Method and device for fastening joint corner position of sealing strip of front door of automobile

A technology for sealing strips and front doors, which is applied to sealing devices, engine seals, and vehicle components, etc. It can solve problems such as extrusion deformation of sealing strips, easy loosening of clamping guide rails, and improper installation of rubber strips, etc., and achieves simple structure, Solve the effect of water leakage and dust leakage and avoid water leakage and dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

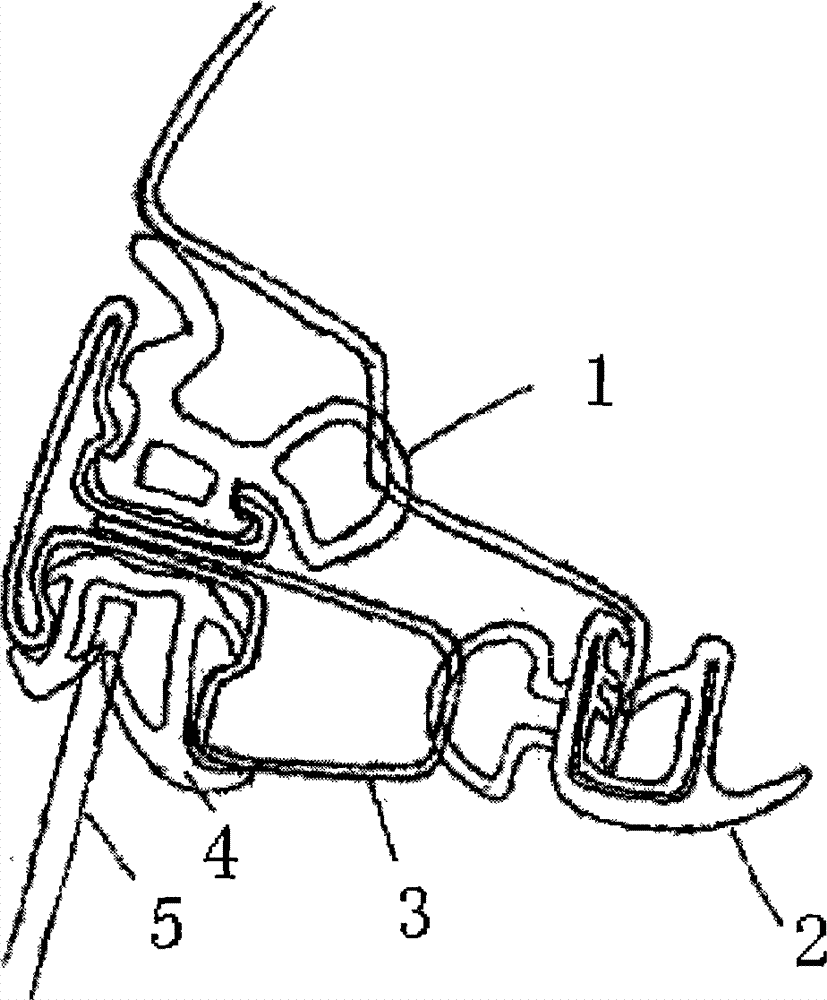

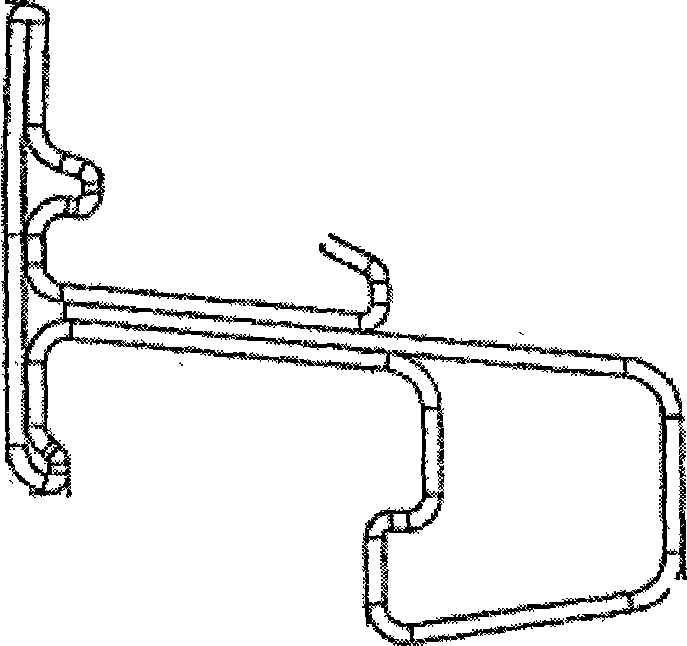

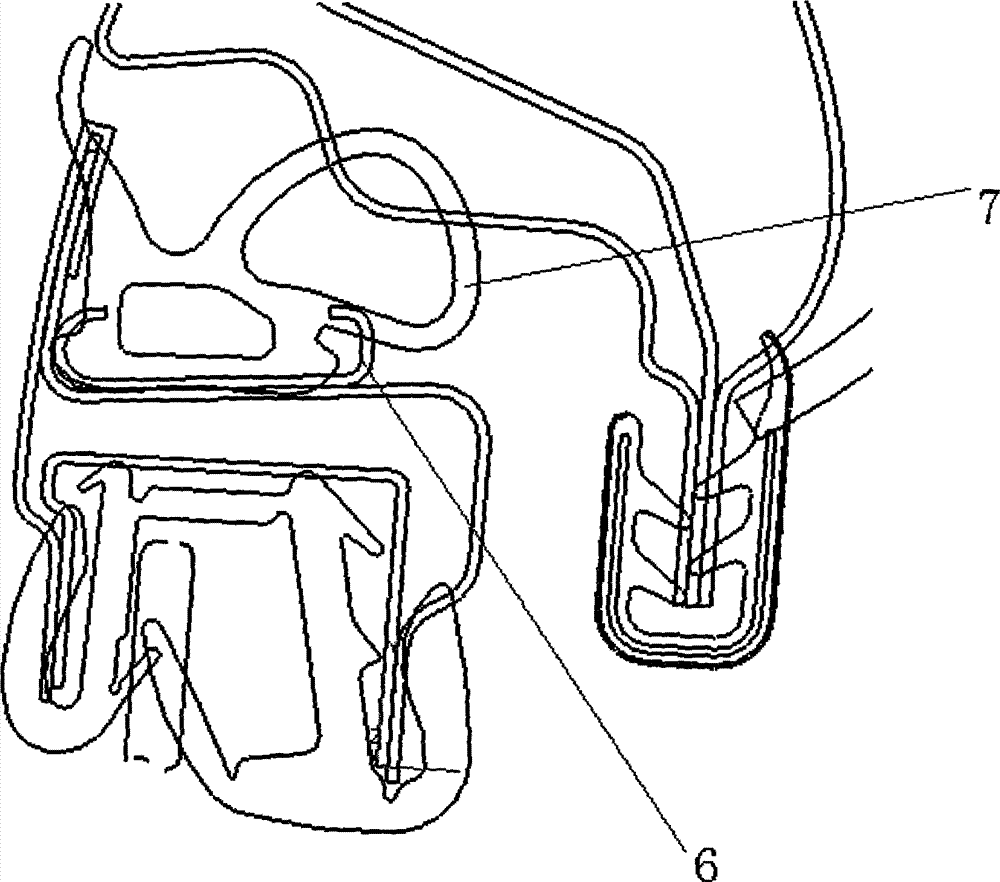

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] A method for fastening corners of automobile front door sealing strips, comprising the following steps:

[0043] The upper half of the front door sealing strip is close to the edge of the guide rail 20mm to 40mm (preferably 30mm), and the inserting piece is arranged at the bottom of the sealing strip. The insertion piece can slide freely in the welding guide rail;

[0044] When assembling, first slide the insert into the guide rail, and then install and fasten the sealing strip.

[0045] The thickness of the insertion piece is 0.5mm to 3mm, preferably the thickness of the insertion piece is 1mm to 1.2mm. The length of the insertion piece is 15mm to 35mm, preferably the length of the insertion piece is 20mm to 25mm. The material of the inserting piece is hard plastic or metal, and the inserting piece is bonded to the bottom of the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com