The treatment method of the steel casing sinking and meeting the boulder, the structure of the steel casing and the bored pile

A processing method, steel casing technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as jamming and edge curling at the bottom of steel casings, and achieve high efficiency, high reliability, and low efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

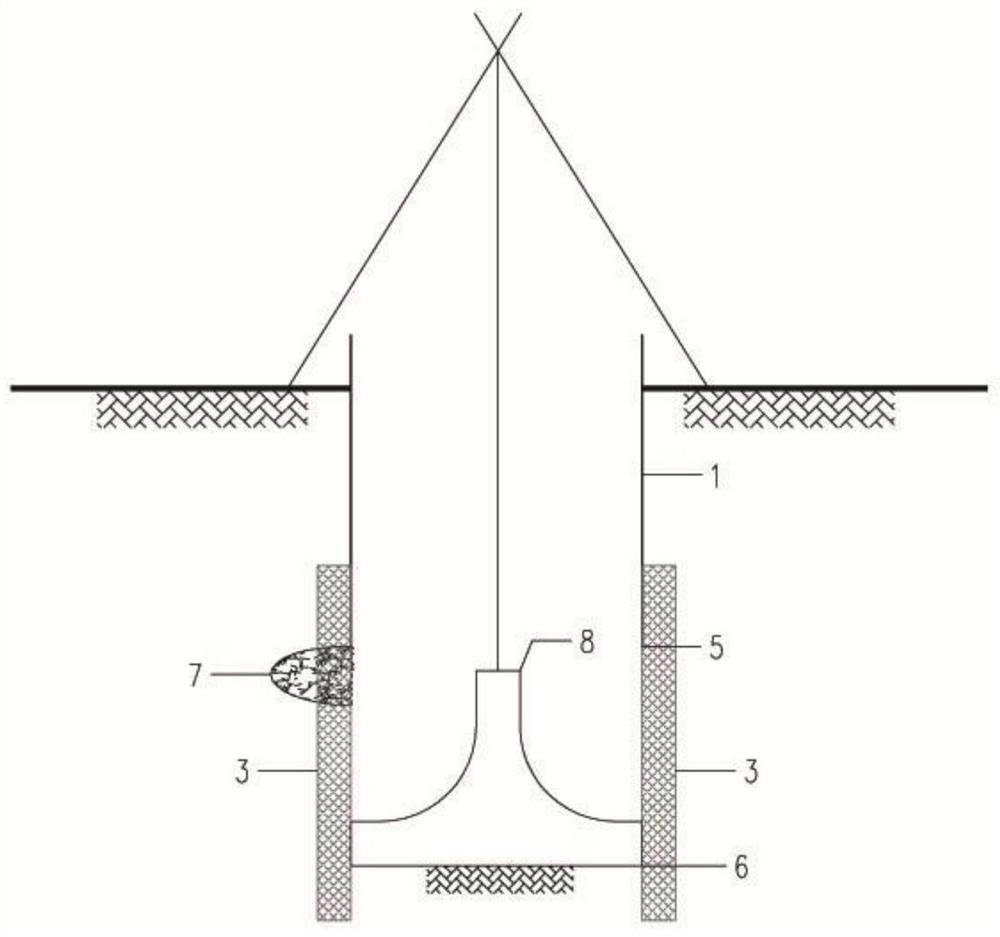

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The embodiment of the present invention provides a treatment method for steel casings sinking and encountering boulders, which is used for the construction of steel casings for piles with boulders 7, which is characterized in that it includes the following steps:

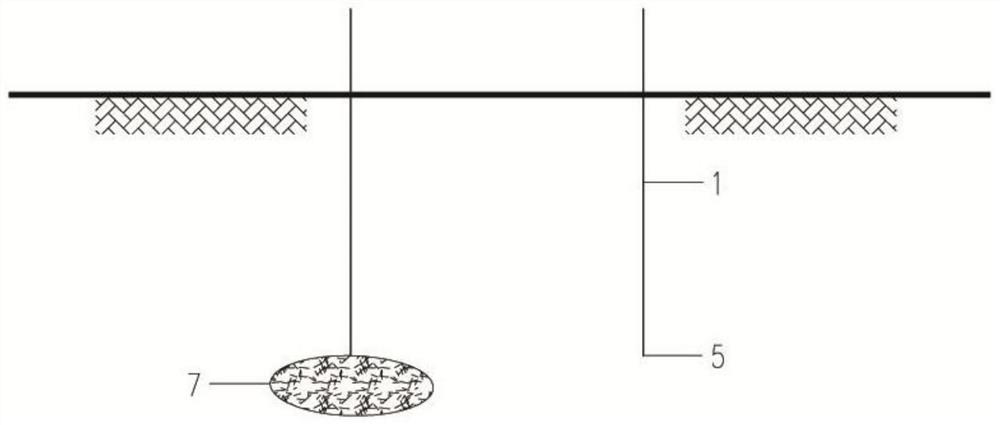

[0039] S1. At the designed pile position, insert the first steel casing 1 until the bottom of the first steel casing 1 encounters the boulder 7. The diameter of the first steel casing 1 is larger than the designed pile hole diameter, see figure 1 shown.

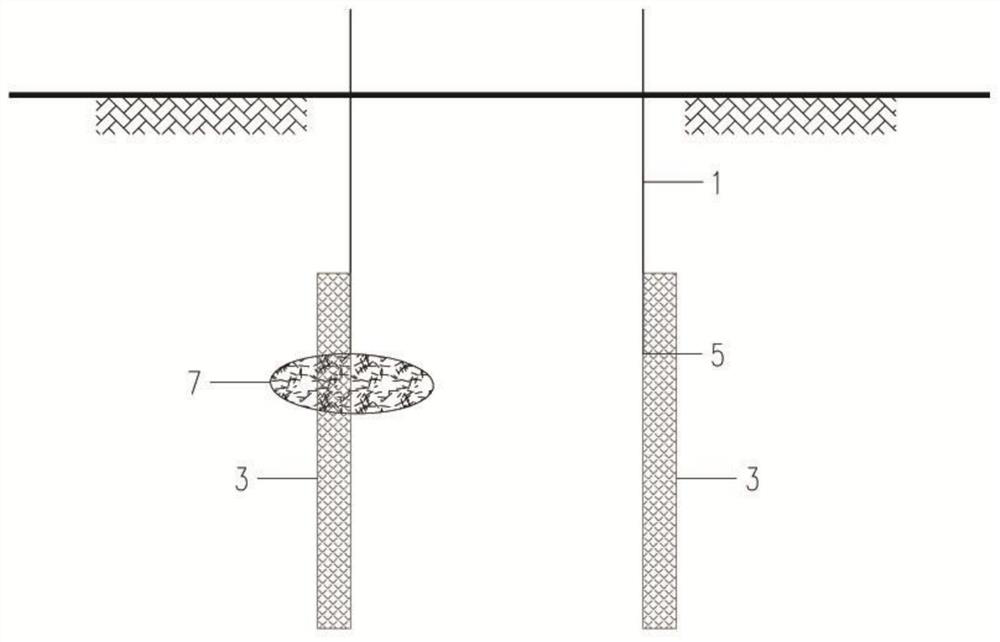

[0040] S2. Carry out the hole sweeping operation along the inner wall of the first steel casing 1, break the boulder 7 at the hole wall, and excavate the pile hole until the bottom reaches the steel casing bottom elevation 6 required by the design, see figure 2 shown. Wherein, preferably, the excavation of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com