Patents

Literature

54results about How to "Stable organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terylene comfortable cotton velvet woolen blanket and preparing method thereof

The invention relates to a comfortable cotton velvet blanket and the technical field of the manufacturing method. The polyester comfortable cotton velvet blanket of the invention adopts the DTY polyester yarns of 0.39 to 3.12dtex and the FDY polyester yarns of 55 to 167dtex, and after warp knitting fabric manufacture, the polyester comfortable cotton velvet blanket is manufactured by that the grey cloth is sequentially treated with slitting, combing, ironing and shearing, heat setting, printing or dyeing, post treatment, back fuzzing sorting, and napping typing. The invention selects suitable materials, preparation procedures and equipment, the finished products of the polyester comfortable cotton velvet blanket have stable gram weight and strong stereoscopic impression of the hair side, and the hair height reaches ideal feeling; the suede of the blanket is like cotton, which has soft hand feeling and is fluffy; and the blanket also has very good hydroscopic property and no depilation phenomenon, is mould proofing and moth proofing, is bright in color, and can directly touch the skin, thus being sure to obtain the favour of the people.

Owner:徐建平

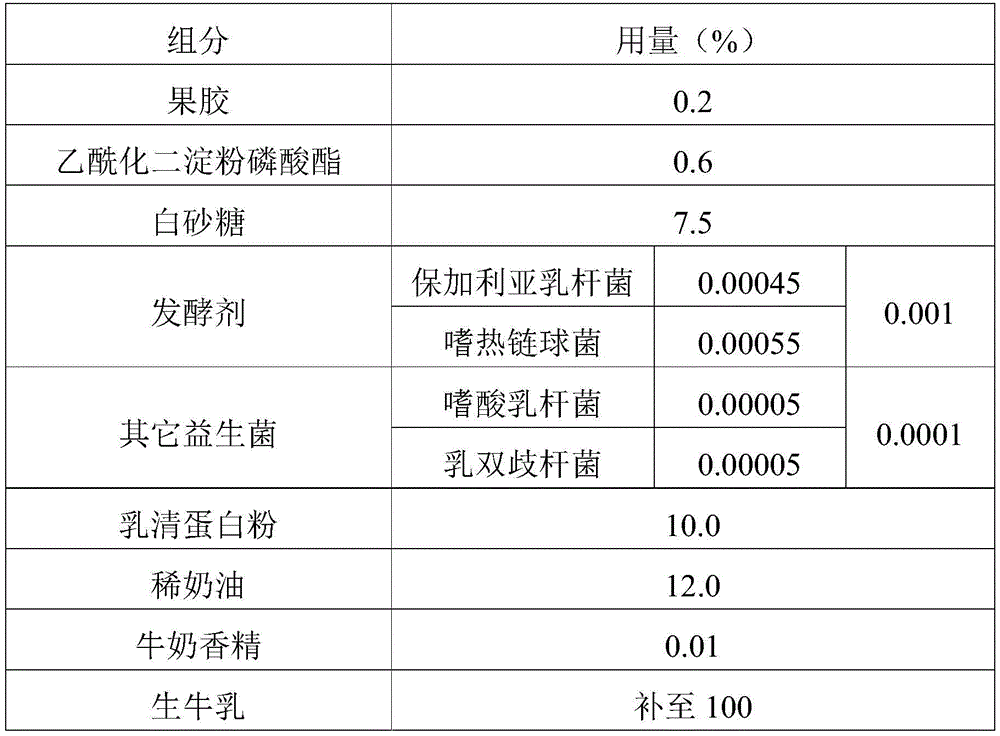

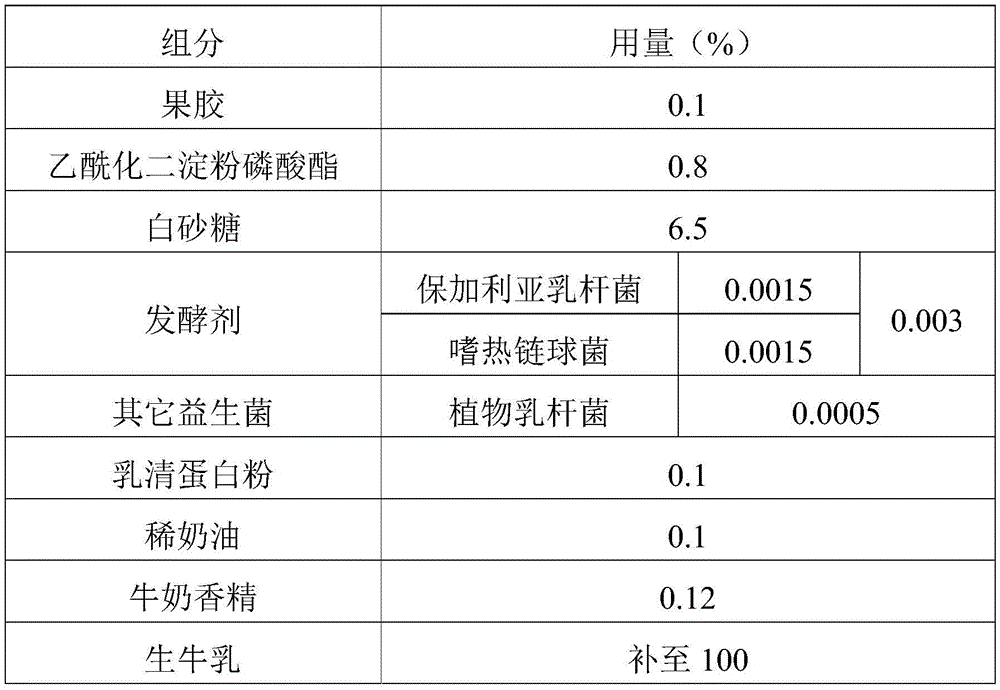

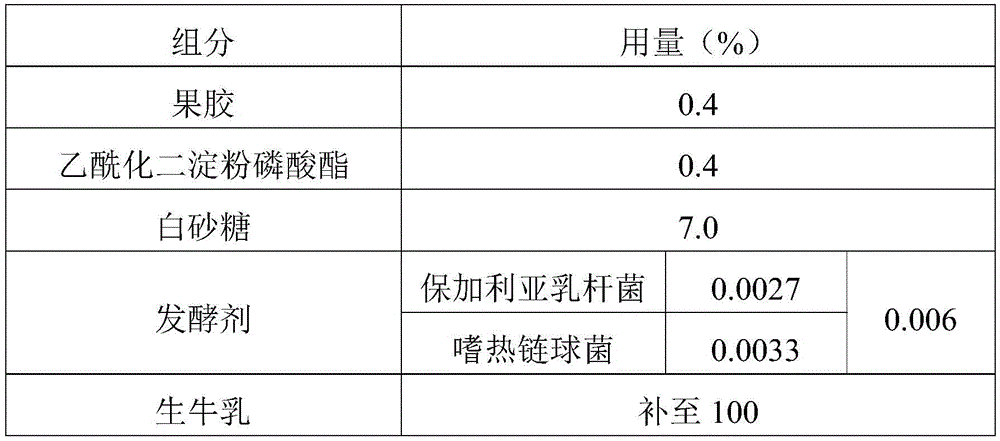

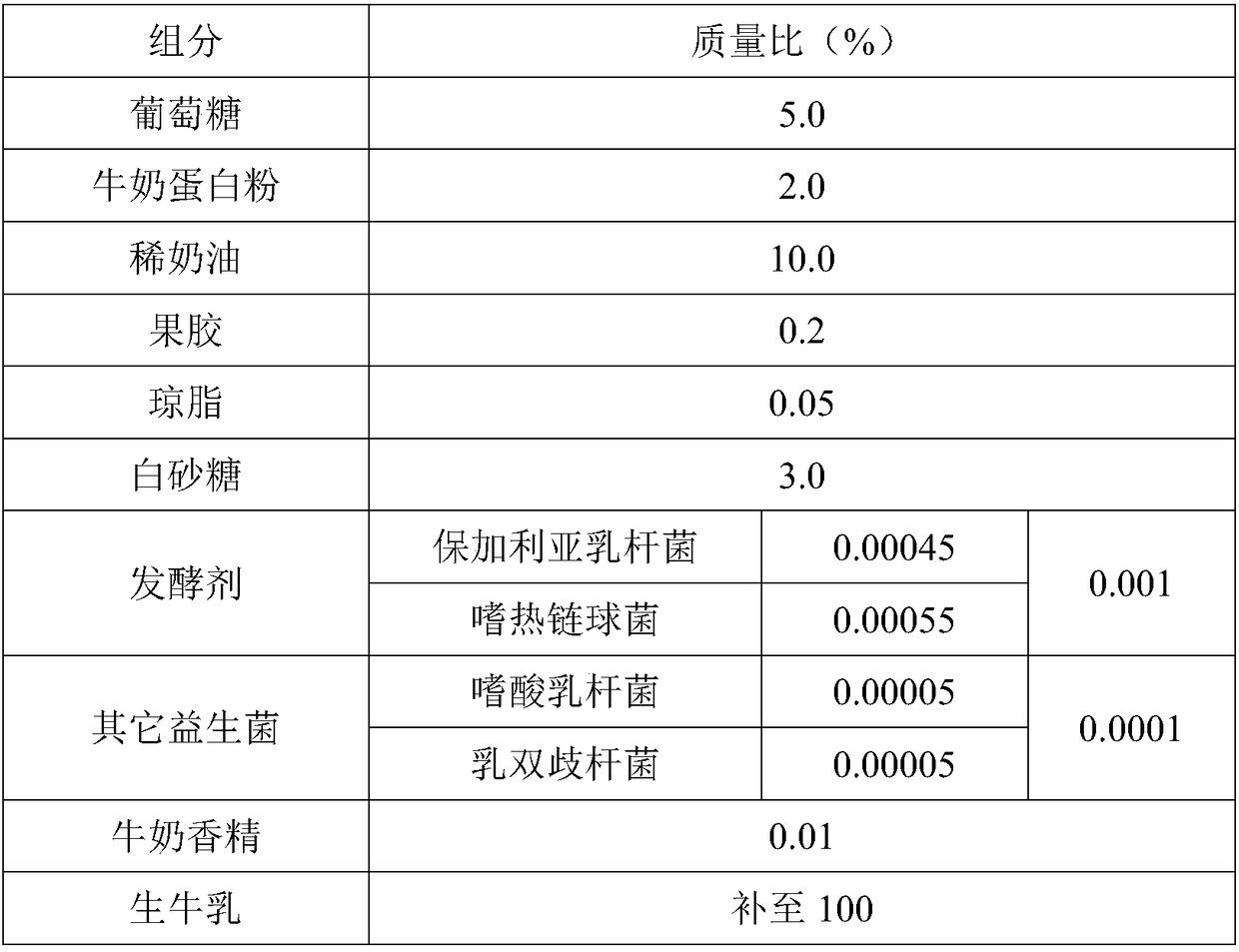

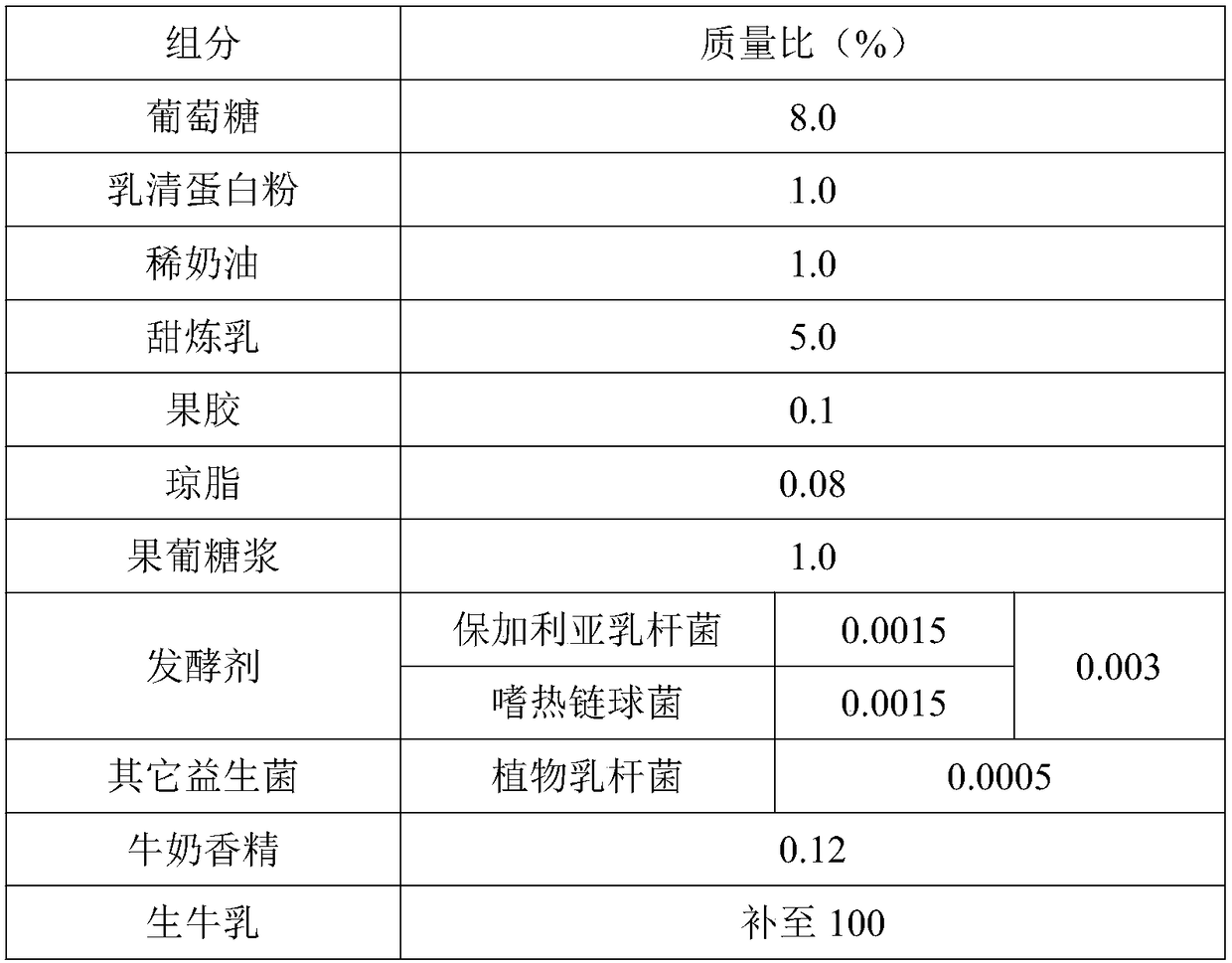

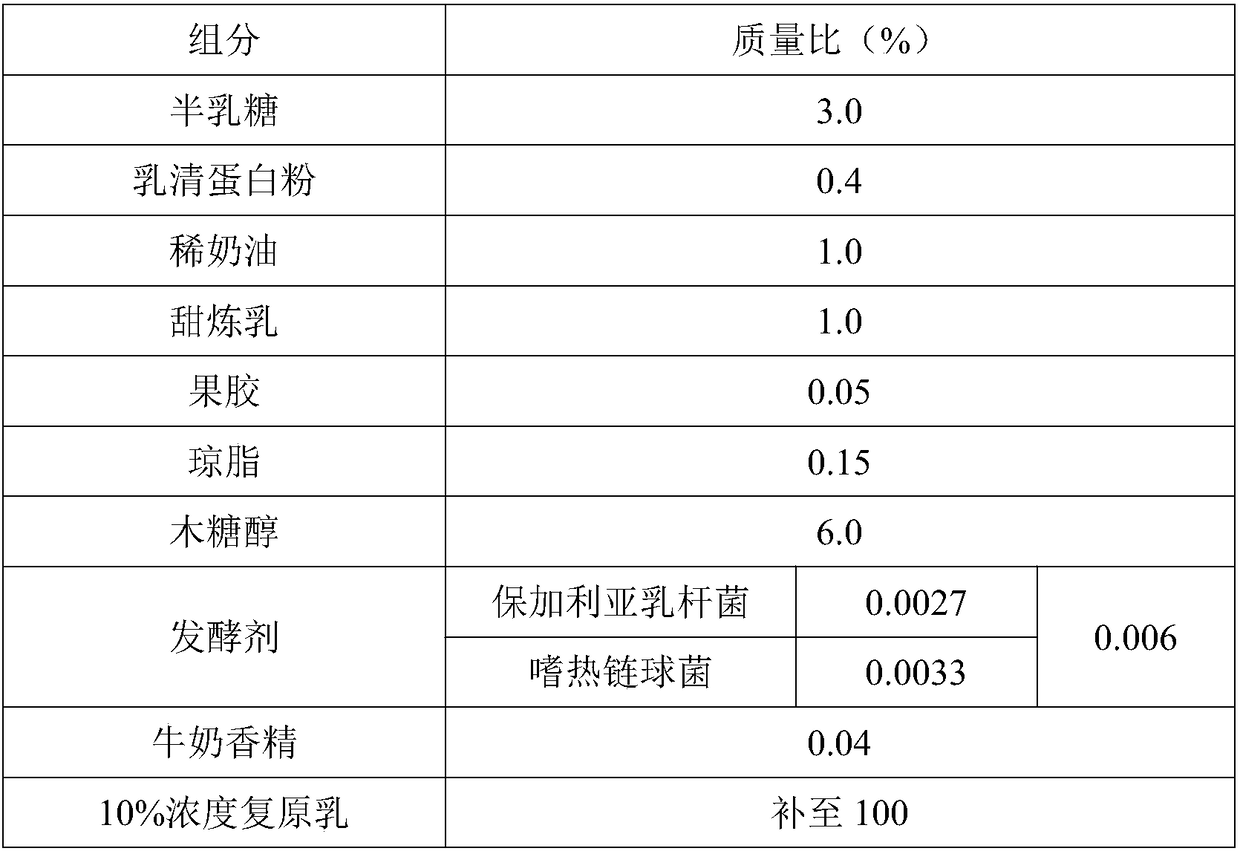

Drinking type fermented milk and preparation method thereof

InactiveCN105558012AStable organizationNo separationMilk preparationLactobacillusPhosphateFermentation

The invention discloses drinking type fermented milk and a preparation method thereof. The fermented milk is prepared from the following raw materials of a stabilizing agent which consists of 0.1%-0.4% of pectin and 0.4%-0.8% of acetylated distarch phosphate, 0.01%-10.0% of a sweetening agent, 0.001%-0.006% of a fermenting agent and the balance being raw milk. The preparation method of the fermented milk comprises the following steps of (1) uniformly mixing the raw milk with the sweetening agent, the pectin and the acetylated distarch phosphate so as to obtain feed liquid A; (2) performing homogenizing, sterilizing and cooling on the feed liquid A so as to obtain feed liquid B; (3) inoculating the fermenting agent in the feed liquid B, performing uniform mixing, and then performing fermentation so as to obtain feed liquid C; and (4) performing bacteria-free homogenizing, cooling and after-cooking on the feed liquid C, wherein the bacteria-free homogenizing pressure is 0-5 MPa, and the temperature is 37-45 DEG C. The fermented milk prepared by the method disclosed by the invention is low in stickiness, and refreshing and smooth in mouth feel, and contains viable bacteria, and tissue states are stable within the guarantee period.

Owner:BRIGHT DAIRY & FOOD

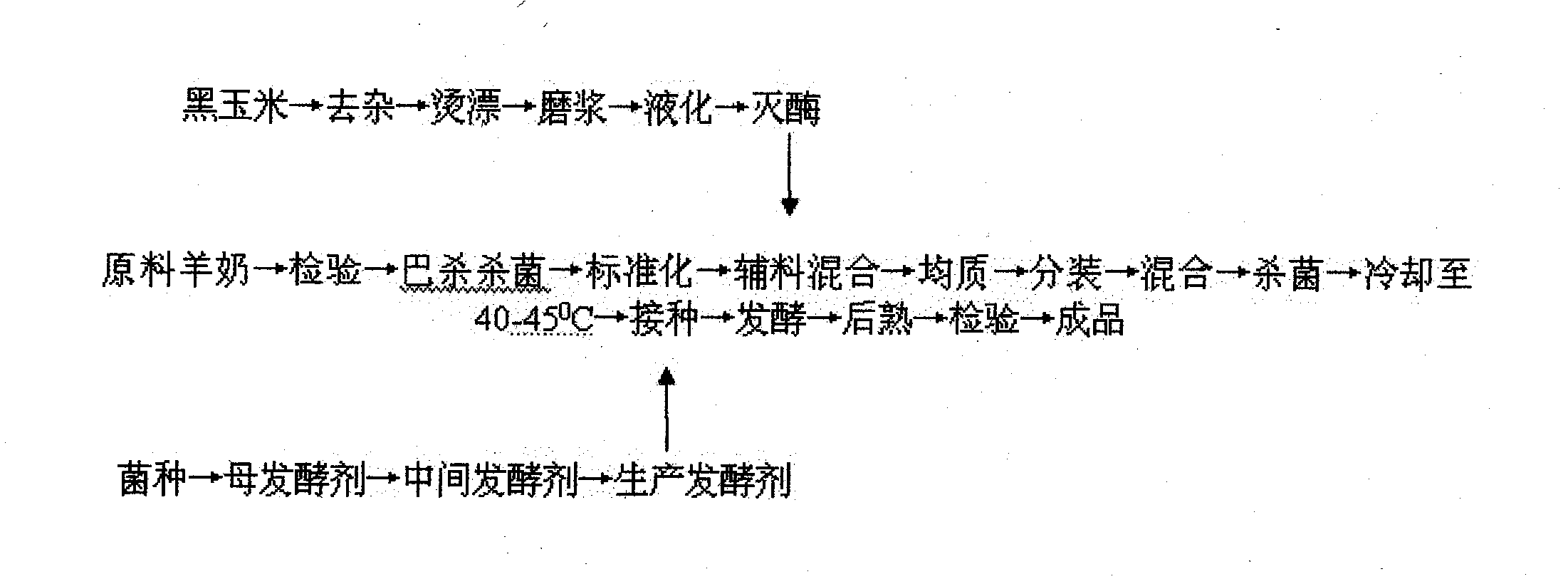

Black corn sour milk and preparation method thereof

InactiveCN102613290AIncrease water soluble melaninIncrease trace elementsMilk preparationDietary fiberAdditive ingredient

The invention discloses a black corn sour milk drink. The sour milk drink is prepared by fermenting raw materials comprising a black corn puree, high quality goat milk, a stabilizing agent and a fermenting agent. The sour milk drink obtained in the invention has the advantages of good solidification state, no whey precipitation, slip and fine mouthfeel, large amounts of nutrients of dietary fibers, flavonoids, trace elements, VE and the like, and possessing of health and eating nutrition functions.

Owner:NORTHWEST A & F UNIV

Sour milk contg. fruit meat of litchi chinensis, and its prepn. method

A sour litchi milk with unique taste and nutritive and health-care functions is prepared through dissolving the mixture of methoxy pectin, modified starch and propanediestor alginate in water, removing peel and kernel from litchi fruit, breaking, mixing it with said solution, adding conventional sour milk and stirring.

Owner:SOUTH CHINA AGRI UNIV

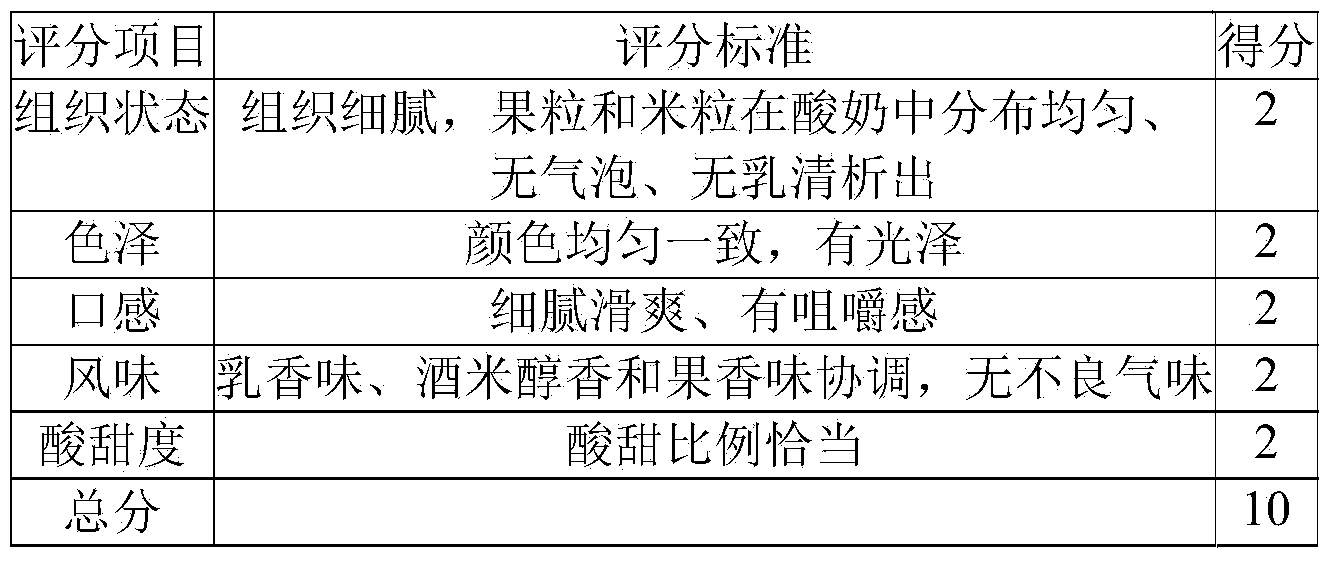

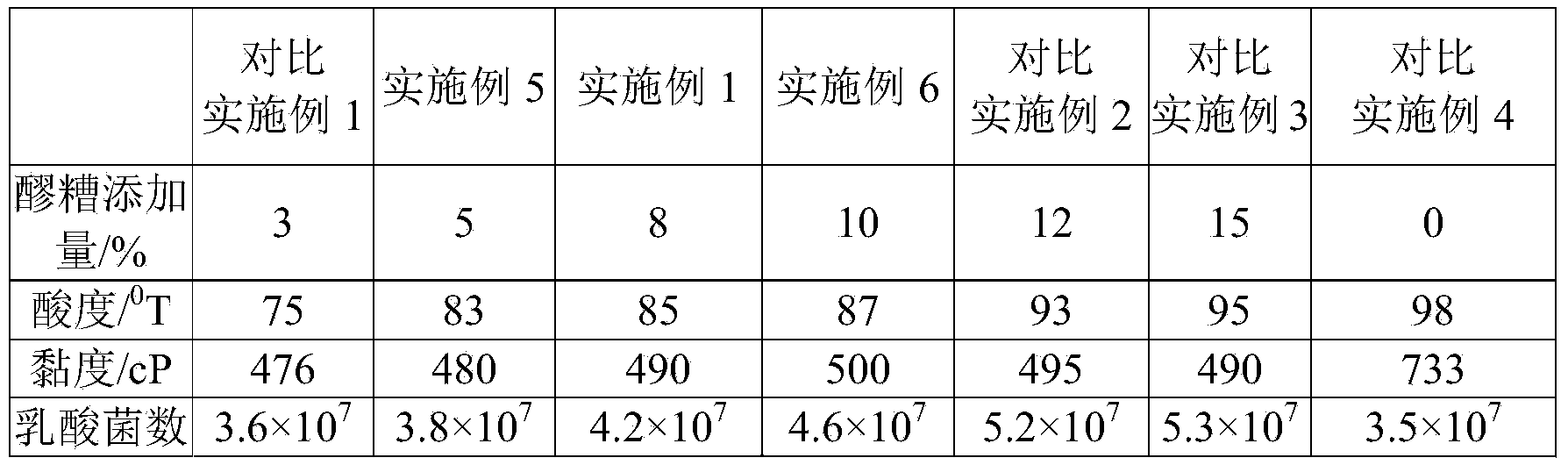

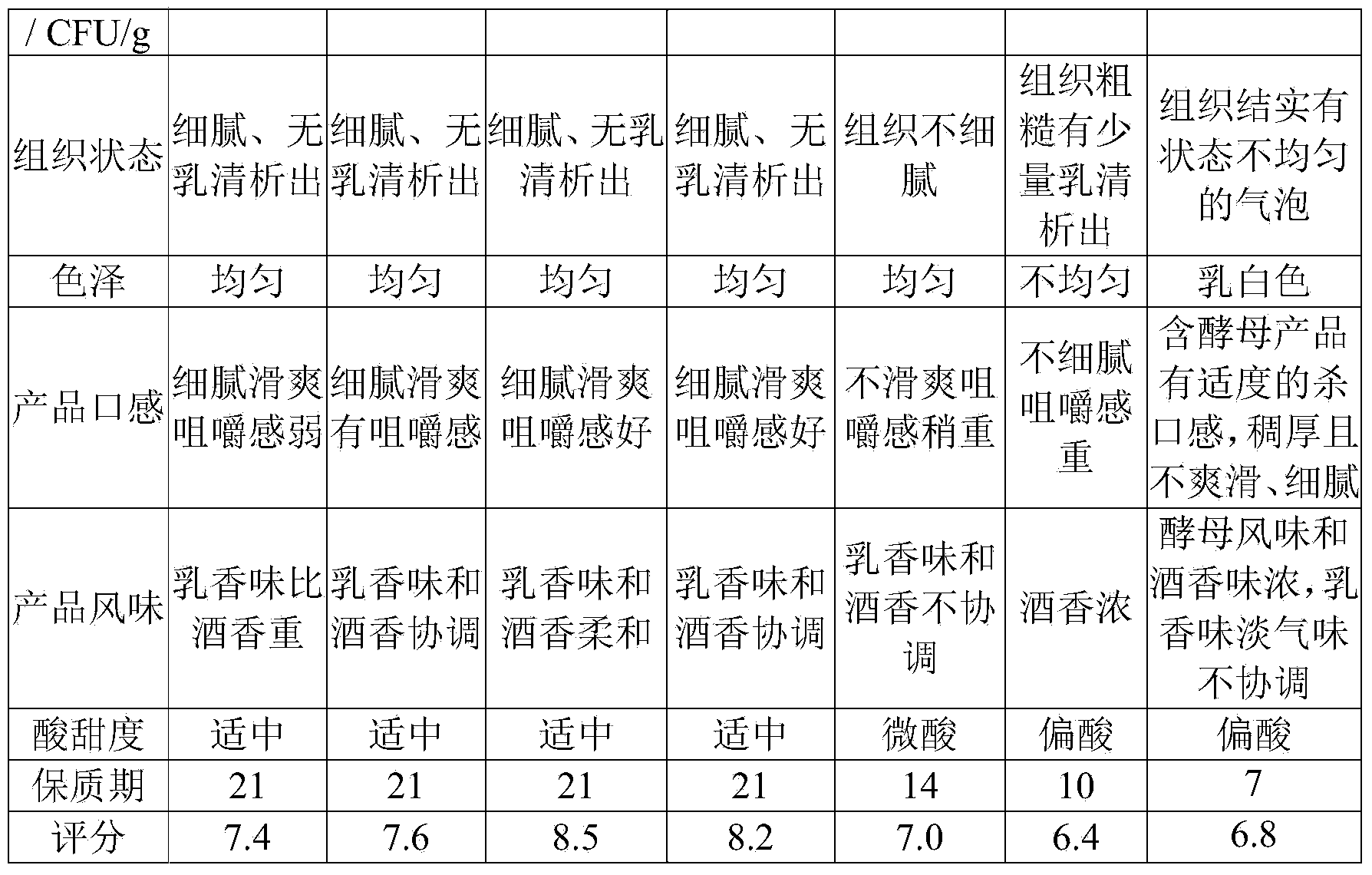

Yogurt containing fermented glutinous rice and fruit granules and preparation method of yogurt

The invention discloses yogurt containing fermented glutinous rice and fruit granules and a preparation method of the yogurt. The yogurt comprises components of raw materials as follows: raw milk, a stabilizer, a leavening agent, a sweet substance, fermented glutinous rice and fruit granules. The preparation method of the yogurt comprises the following steps: (1), the raw milk, the stabilizer and the sweet substance are uniformly mixed to obtain a feed liquid A; (2), the feed liquid A is homogenized, sterilized, and cooled to obtain a feed liquid B; (3), the leavening agent is inoculated to the feed liquid B for fermentation to obtain fermented milk, and the fermented milk is cooled; and (4), the fermented glutinous rice and the fruit granules are added to the cooled fermented milk on line, and cold fermentation is performed after filling to obtain a product. The prepared yogurt containing the fermented glutinous rice and the fruit granules is fine, smooth, and has good rice chewing sensation, mellow and milk scent coordination, both taste of pulp and rice and nutritional values of yogurt, fruit and rice wine, fine and stable texture, good flavor, long quality guarantee period, good stability in shelf period and broader market prospect.

Owner:BRIGHT DAIRY & FOOD

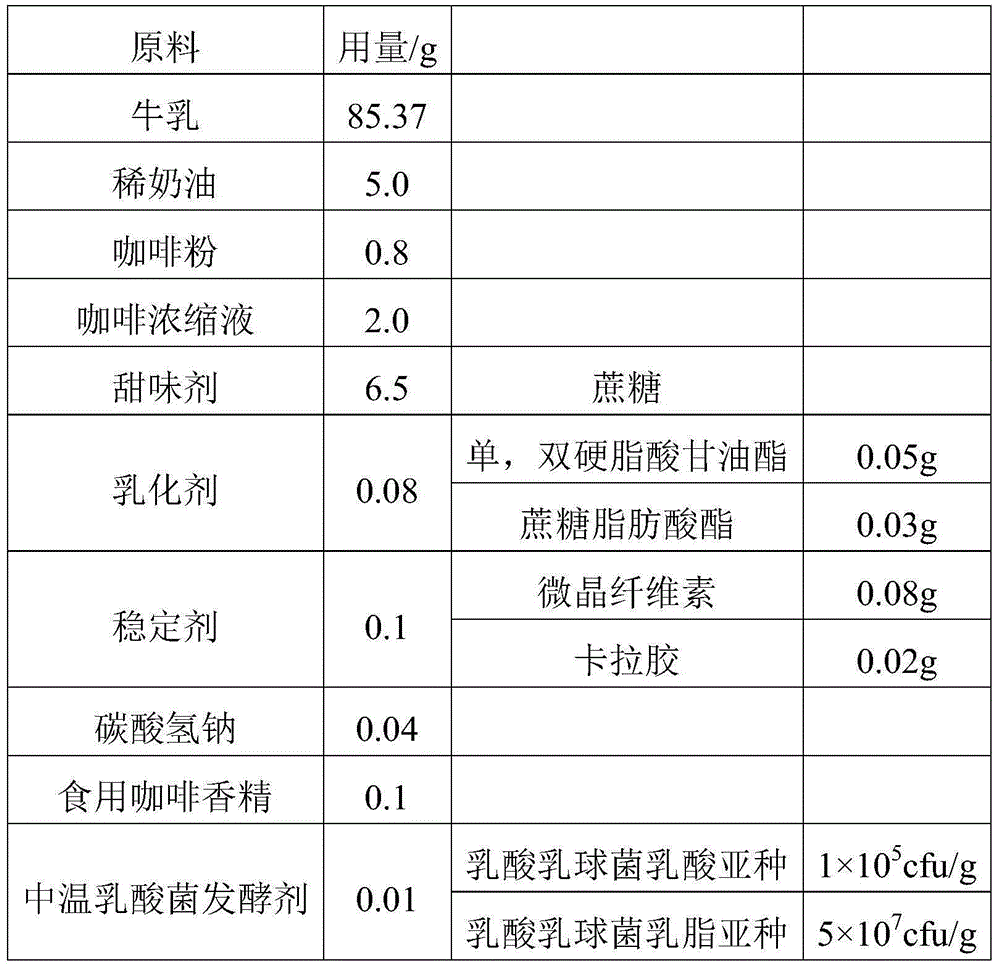

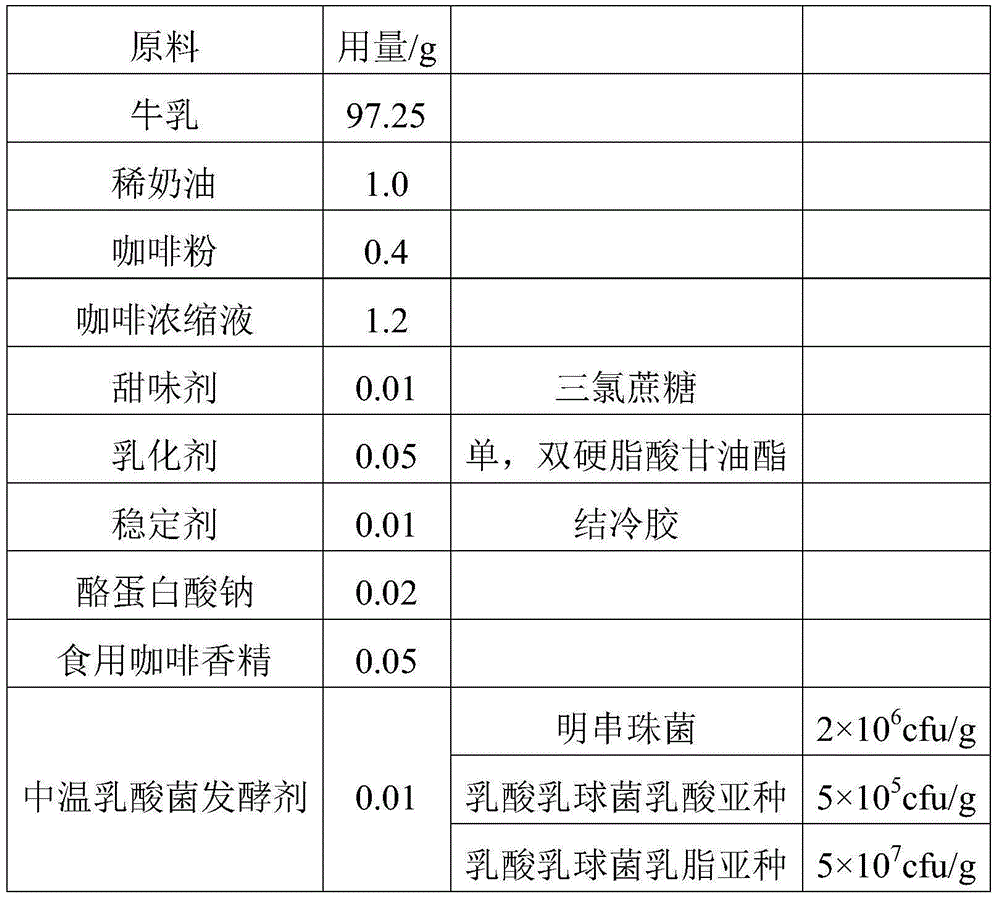

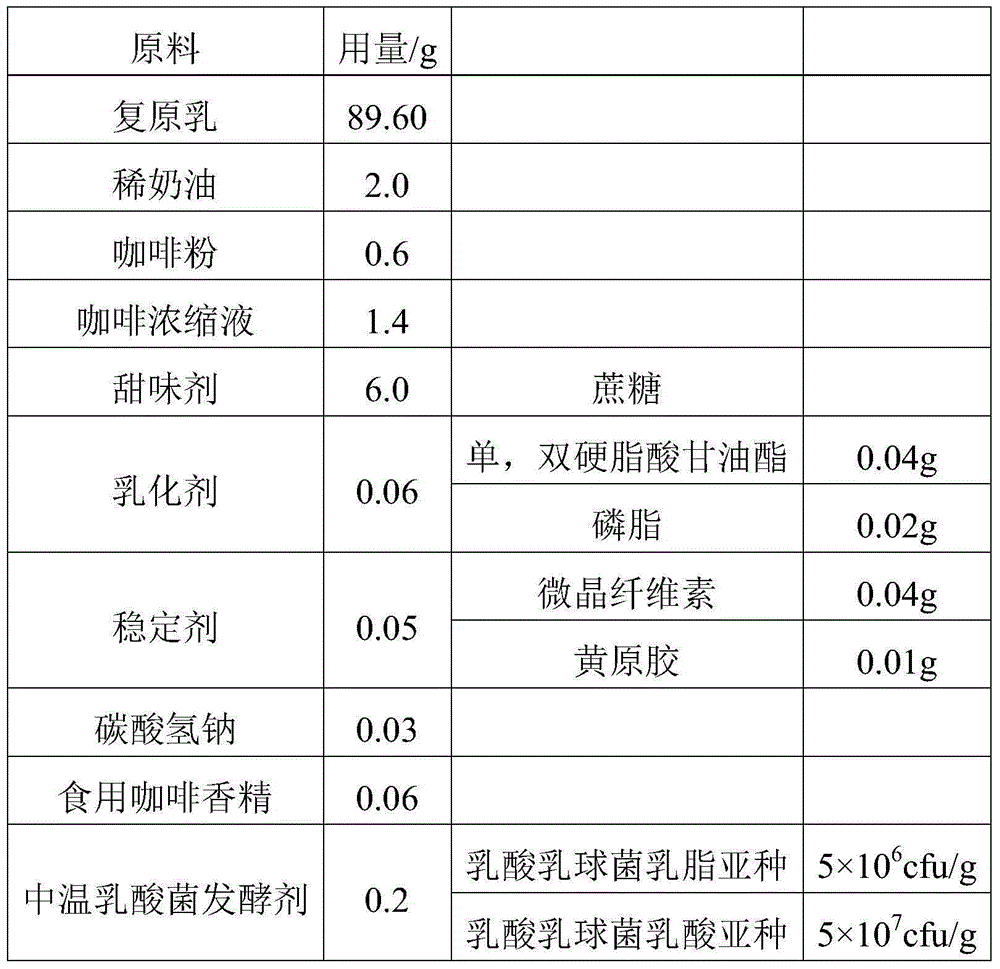

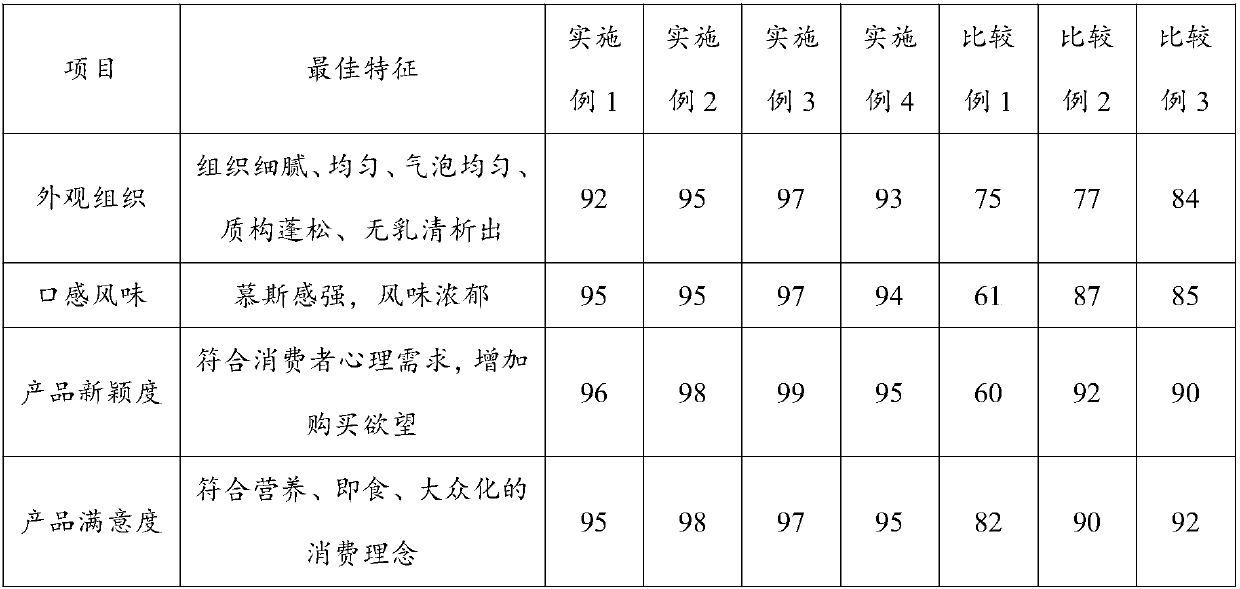

Coffee yogurt and preparation method thereof

ActiveCN105010533AAchieve mass productionRealize industrializationMilk preparationSodium bicarbonateSodium Caseinate

The invention discloses coffee yogurt and a preparation method thereof. Raw materials include 85.3-97.3% of raw milk, 1-5% of single cream, 0.4-0.8% of coffee powder, 1.2-2.0% of coffee concentrated liquor, 0.01-6.5% of sweetening agents, 0.05-0.08% of emulsifiers, 0.01-0.1% of stabilizers, 0.02-0.04% of one or more of sodium bicarbonate or sodium caseinate and 0.01-0.2% of intermediate-temperature lactic acid bacteria starters. The preparation method includes the steps that firstly, the raw milk is heated and mixed with the single cream, the coffee powder, the coffee concentrated liquor, the emulsifiers, the stabilizers, the sodium bicarbonate and the like, heat preservation is performed, and materials A are obtained; secondly, homogenizing and sterilization are performed, and a fermentation substrate is obtained; thirdly, temperature is lowered, and fermentation agents are added at the temperature of 35-38 DEG C for fermentation. The structural state of the coffee yogurt is stable, and the coffee yogurt has the special aroma of coffee milk and the milk aroma of yogurt. The preparation method is easy and convenient to operate and favorable for large-scale production.

Owner:BRIGHT DAIRY & FOOD

Inflatable fermented milk and preparation method thereof

The invention discloses inflatable fermented milk and a preparation method thereof. The fermented milk contains the following raw materials in percentage by weight: 8%-12% of saccharose, 0-15% of watery cream, 0-0.15% of an emulsifying agent, 0-0.25% of pectin, 0.5%-2% of gelatin, 0.7%-1.5% of starch, 0.004%-0.008% of a fermenting agent and the balance of raw material milk; and fermented milk is further inflated with nitrogen, and the inflation amount of the nitrogen is 75%-85% of the volume of the fermented milk. The inflatable fermented milk is prepared by the steps of mixing all raw materials except the fermenting agent, carrying out homogenization and sterilization, cooling, inoculating the fermenting agent for fermentation, and carrying out encapsulation. The fermented milk is inflated with nitrogen, and the proportion of the raw materials is optimized, so that the inflatable fermented milk with a fluffy, silky and soft texture is obtained; and the obtained inflatable fermented milk has a relatively high viable count, has the stable tissue state in a guarantee period and simultaneously has the sour and sweet flavors of the fermented milk and the taste of a soft mousse cake, and the overflowing of gas is avoided.

Owner:BRIGHT DAIRY & FOOD

Coconut-flavored active lactic acid bacteria beverage and producing method thereof

InactiveCN101204175AConsumption satisfactionRetain nutrientsMilk preparationAdditive ingredientEconomic benefits

The invention discloses an active lactic acid bacteria drink with coconut juice taste, which is conciliated by yoghurt, coconut juice diluents, citric acid, sugar and coconut juice essence. The method in particular includes the processes: adopting the coconut juice extracted by mixing coconut water and coconut meat to dilute; conciliating with the yoghurt under sterile condition; adding stabilizer in right amount and seasoning with the sugar and the citric acid; sterile-filling to finish the products after homogenization. The active lactic acid bacteria drink in the invention has special taste, sour, sweet and delicious taste as well as strong milk taste and coconut taste; the drink greatly preserves nutrition components of the coconut meat and the coconut water and has good economic benefits and market prospect.

Owner:SOUTH CHINA AGRI UNIV

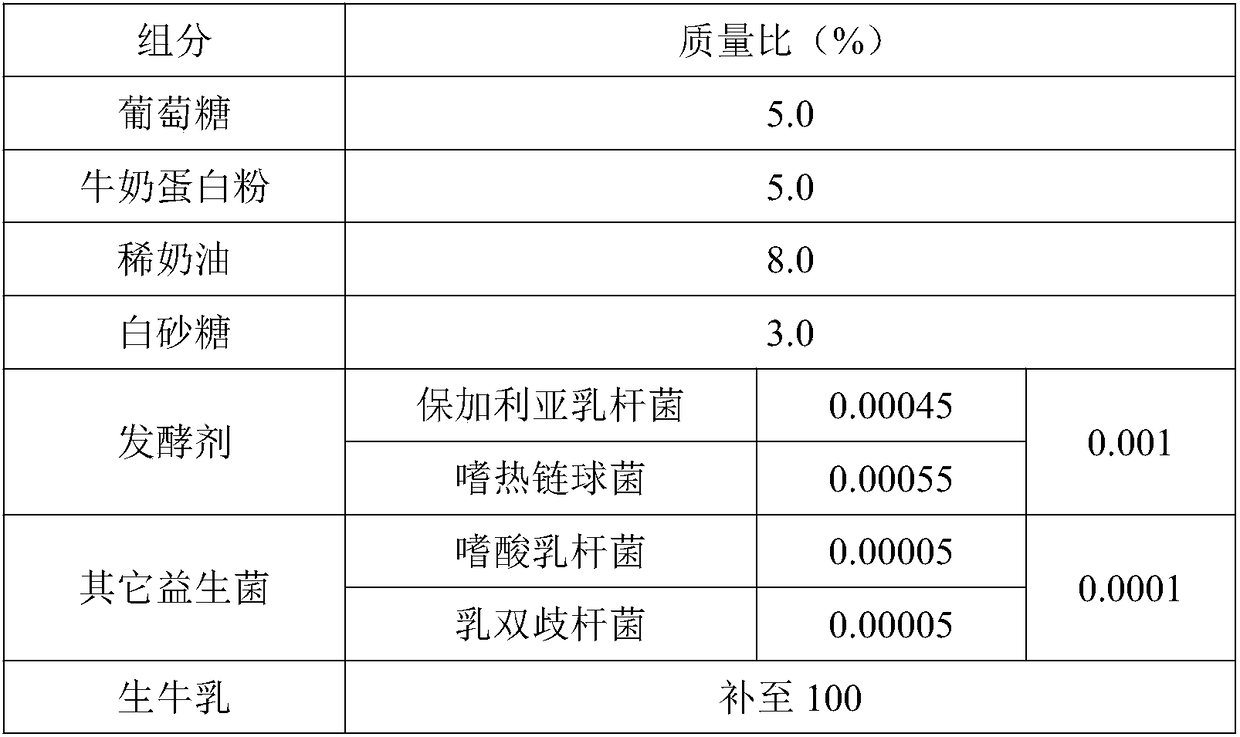

Brown solidified fermented milk and preparation method thereof

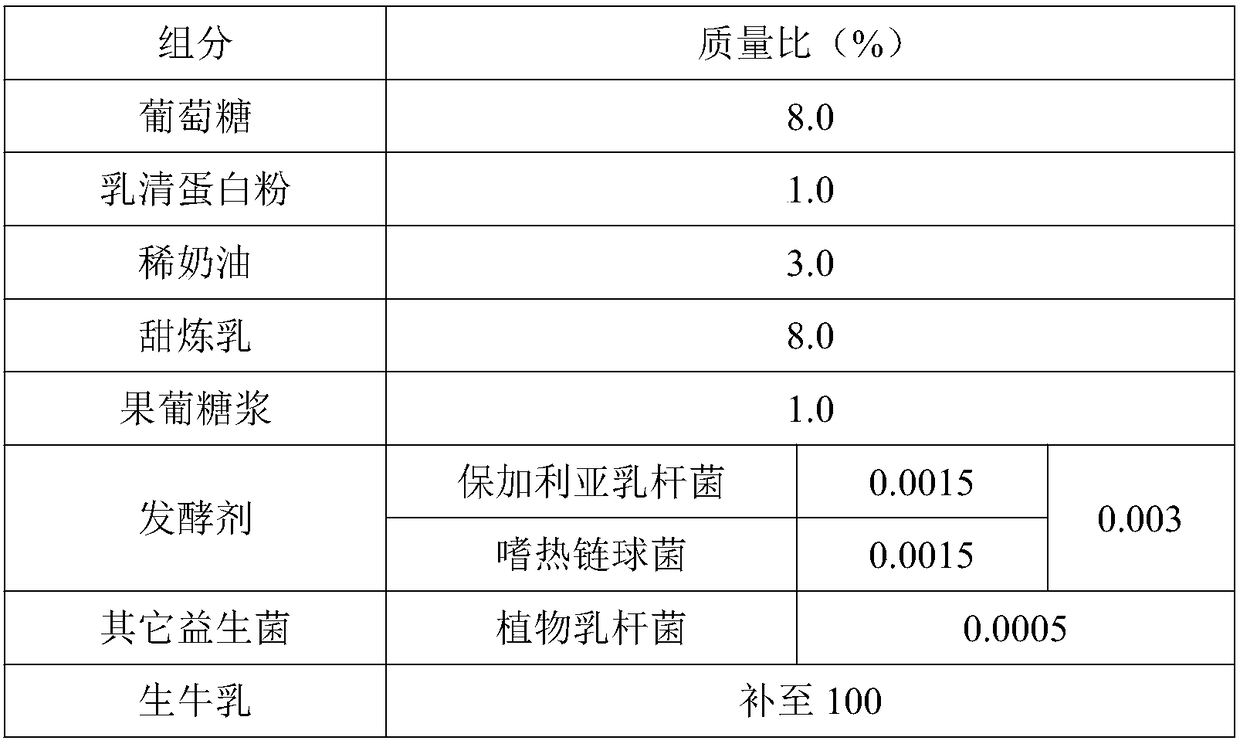

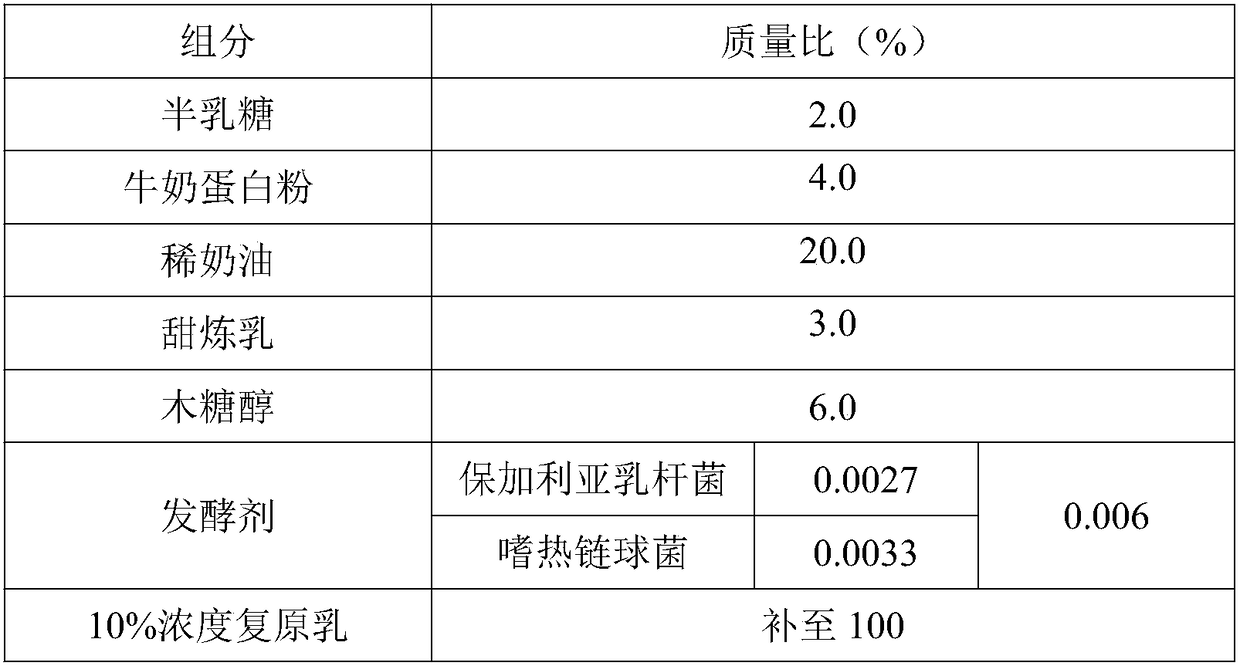

InactiveCN108077427ADelicate tasteUnique flavorMilk preparationCream preparationBiotechnologyTotal solid content

The invention discloses brown solidified fermented milk and a preparation method thereof. The fermented milk is prepared from the following raw material in mass ratio: 2.0 to 9.0% of reducing sugar, 1.0 to 5.0% of albumen powder, 3 to 20% of fat milk, 1.0 to 6.0% of sweet substance, 0.001 to 0.006% of fermenting agent and raw milk supplemented to 100.0%. The preparation method comprises the following steps: (1) mixing the raw milk with the reducing sugar, warming and keeping warm to obtain a material A; (2) cooling the material A and mixing the material A with other raw materials to obtain a material B; (3) homogenizing the material B, sterilizing, cooling and inoculating the fermenting agent to obtain a material C; (4) filling the material C, fermenting, cooling and after ripening to obtain the brown solidified fermented milk. According to the brown solidified fermented milk disclosed by the invention, a total solid content is improved by optimizing a formula and technologies; the prepared brown solidified fermented milk has the advantages of fine and smooth taste, unique flavor, stable tissue state within an expiration data and not milk-water separation phenomenon.

Owner:BRIGHT DAIRY & FOOD CO LTD

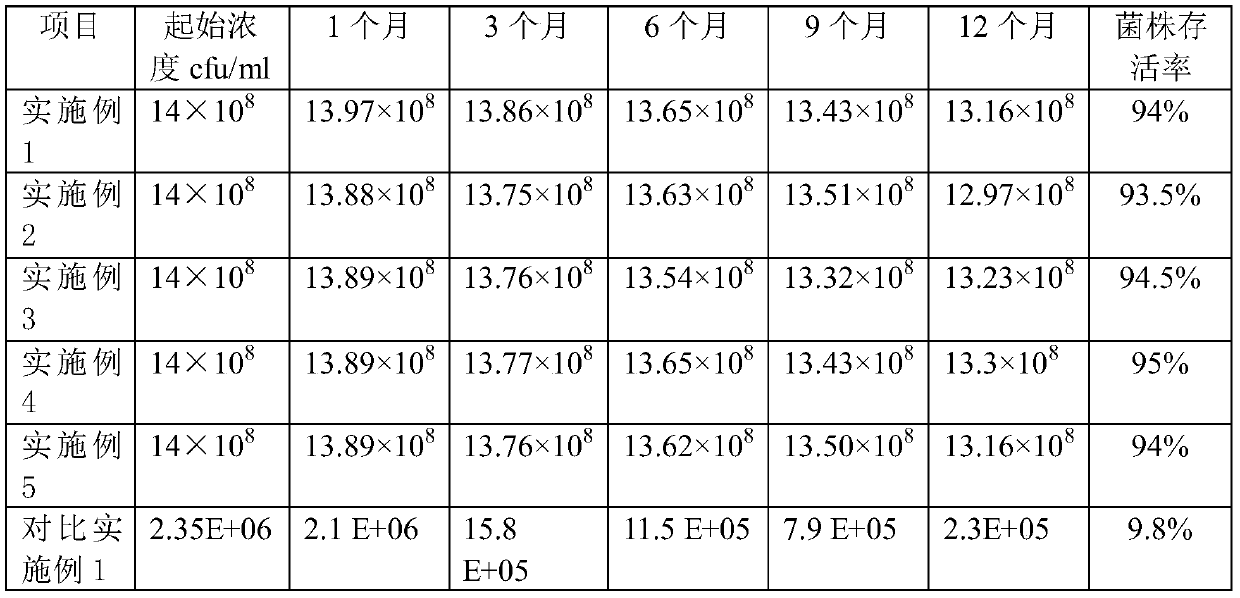

Probiotic ice cream and production process thereof

The invention discloses a probiotic ice cream and a production process thereof. The probiotic ice cream comprises, by weight, more than 20% of full-cream milk powder, more than 15% of sugar, more than or equal to 14*108cfu / ml of probiotics and the balance water. The invention further discloses a production process of the probiotic ice cream. The production process is simple to operate, and the prepared probiotic ice cream tastes smooth, sour, sweet and delicious and has high structure stability and melting resistance.

Owner:内蒙古利尔健奶制品分解科技有限公司

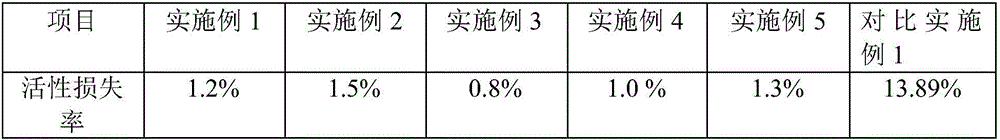

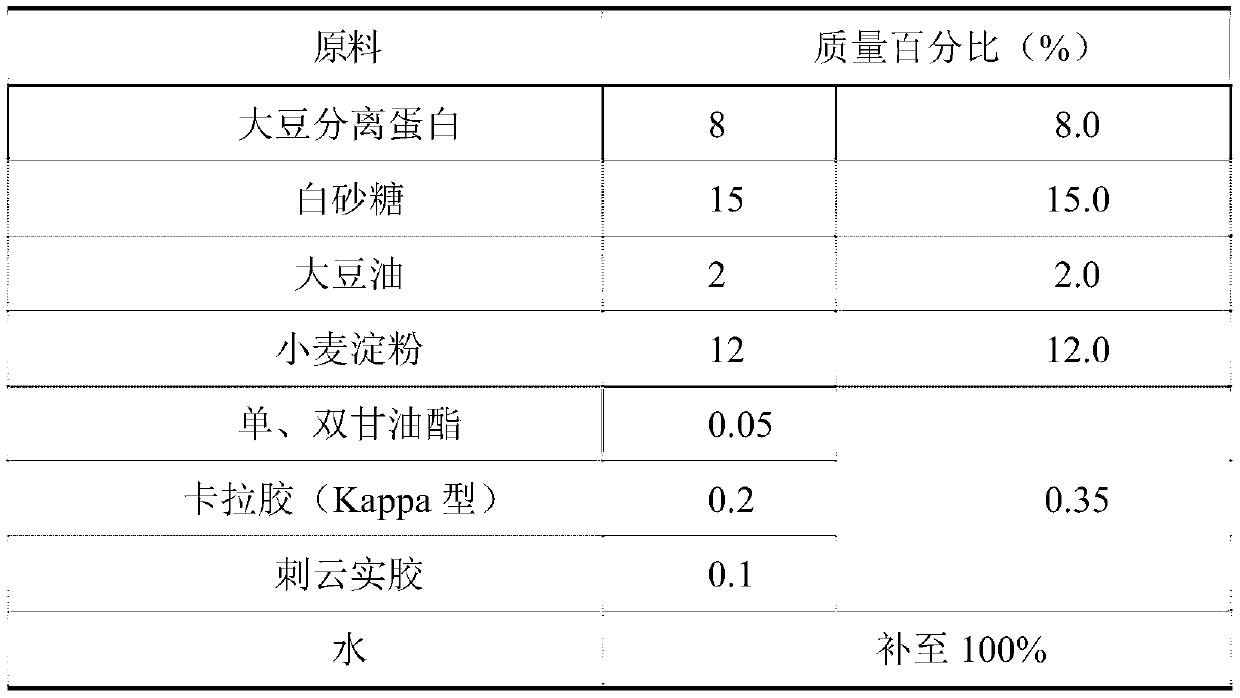

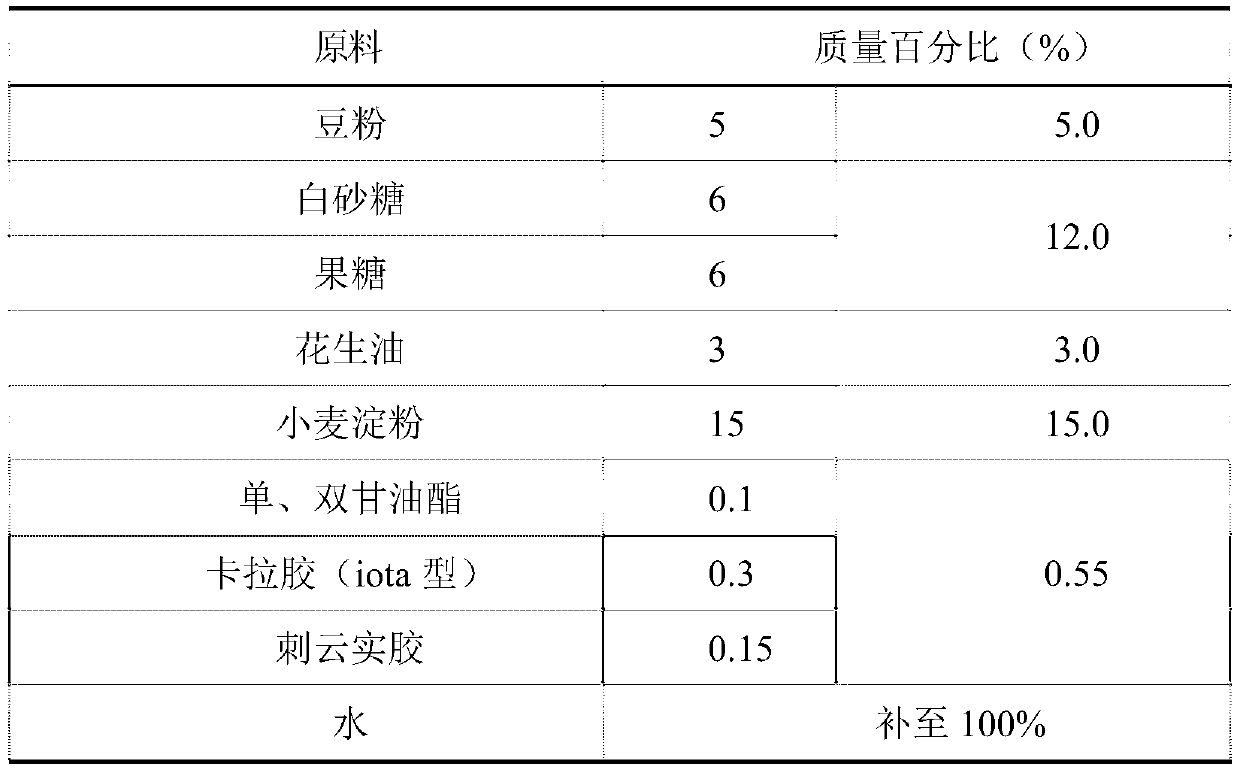

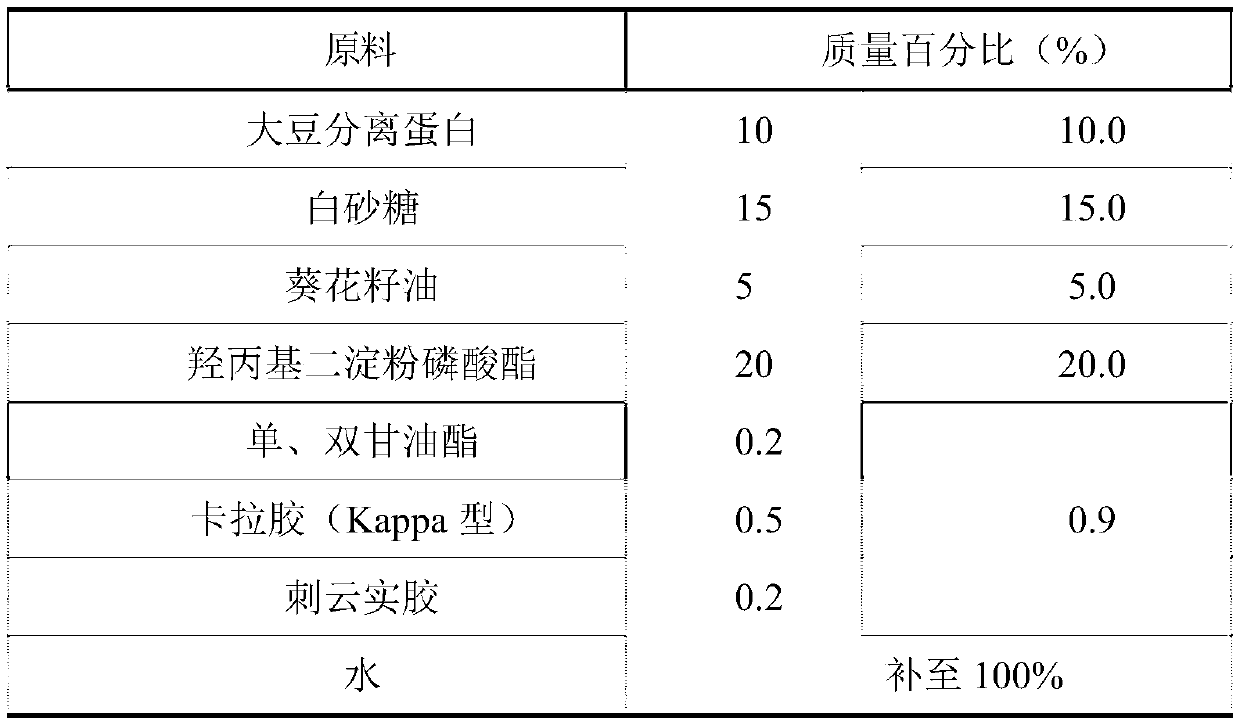

Bean-based pudding and manufacturing method thereof

InactiveCN110463779AStable organizationFull of nutritionCheese manufactureFood scienceFlavorVegetable oil

The invention provides a bean-based pudding and a manufacturing method thereof. The soy-based pudding comprises, by mass, 5-10% of soybean protein isolate and / or soybean flour, 10-15% of a sweetener,2-5% of vegetable oil, 12-20% of starch, 0.05-0.2% of mono- and diglycerides, 0.2-0.5% of carrageenan, 0.1-0.2% of Tara gum, and the balance of water. The soybean protein and / or soybean flour are / is used as the raw material, so the product is rich in nutrients, has good flavor, state and mouthfeel, has elasticity and a good stability, and does not delaminate after long-term storage.

Owner:SHANGHAI INST OF TECH

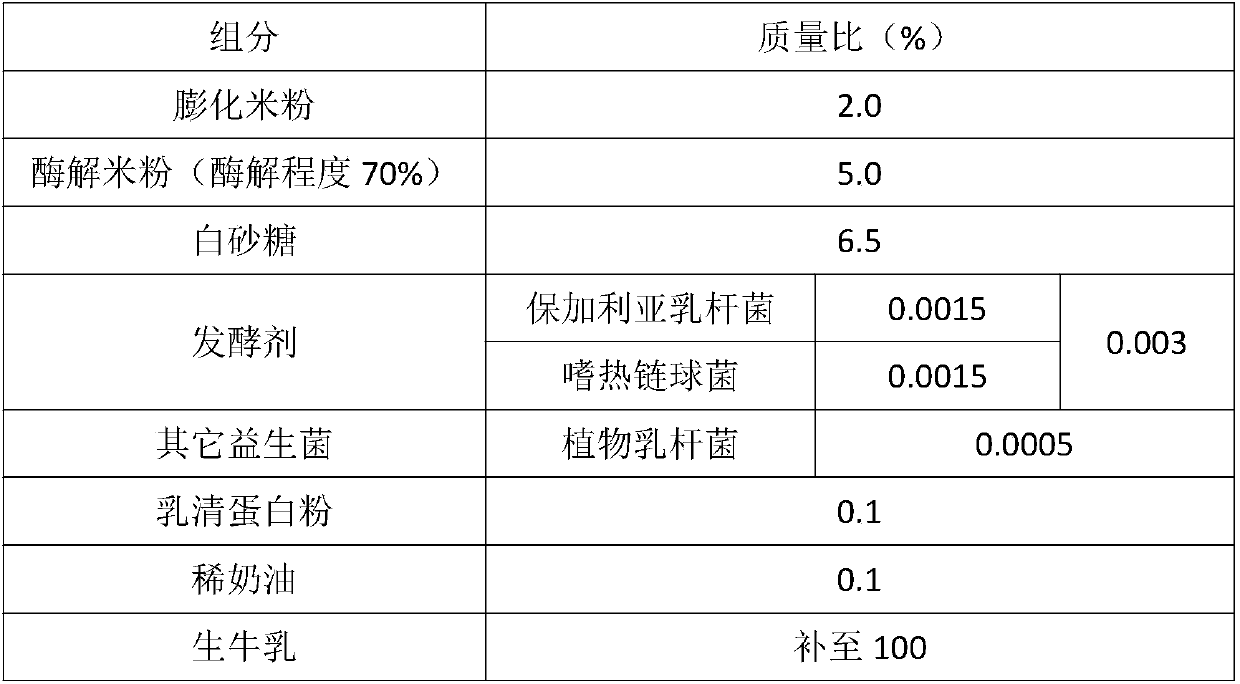

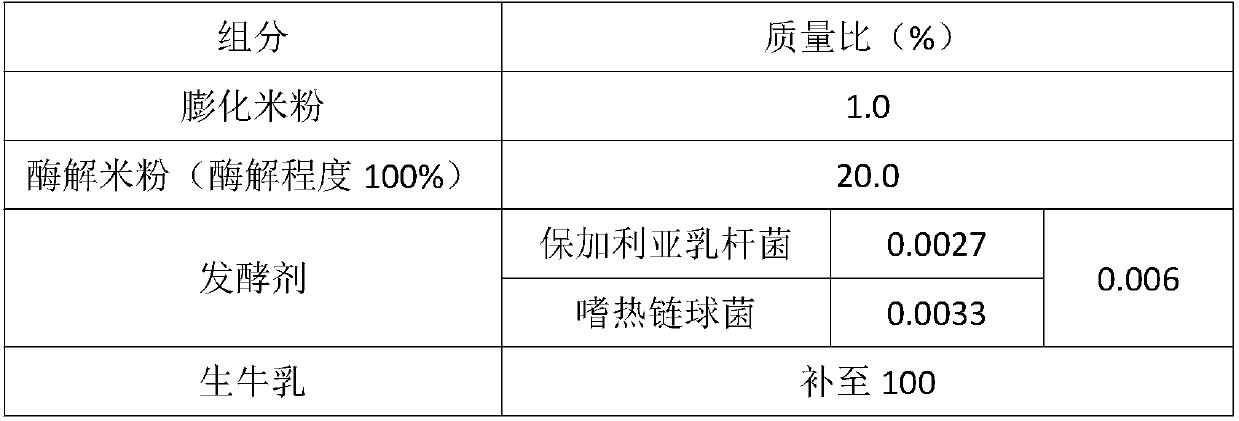

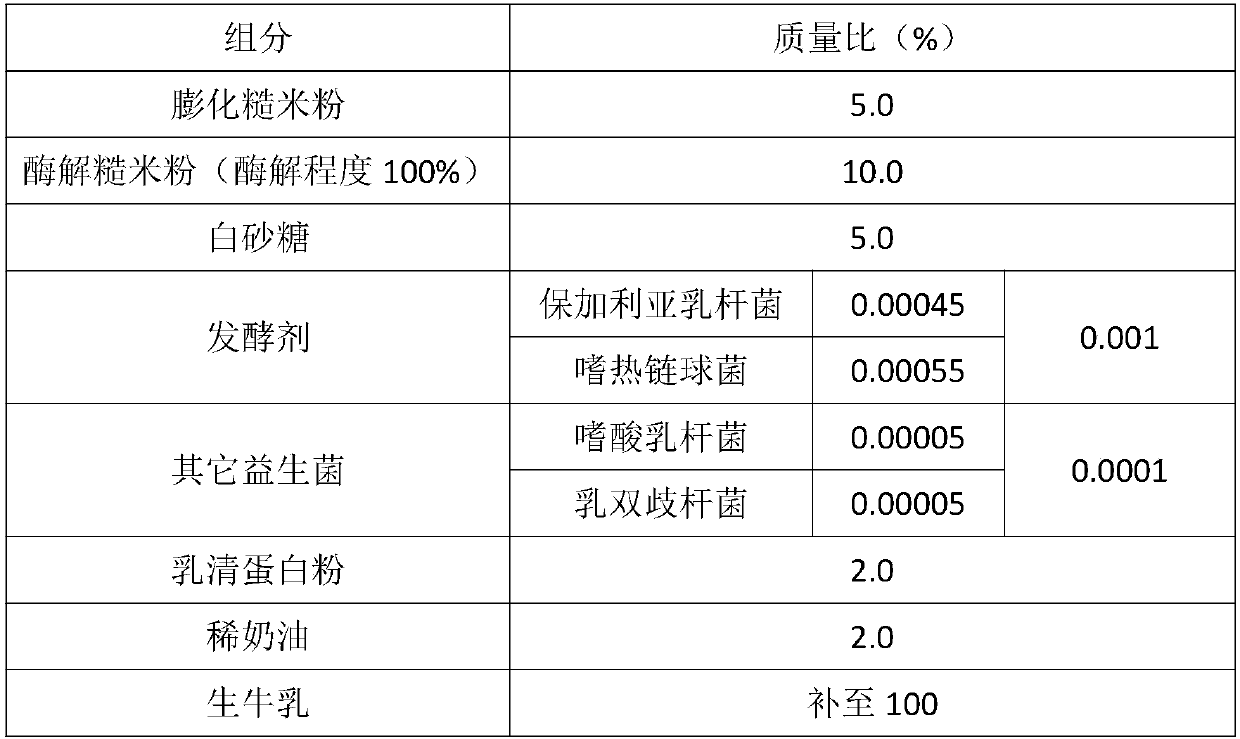

Stirred fermented milk and preparation method thereof

The invention discloses stirred fermented milk and a preparation method thereof. The stirred fermented milk comprises the following raw materials in percentage by mass: 1.0-5.0% of puffed rice flour,0-20.0% of rice flour endured enzymatic hydrolysis, 0.001-0.006% of a fermentation agent, and the balance of raw-material milk so as to ensure a total percentage of 100.%. The preparation method of the stirred fermented milk comprises the following steps: (1), uniformly mixing the raw-material milk, the puffed rice flour and the rice flour endured enzymatic hydrolysis so as to obtain a material A;(2), homogenizing the material A, carrying out sterilization, and carrying out cooling so as to obtain a material B; (3), inoculating the fermentation agent into the material B, and carrying out fermentation so as to obtain a material C; and (4), filling the material C, carrying out cooling, and carrying out post-curing so as to obtain the stirred fermented milk. According to the preparation method of the stirred fermented milk, the rice flour with relatively high addition amounts jointly takes part in the fermentation without addition of additives so that the prepared stirred fermented milkis refreshing in flavor, mellow in rice aroma, and fine and smooth in texture; moreover, the stirred fermented milk is stable in tissue state and free of milk-water separation within shelf life. And thus, existing production and preparation methods are met, and large-scale production is suitable.

Owner:BRIGHT DAIRY & FOOD CO LTD

Chlorine ion corrosion resistant high-strength anti-seismic steel bar and production method and application thereof

ActiveCN109881121AImprove mechanical propertiesAccelerated corrosionProcess efficiency improvementOperation modeOxygen

The invention discloses a chlorine ion corrosion-resistant high-strength anti-seismic steel bar and a production method and application of the chlorine ion corrosion resistant high-strength anti-seismic steel bar. The steel bar contains the following elements of, by mass percentage, less than or equal to 0.65% of Ni, 0.25-7.00% of Cr, 0.028-0.029% of V and less than or equal to 1.4% of Mn, whereinNi / Cr is 0.45-1.92%. In the method, a converter is used for smelting according to a conventional smelting process, and corrosion-resistant alloy elements such as Cr, Ni and V are added into molten steel according to a conventional operation mode. The content of oxygen, sulfur and inclusions in steel is reduced by refining white slags in an LF furnace. A continuous casting crystallizer adopts an electromagnetic stirring technology, and production can be realized in most steel bar manufacturers in China. Compared with the prior art, a nickel-chromium-vanadium micro-alloying process adopted to produce the chloride ion corrosion-resistant high-strength anti-seismic steel bar has the advantages of accurately controlling the components of molten steel, being high in yield, easy to carry out andwide in applicability and the like.

Owner:YANGCHUN NEW STEEL CO LTD

Special stabilizing agent for normal temperature fermented soybean milk and applications thereof

InactiveCN108669234AStable textureStable organizationLactobacillusStrepto/lacto-coccusChemistryFlavor

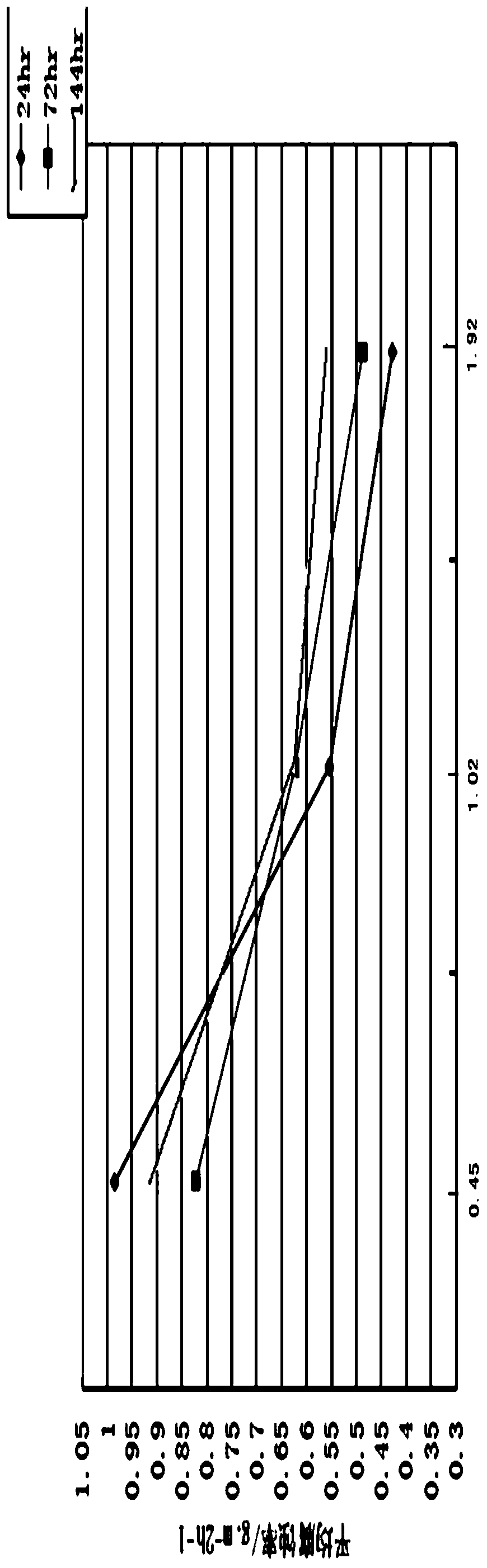

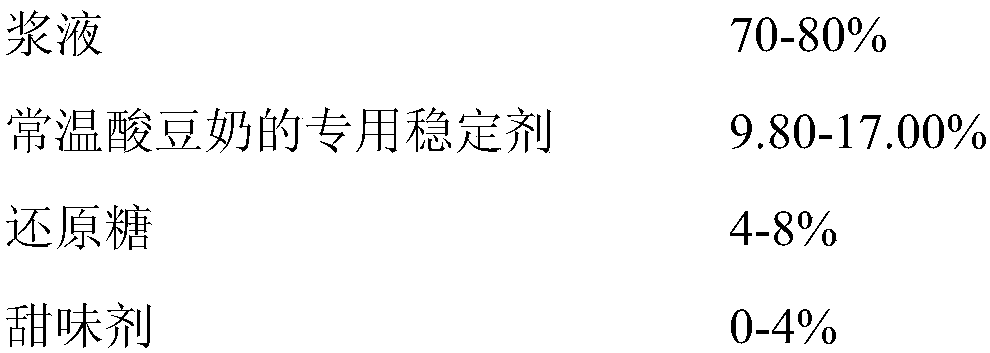

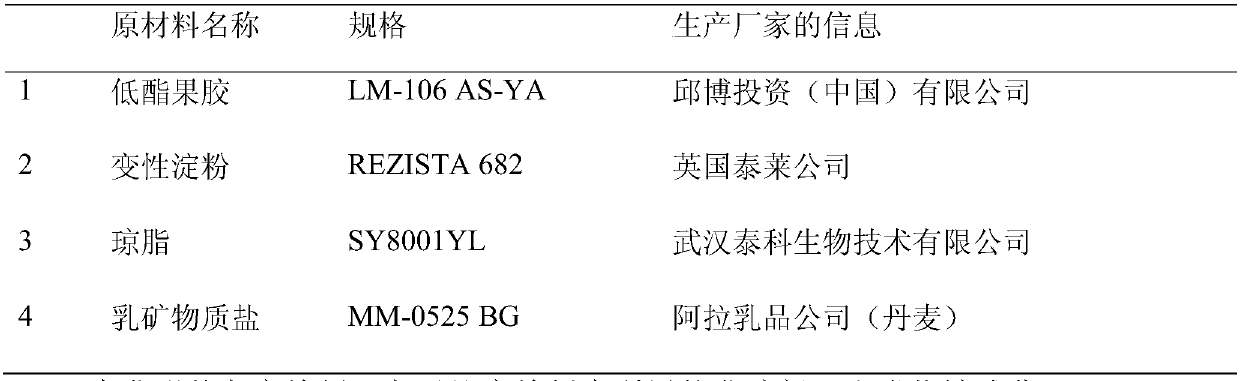

The invention discloses a special stabilizing agent for normal temperature fermented soybean milk and applications thereof. The stabilizing agent comprises following components in parts by weight: 1.00 to 1.50 parts of low-ester pectin, 1.00 to 1.50 parts of agar, 8.00 to 12.00 parts of modified starch, and 0.80 to 2.00 parts of milk minerals. The stabilizing agent is used to prepare normal temperature fermented soybean milk. The stabilizing agent accounts for 10.80 to 17.00 wt% of the total weight of raw materials during the preparation process. The normal temperature fermented soybean milk prepared from the special stabilizing agent can tolerate a secondary pasteurization treatment, whey precipitation caused by shrinkage and contraction of proteins is prevented, after cooling, the normaltemperature fermented soybean milk has a unique smooth and fine texture, the appearance is smooth, the soybean odor is removed, the flavor is as good as that of yogurt, and the shelf life can reach 150-180 days at a room temperature.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

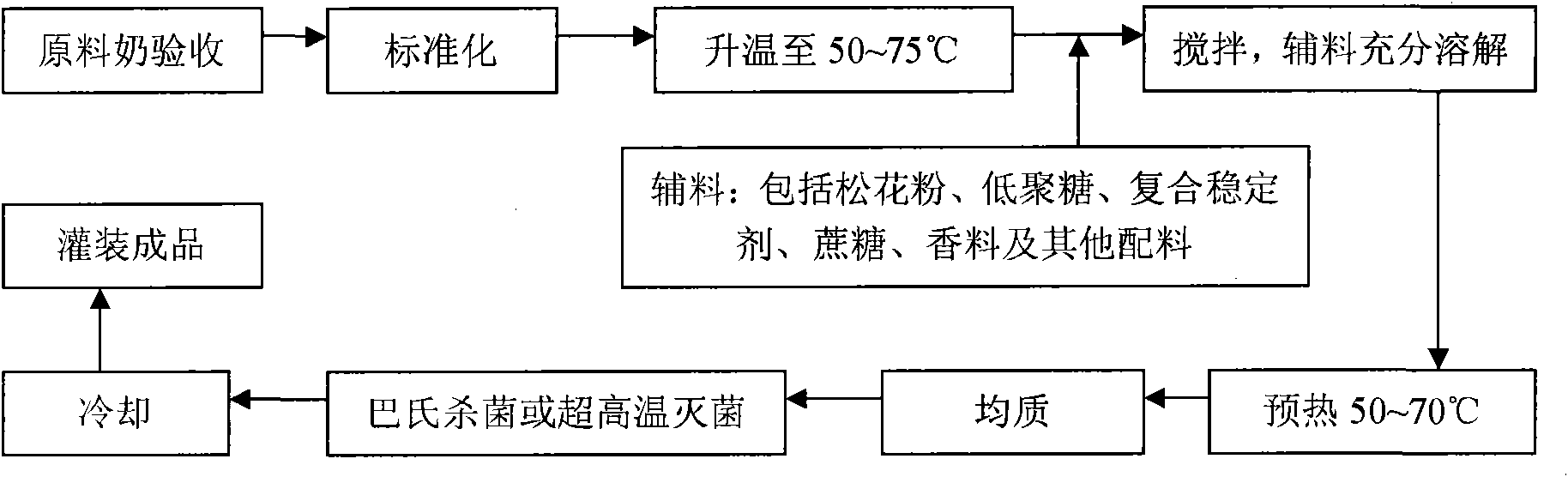

Pine pollen-seasoned milk and preparation method thereof

The invention discloses pine pollen-seasoned milk, which belongs to the field of dairy product processing. The milk product uses milk and pine pollen as basic raw materials and is prepared from the following components in percentage by weight: 80 to 90 percent of milk, 0.5 to 1.0 percent of pine pollen, 0.1 to 0.5 percent of composite deflocculant, 0.01 to 0.05 percent of polyphosphate, 5 to 11 percent of other auxiliary materials and the balance of water. The seasoned milk of the invention is prepared by weighing the raw material milk according a mixing ratio, heating the milk to 50 to 70 DEG C, adding the pine pollen, composite deflocculant, polyphosphate, other auxiliary material and water according to the mixing ratio; and fully mixing, dissolving, heating to 50 to 70 DEG C, homogenizing and sterilizing at ultrahigh temperature. The seasoned milk has high pine pollen content and overcomes the drawbacks of the milk in terms of nutritive functions such as regulating gastrointestinal balance and resisting fatigue. The flavor and appearance quality of the milk are not affected by the bitter taste and insolubility of pine pollen.

Owner:CHINA AGRI UNIV

Coconut-flavored active lactic acid bacteria beverage and producing method thereof

InactiveCN101204175BConsumption satisfactionRetain nutrientsMilk preparationBiotechnologyLactic acid bacterium

The invention discloses an active lactic acid bacteria drink with coconut juice taste, which is conciliated by yoghurt, coconut juice diluents, citric acid, sugar and coconut juice essence. The method in particular includes the processes: adopting the coconut juice extracted by mixing coconut water and coconut meat to dilute; conciliating with the yoghurt under sterile condition; adding stabilizer in right amount and seasoning with the sugar and the citric acid; sterile-filling to finish the products after homogenization. The active lactic acid bacteria drink in the invention has special taste, sour, sweet and delicious taste as well as strong milk taste and coconut taste; the drink greatly preserves nutrition components of the coconut meat and the coconut water and has good economic benefits and market prospect.

Owner:SOUTH CHINA AGRI UNIV

Method for manufacturing standard test blocks used for 300M steel tempering acid etch detection

InactiveCN102374946ADetermining the parameters of the acid etching processSuitable acid etching process parametersPreparing sample for investigationAcid etchingSurface integrity

The invention provides a method for manufacturing standard test blocks used for a 300M steel tempering acid etch detection, which solves the defect that the current process parameters fluctuate with the change of the solution concentration. The method of the invention is characterized in that the standard test blocks with seven different structural states are prepared. According to the invention, the color of seven standard test blocks which are performed acid etching are observed for judging the suitability of a tempering acid etch reagent and tank liquid concentration process parameters; as well as for comparing and judging after the components are performed acid etching. Because test blocks with different states have different structures, the colors are different after being acid etched by using same reagent and tank liquid. The completeness of surface of 300M steel components can be contrasted and inspected by the test blocks, and the verification of the suitability of the acid etch technology can be realized by the standard test blocks simultaneously. The acid etch process parameters matched with concentration of the acid etch reagent and the tank liquid can be determined. The standard test block with each state is prepared individually, so that the structural state is stable and the standard test blocks enable repeated use. The method of the invention has the advantage of simple and convenient operation. The method for manufacturing standard test blocks is used for the 300M steel tempering acid etch detection.

Owner:贵州龙飞航空附件有限公司

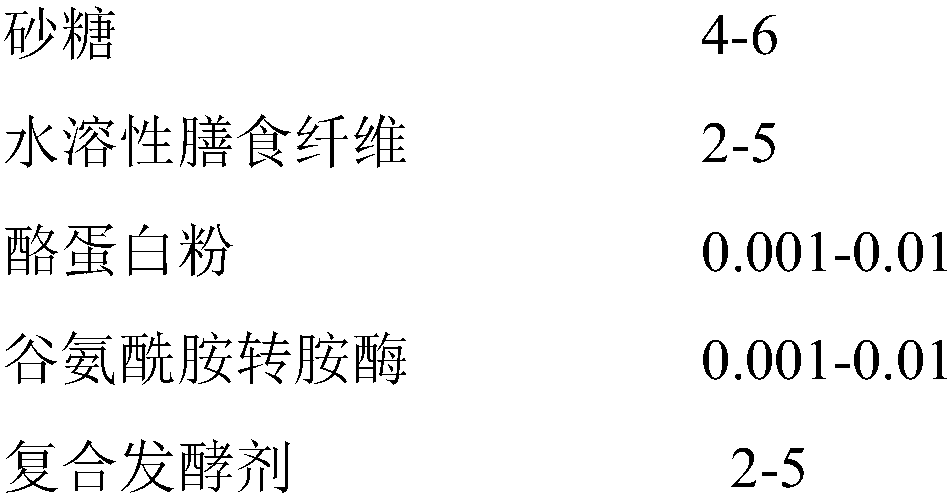

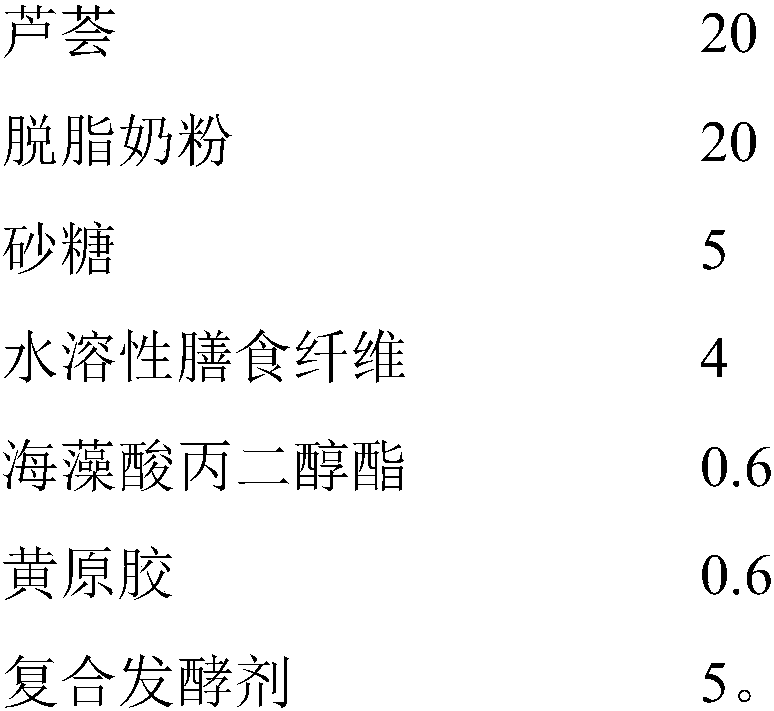

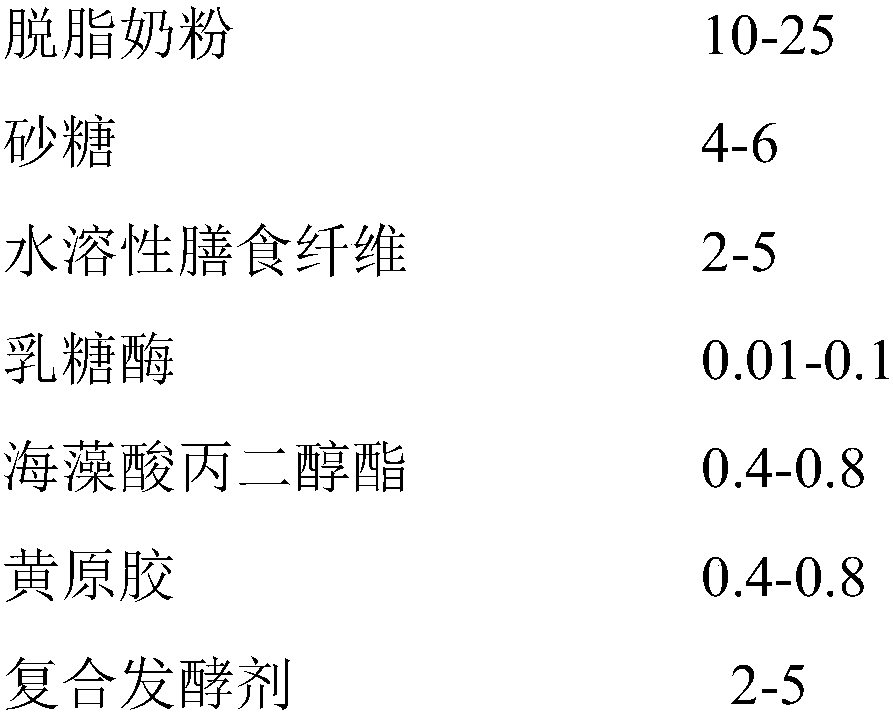

Solidification type aloe yoghourt and preparation method thereof

InactiveCN108354012ANutrients are stableRetain nutrientsMilk preparationNutritive valuesDietary fiber

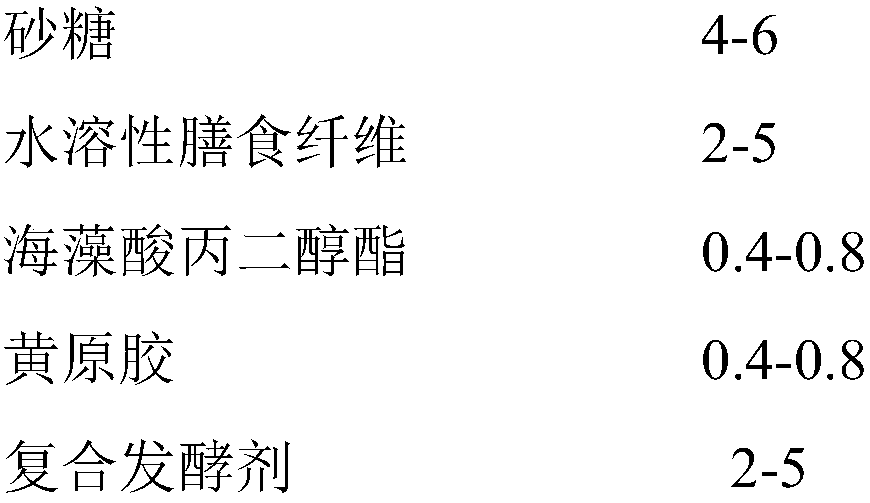

The invention discloses solidification type aloe yoghourt. The raw materials of the solidification type aloe yoghourt adopting the formula comprise the following components in parts by weight of 10-20parts of aloe, 10-25 parts of nonfat dry milk, 4-6 parts of granulated sugar, 2-5 parts of water soluble dietary fibers, 0.001-0.01 part of casoik flour, 0.001-0.01 part of transglutaminase and 2-5 parts of a composite fermenting agent. The casoik flour and the transglutaminase are used for replacing a stabilizing agent which is added, through controlling the activity of alpha-casein substrates in the casoik flour, and through catalytic conversion of the transglutaminase, the solidification property of the yoghourt is effectively improved, the nutrient value of the nonfat dry milk and the nutrient value of the aloe are reserved, the mouth feel of milk products is improved, and the tissue state is stable; and besides, the water soluble dietary fibers are added, so that the prepared yoghourt is healthier. The invention further discloses a preparation method of the aloe yoghourt. The preparation method comprises the steps of preparing materials, pretreating the aloe, performing sterilization, performing blending, performing homogenizing, performing sterilization, performing cooling, performing inoculation, performing fermentation, performing cold storage and performing mixing. In addition, compared with conventional solidification type yoghourt, the solidification type aloe yoghourt disclosed by the invention has better solidification property and smoothness, and whey separationis reduced.

Owner:杨春建

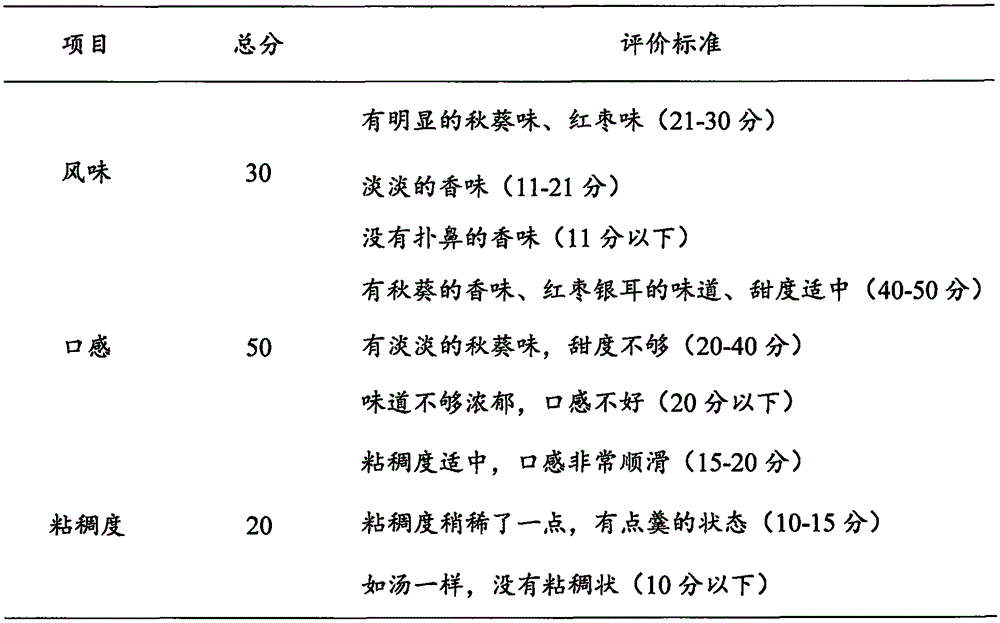

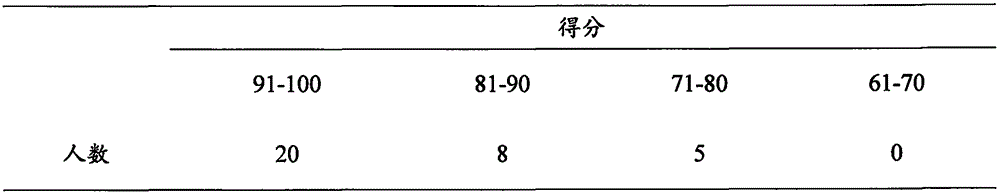

Abelmoschus esculentus, red date and white fungus thick soup and preparation method thereof

The present invention discloses an abelmoschus esculentus, red date and white fungus thick soup and belongs to the technical filed of food processing. The thick soup consists of the following raw materials in parts by weight: 1-3 parts of abelmoschus esculentus powder, 6-18 parts of white granulated sugar, 3-9 parts of white fungus powder, 4-12 parts of red date powder, and 200-600 parts of water. A production method is as follows: according to the ratio of the raw materials, the prepared abelmoschus esculentus powder, white fungus powder, red date powder and white granulated sugar are thoroughly mixed to obtain a mixture, and the thick soup is obtained by adding hot water to brew. The thick soup enriches the mouthfeel and nutritional value of meal replacement powder, and also has efficacies of beautifying features and nourishing skin, and protecting stomach.

Owner:BOHAI UNIV

Fructus hibiscus coccineus buffalo milk yogurt and preparation method thereof

ActiveCN107307079AUnique flavorStable organizationMilk preparationLactobacillusMacromolecular SubstancesLeavening agent

The invention relates to the technical field of food processing, and particularly relates to fructus hibiscus coccineus buffalo milk yogurt and a preparation method thereof. The fructus hibiscus coccineus buffalo milk yogurt disclosed by the application is prepared from the following raw materials in parts by weight: 10 to 20 parts of fructus hibiscus coccineus juice, 3 to 7 parts of white sugar, 80 to 150 parts of buffalo milk, and 7 to 10 parts of a yogurt leavening agent, wherein the leavening agent is prepared from lactobacillus delbrueckii subspecies bulgaricus, streptococcus thermophilus, bifidobacterium pseudolongum and lactobacillus plantarum in a mass ratio of 2 to 1 to 1 to 1; the lactobacillus plantarum in the leavening agent is obtained by carrying out separation from three-way crossbred buffalo milk of self-breeding variety by an inventor, macromolecular substances such as proteins, cellulose and pectin can be converted into small molecule substances which are easily absorbed by a human body, and lactase and the like also can be produced so as to be beneficial for the human body to digest lactose; moreover, the buffalo milk yogurt has a plurality of physiological functions of protecting the stomach and the liver, preventing aging, increasing the endurance, resisting cancers and the like.

Owner:广州煜景科技服务有限公司

Brown stirred yoghourt containing morchella esculenta and preparation method of brown stirred yoghourt containing morchella esculenta

The invention discloses brown stirred yoghourt containing morchella esculenta powder and a preparation method of the brown stirred yoghourt containing morchella esculenta powder. The stirred type yoghourt comprises the following components in parts by mass: 2-3 parts of morchella esculenta powder, 1-2 parts of hericium erinaceus juice, 80-85 parts of fresh milk, 4-6 parts of mixed sugar, 3-4 partsof a composite fermenting agent and 0.3-0.5 part of an emulsion stabilizer, wherein the mixed sugar consists of cane sugar and levulose in the mass ratio of the cane sugar to the levulose being (2-2.5) to 1. The preparation method of the brown stirred type yoghourt comprises the following steps of preparing raw materials, performing homogenizing, performing brown stains, performing fermentation and performing after-ripening. The stirred type yoghourt prepared by the method is stable in properties. The stirred type yoghourt prepared by the method disclosed by the invention is moderate in color, the technical problems that milk (goat milk) is difficult to ferment during high glucose fermentation after long-time high-temperature brown stain, and is poor in fermentation flavor and tissue state, can be solved, the product namely the brown stirred yoghourt is excellent in scorch aroma flavor and fermentation flavor, uniform, fine and smooth in tissue state, short in fermentation time and high in quality, and through combination of the special efficacy of morchella esculenta and hericium erinaceus, the brown stirred yoghourt can be suitable for various crowds to eat.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

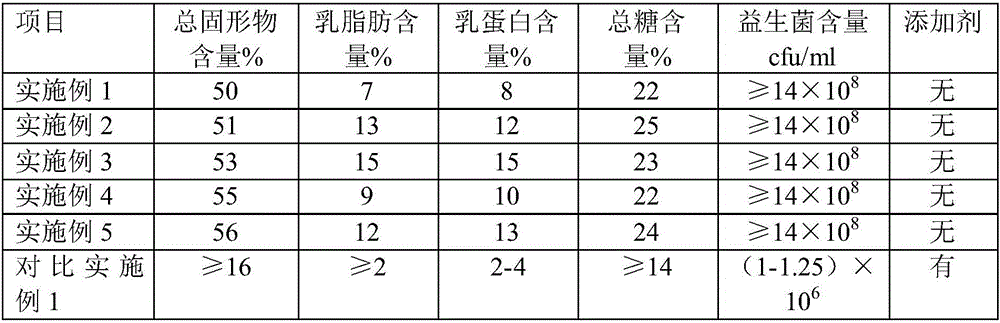

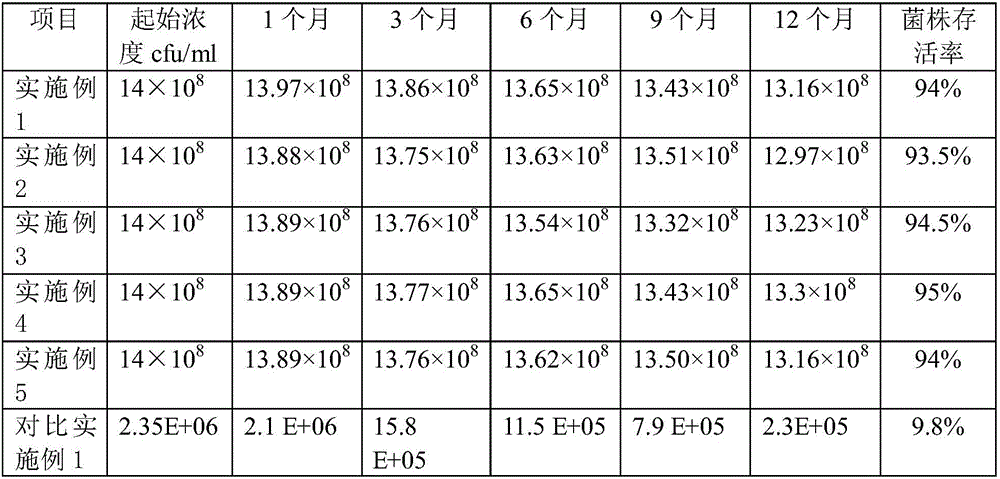

A kind of probiotic ice cream or ice cream and its production process

ActiveCN105994925BAvoid inhibitionGood sweet and sour ratioFrozen sweetsCocoaBiotechnologyCold drinks

A probiotic ice cream or ice cream belongs to the technical field of cold drinks, and comprises the following components by weight: whole milk powder > 20%, sugar > 15%, and probiotic content ≥ 14×10 8 cfu / ml, the balance is water. The invention also discloses a production process of the probiotic ice cream or ice cream. The production process is simple to operate, and the prepared probiotic ice cream or ice cream has a delicate taste, sweet and sour taste, good tissue stability and melting resistance.

Owner:内蒙古利尔健奶制品分解科技有限公司

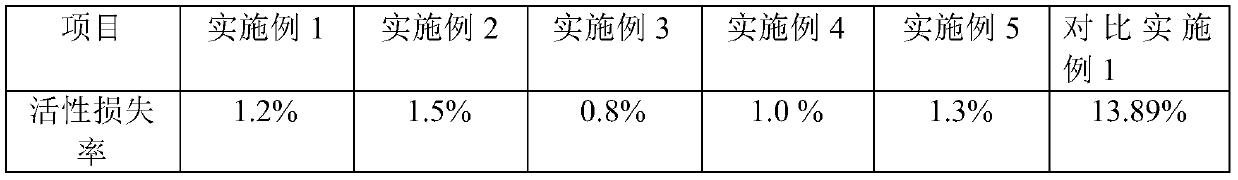

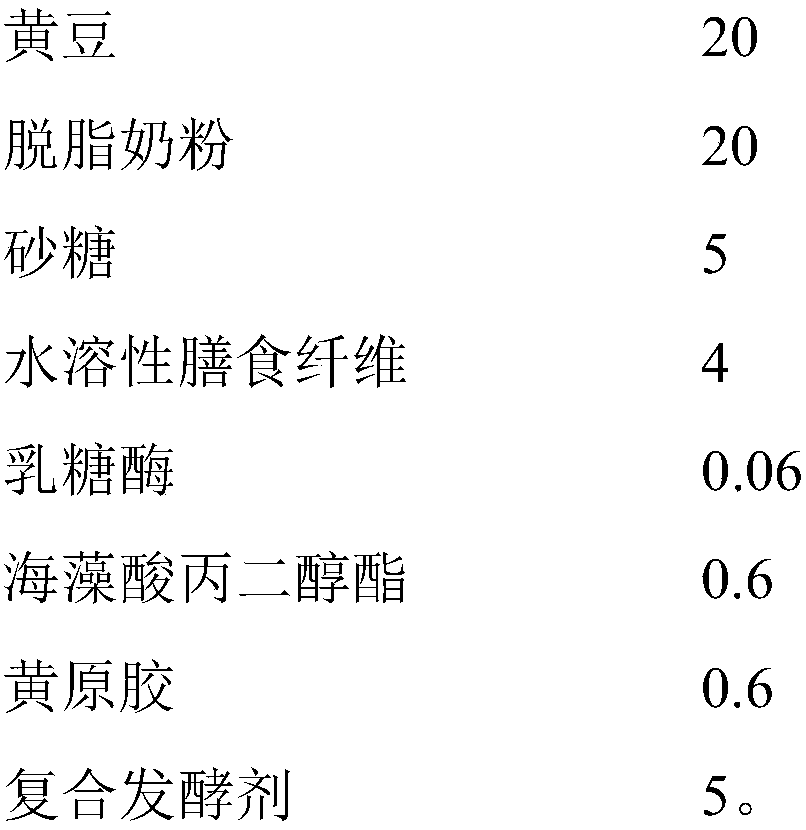

Low-lactose soybean-milk-flavored yoghourt and preparation method thereof

InactiveCN108244243ALower blood sugarLubricating NutrientsMilk preparationNutritive valuesSolubility

The invention discloses low-lactose soybean-milk-flavored yoghourt. The raw materials of the low-lactose soybean-milk-flavored yoghourt comprise the following components in parts by weight of 10-20 parts of soybeans, 10-25 parts of nonfat dry milk powder, 4-6 parts of granulated sugar, 2-5 parts of water-soluble dietary fibers, 0.01-0.1 part of lactase, 0.4-0.8 part of xanthan gum, 0.4-0.8 part ofpropylene glycol alginate, and 2-5 parts of a composite fermentation agent, wherein the lactase is added, so that the lactose low in sweetness and solubility in milk can be converted into monosaccharide (glucose and galactose) high in sweetness and solubility; the possibility that the lactose in the milk is crystallized and separated out is reduced; and besides, in the fermentation process, the lactose which cannot be used by general yeast can be hydrolyzed to form the glucose for use. The invention further discloses a preparation method of the low-lactose soybean-milk-flavored yoghourt. Thepreparation method comprises the following steps of preparing materials, pretreating the soybeans, performing soaking, performing grinding to obtain soybean milk, performing filtering, performing sterilization, performing blending, performing homogenizing, performing sterilization, performing cooling, performing inoculating, performing fermentation and performing cold storage. The low-lactose soybean-milk-flavored yoghourt is simple to process, low in cost, high in nutrient value and convenient to eat, and is favorable for health of human bodies, and the preparation method is suitable for preparation of the low-lactose soybean-milk-flavored yoghourt.

Owner:杨春建

Preparation method of kudzuvine root fruit milk

InactiveCN110810520AFull of nutritionMild tasteMilk preparationFood ingredient as taste affecting agentPectinaseNutrition

The invention discloses a preparation method of kudzuvine root fruit milk. The method comprises the following steps: selecting kudzuvine roots, removing impurities, and performing cleaning; putting the cleaned kudzuvine roots into a steam box, performing heating, and performing cooking with water vapor; putting the cooked kudzuvine roots into an oven, and performing baking to continuously soften the kudzuvine roots; performing grinding, adding pectinase and cellulase, and performing treating in an ultrasonic generator; pouring milk into the treated kudzuvine roots, performing grinding, performing uniform mixing, and performing sterilization treatment; culturing strains, inoculating the sterilized mixed solution of the kudzuvine roots and the milk with the cultured strains, and performing fermentation; and carrying out ultrahigh-temperature instantaneous sterilization on the fermented product to obtain the kudzuvine root fruit milk. The method makes the whole fruit milk stable in tissuestate, and reserves the maximum nutrition of the kudzuvine roots.

Owner:ZHANGJIAJIE ANFU TOURISM FOOD CO LTD

Pepino-melon buffalo-milk sour milk and preparation method thereof

InactiveCN108935676AUnique flavorStable organizationMilk preparationLactobacillusMacromolecular SubstancesLower blood pressure

The invention relates to the technical field of food processing, and specifically relates to pepino-melon buffalo-milk sour milk and a preparation method thereof. The pepino-melon buffalo-milk sour milk is prepared from the following raw materials in parts by weight: 10-20 parts of pepino melon juice, 3-7 parts of white granulated sugar, 80-150 parts of buffalo milk, and 7-10 parts of a sour milkfermentation agent. The sour milk fermentation agent is composed of Lactobacillus delbrueckii subspecies bulgaricus, streptococcus thermophilus, bifidobacterium pseudolongum and lactobacillus plantarum at a mass ratio of 2:1:1:1; and the lactobacillus plantarum is prepared by performing separation on milk of three-variety hybrid buffaloes which are bred by the inventor himself / herself. Thus, macromolecular substances, including proteins, cellulose, pectin and the like, are conversed into small-molecular substances which can be easily absorbed by the human body; moreover, lactose easy for the human body to digest, including lactase and the like, are produced, so that the pepino-melon buffalo-milk sour milk has the functions of resisting cancer, delaying senility, lowering blood pressure, reducing blood glucose, diminishing inflammation, supplementing calcium and beautifying.

Owner:孙香梅

Peanut yoghurt and preparation method thereof

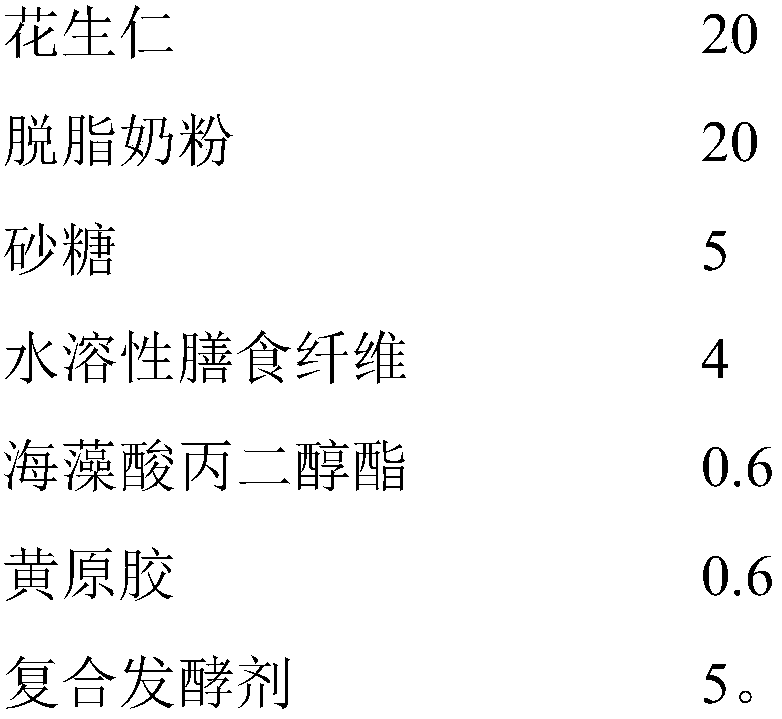

The invention discloses peanut yoghurt. The raw materials of the peanut yoghurt comprise the following components in parts by weight of 10-20 parts of peanut kernels, 10-25 parts of nonfat dry milk powder, 4-6 parts of granulated sugar, 2-5 parts of water soluble dietary fibers, 0.4-0.8 part of xanthan gum, 0.4-0.8 part of propylene glycol alginate and 2-5 parts of a composite fermenting agent, wherein the xanthan gum and the propylene glycol alginate are used as stabilizing agents, so that the peanut yoghurt is rich in nutrients and smooth in mouth feel; the water soluble dietary fibers are added, so that nutrient components in the peanut kernels can be effectively reserved; and besides, protein and lipomicron in homogenized material liquid are sufficiently emulsified, so that the peanutdairy products are stable. The invention further discloses a preparation method of the peanut yoghurt. The preparation method comprises the following steps of preparing materials, pretreating the peanut kernels, performing soaking and grinding to obtain pulp, performing filtering, performing sterilization, performing blending, performing homogenizing, performing sterilizing, performing cooling, performing inoculating, performing fermentation and performing cold storage. The peanut yoghurt is simple to process, low in cost, convenient to transport, high in nutrient value, good in taste and convenient to eat, is favorable for health of human bodies, and meets requirements of people. The preparation method is suitable for preparation of the peanut yoghurt.

Owner:杨春建

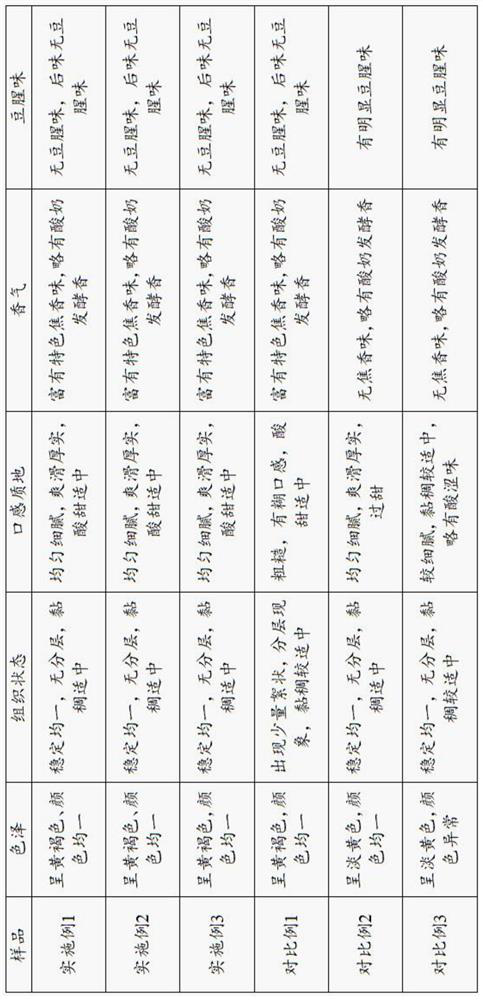

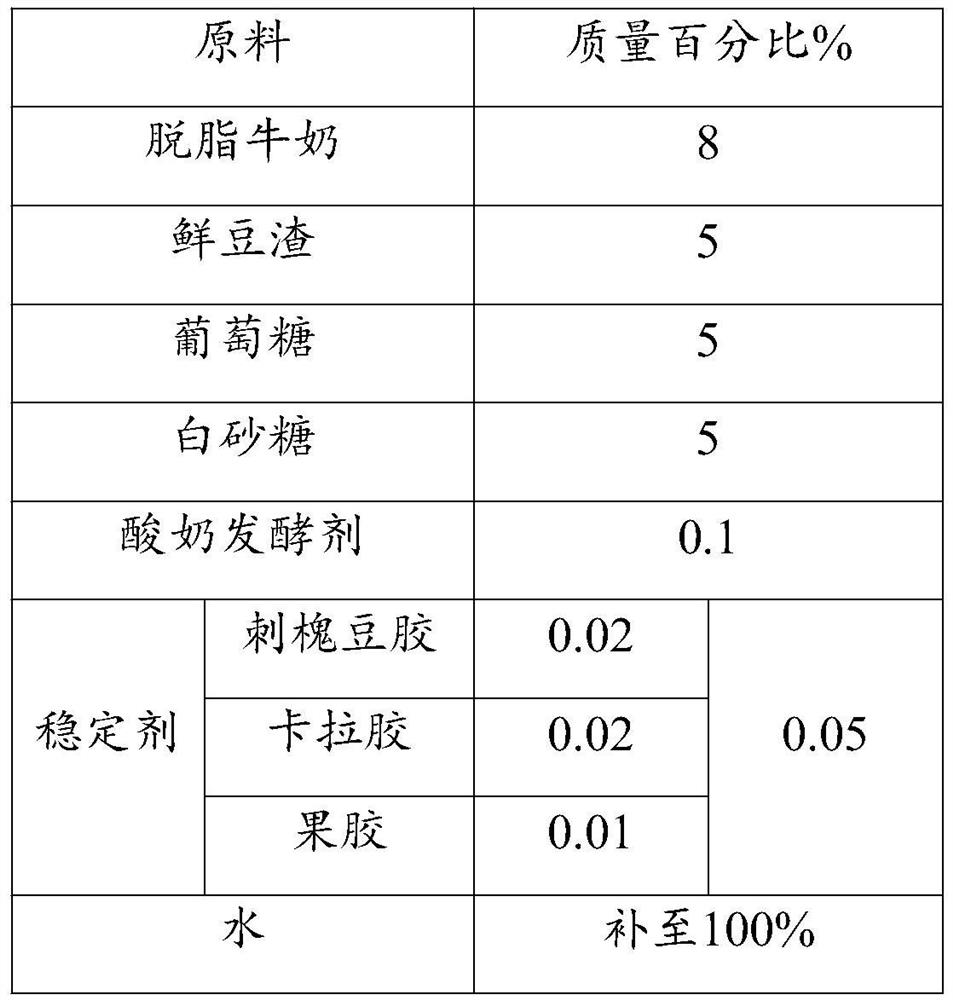

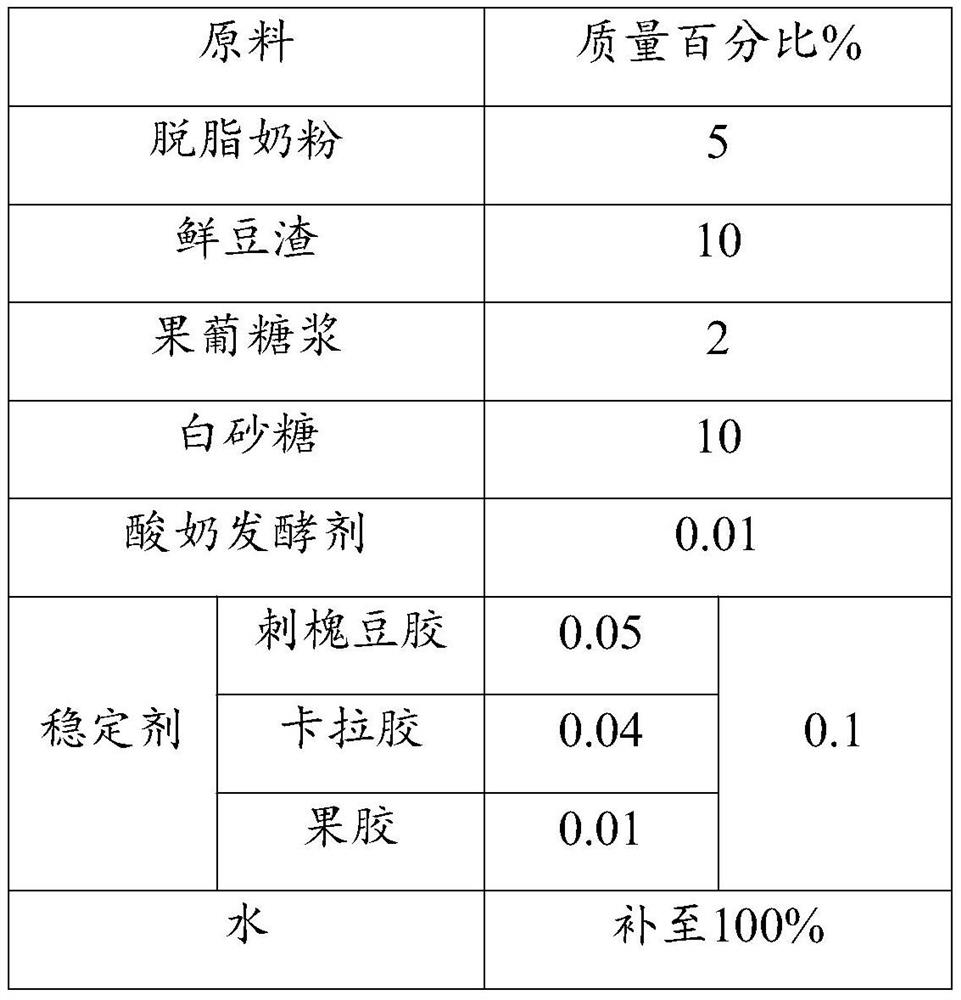

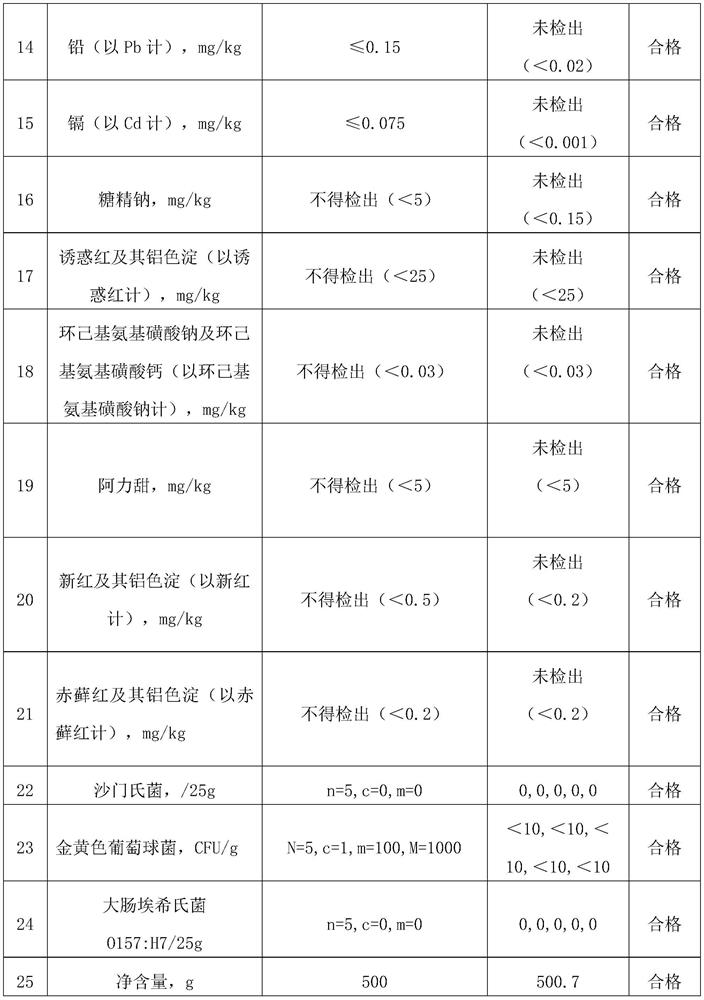

Bean dreg brown fermented milk beverage and preparation method thereof

The invention discloses a bean dreg brown fermented milk beverage and a preparation method thereof. The bean dreg brown fermented milk beverage comprises the following components in percentage by mass: 5-20% of skimmed milk, 1-10% of fresh bean dregs, 1-8% of reducing sugar, 2-10% of white granulated sugar, 0.01-0.1% of a yoghurt starter, 0.05-0.3% of a stabilizer and the balance of water. The bean dreg brown fermented milk beverage prepared by the preparation method disclosed by the invention is free from beany flavor, has a special scorch aroma, and is smooth in mouth feel, moderate in sour and sweet degrees, not obvious in bean dreg granular sensation and stable in tissue state. The bean dreg brown fermented milk beverage product development improves the bean dreg utilization rate and the market additional value, and solves the problem of bean dreg recycling. Meanwhile, the bean dreg brown fermented milk beverage is low in raw material cost, and the method is simple and easy to implement.

Owner:赵元泰 +2

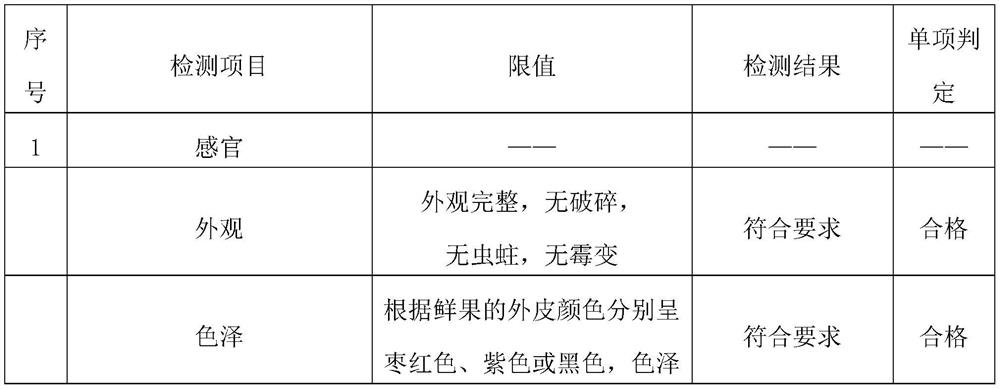

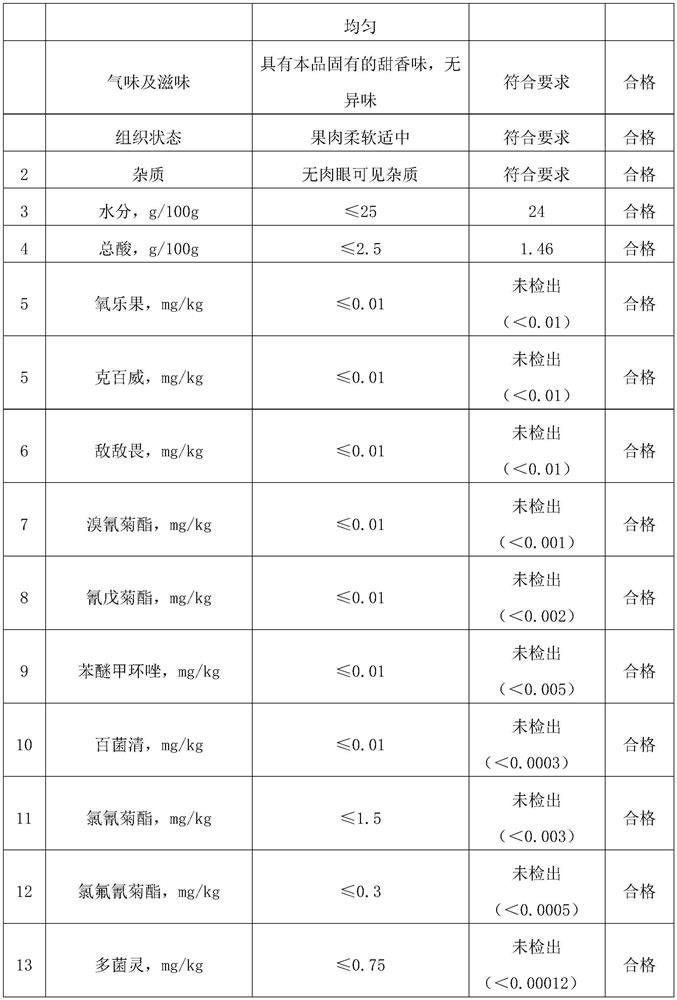

Amethystine jujube processing technology

PendingCN111616330ASimple processEasy to operateFood thermal treatmentFood dryingBiotechnologyFood additive

The invention relates to an amethystine jujube processing technology. The amethystine jujube processing technology takes red jujubes in the yellow river beach as a raw material and comprises five steps of precooking, cooling, drying, airing and secondary drying. Compared with the prior art, the amethystine jujube processing technology has the following beneficial effects: (1) the amethystine jujube processing technology is simple, convenient to operate and low in process cost, the taste of a product is greatly improved by precooking treatment and secondary drying technologies, and the amethystine jujube product is stable in texture and suitable for industrial production; (2) third-party detection shows that the heavy metal content, the pesticide residue, the food additive content and the bacterial content of the amethystine jujube product obtained with the amethystine jujube processing technology meet the requirements of NY / T1041-2018 Green Food Dried Fruit.

Owner:山西万锋天然枣业开发有限公司

Brown solidification type fermented milk and making method thereof

The invention discloses brown solidification type fermented milk and a making method thereof. The fermented milk comprises the following raw materials in percentage by mass: 2.0-9.0% of reducing sugar, 0.4-2.0% of protein powder, 1-20% of milk containing fat, 0.1-0.4% of a stabilizing agent, 0.001-0.006% of a fermenting agent and the balance of raw milk, wherein all the components are 100.0%. Themaking method comprises the following steps of (1) mixing the raw milk with the reducing sugar, performing warming, and performing heat preservation so as to obtain a material A; (2) reducing the temperature of the material A, and mixing the material after temperature reduction with other raw materials so as to obtain a mixture B; (3) homogenizing the material B, performing sterilization, performing cooling, and performing inoculation with the fermenting agent so as to obtain a material C; and (4) filling the material C, performing fermentation, performing cooling and performing after-ripeningso as to obtain the fermented milk. A formula and a technology are optimized, so that the brown solidification type fermented milk is made and is fine and smooth in mouth feel and unique in flavor, besides, a tissue state is stable within a quality guarantee period, and a milk-water separation phenomenon does not appear.

Owner:BRIGHT DAIRY & FOOD CO LTD

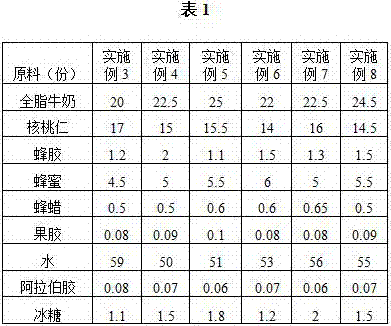

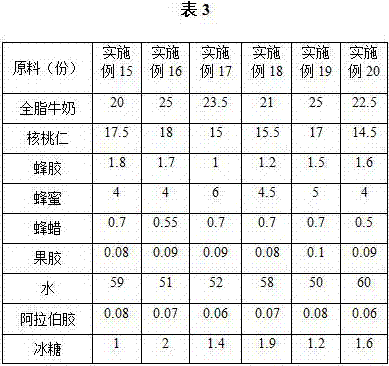

Propolis walnut milk with defecating function

The invention relates to propolis walnut milk with a defecating function. The proplis walnut milk is prepared from the following raw materials in parts by weight: 20 to 25 parts of full-grease milk, 14 to 18 parts of walnut kernels, 1 to 2 parts of propolis, 4 to 6 parts of honey, 0.5 to 0.7 part of beewax, 0.08 to 0.1 part of pectin, 50 to 60 parts of water, 0.06 to 0.08 part of Arabic gum, and 1 to 2 parts of rock candies. The propolis walnut milk provided by the invention is good in taste, stable in tissue state, remarkable in curative effect for constipation, and suitable for constipation crowd to eat for a long time.

Owner:刘国灿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com