Loading transition mechanism and loading device comprising same

A transition mechanism and material feeding technology, which is applied in the direction of packaging, etc., can solve the problems of difficult timing control at the end of the direct vibration material channel, limiting the running speed of the machine, and prone to material dropouts, etc., to achieve simple structure, improve production efficiency, and reduce material dropouts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0028] Such as Figure 1 to Figure 7 Drawings of embodiments of the invention.

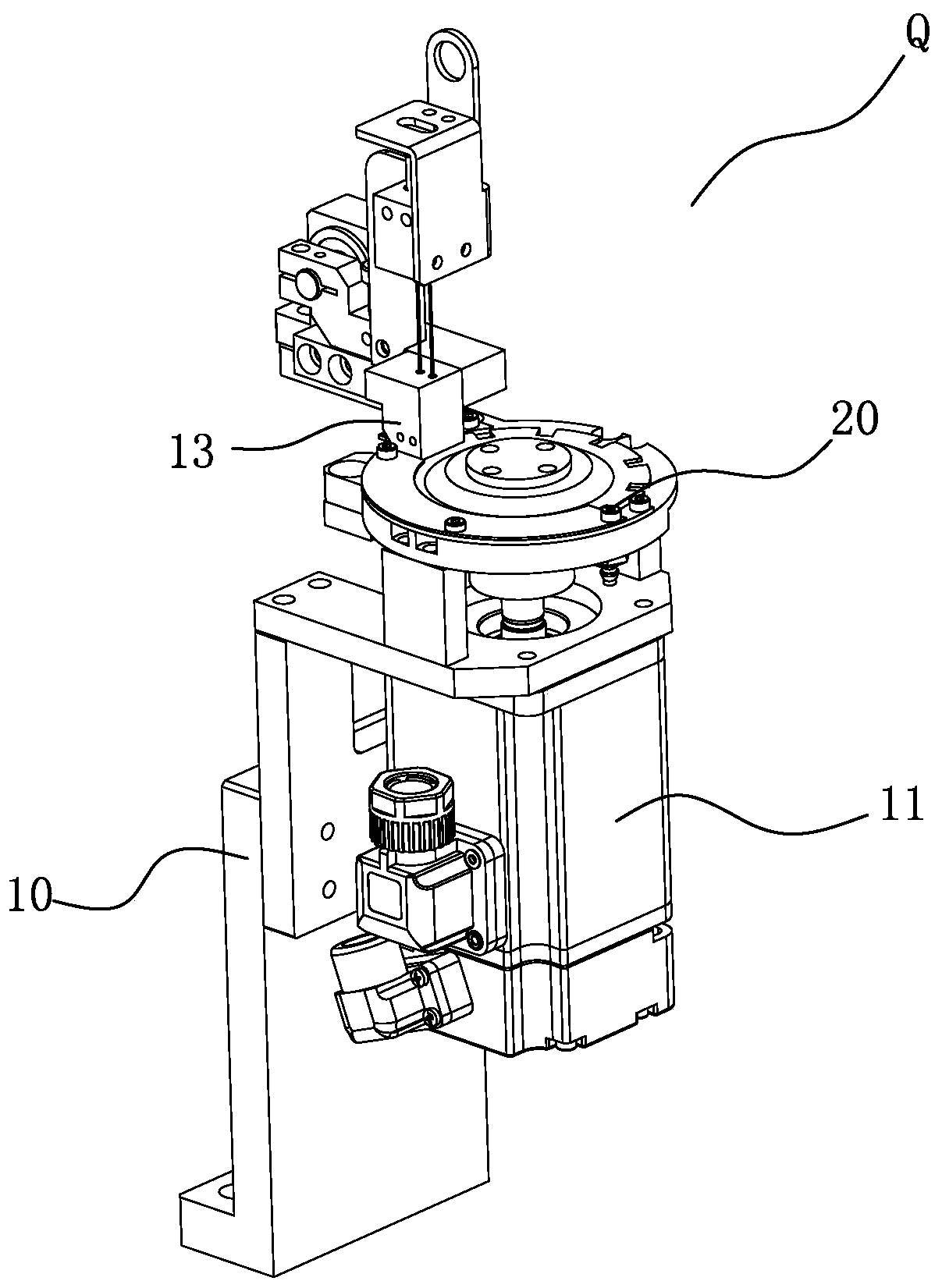

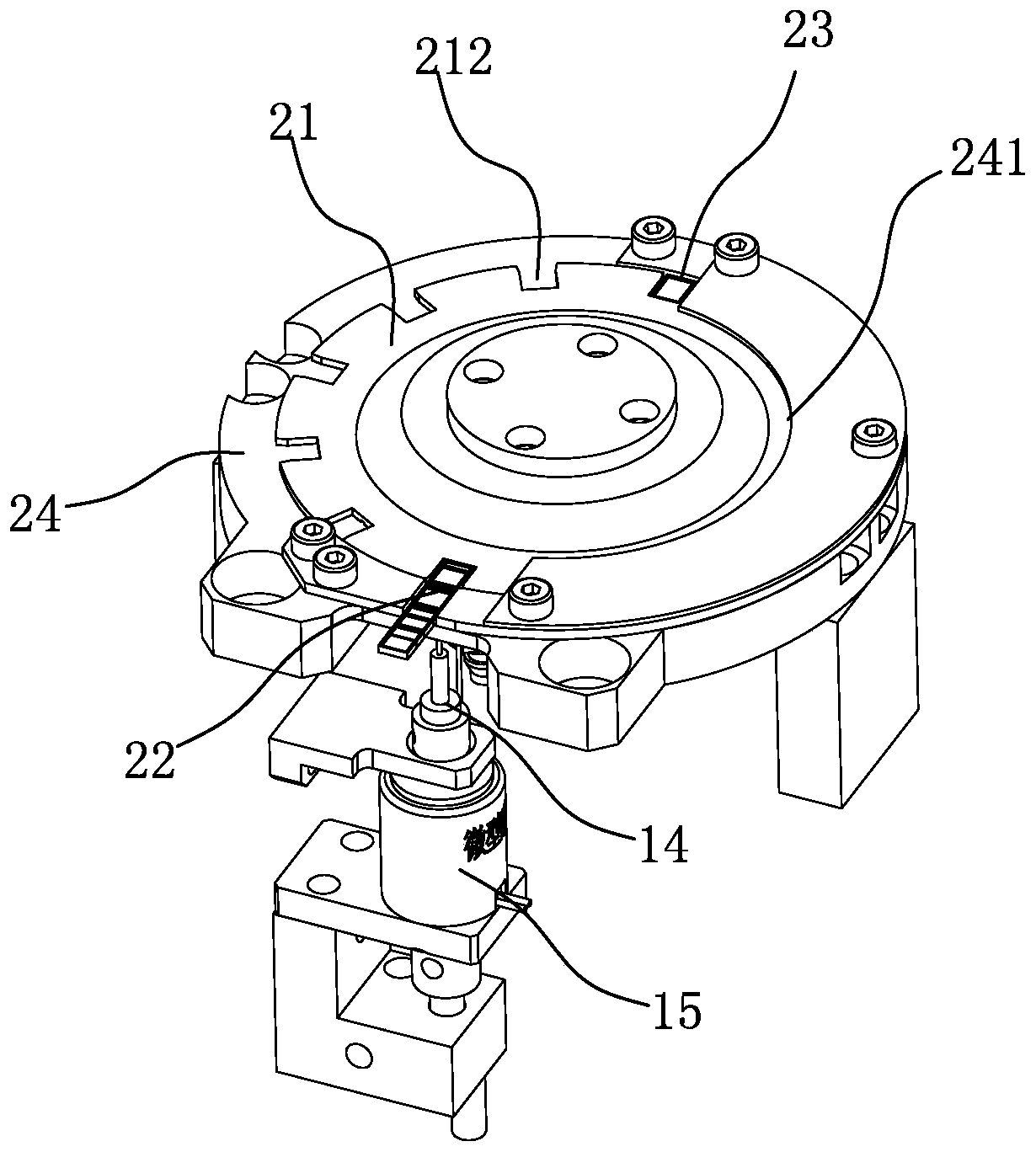

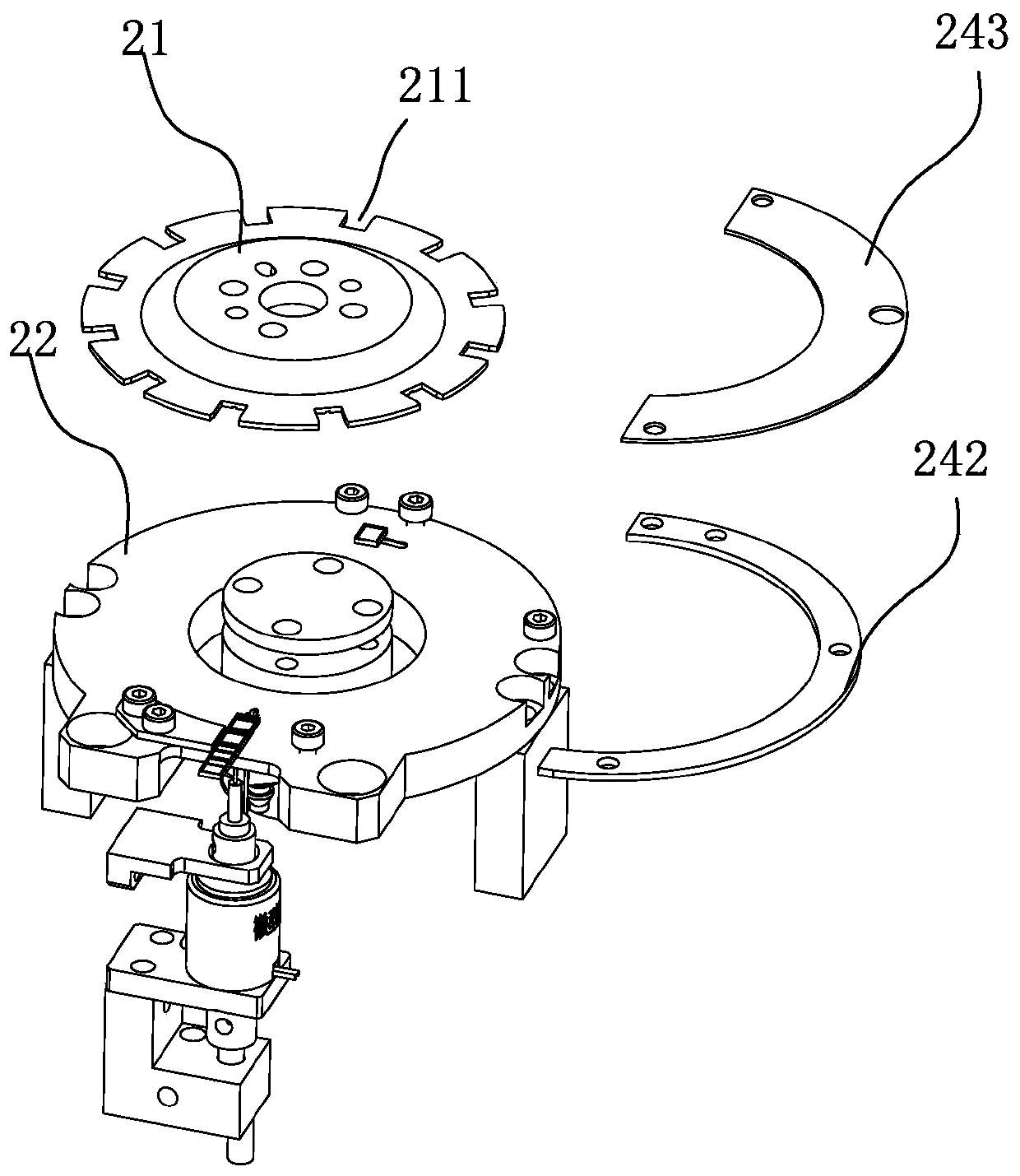

[0029] A transition mechanism Q for feeding, such as Figures 1 to 6 As shown, it includes a mounting frame 10 , a feeding power part 11 arranged on the mounting frame 10 , and a feeding assembly 20 arranged at the power output end of the feeding power part 11 . The feeding assembly 20 is provided with a turntable 21 that is transmission-coupled with the feeding power member 11 . The turntable 21 rotates between the provided loading level 22 and the loading level 23 , so that the material is transferred from the loading level 22 to the loading level 23 .

[0030] The feeding assembly 20 includes a chuck bottom plate 24 fixed on the installation frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com