Battery pole piece and method for preventing battery pole piece from being curled

A battery pole piece, curling technology, applied in battery electrodes, electrode carriers/current collectors, non-aqueous electrolyte battery electrodes, etc., can solve problems such as increasing costs and wasting active materials, saving costs, improving production efficiency, and enhancing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

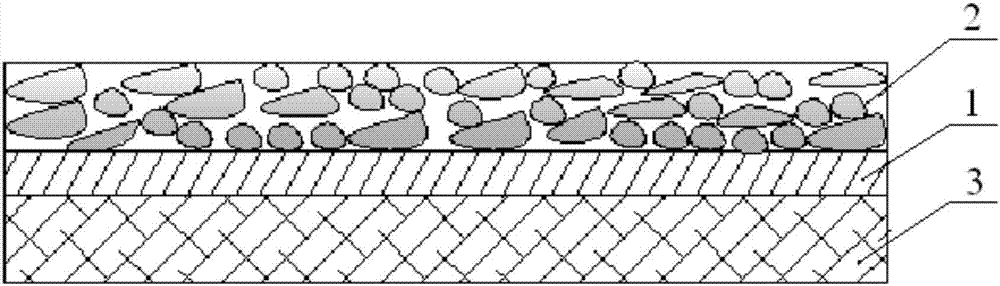

[0034] like figure 1 As shown, a battery pole piece includes a metal current collector 1, an active material layer 2 is provided on one side of the metal current collector, and a polymer material layer 3 is provided on the other side.

[0035] By arranging a polymer material layer on the side of the metal current collector that does not require an active material layer, it can offset or partially offset the stress caused by the extension of the active material after rolling, so as to solve the problem caused by the single-side coating of the pole piece after rolling. Pole sheet rolling problem. By solving the problem of pole piece curling, the production efficiency of subsequent battery assembly is improved, and the use of polymer material layers saves costs and facilitates automatic production. Sheet tearing and breakage.

[0036] In this embodiment, the metal current collector 1 is a positive electrode current collector or a negative electrode current collector. When the m...

Embodiment 2

[0046] This embodiment discloses a method for manufacturing a lithium battery in an aluminum-plastic flexible package, which specifically includes the following steps:

[0047]Step 1) Prepare the positive electrode sheet: the positive electrode active material lithium cobaltate, the binder polyvinylidene fluoride (PVDF) and the conductive agent conductive carbon black are mass ratio (94~98):(1~3):(1 ~3) Mix evenly with the solvent N-methylpyrrolidone, stir at a high speed to obtain a uniformly dispersed positive electrode slurry, and then evenly coat the positive electrode slurry on a 10-14 μm thick positive electrode current collector single-sided aluminum foil, and then blow it After drying, the polyester PET film with a thickness of 45-55 μm is laminated on the aluminum foil on the other side, and then cold-pressed and die-cut to obtain a positive pole piece of the corresponding size. In this embodiment, the thickness of the positive pole piece is 120 μm, the width is 21mm,...

Embodiment 3

[0053] This embodiment discloses a method for manufacturing a lithium battery in an aluminum-plastic flexible package, comprising the following steps:

[0054] Prepare the positive electrode sheet: prepare the positive electrode sheet according to the step 1 of Example 2, the thickness of the positive electrode sheet 4 in this embodiment is 120 μm, the width is 42.2 mm, and the height is 25 mm, such as figure 2 shown;

[0055] Prepare the negative electrode sheet: prepare the negative electrode slurry according to the step 2 of Example 2, then apply the negative electrode slurry on both sides of the 9 μm copper foil, and then cold press and die-cut to obtain a thickness of 148 μm and a width of 22 mm. High is the negative pole piece 5 of 26mm, such as image 3 shown;

[0056] Make electrolyte, make electrolyte the same as step 3) of embodiment 2;

[0057] A piece of positive pole piece 4 prepared is wrapped around a piece of negative pole piece 5, and a separator is set be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com