Fully electric melting kiln for glass bottle materials

A glass bottle, all-electric melting technology, applied in the field of electric kilns, can solve the problems of poor kiln charging fluctuation, easy calculus in electric melting kilns, shortened kiln body life, etc., and achieves less kiln calculi, stable power supply, and enhanced hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

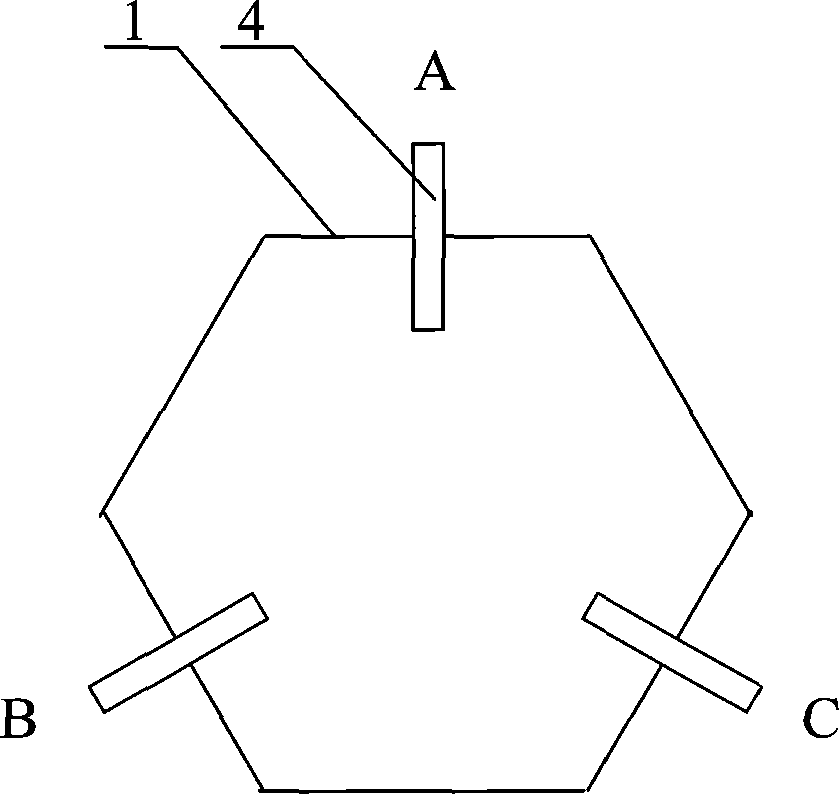

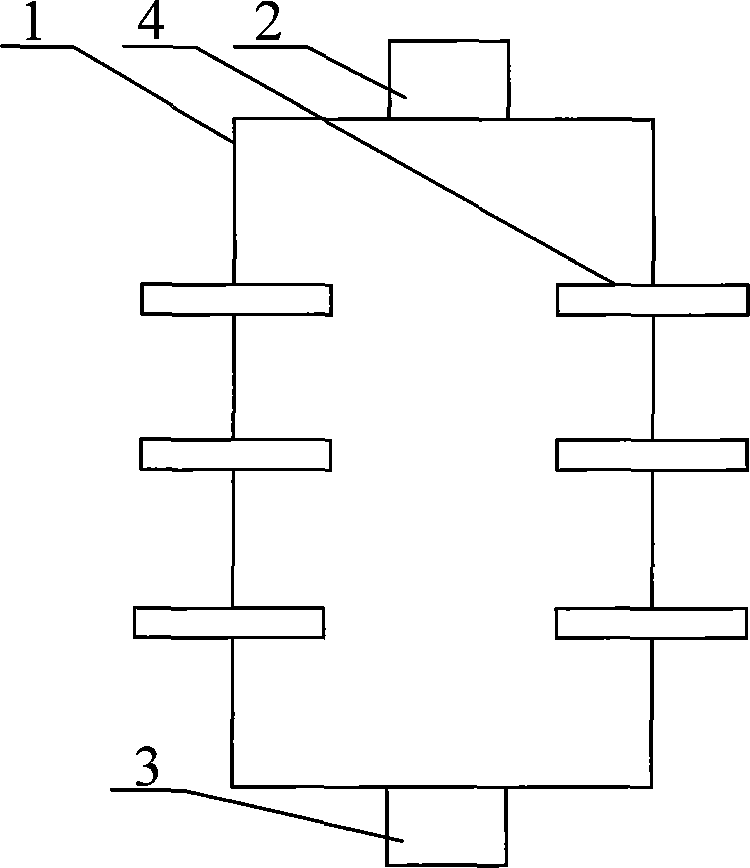

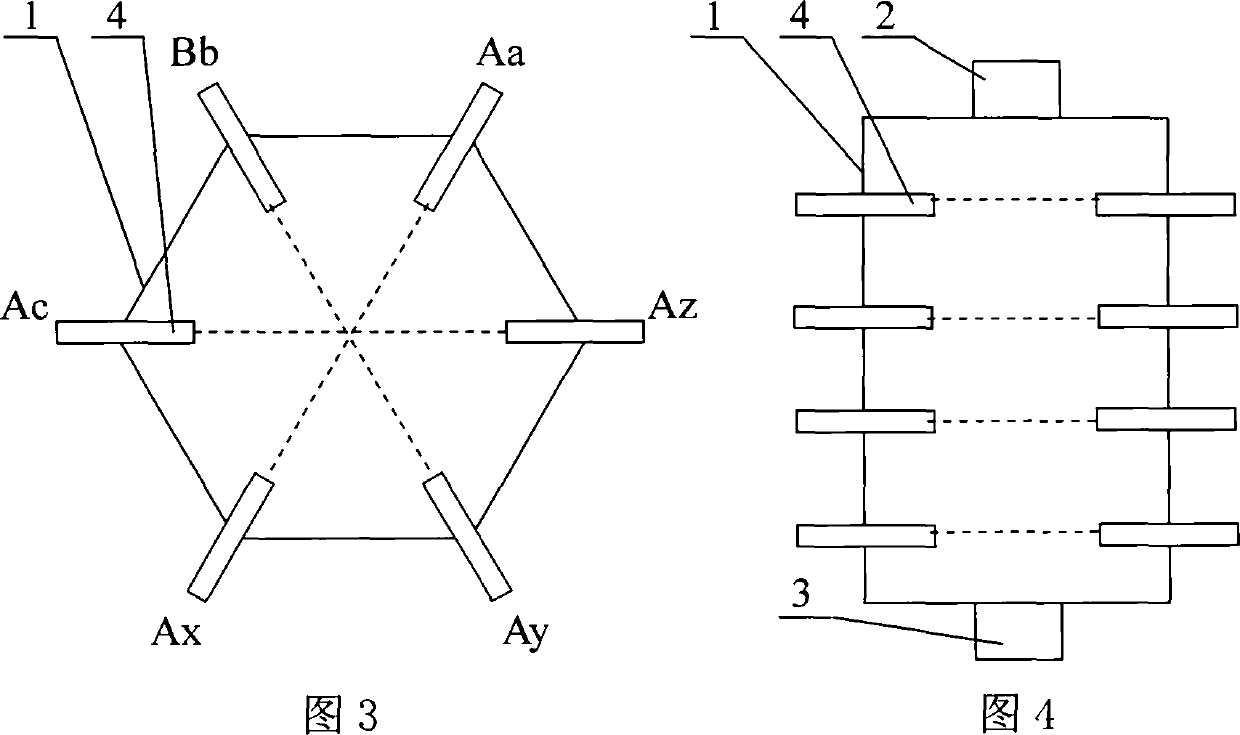

[0022] like image 3 As shown, an all-electric melting furnace for glass bottle materials is composed of a furnace body 1, a feed port 2, a discharge port 3, a molybdenum electrode 4 and a transformer in front of the kiln. The kiln body is hexagonal and is a vertical kiln. The feed port and the discharge port are respectively set at the upper and lower ends of the kiln body. Molybdenum electrodes are inserted into the interior of the kiln body in layers. Each layer of molybdenum electrodes is six, and they are fixed on the six corners of the hexagonal kiln body in the shape of a rice. superior. The molybdenum electrodes are divided into four layers for 24 molybdenum electrodes. The output terminals of the transformer in front of the kiln are electrically connected to the molybdenum electrodes respectively.

[0023] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com