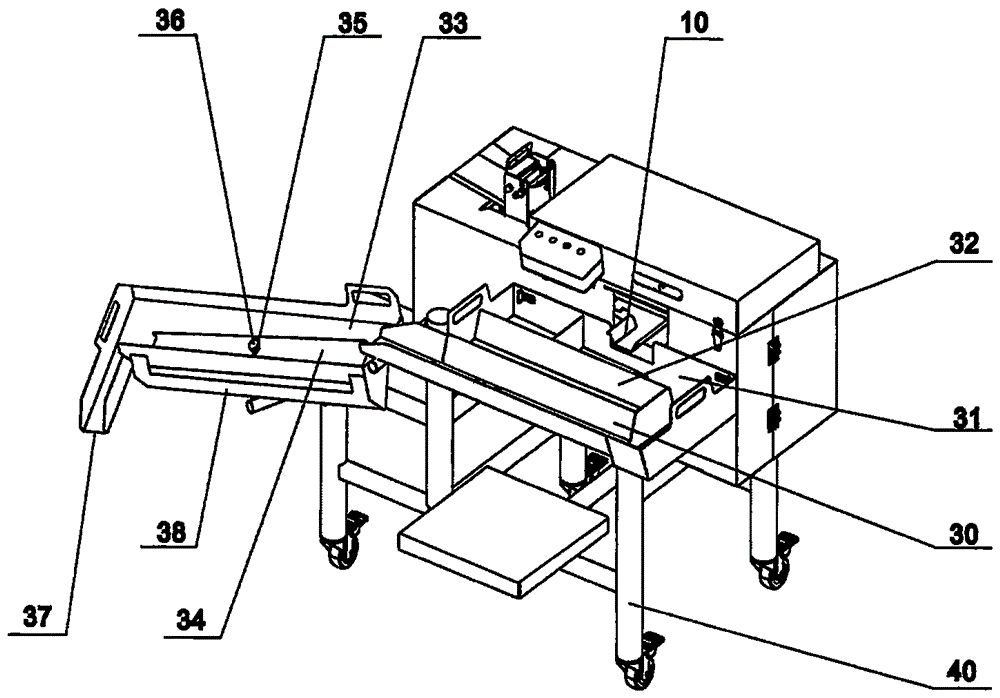

[0037] As shown in the figure, an automatic egg breaking and separating eggshell, egg white and egg yolk machine includes an egg tray 1, a front wall panel 2, a rear wall panel 3, a receiving device 4, a pressing device 5, an egg breaking device 6, and a power input shaft 7 , transmission sprocket 8, transmission chain 9, egg white and egg yolk outlet 10, egg shell outlet 11; egg tray 1 is arranged on the upper left side, front wallboard 2 and rear wallboard 3 are respectively arranged symmetrically on the front and rear sides, and the receiving device 4 It is arranged on the lower part of the egg tray 1, and the pressing device 5 is arranged on the upper part between the front wallboard 2 and the rear wallboard 3; the egg breaking device 6 is arranged at a position between the front wallboard 2 and the rear wallboard 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com