Inflatable fermented milk and preparation method thereof

A fermented milk and starter technology, applied in the field of aerated fermented milk and its preparation, can solve the problems of poor gas retention, texture collapse, and instability of aerated fermented milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

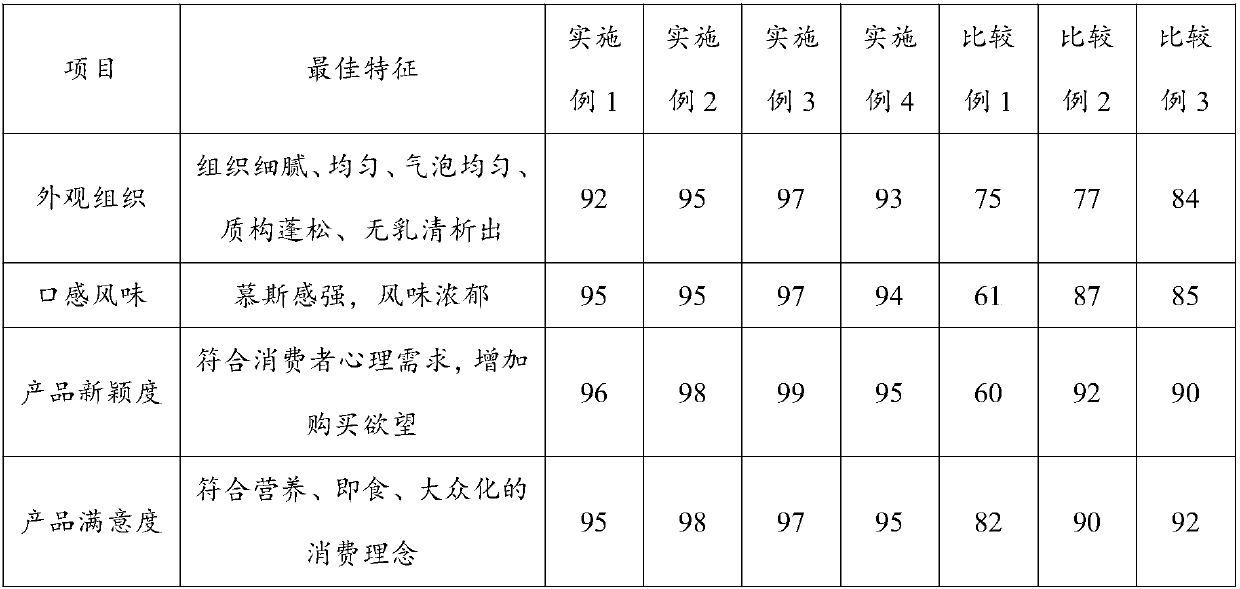

Examples

preparation example Construction

[0024] A method for preparing aerated fermented milk, the fermented milk comprises the following raw materials in mass ratio: 8-12% of sucrose, 0-15% of cream, 0-0.15% of emulsifier, 0-0.25% of pectin, 0.5-2% of gelatin %, 0.7-1.5% of starch, 0.004-0.008% of starter, and the rest is raw milk. The fermented milk is also filled with nitrogen, and the filling amount of nitrogen is 75-85% of the volume of the fermented milk.

[0025] The aerated fermented milk of the present invention is filled with nitrogen, and gelatin and starch are added to the raw materials to increase the solid content, and the obtained aerated fermented milk is solidified, has a novel texture, is silky and delicate, and has a soft taste like a mousse cake.

[0026] Wherein, the starch is modified starch, and the proportion of branched chains in the modified starch is less than 50%. The modified starch has good stability, and when added to fermented milk, the fermented milk can be aerated to maintain good st...

Embodiment 1

[0049] An aerated fermented milk comprises the following raw materials by mass ratio: 8% sucrose, 2% gelatin, 0.7% modified starch, 0.004% starter, and the balance is raw milk. The fermented milk is also filled with nitrogen gas. It is 75% of the volume of the fermented milk.

[0050] The preparation method of the aerated fermented milk comprises the following steps:

[0051] (1) Heating the raw material milk to 60°C, mixing sucrose, gelatin, and modified starch into the raw material milk evenly, and stirring for 15 minutes to obtain material liquid A;

[0052] (2) Homogenize the feed liquid A obtained in step (1), the homogenization pressure is 18Mpa, the temperature is 60°C, after homogenization, sterilize at 90°C for 10min, and then cool to 35°C to obtain the feed liquid B;

[0053] (3) Inoculate the starter BD-100 (including Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus) in the feed liquid B obtained in step (2), ferment for 6 hours at 35°C, a...

Embodiment 2

[0058] A kind of aerated fermented milk comprises the following raw materials in mass ratio: 12% of sucrose, 15% of cream, 0.1% of mono- and diglyceride fatty acid ester, 0.05% of pectin, 0.5% of gelatin, 1.5% of modified starch, 0.008% of leavening agent, The remainder is raw cow's milk, and the fermented milk is also filled with nitrogen, and the charged amount of nitrogen is 80% of the volume of the fermented milk.

[0059] The preparation method of the aerated fermented milk comprises the following steps:

[0060] (1) Heat the raw material milk to 80°C, mix sucrose, cream, mono- and diglyceride fatty acid esters, pectin, gelatin, and modified starch, and add them to the raw material milk, stir for 30 minutes to obtain material liquid A ;

[0061] (2) Homogenize the feed liquid A obtained in step (1), the homogenization pressure is 25Mpa, the temperature is 65°C, after homogenization, sterilize at 95°C for 5min, and then cool to 37°C to obtain the feed liquid B;

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com