Spinning method of spinning machine

A textile machine and loom technology, applied in the textile field of textile machines, can solve the problems of low product quality, low production and maintenance efficiency, insufficient precision, etc., and achieve the effects of high product quality, fast assembly efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

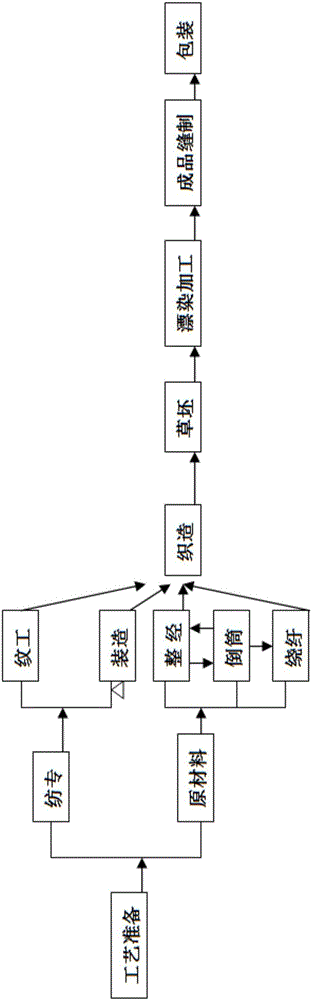

[0057] Such as figure 1 Shown, a kind of textile machine weaving method, the steps are as follows:

[0058] A. Pre-weaving process preparation includes the preparation of the textile machine and the preparation of raw materials;

[0059] 1) Prepare the textile machine:

[0060] Carry out the flat car process first, disassemble and overhaul the textile machine, the specific method is as follows: a method for disassembling a jacquard loom, including the following steps:

[0061] A. Car dismantling: remove the original loom parts, retain the wall panels and frame, disassemble the loom parts in turn, and repair the worn shafts after disassembly; the worn shafts include the rear rod shaft, the rear beam, the central shaft, and the bent shaft , rocking shaft, warp let-off shaft, bristling roller, reed clamping shaft. Repaired components provide parts for new looms, ready for subsequent production.

[0062] B. Loading: Install the loom components that need to be installed on the ...

Embodiment 2

[0106] Embodiment 2 is basically the same as Embodiment 1, and also includes installing the central shaft in step B of disassembling and assembling the textile machine, and adjusting the tightness of the four carriage screws up and down on the spherical bearing to ensure that the gap between the left and right of the central shaft is within 1mm. The positioning axis can be quickly adjusted by using the screw, and the relative rotation of the spherical surface can be realized, and the letter can be rotated flexibly with one hand to ensure the flexible movement of the loom.

Embodiment 3

[0108] Embodiment 3 is basically the same as Embodiment 1 or 2, and it also includes that the front and rear of the rocking shaft and the middle main shaft maintain a certain position and are fixed with regular rules, and the gap between the left and right of the rocking shaft is within 1mm. When correcting, fasten a sley support on the rocking shaft, and it should be able to fall automatically at 45° front and rear. Due to the eccentricity of the sleeve, the gap between the rocking shaft and the sleeve accessories is large, which makes the total eccentricity large, and it cannot be four-centered. Flexible, in this case, ensure that the sleeve screw is at the bottom, and the front and rear 45° can automatically fall, that is, the three-center is flexible, ensuring the flexibility of the rocker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com