Yogurt containing fermented glutinous rice and fruit granules and preparation method of yogurt

A technology for fruit and yogurt, applied in milk preparations, dairy products, applications, etc., can solve the problems of no rice grains intuition and chewing, damage to the tissue state of yogurt, irritating sour taste, etc., and achieve good flavor and texture. Delicate and good chewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

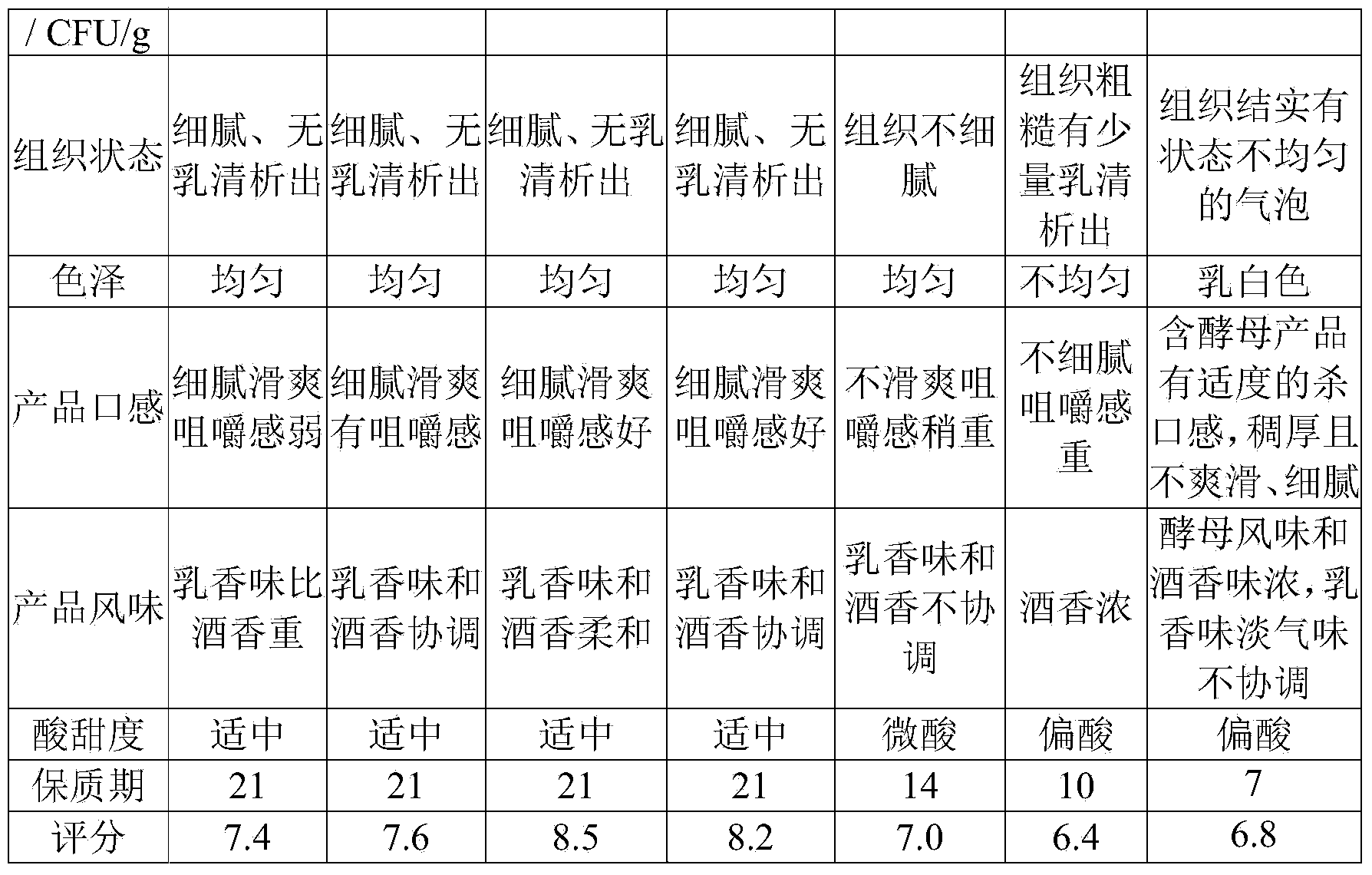

Embodiment 1

[0055] (1) After preheating 78.84% raw milk to 35°C, add 8.0% white granulated sugar, 1.0% modified starch, 0.05% agar, and 0.08% pectin, stir for 20 minutes, mix well, and obtain a feed liquid A;

[0056] (2) Homogenize feed liquid A at 60°C under a pressure of 18 MPa, sterilize at 90°C for 10 minutes, and cool to 37°C to obtain feed liquid B;

[0057] (3) Feed liquid B is inoculated with the starter of model 0925-B, and the amount of starter added is 150 DCU per ton of raw milk for fermentation, and when the titrated acidity reaches 70 ° T, the fermentation is terminated to obtain fermented milk;

[0058] (4) Turn over the fermented milk and cool it to 16°C;

[0059] (5) Add 8.0% fermented glutinous rice, 4.0% fruit grains and 0.03% yogurt essence to the cooled fermented milk online, and fill it into a packaging container. Hourly yoghurt with mellow fruity flavor and grains of rice crackers.

[0060] The above-mentioned percentages are the mass percentages of each compone...

Embodiment 2

[0062] (1) After preheating 83.74% of raw milk to 40°C, add 0.02% of acesulfame K, 0.01% of aspartame, 1.0% of modified starch, and 0.2% of agar, stir for 15 minutes, and mix well. Feed liquid A;

[0063] (2) Homogenize feed liquid A at 65°C under a pressure of 20MPa, sterilize at 95°C for 5 minutes, and cool to 39°C to obtain feed liquid B;

[0064] (3) Feed liquid B is inoculated with starters of model YF-L812 and LAFTI-L10DSL, the amount of starter added is 200 DCU per ton of raw milk for fermentation, and when the titrated acidity reaches 75 ° T, the fermentation is terminated to obtain fermented milk;

[0065] (4) Turn over the fermented milk and cool it to 18°C;

[0066] (5) Add 10.0% fermented glutinous rice, 5.0% fruit grains and 0.03% yogurt essence to the cooled fermented milk online, and fill it into a packaging container. The product is quickly placed in an environment of 6°C, and fermented for 24 hours after refrigeration. Hours, you get delicate, smooth, sweet ...

Embodiment 3

[0069] (1) After preheating 84.19% raw milk to 42°C, add 5.0% white granulated sugar, 2.0% xylitol, 0.01% sucralose, 0.5% modified starch, 0.18% agar and 0.12% pectin, stirred for 16 minutes, and mixed evenly to obtain material liquid A;

[0070] (2) Homogenize feed liquid A at 68°C under a pressure of 21 MPa, sterilize at 100°C for 8 minutes, and cool to 40°C to obtain feed liquid B;

[0071] (3) Inoculate feed liquid B with the starter of model 0925-A, add 200 DCU per ton of raw milk for fermentation, stop fermentation when titrated acidity reaches 78 ° T, and obtain fermented milk;

[0072] (4) Turn over the fermented milk and cool it to 20°C;

[0073] (5) Add 5.0% fermented glutinous rice and 3.0% fruit grains to the cooled fermented milk online, and fill it into a packaging container. The product is quickly placed in an environment of 8°C, refrigerated and fermented for 12 hours to obtain a fine and smooth texture. , unique flavor of yoghurt with rice crackers.

[0074] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com