Drinking type fermented milk and preparation method thereof

A drinking-type, fermented milk technology, applied in the field of drinking-type fermented milk and its preparation, can solve the problems of cumbersome process, no live bacteria, bad flavor and taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

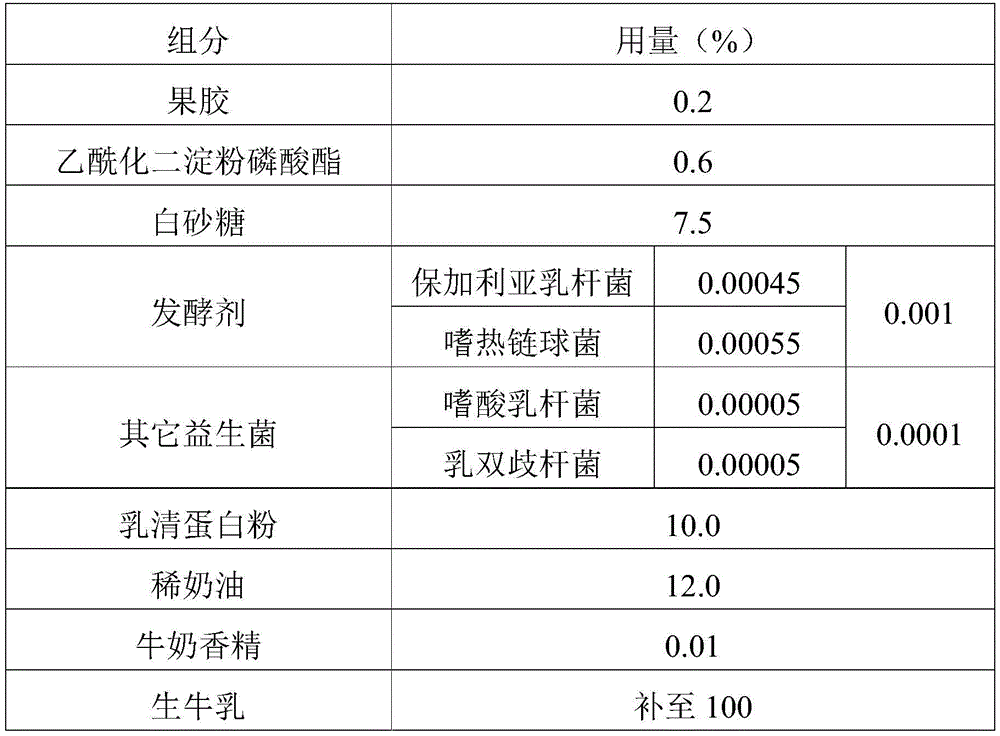

[0047] A kind of drinkable fermented milk, it comprises raw material components and consumption as shown in the table below:

[0048]

[0049] The preparation method of this drinking type fermented milk comprises the steps:

[0050] (1) According to the above ratio, premix pectin, acetylated distarch phosphate, white sugar, and whey protein powder evenly, then dissolve the obtained premix and cream in raw milk at 40°C, and stir 30min, obtain material liquid A;

[0051] (2) Homogenize the material liquid A, wherein the first-stage homogenization pressure is 16MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 65°C. After homogenization, sterilize at 85°C for 10 minutes, and then cool to 45°C. Feed liquid B;

[0052] (3) Inoculate starter and other probiotics in feed liquid B, the inoculation temperature is 45°C, stir and mix feed liquid B, starter and other probiotics at 200rpm for 5min, then ferment at 45°C until the final acidity...

Embodiment 2

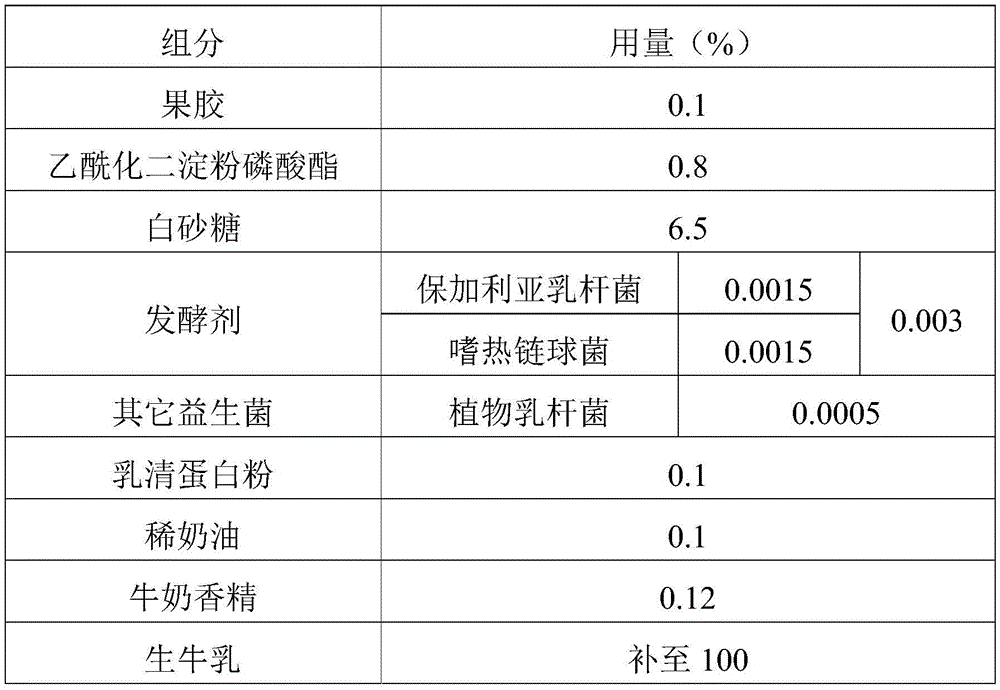

[0056] A kind of drinkable fermented milk, it comprises raw material components and consumption as shown in the table below:

[0057]

[0058] The preparation method of this drinking type fermented milk comprises the steps:

[0059] (1) According to the above ratio, premix pectin, acetylated distarch phosphate, white sugar, and whey protein powder evenly, then dissolve the obtained premix and cream in raw milk at 50°C, and stir 15min, obtain material liquid A;

[0060] (2) Homogenize the material liquid A, wherein the first-stage homogenization pressure is 17MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 68°C. After homogenization, sterilize at 95°C for 5 minutes, and then cool to 37°C. Feed liquid B;

[0061] (3) Inoculate starter and other probiotics in material liquid B, stir and mix material B, starter and other probiotics at 100 rpm for 10 minutes, then ferment at 37°C until the final acidity is 70°T, and the fermentation...

Embodiment 3

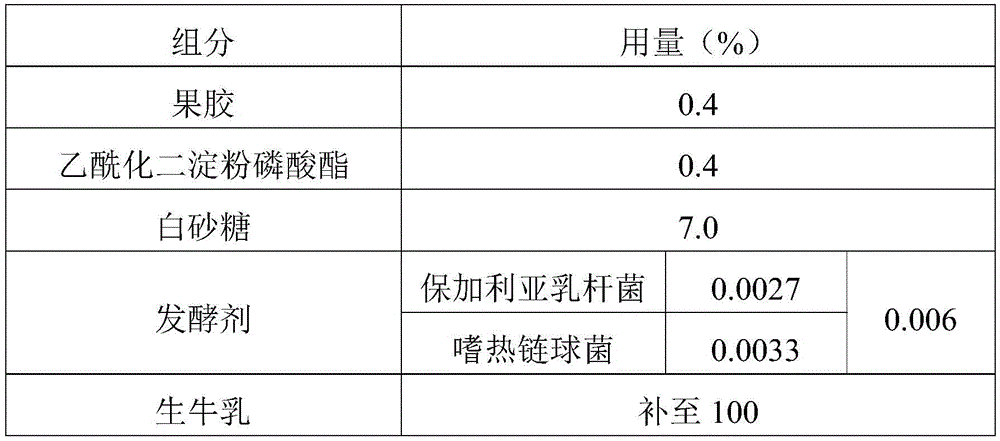

[0065] A kind of drinkable fermented milk, it comprises raw material components and consumption as shown in the table below:

[0066]

[0067] The preparation method of this drinking type fermented milk comprises the steps:

[0068] (1) According to the above ratio, mix pectin, acetylated distarch phosphate and white sugar evenly, dissolve in raw milk at 45°C, stir for 20 minutes, and obtain feed liquid A;

[0069] (2) Homogenize the material liquid A, wherein the first-stage homogenization pressure is 16.5MPa, the second-stage homogenization pressure is 4MPa, and the homogenization temperature is 58°C. After homogenization, sterilize at 90°C for 8 minutes, and then cool to 42°C , to obtain feed liquid B;

[0070] (3) Inoculate the starter in the material liquid B, the inoculation temperature is 42°C, after mixing the feed liquid B and the starter at 150rpm for 8 minutes, ferment at 42°C until the terminal acidity is 75°T, and the fermentation time is about 6h, to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com