Cast iron stone electric cooker inner pot and production method thereof

A production method and technology of an electric rice cooker, applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of residual poisons in the human body, and achieve the effect of retaining nutrients, advanced technology, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

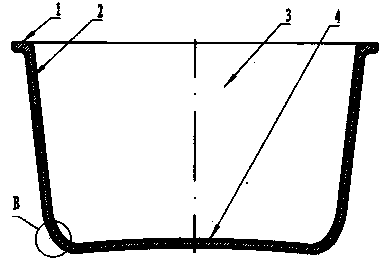

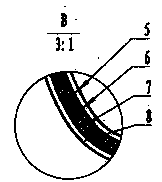

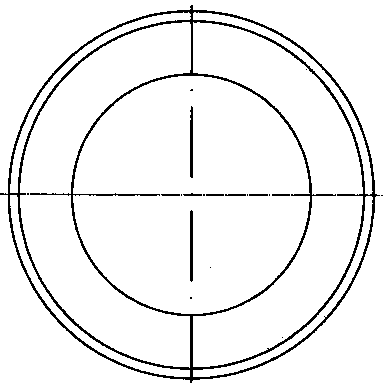

[0019] Embodiment 1, a pig iron stone electric rice cooker gall and its production method, including pot ears, pot body, inner cavity, pot bottom, stone powder layer, inner lining layer, body, enamel layer, characterized in that the body (7) The outer layer is an enamel layer (8), the inner lining layer (6) is inside the body (7), and the stone powder layer (5) is outside the inner lining layer (6). The stone powder layer (5) contains quartz, silicate, and granite. Between the lining layer (6) and the enamel layer (8) is the body (7). There are more than one layer of lining layer (6) in the body (7). More than one layer of stone powder layer (5) is arranged in the body (7).

[0020] The production process and equipment are: molten iron melting in intermediate frequency furnace → double sand mold forming → sand cleaning by shot blasting machine → machining → annealing treatment → spraying daily-use enamel material on the outer diameter of the pot → spraying metal and stone bo...

Embodiment 2

[0021] Example 2, the pot ears (1) are turned outward at the top port of the pot body (2), and the pot body (2) is made as follows: ①The molten iron is smelted in an intermediate frequency electric furnace and formed by a double-sand mold process. ②Sand blasting with a shot blasting machine. ③ Machine tool processing. ④ Annealing oxidation treatment is 900 ℃. ⑤The outer diameter of the pot is sprayed with daily-use enamel paint with a thickness of 0.5mm, and the inner layer is sprayed with multiple layers of stone powder adhesive material with a thickness of 0.3mm, and then dried at 150°C. ⑥Use a ball mill to grind the stone to 150 mesh, add 0.1 borax and 0.5 parts by mass of soda ash and clay, stir and spray the inner layer evenly, with a thickness of about 1 mm. ⑦ The inner pot is dried at 800°C. The structure of the pot is: the outer layer of the main body (7) is an enamel layer (8), the inner lining layer (6) is inside the main body (7), the outer lining layer (6) is a ...

Embodiment 3

[0022] Example 3, referring to the production process and structure of Example 1 and Example 2, the outer enamel layer (8) is sprayed on the outer diameter of the body (7) pot for 3 to 20 minutes, and then the inner lining layer (6) is sprayed on the inner diameter of the pot , the inner lining layer (6), spraying with metal powder for 3 to 20 minutes, and then spraying the stone powder layer (5) to the adhesive state, and then baking at a temperature of 800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com