Bean dreg brown fermented milk beverage and preparation method thereof

A fermented milk beverage, brown technology, applied in dairy products, milk preparations, applications, etc., can solve problems that affect food safety, endanger human health, and loss of nutrients, and achieve recycling, simple methods, and organization The effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

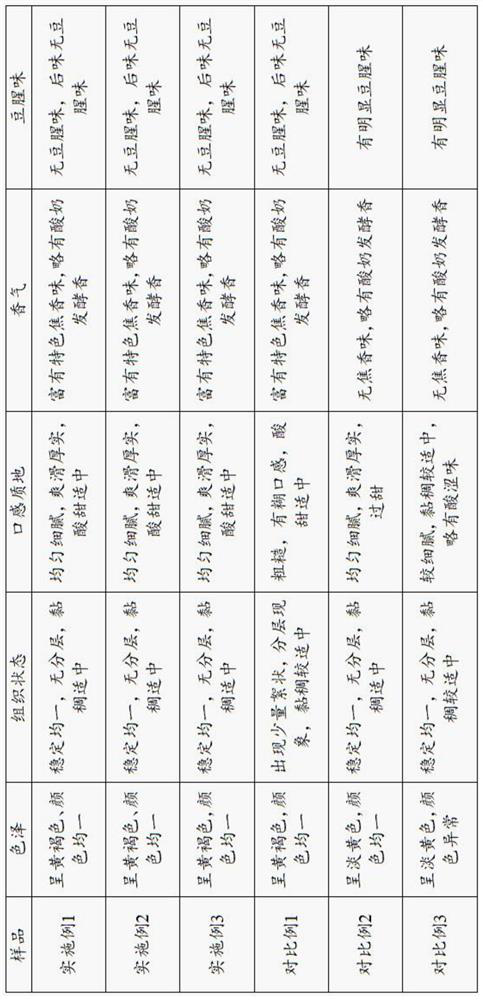

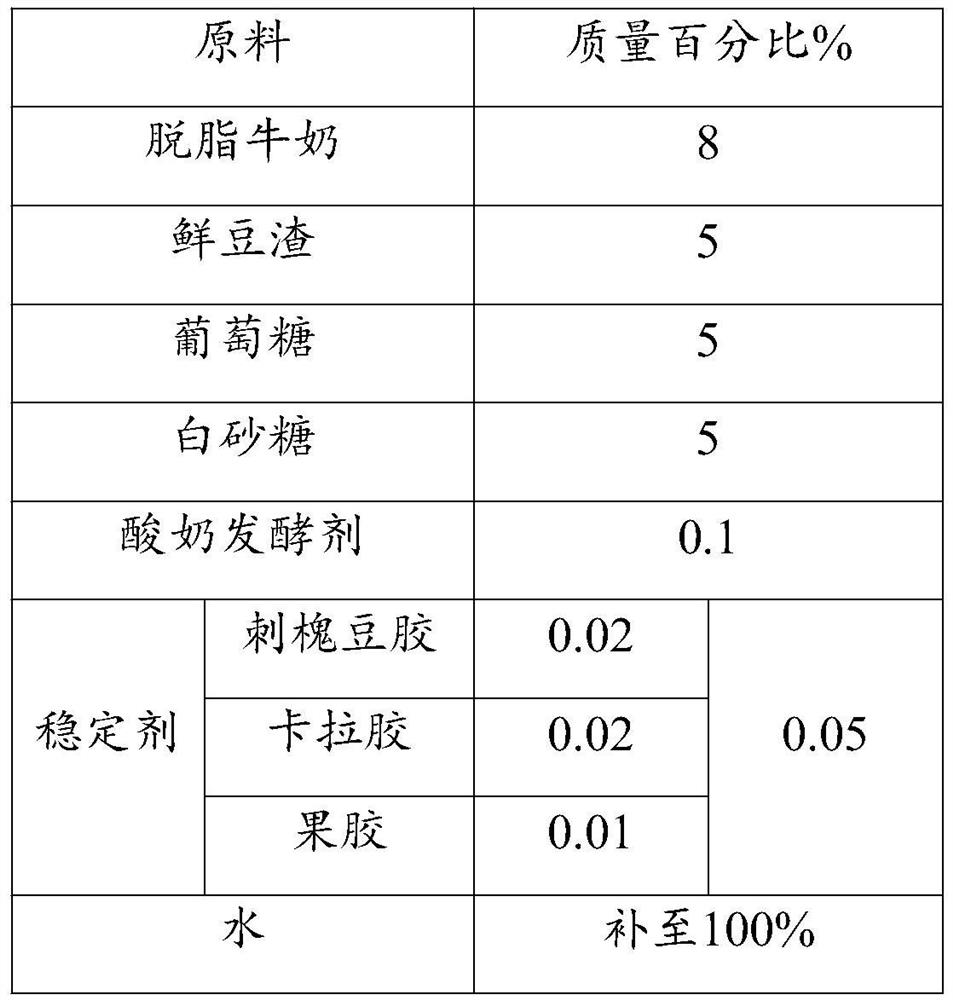

[0031] A kind of bean dregs brown fermented milk beverage, formula as shown in table 1:

[0032] Table 1

[0033]

[0034] The preparation method of the above-mentioned okara brown fermented milk beverage comprises the following steps:

[0035] Step 1) Hydration: Add reducing sugar to skim milk, add water, stir and mix well, then stand at 40°C for 90 minutes for hydration;

[0036] Step 2) Maillard reaction: heating the hydrated feed liquid until browning, the browning temperature is 90°C, and the browning time is 150min. After the browning is completed, sterilize, the sterilization condition is 85°C, 60min, and cool to room temperature. to obtain a brown base;

[0037] Step 3) brown base material fermentation: add yogurt starter to the brown base material obtained in step 2) according to the formula amount for fermentation, ferment at a constant temperature of 40°C for 80 hours, perform demulsification, stirring, cooling, and homogenization to obtain a mixed solution A, ...

Embodiment 2

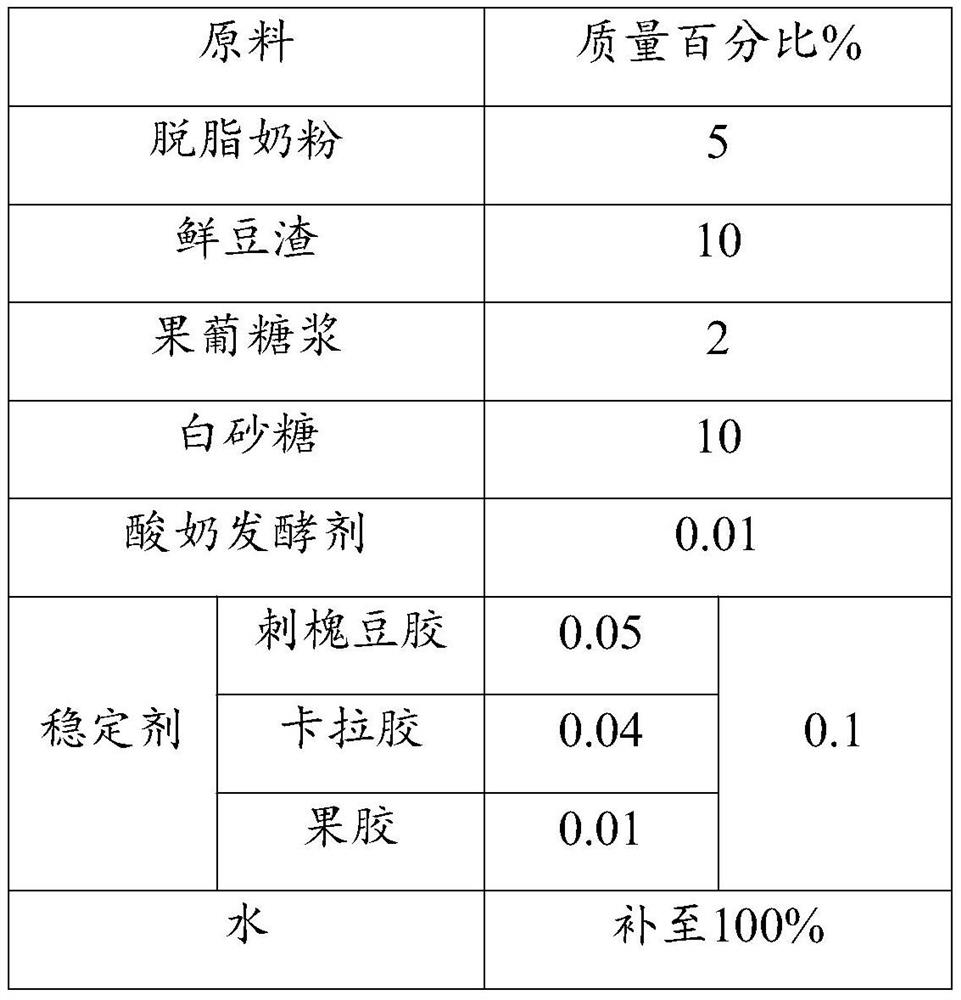

[0041] A kind of bean dregs brown fermented milk beverage, formula as shown in table 2:

[0042] Table 2

[0043]

[0044] The preparation method of the above-mentioned okara brown fermented milk beverage comprises the following steps:

[0045] Step 1) Hydration: Add reducing sugar to skim milk, add water, stir and mix well, then stand at 65°C for 30 minutes for hydration;

[0046] Step 2) Maillard reaction: heat the hydrated feed solution until browning, browning temperature is 80°C, browning time is 200min, after browning is completed, sterilize, sterilization condition is 95°C, 45min, cool to room temperature, to obtain a brown base;

[0047] Step 3) Fermentation of brown base material: add yogurt starter to the brown base material obtained in step 2) according to the formula amount for fermentation, ferment at a constant temperature of 42°C for 75 hours, perform demulsification, stirring, cooling, and homogenization to obtain a mixed solution A, Refrigerate at 2-4°C ...

Embodiment 3

[0051] A kind of bean dregs brown fermented milk beverage, formula as shown in table 3:

[0052] table 3

[0053]

[0054]

[0055] The preparation method of the above-mentioned okara brown fermented milk beverage comprises the following steps:

[0056]Step 1) Hydration: Add reducing sugar to skim milk, add water, stir and mix well, then let stand at 60°C for 45 minutes for hydration;

[0057] Step 2) Maillard reaction: heat the hydrated feed liquid until browning, browning temperature is 100°C, browning time is 120min, after browning is completed, sterilize, sterilization condition is 115°C, 15min, cool to room temperature, to obtain a brown base;

[0058] Step 3) Fermentation of brown base material: add yogurt starter to the brown base material obtained in step 2) according to the formula amount for fermentation, ferment at a constant temperature of 45°C for 60 hours, perform demulsification, stirring, cooling, and homogenization to obtain a mixed solution A, Refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com