Edge aligning device for hot melting compound machine

A technology of a laminating machine and an edge-holding device, which is applied in the field of the edge-to-edge device of a hot-melt laminating machine, can solve the problems of affecting the overall shape and size, low compounding production efficiency, low product bonding strength, etc. Labor intensity and production cost, the effect of solving material hemming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

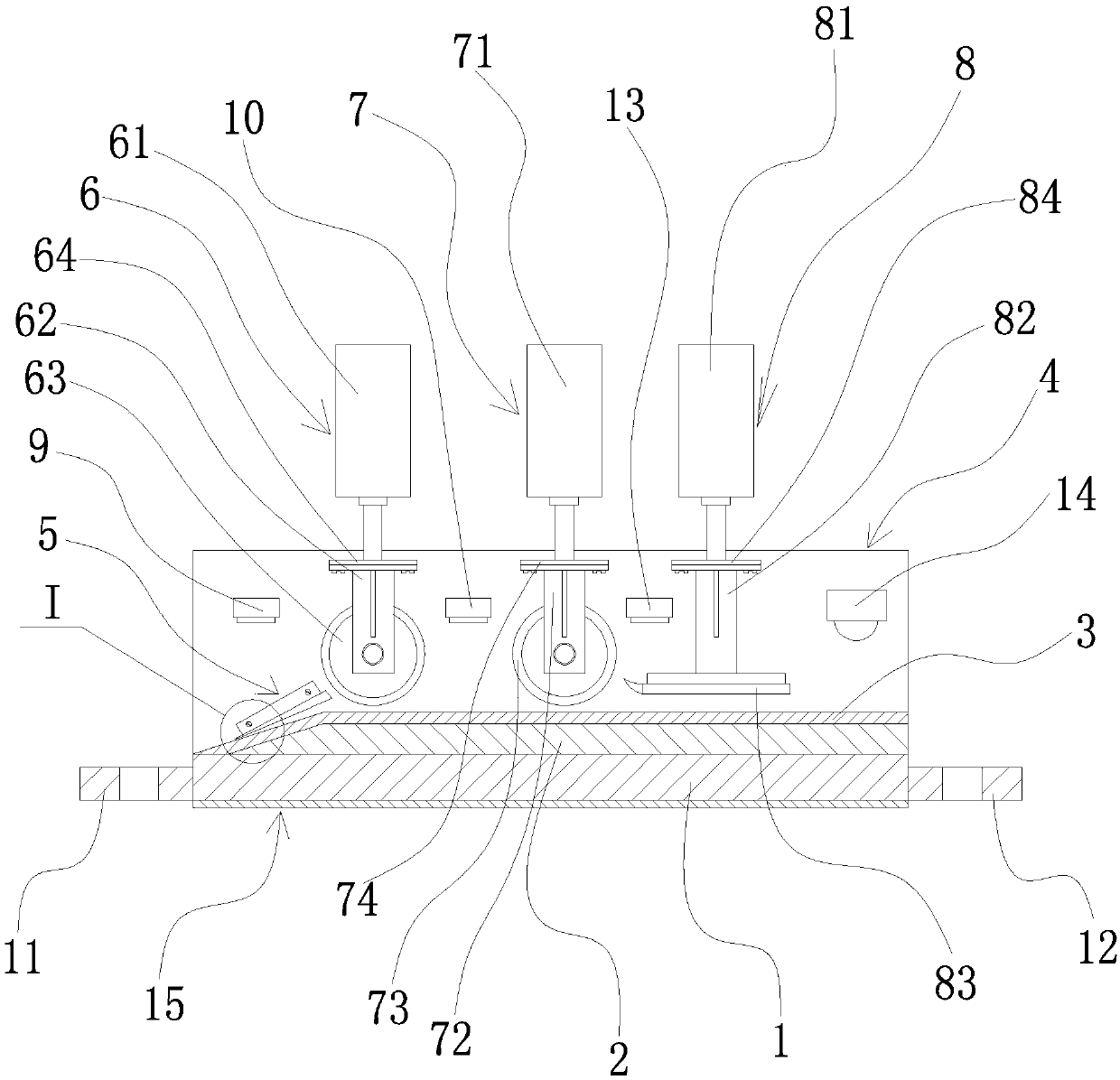

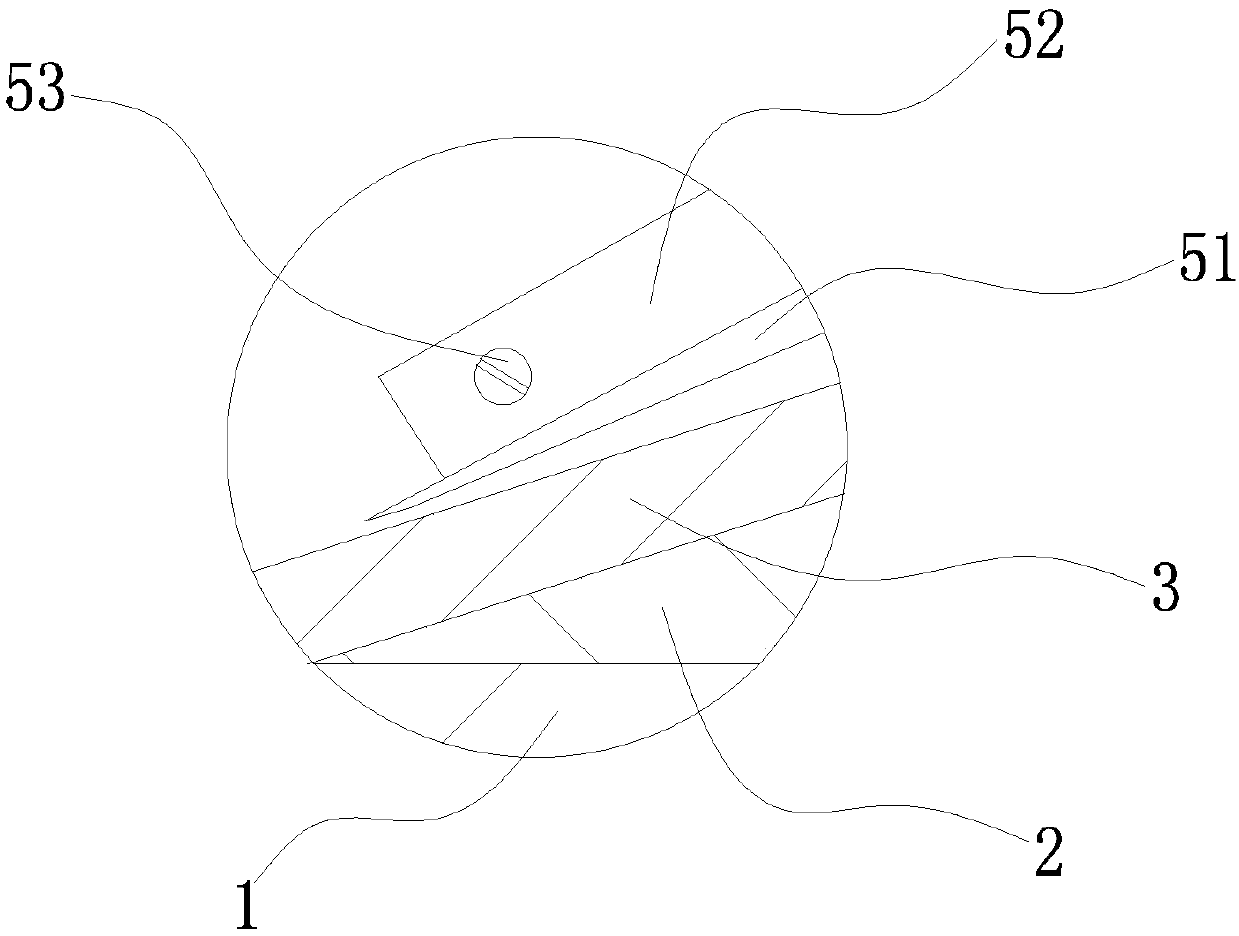

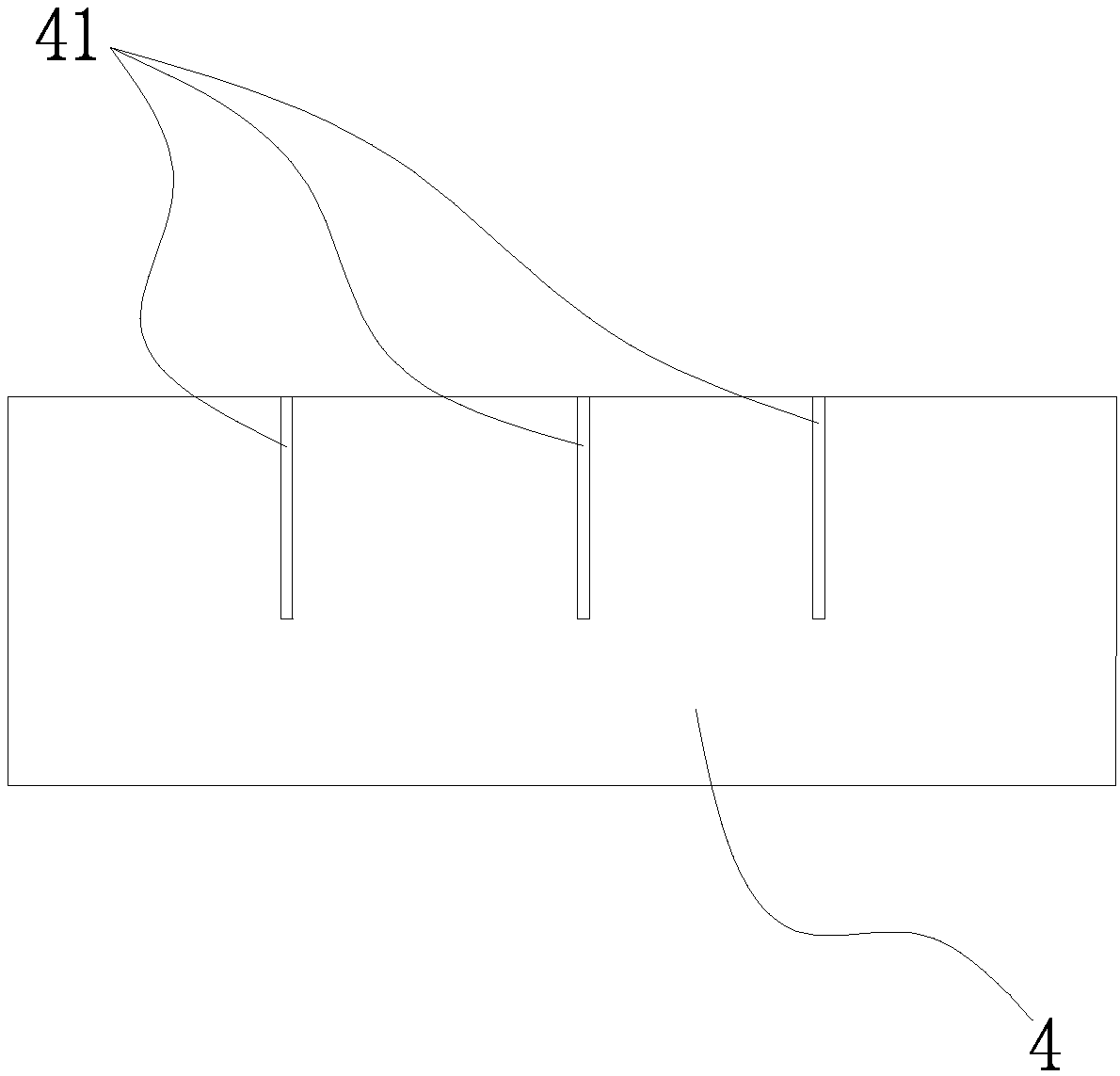

[0021] Example: such as figure 1 , figure 2 with image 3 As shown, a side-to-edge device of a hot-melt compound machine includes a bottom plate 1, a left connecting plate 11 is integrally provided on the left end of the bottom plate 1, and a right connecting plate 12 is integrally provided on the right end of the bottom plate 1, and the upper part of the bottom plate 1 A guide plate 2 is integrally arranged on the end surface, and a layer of stainless steel surface layer 3 is fixedly arranged on the upper surface of the guide plate 2; a limit plate 4 is fixedly arranged on the rear end surface of the bottom plate 1, and the stainless steel surface layer 3. A curling adjustment device 5, a first curling device 6, a second curling device 7 and a third curling device 8 are arranged in sequence from the middle to the right directly above, and the limiting plate 4 is arranged in sequence from left to right There are a first lighting device 9 , a second lighting device 10 , a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com