Brown solidification type fermented milk and making method thereof

A fermented milk and coagulation technology, which is applied to bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of single color, high cost, and complicated preparation methods, and achieve unique flavor, stable tissue state, and good taste delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing brown coagulated fermented milk, the fermented milk comprises the following raw materials in mass ratio: reducing sugar 2.0-9.0%, protein powder 0.4-2.0%, fat-containing milk 1-20%, stabilizer 0.1-0.4%, Starter 0.001-0.006% and supplemented to 100.0% raw milk,

[0027] Described preparation method comprises the steps:

[0028] (1) heating the raw material milk to 40-50°C and mixing it with reducing sugar, then raising the temperature to 90-95°C, and keeping it warm to obtain material A;

[0029] (2) Cool the material A obtained in step (1) to 40-50°C and mix it with protein powder, fat-containing emulsion, and stabilizer to obtain material B;

[0030] (3) Homogenize the material B obtained in step (2), sterilize, cool, and inoculate the starter to obtain material C;

[0031] (4) The material C obtained in step (3) is filled, fermented, cooled and then cooked.

[0032] The fermented milk of the present invention is prepared through inoculation a...

Embodiment 1

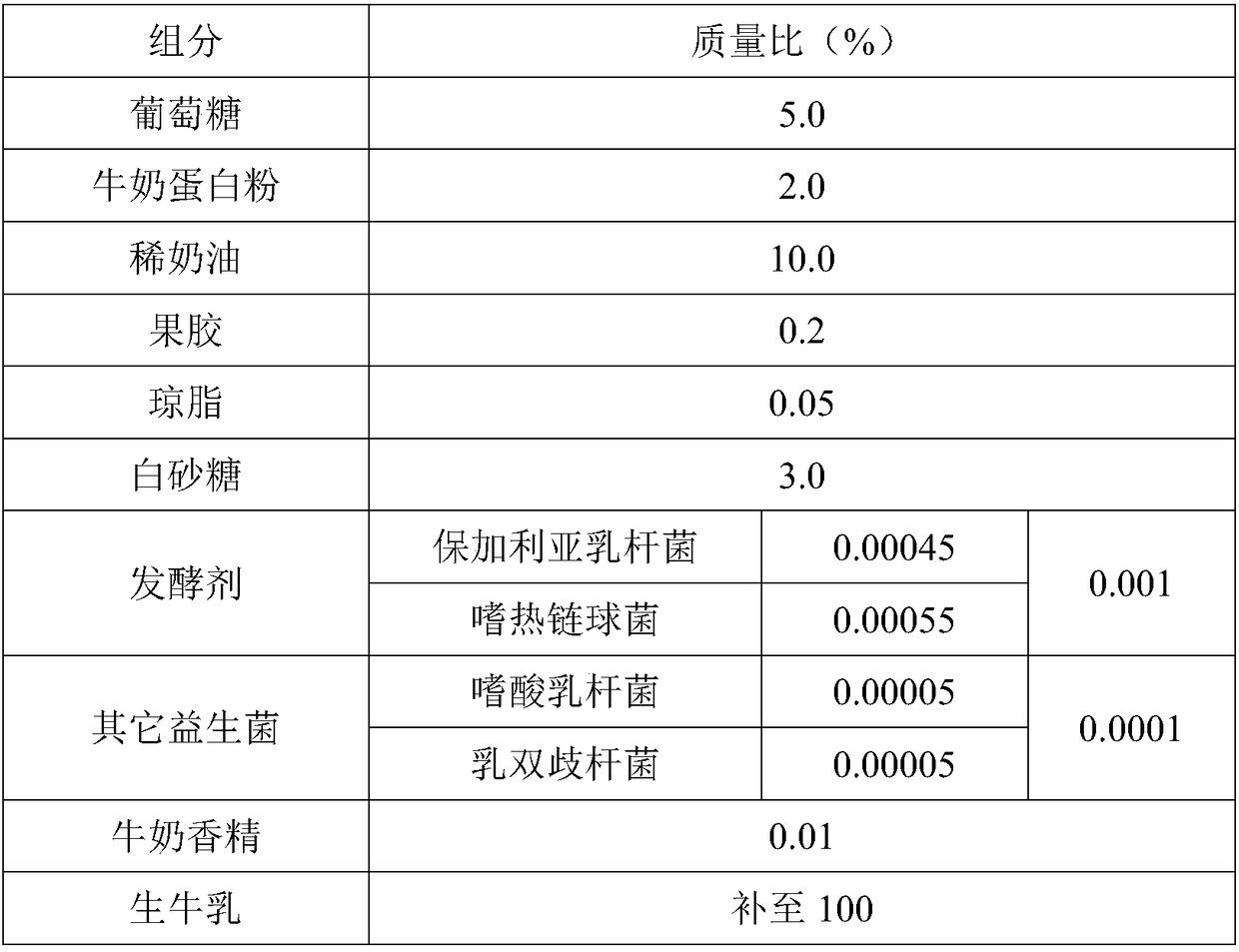

[0058] A kind of brown coagulation type fermented milk, it comprises raw material components and mass ratio as shown in table 1:

[0059] Table 1

[0060]

[0061] The preparation method of this brown coagulation type fermented milk comprises the steps:

[0062] (1) According to the above ratio, dissolve glucose in raw milk at 40°C, raise the temperature to 90°C, and keep it warm for 2.0 hours to obtain material A;

[0063] (2) Cool material A to 45°C, premix milk protein powder, pectin, agar, and white granulated sugar according to the above ratio, and then dissolve the obtained premix and cream respectively in the cooled to 45°C In material A, stir for 15 minutes to obtain material B;

[0064] (3) Homogenize material B, wherein the first-stage homogenization pressure is 16MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 65°C. After homogenization, sterilize at 85°C for 10 minutes, then cool to 45°C, and inoculate Starter and ...

Embodiment 2

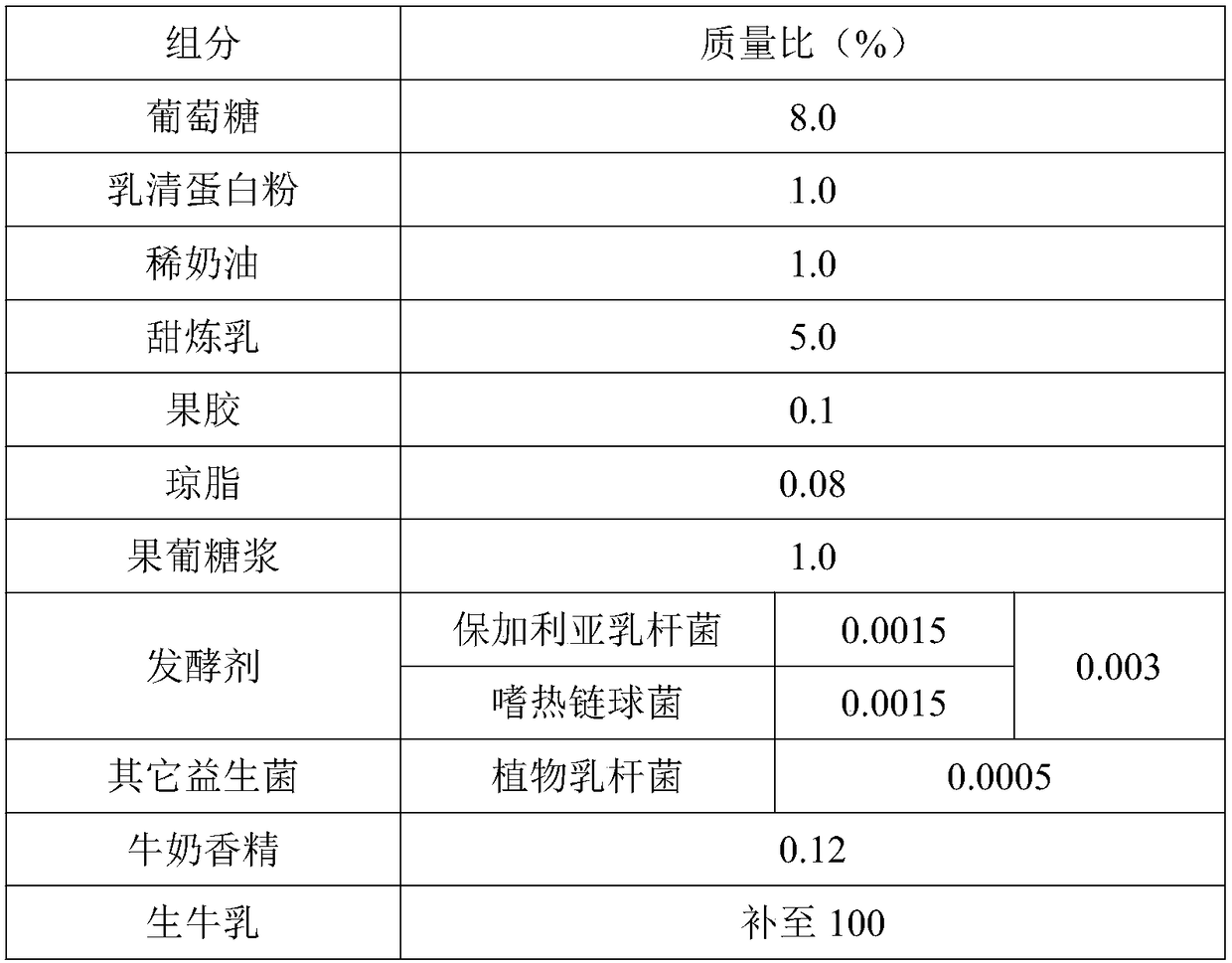

[0068] A kind of brown coagulation type fermented milk, it comprises raw material components and mass ratio as shown in table 2:

[0069] Table 2

[0070]

[0071] The preparation method of this brown coagulation type fermented milk comprises the steps:

[0072] (1) According to the above ratio, dissolve glucose in raw milk at 50°C, raise the temperature to 95°C, and keep it warm for 1.5h to obtain material A;

[0073] (2) Cool material A to 50°C, premix whey protein powder, pectin, and agar according to the above ratio, and then dissolve the obtained premix, cream, sweetened condensed milk, and fructose syrup in In material A cooled to 50°C, stir for 30 minutes to obtain material B;

[0074] (3) Homogenize material B, wherein the first-stage homogenization pressure is 17MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 68°C. After homogenization, sterilize at 95°C for 5 minutes, then cool to 37°C, and inoculate Starter and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com