Super-elastic non-hemming denim fabric and preparation method thereof

A technology for denim fabrics and hemming, applied in the direction of trimming, weaving, yarn, etc., can solve the problems of elastic recovery and elastic growth that are difficult to meet the standard requirements of downstream customers, difficult to correct, and hemming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

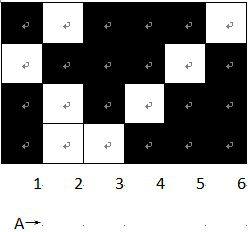

[0054] refer to figure 1 , A direction is from the ground tissue outward along the weft direction. figure 1 The middle is the two cycle units of side weave, among which (1, 2) are plain weave units, specifically the change of 2 up and 1 down through heavy flat weave; (3, 4, 5, 6) are twill weave units, specifically The right twill weave with 3 up and 1 down; figure 1 Each square in the table represents a weaving point, where the black square indicates that the warp yarn is on top, and the white square indicates that the weft yarn is on top.

[0055] The super-elastic non-curling denim fabric of the present embodiment comprises a ground weave and two side weaves, the ground weave is a right twill weave, and the two side weaves are mirror-symmetrically distributed on the left and right sides of the ground weave; figure 2 The edge organization of is the edge organization on the right side of the ground organization.

[0056] The side weave includes two cyclic units: plain wea...

Embodiment 2

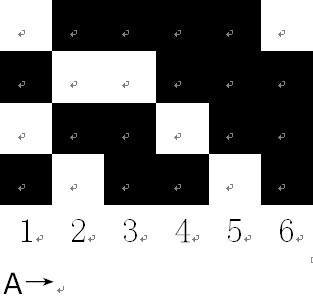

[0062] refer to figure 2 , A direction is from the ground tissue outward along the weft direction. figure 2 The middle is two cycle units of side weave, among which (1, 2) are plain weave units, specifically 1 up and 1 down plain weave; (3, 4, 5, 6) are twill weave units, specifically 3 Upper and lower left twill weave; figure 2 Each square in the table represents a weaving point, where the black square indicates that the warp yarn is on top, and the white square indicates that the weft yarn is on top.

[0063] The super-elastic non-curling denim fabric of this embodiment includes a ground weave and two side weaves, the ground weave is a twill weave, and it is characterized in that: the mirror images of the two side weaves are symmetrically distributed on the left and right sides of the ground weave;

[0064] The side weave includes two cyclic units: a plain weave unit and a twill weave unit; the plain weave unit is a plain weave with 1 upper and 1 lower. The twill weave...

Embodiment 3

[0070] The super-elastic non-curling denim fabric of this embodiment includes a ground weave and two side weaves, the ground weave is a twill weave, and it is characterized in that: the mirror images of the two side weaves are symmetrically distributed on the left and right sides of the ground weave;

[0071] The side weave includes two cyclic units: a plain weave unit and a twill weave unit; the two cyclic units are the same as in Example 1, and the plain weave unit is a double-up and one-down re-flat weave. The twill weave unit is 3 up and 1 down right twill weave. The warp yarn ratio of the plain weave unit and the twill weave unit is 1:2;

[0072] The weave structure of the side weave, from the ground weave to the outside along the weft direction, is as follows: plain weave unit cycle 12 times, twill weave unit cycle 1 time, plain weave unit cycle 16 times, twill weave unit cycle 1 time, plain weave unit cycle 18 times;

[0073] The preparation method of the superelastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com