Method for manufacturing standard test blocks used for 300M steel tempering acid etch detection

A technology for detection standards and production methods, applied in the preparation of test samples, etc., can solve problems affecting product quality, repetitive work, etc., and achieve the effect of simple operation and stable organizational state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

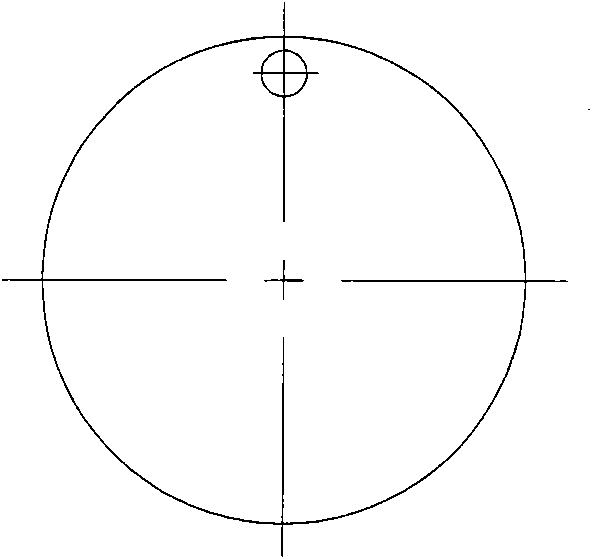

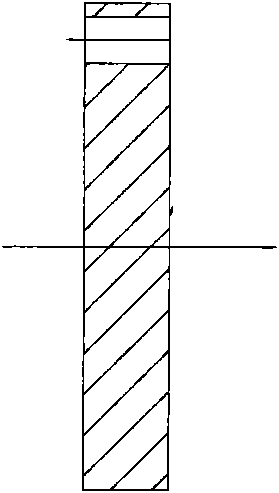

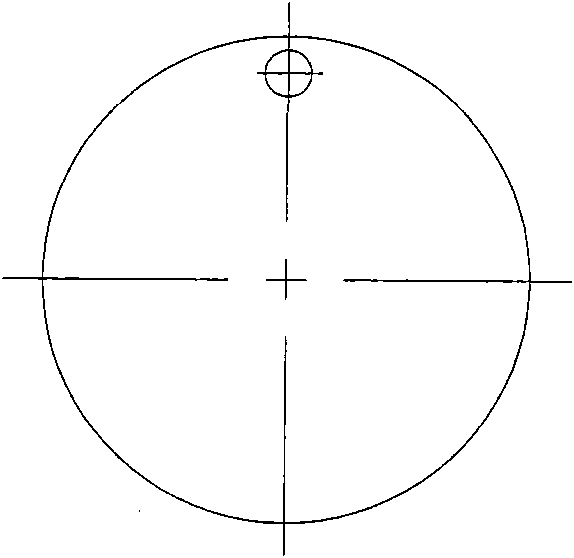

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment thereof:

[0014] Based on the standard heat treatment state of 300M steel, combined with the fact that the introduction of bad heat sources during processing will affect the 300M steel matrix, the "material supply state", "untempered state", "standard heat treatment state", and "400°C overheated state" were made. Standard test blocks in seven different organizational states, including "tempered state", "500°C over-tempered state", "600°C over-tempered state" and "700°C over-tempered state".

[0015] The heat treatment parameters for the production of the standard test block of the material supply state are: 925±10°C heat preservation, air cooling and normalizing, then 680±10°C high temperature tempering for 4 hours, and air cooling. After acid etching, the surface color is dark brown black.

[0016] The heat treatment parameters of the standard test block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com