Black corn sour milk and preparation method thereof

A technology of yogurt and corn, applied in the direction of milk preparations, dairy products, applications, etc., to achieve the effect of rich nutrition, smooth taste and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

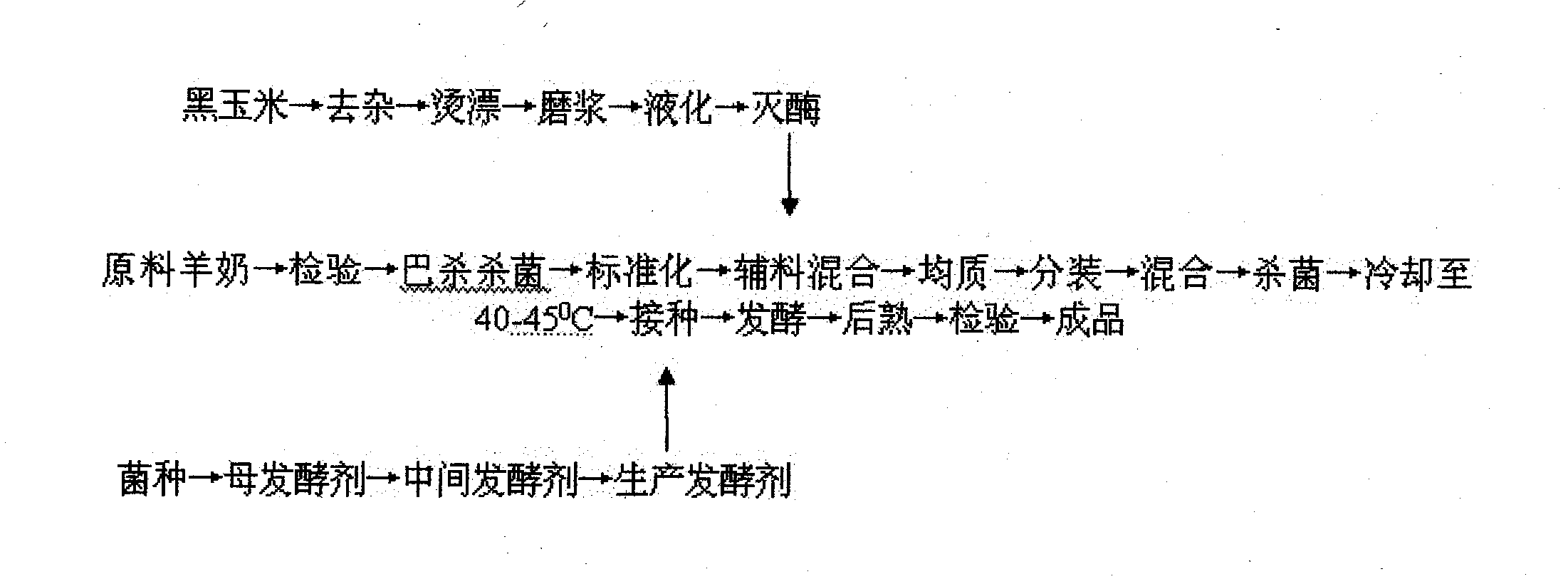

Method used

Image

Examples

Embodiment 1

[0040] Black corn pulping: take black corn kernels, boil and blanch them for ripening, deenzyme treatment, add water to the black corn kernels after deenzyme, black corn: water ratio 1:3-4, use α-amylase after beating Carry out liquefaction for 40-50min, liquefaction conditions: pH=6.0-6.5, temperature adjustment 55-65°C, enzyme amount: 12-16μg / g corn; then adjust pH=4.5-5.0, temperature 60-65°C, add glucose starch Enzyme (200-240μg / g) for saccharification, the saccharification time is about 2 hours; finally 95-100 ℃ for 5 minutes to inactivate the enzyme, the DE value of black corn steep liquor is preferably 95-98%.

[0041] Milk product preparation: Pre-pasteurize the raw milk (goat milk) that has passed the quality inspection. The pre-pasteurization is sterilized at 80-85°C for 15 seconds. The control of raw milk is very important to product quality. The degree and safety factors directly affect the quality of finished milk. It is required that the milk temperature should n...

Embodiment 2

[0049] Black corn pulping: take black corn kernels, boil and blanch them for ripening, deenzyme treatment, add water to the black corn kernels after deenzyme, black corn: water ratio 1:3-4, use α-amylase after beating Carry out liquefaction for 40-50min, liquefaction conditions: pH=6.0-6.5, temperature adjustment 55-65°C, enzyme amount: 12-16μg / g corn; readjust and adjust pH=4.5-5.0, temperature 60-65°C, add Glucoamylase (200-240μg / g) is used for saccharification, and the saccharification time is about 3 hours; finally, the enzyme is inactivated at 95-100°C for 5 minutes, and the DE value of black corn steep liquor is preferably 95-98%.

[0050] Milk product preparation: Pre-pasteurize the raw milk (goat milk) that has passed the quality inspection. The pre-pasteurization is sterilized at 80-85°C for 15 seconds. The control of raw milk is very important to product quality. The degree and safety factors directly affect the quality of finished milk. It is required that the milk ...

Embodiment 3

[0057] Embodiment 3 comparative process embodiment

[0058] Black corn pulping: take black corn kernels, soak them in warm water at 35-40°C until they absorb water and swell completely, beat them with warm water below 50°C, the ratio of material to water is 1:5, and then filter them with a 200-mesh filter cloth. Add liquefaction enzyme, adjust the pH value to 6 with citric acid, heat to 95° C., and keep it warm for 1 hour to obtain black corn puree.

[0059] Milk product preparation: Pre-pasteurize the raw milk (goat milk) that has passed the quality inspection. The pre-pasteurization is sterilized at 80-85°C for 15 seconds. The control of raw milk is very important to product quality. The degree and safety factors directly affect the quality of finished milk. It is required that the milk temperature should not be higher than 6°C in summer and not higher than 4°C in winter. Combined with alcohol test, titrated acidity, pH, protein, fat and other physical and chemical indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com