Patents

Literature

227 results about "Depilations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-count smooth double-faced wool and production process thereof

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

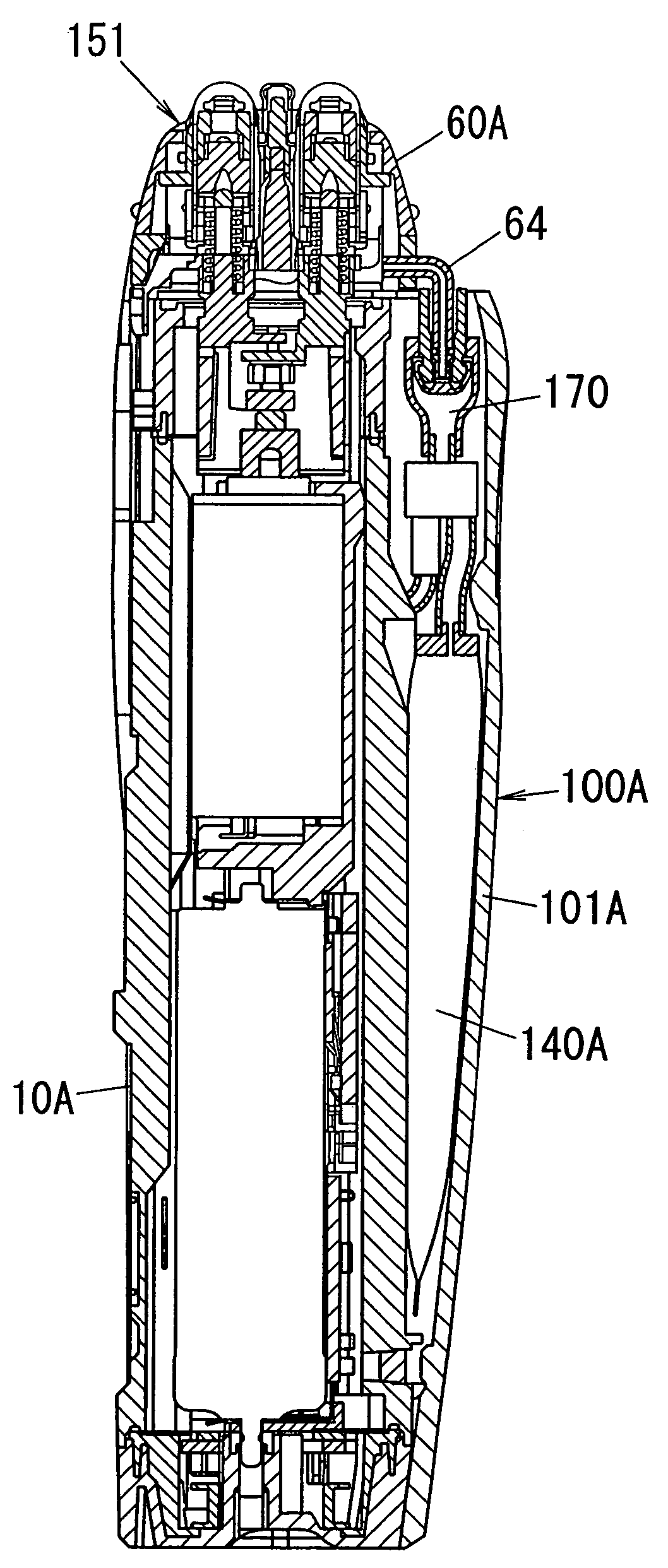

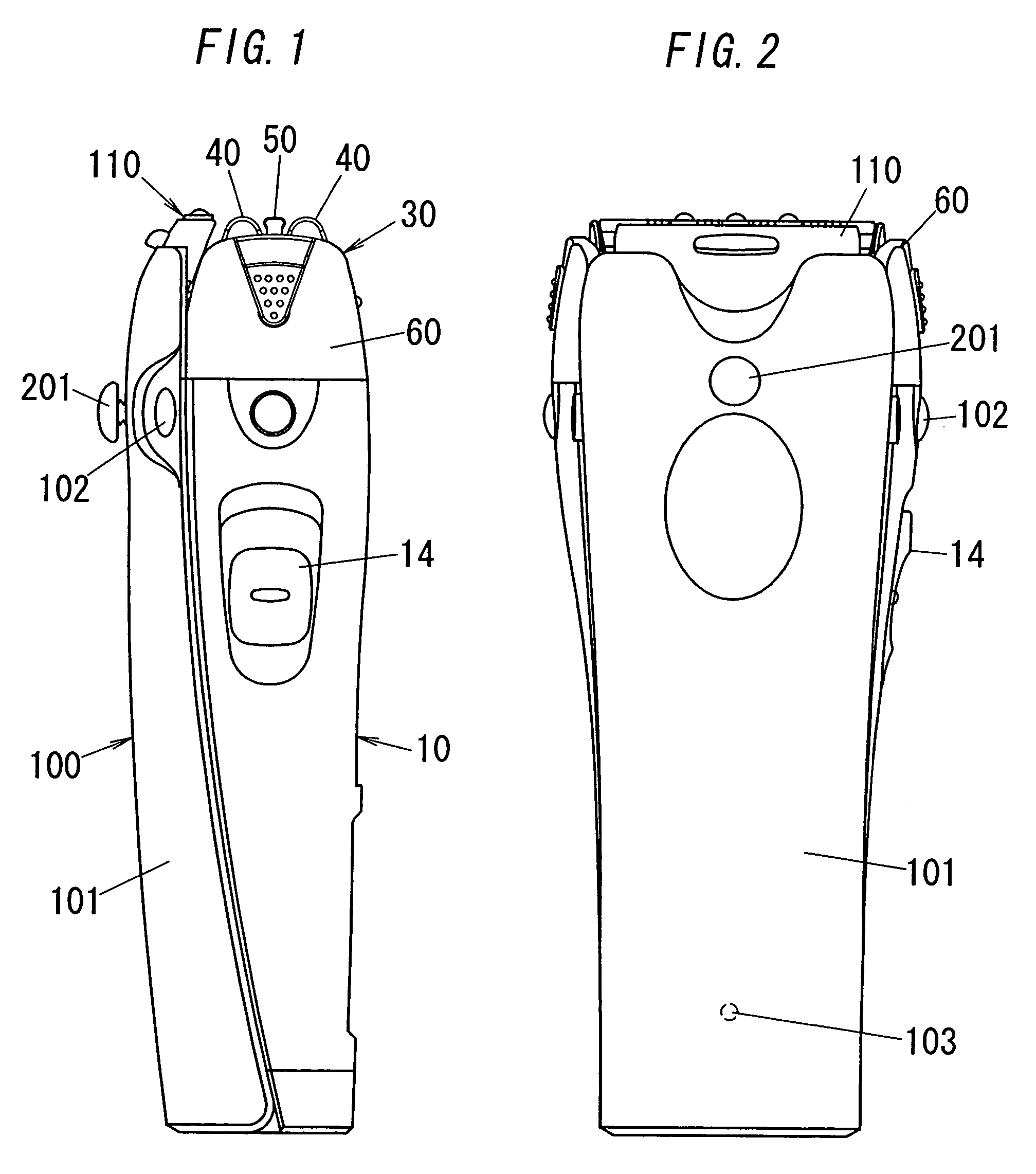

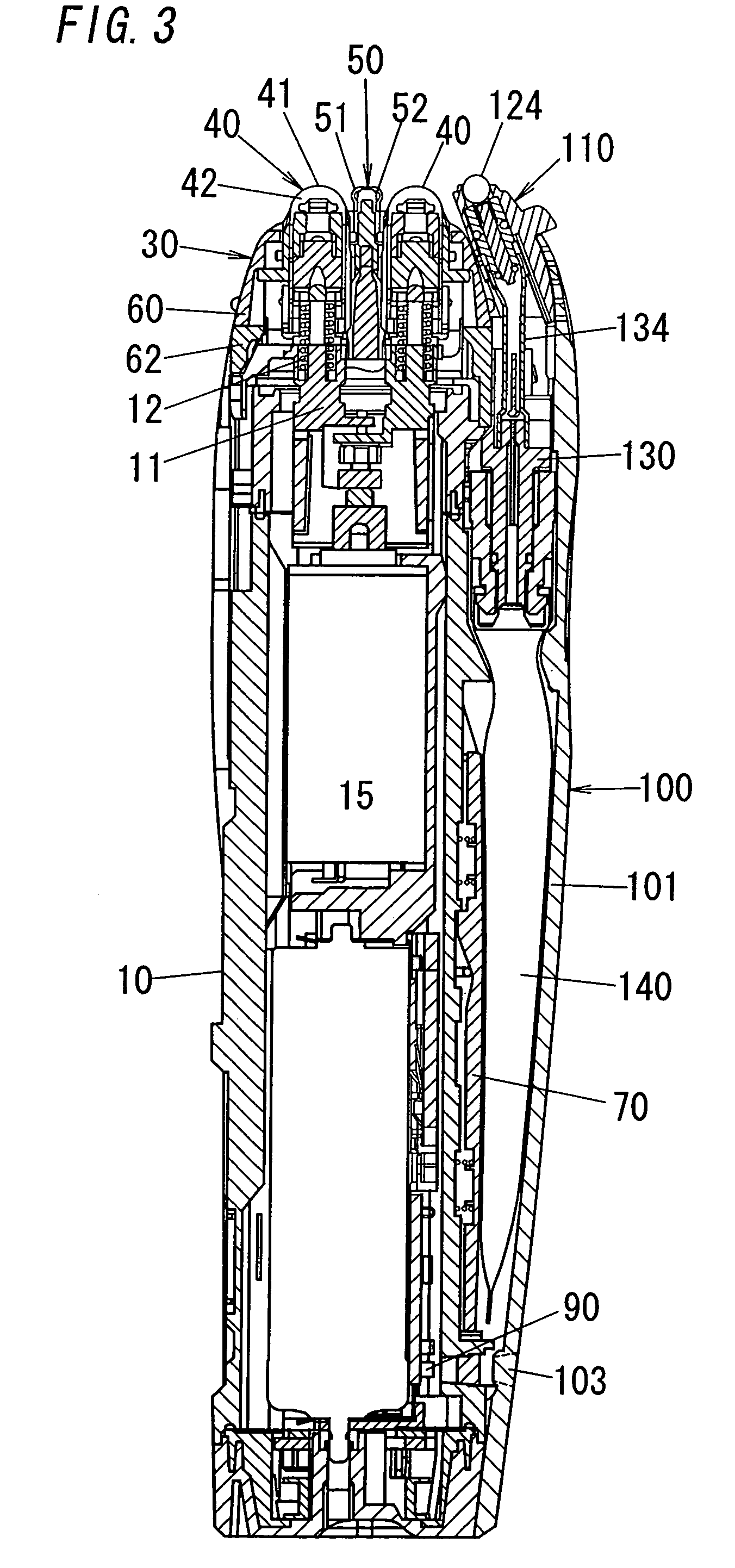

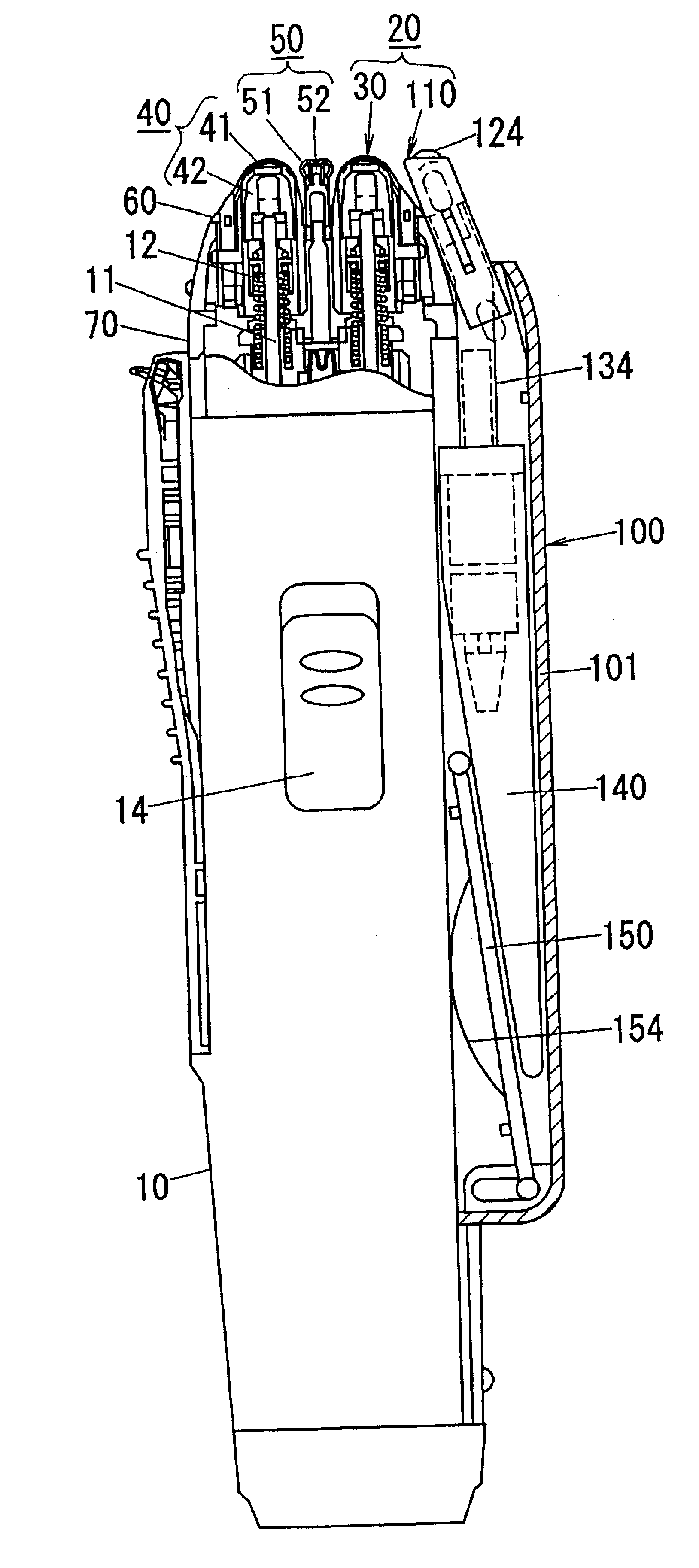

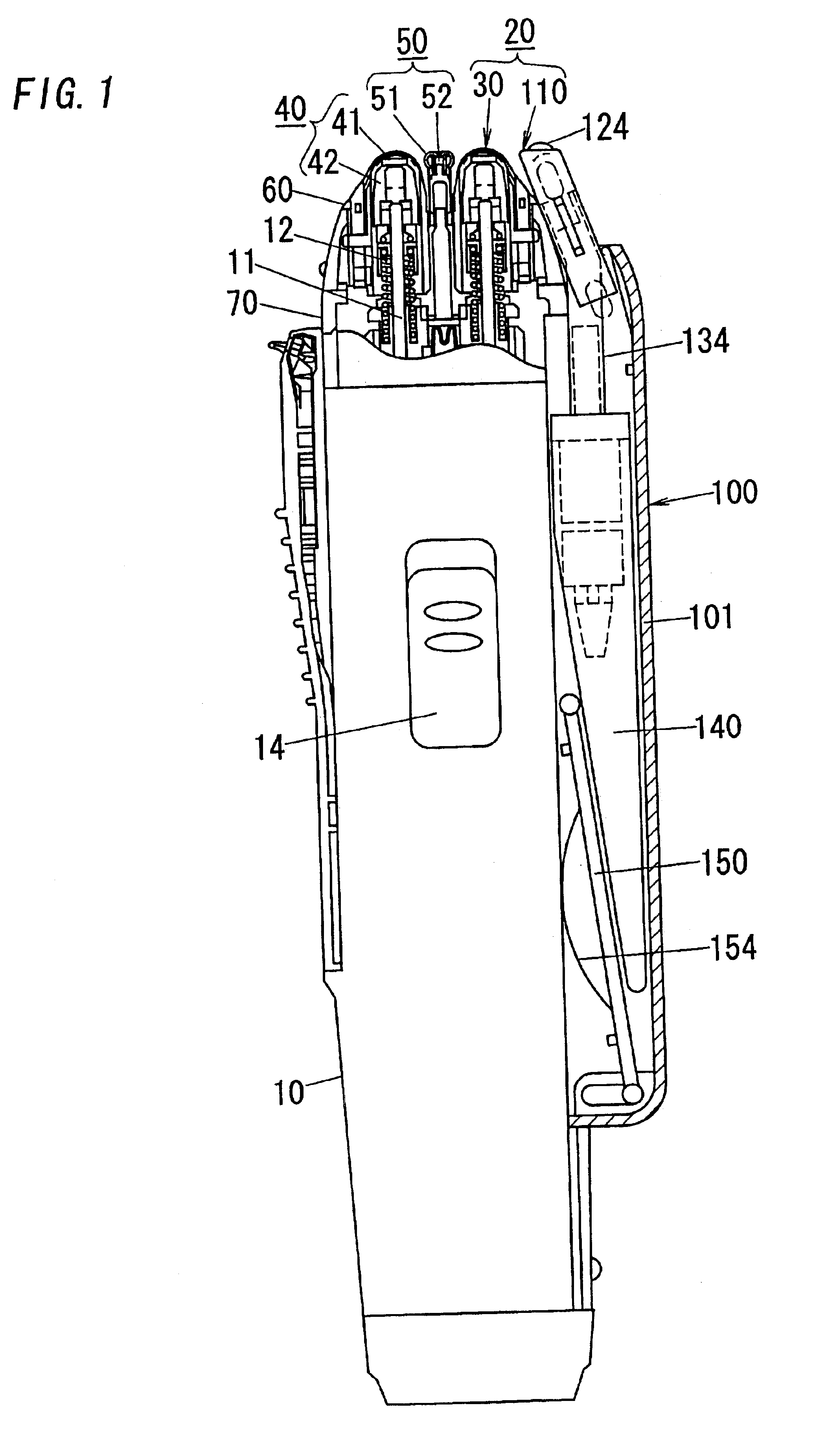

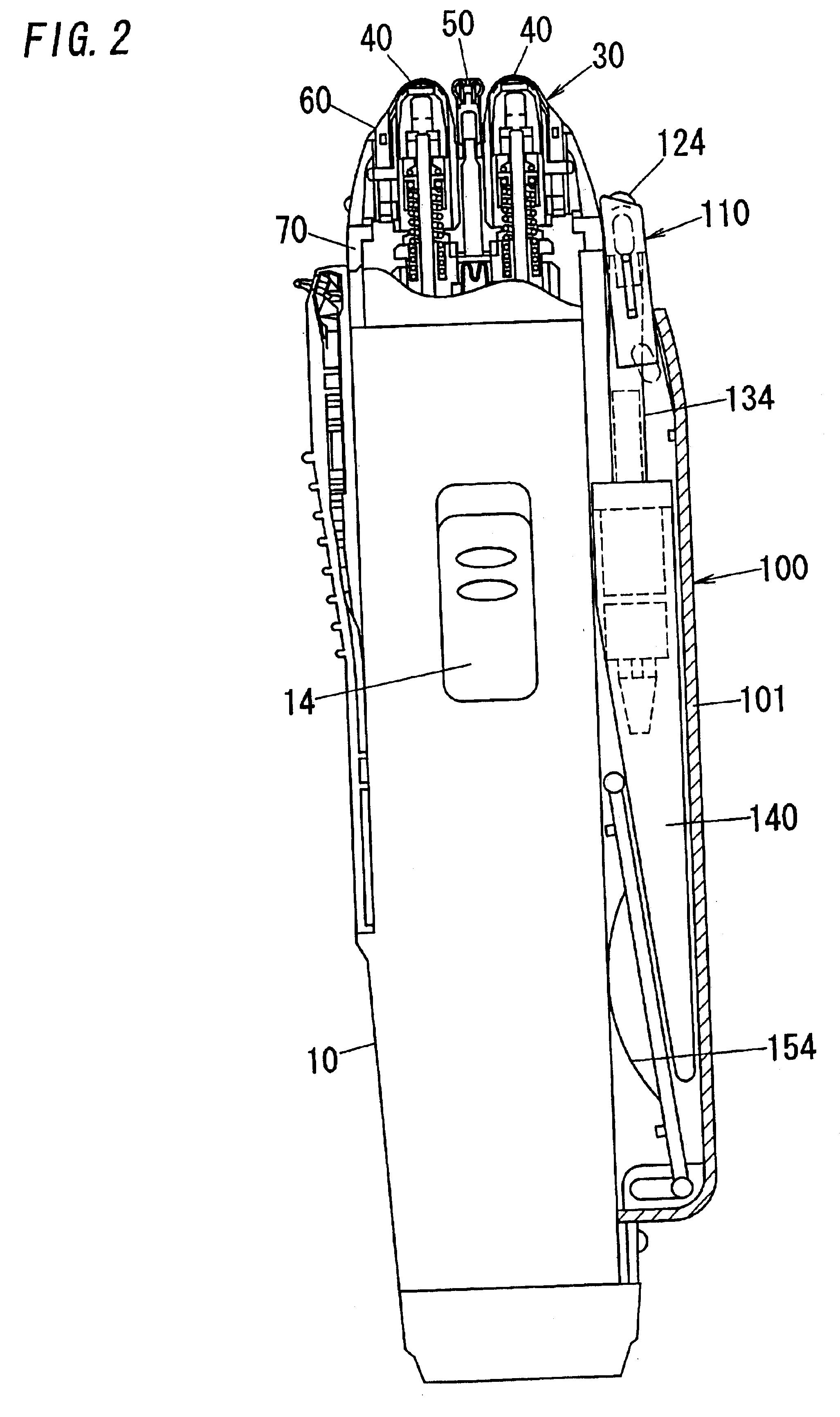

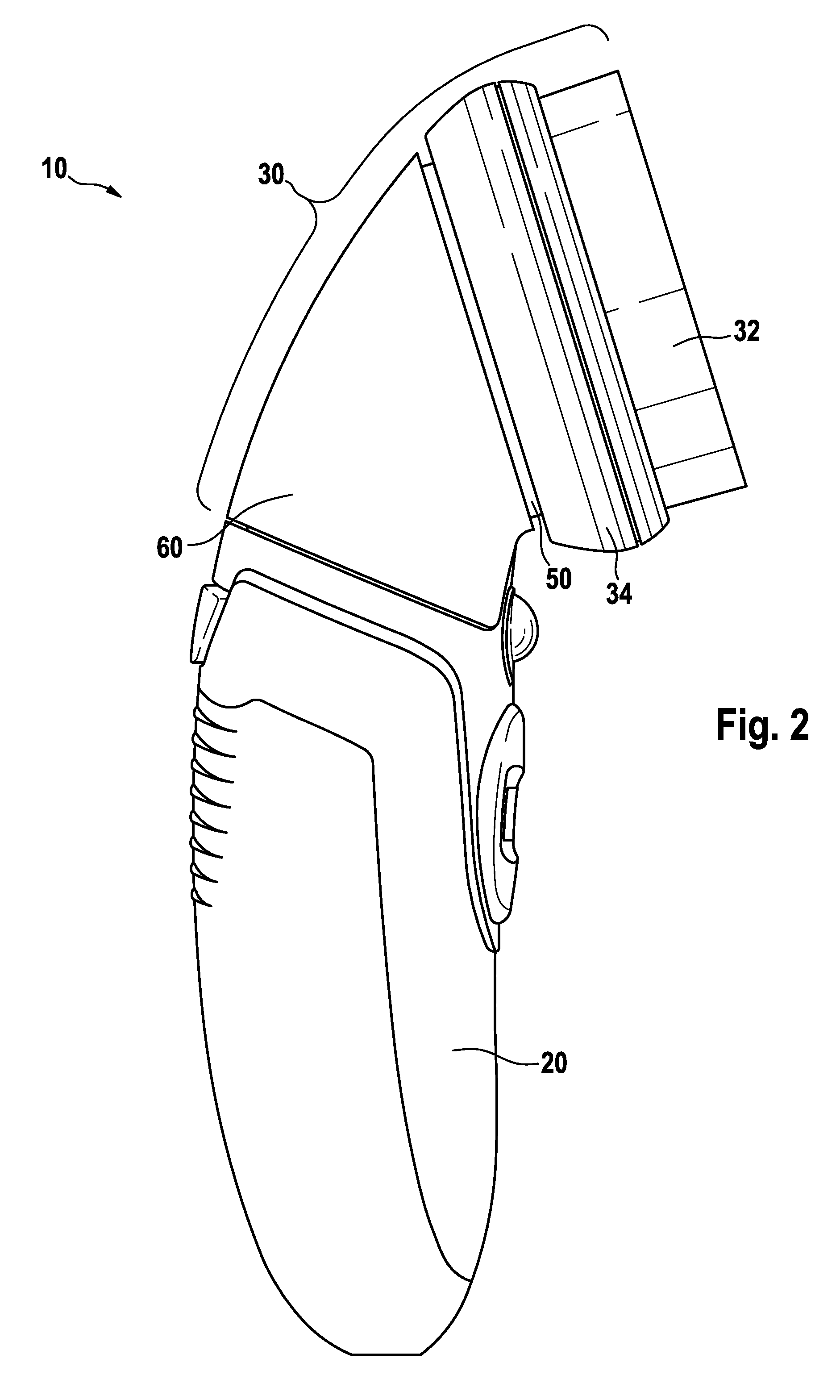

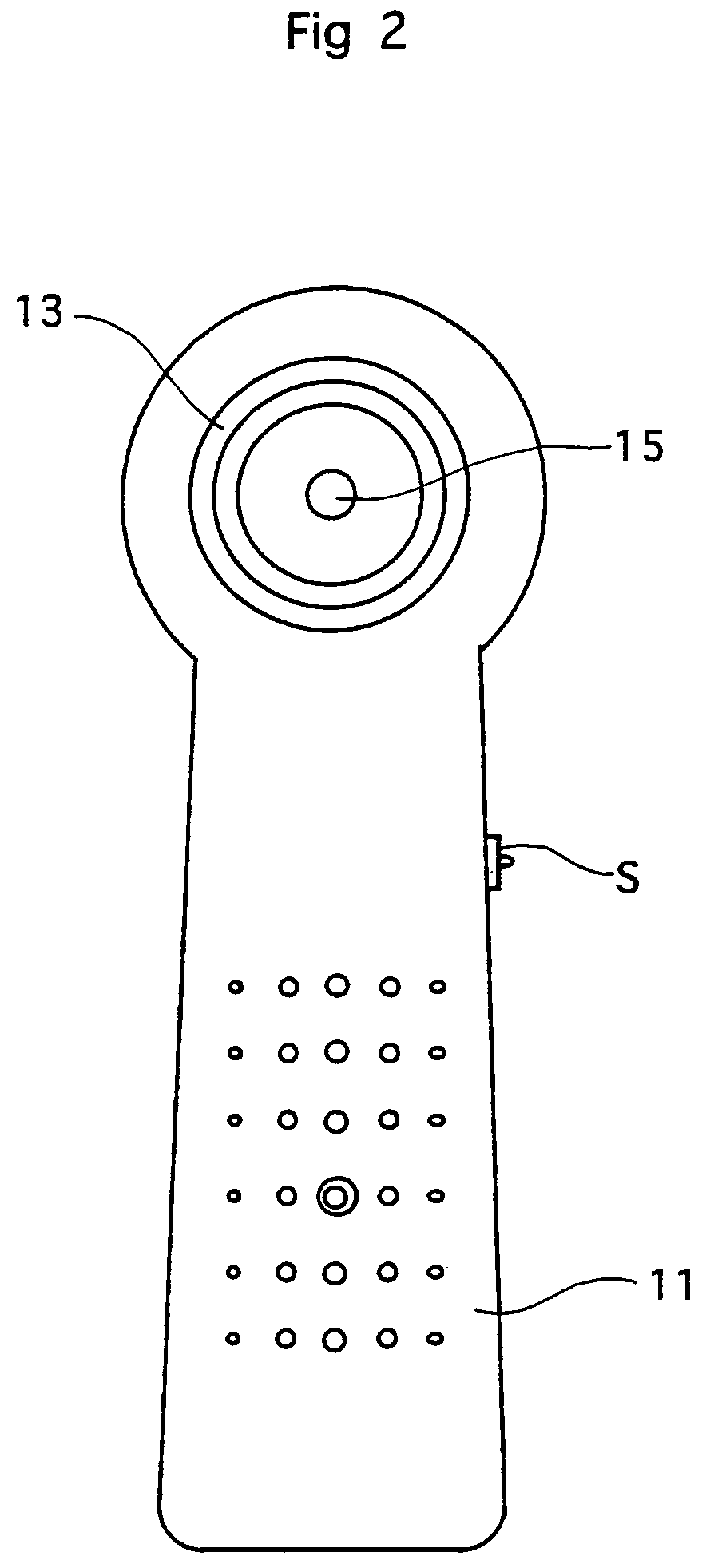

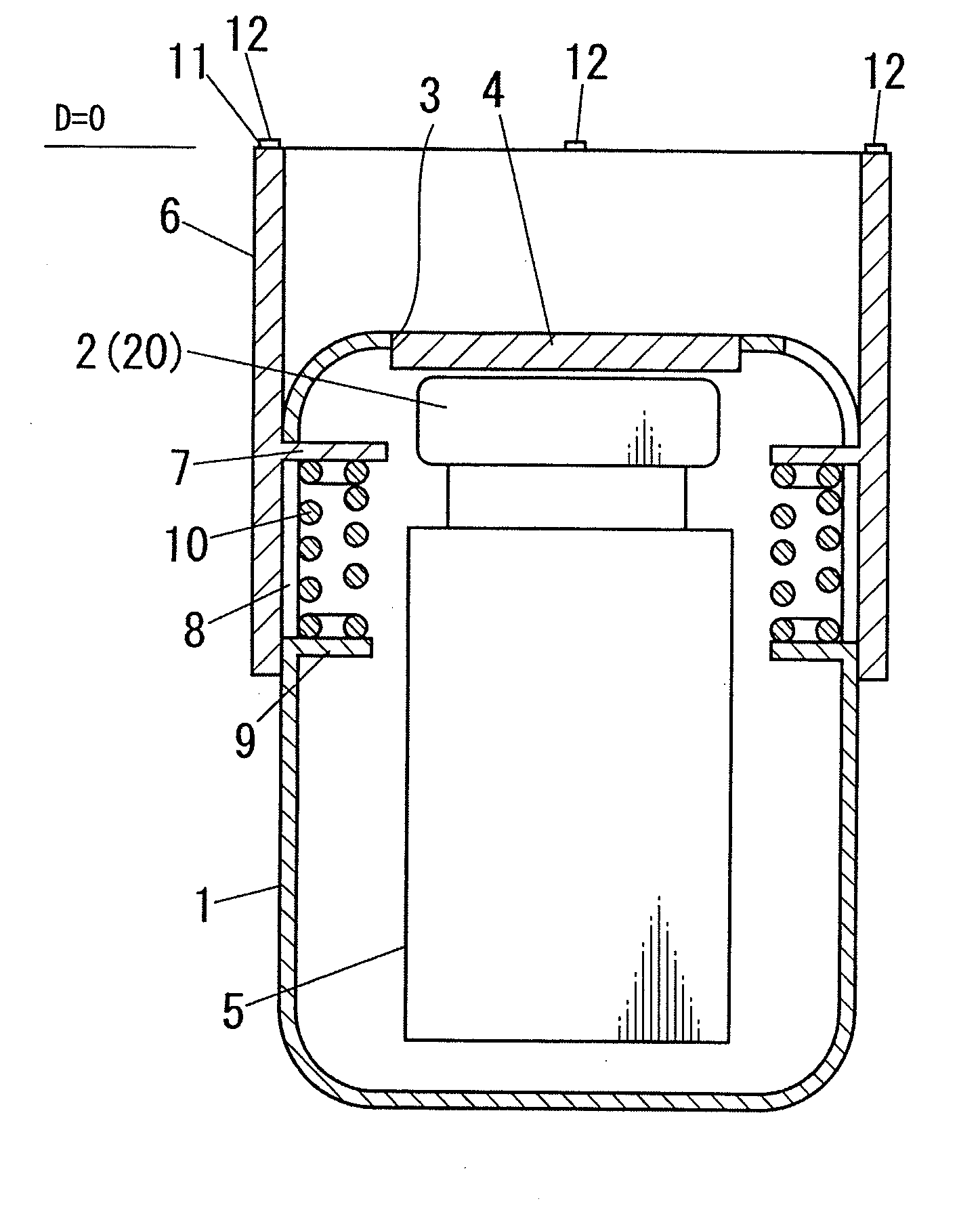

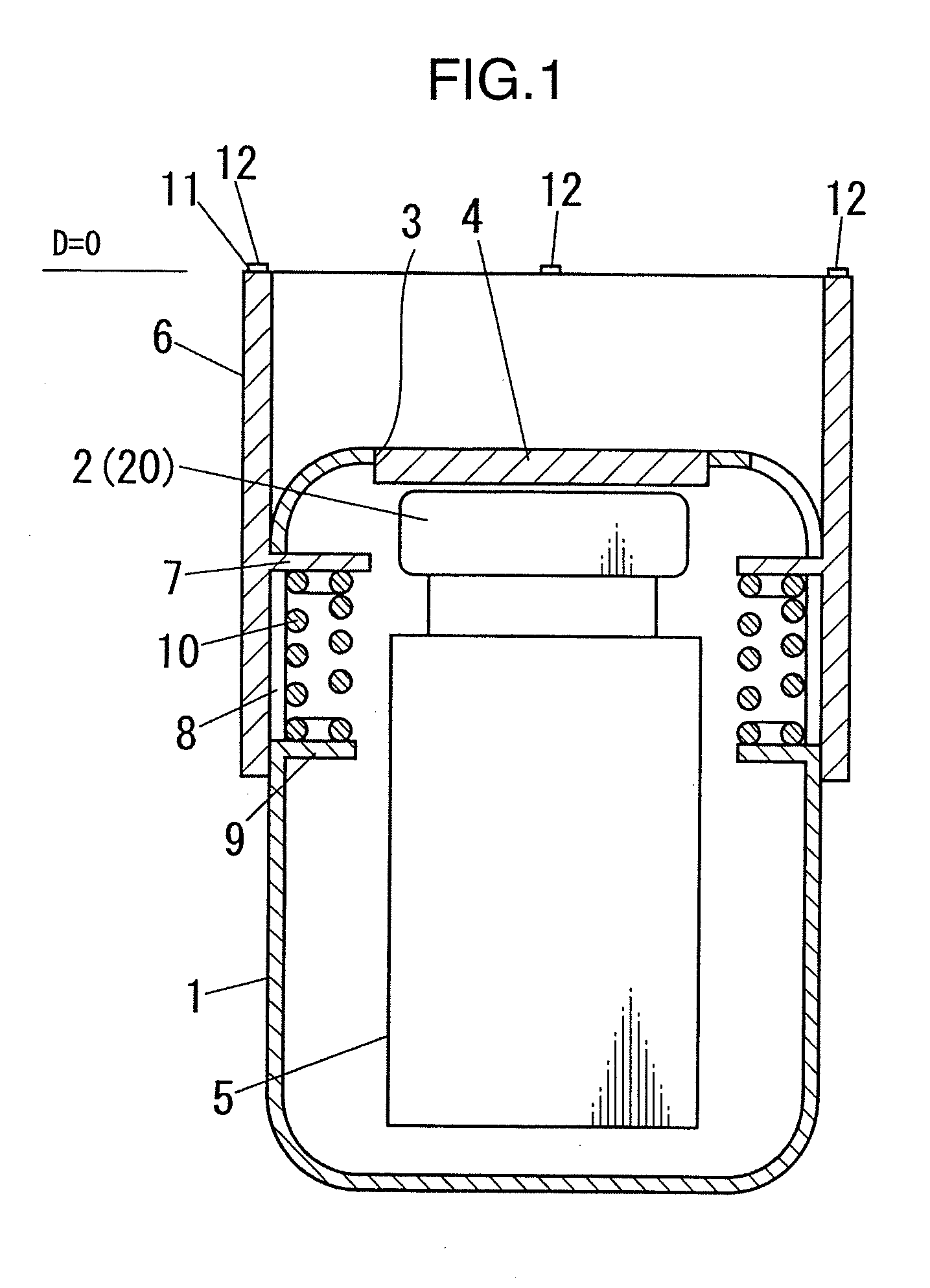

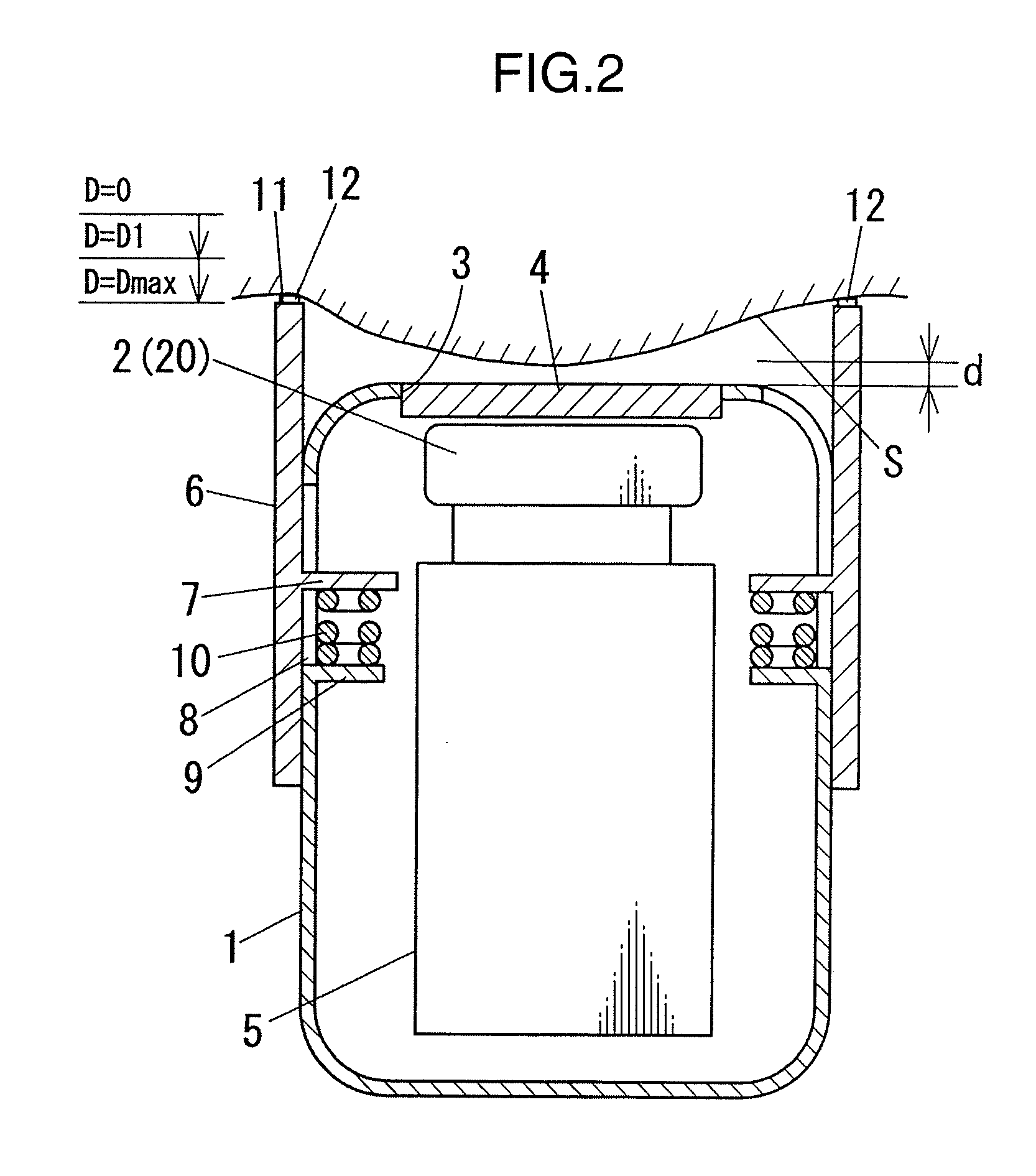

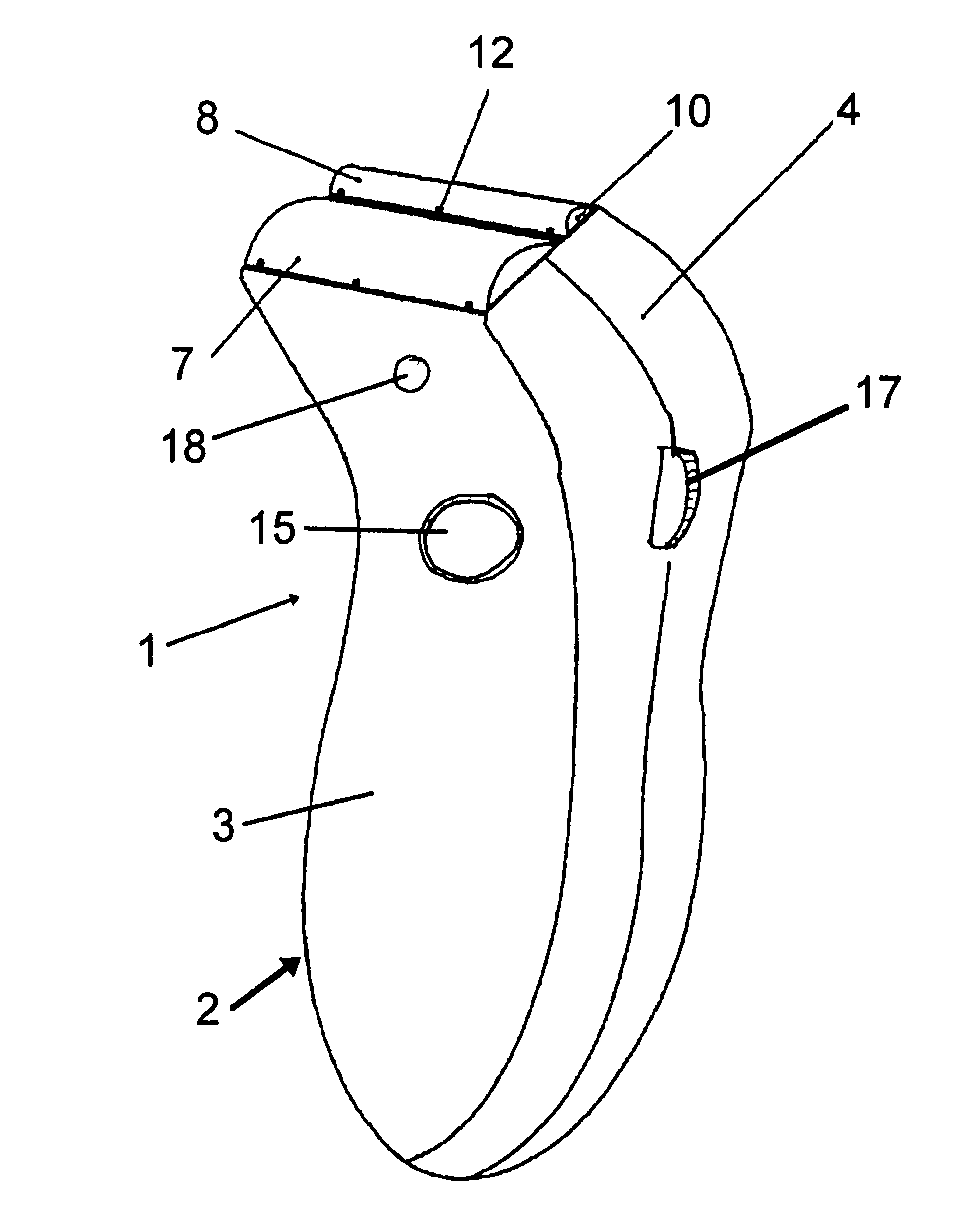

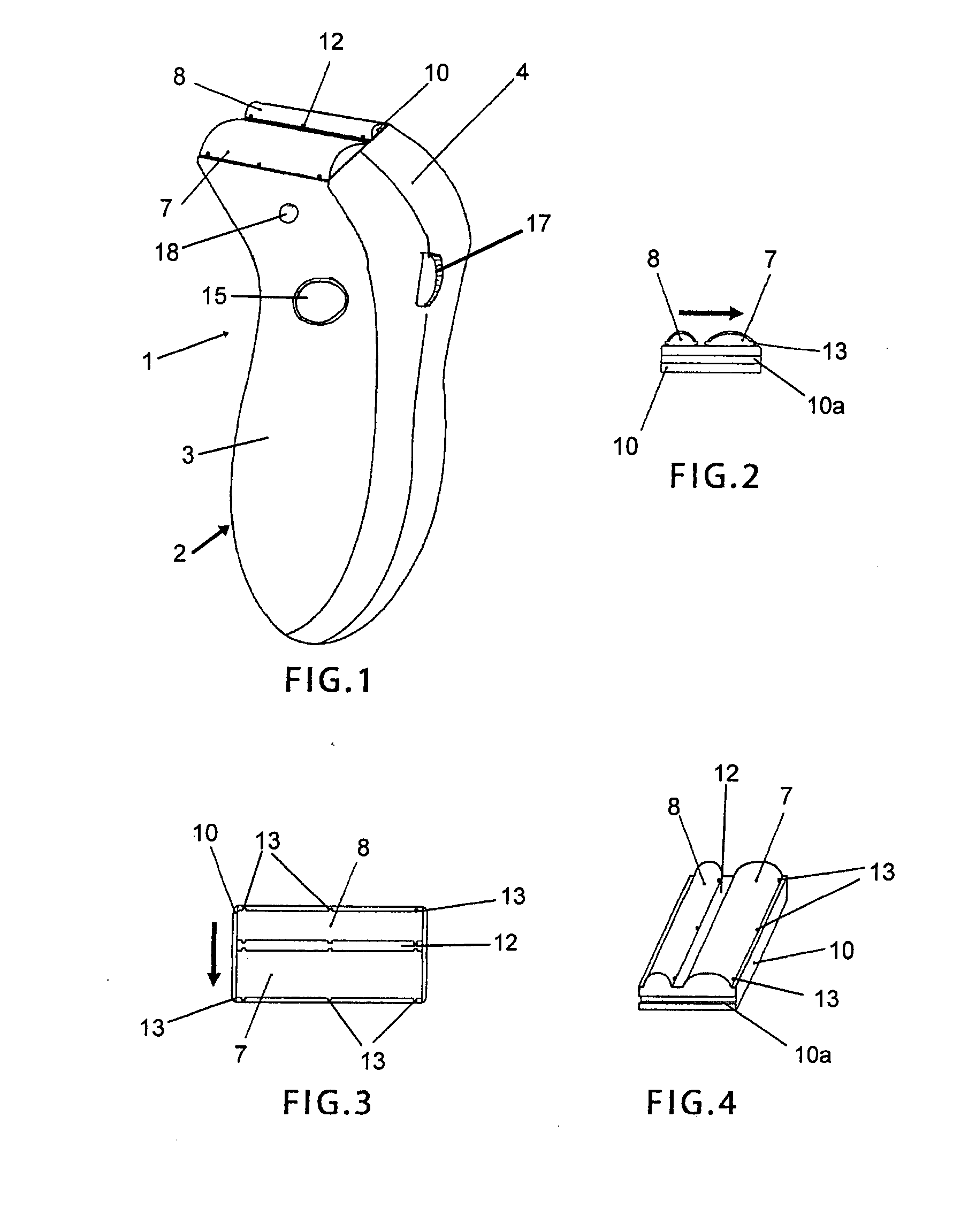

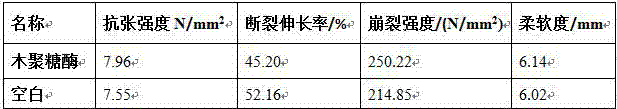

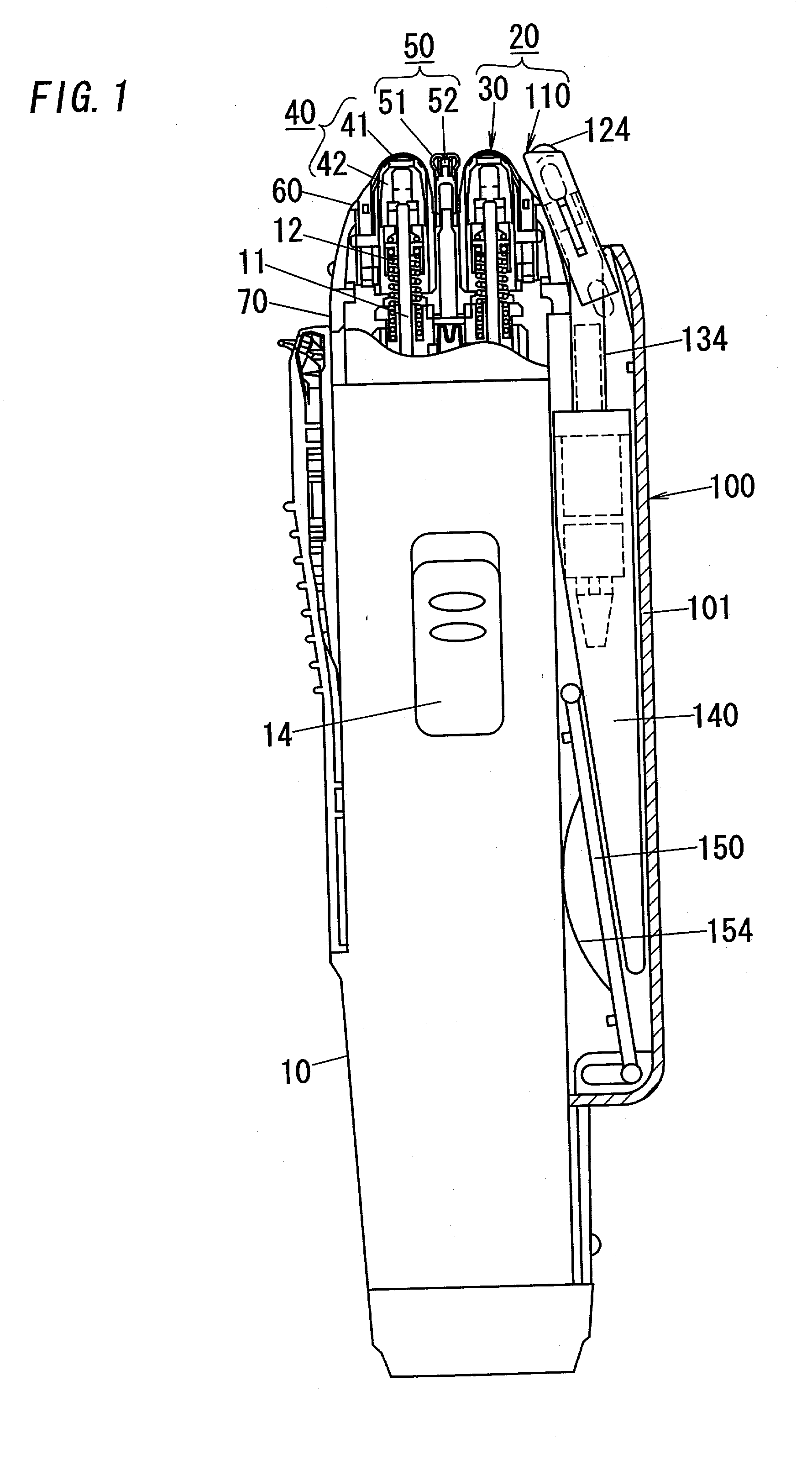

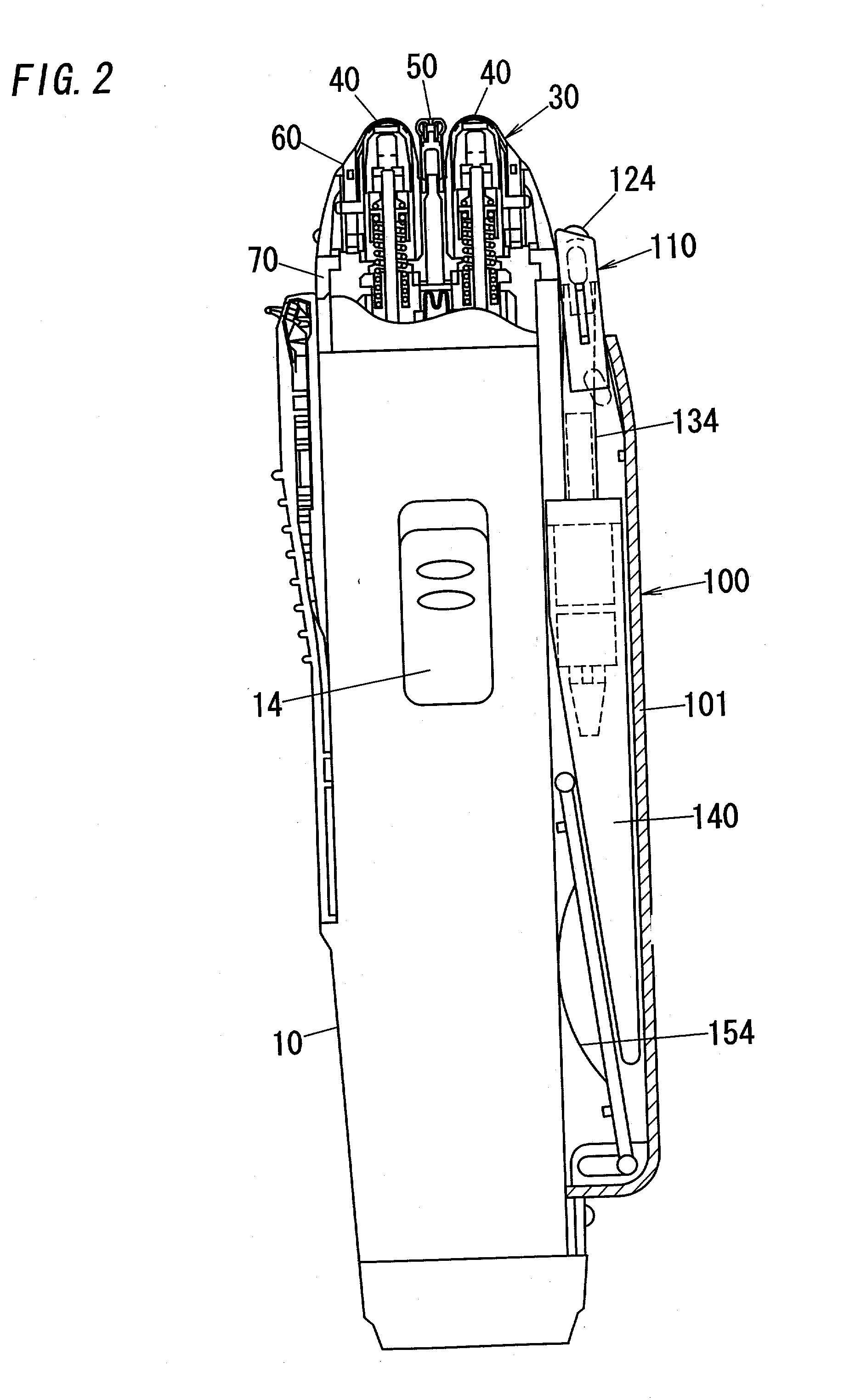

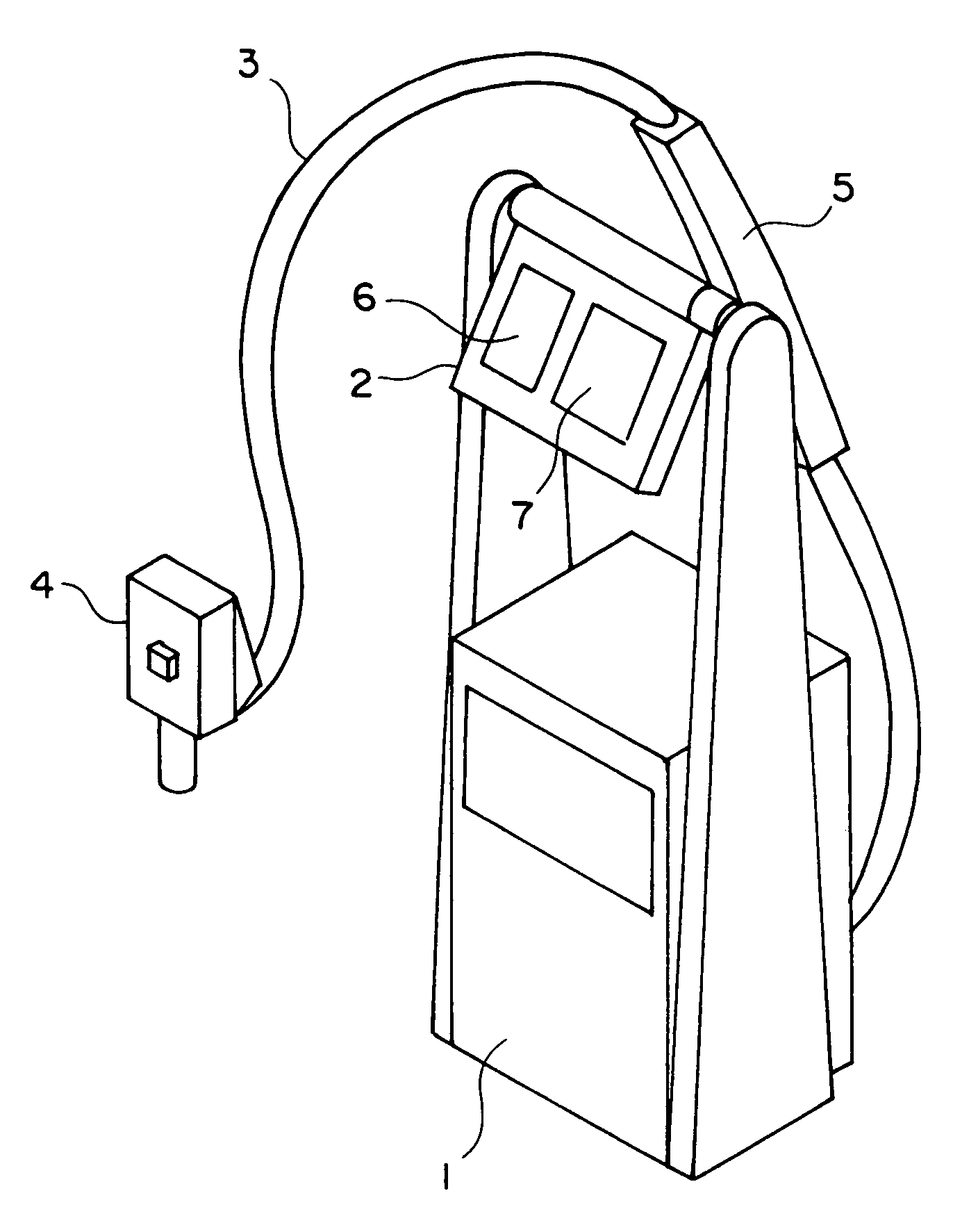

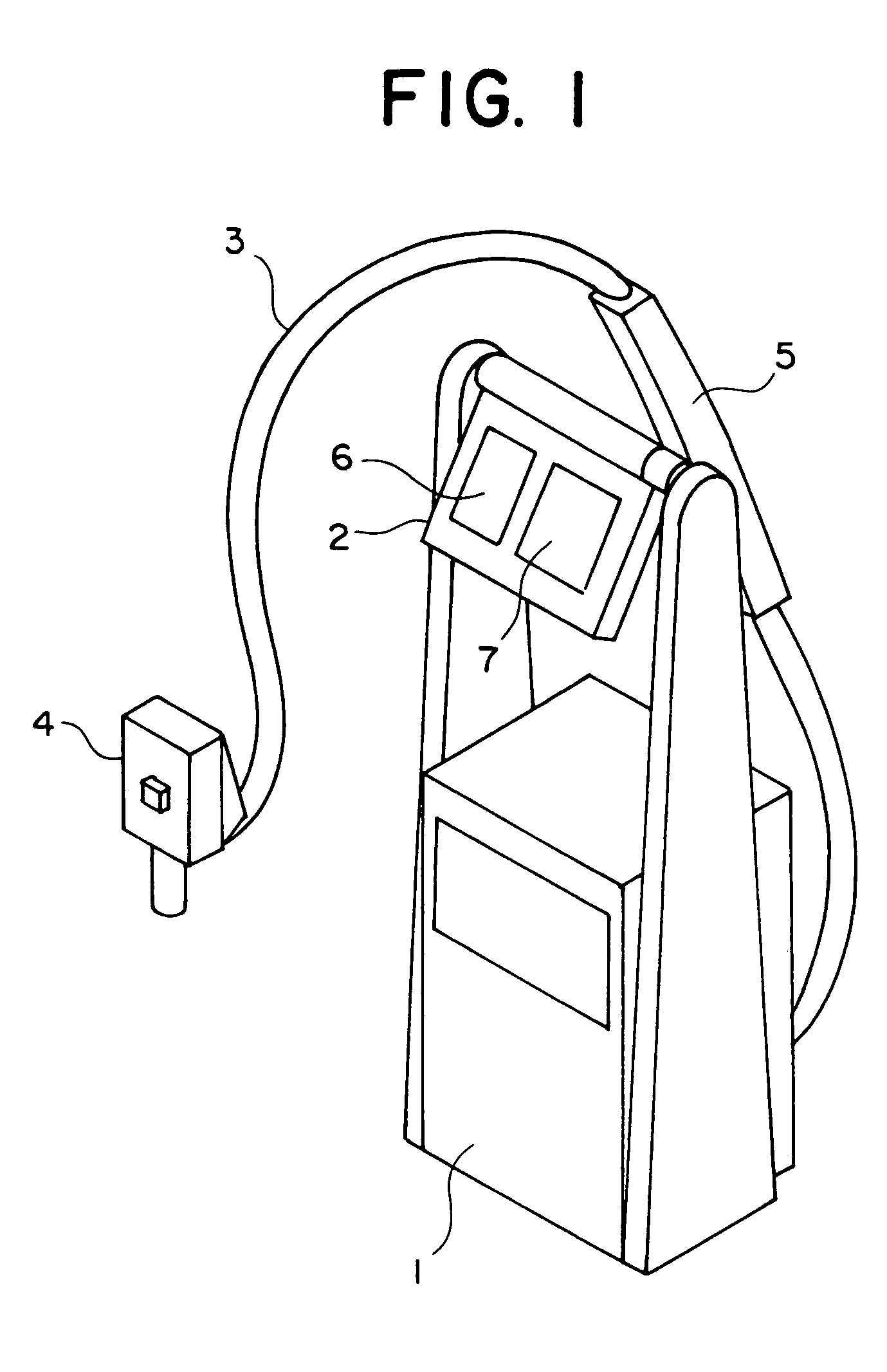

Hair removing device with a lotion applicator

A hair removing device with a lotion applicator includes a housing, a hair removing head mounted to the housing and adapted to be held against a user's skin for hair depilation or hair epilation, an applicator which dispenses a lotion on the user's skin, a tank holding the lotion and a lotion supply mechanism for supplying the lotion from the tank to the applicator. The lotion supply mechanism includes a regulating device, which regulates an amount of the lotion being dispensed from the applicator. The lotion supply mechanism includes a powered pump for expelling the lotion from the tank to the applicator. The regulating device includes a handle for varying pump capacity of the powered pump. The applicator is incorporated into a head frame forming a part of the hair removing head with the head frame being detachable from the housing.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Skin treatment device and method for exfoliation and cellulite reduction

A novel device and method for use in providing multiple cosmetic treatments is disclosed, where a sanding tool is provided with sanding surfaces for use in imparting exfoliation, depilation, and cellulite treatments on the skin of a person. Select sanding surfaces are use for each of the exfoliation, depilation and cellulite treatments with the sanding action being generated by the orbital sanding effects of a palm sander. Specifically, a 100 grit (CAMI) sanding paper is used for exfoliation, a 180 grit (AMI) sanding paper is used for depilation, and the sander pad of the sanding tool of the present invention is used directly on the skin for cellulite reduction.

Owner:FERRARA JOELLA ANN

Animal fur clean depilation and fur fiber loosing method for preparing leather and application thereof

ActiveCN101235421AEliminate pollution and other issuesFine grainPre-tanning chemical treatmentFiberEnzyme system

The invention provides a method for unhairing leather and loosening leather fiber without sodium sulfide and lime in a leather production process and the application of the method. The method is characterized in that a method for combining unhairing by non-sulfur (sodium sulfide) depilatory under the alkaline condition and enzyme fiber loosening under the under the non-lime (lime) alkaline swelling condition are adopted, the enzyme unhearing and the enzyme fiber loosening take protease, lipase, amylase and glucoamylase as a compound enzyme system. The method achieves the effects for unhairing and loosening the leather fiber through adopting the method for combining compound enzyme water immersion, compound enzyme unhairing, unhairing with sodium sulfide depilatory, expansion regulator-sodium hydroxide expansion and the enzyme unhairing under the alkaline condition and eliminates the pollution which is brought by the sodium sulfide and the lime in animal unhairing or leather fiber loosening procedures in the leather production process. The method of the invention is suitable for unhairing and leather fiber dispersed processing of various animal leather of leather with various usages.

Owner:SICHUAN UNIV +1

Viscous compositions containing carbon dioxide

InactiveUS6689339B1Effective treatmentTreating and preventing and ameliorating itchingOrganic active ingredientsAntimycoticsSide effectMusculoskeletal disease

A carbon dioxide-containing viscous composition wherein carbon dioxide bubbles are retained in an aqueous viscous composition. Use of the composition makes it possible to treat or ameliorate itching accompanying mucocutaneous diseases or mucocutaneous disorders, mucocutaneous injury, dental diseases, skin ulcer, cryesthesia and numbness caused by peripheral circulatory disorders, musculoskeletal diseases, nervous system diseases, keratosis, constipation, unwanted hair re-growing after depilation, cosmetic troubles in the skin or hair, partial obesity, etc. while exerting little side effects.

Owner:MEDION RES LAB

Hair removing device with a lotion applicator

A hair removing device capable of feeding a lotion in association with a hair removing operation. The device has a treatment head that is mounted on a housing and includes a hair removing unit for hair depilation or hair epilation and an applicator for supplying a lotion on a user's skin. Also included in the device is a tank holding the lotion and a lotion supply mechanism for supplying the lotion from the tank to the applicator. The treatment head is formed with an actuator which acknowledges an even of the treatment head coming into an operative condition with the skin and activates a lotion supply mechanism to supply the lotion from the tank to the applicator when such event is acknowledged.

Owner:PANASONIC ELECTRIC WORKS CO LTD

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

Cultivation and management method of organic cotton

InactiveCN103004449AGuaranteed pollution-free conditionsAvoid pollutionSeed and root treatmentHorticulture methodsDepilationsBud

The invention provides a cultivation and management method of organic cotton, comprising the following steps: firstly, presowing treatment, comprising land selection, fertilizer application and soil turning in sequence; secondly, seed treatment, comprising seed selection, depilation and hot water treatment in sequence; thirdly, sowing, comprising spot sowing, film covering and interplanting of another crop in sequence; fourthly, field management, comprising seedling management, bud stage management, Blossing and boll-forming stages management and boll opening stage management in sequence; and fifthly, collection. Through the application of the cultivation and management method provided by the invention, any pollution can be prevented in the whole process of cotton cultivation, and external pollution-free conditions of organic cotton planting are ensured. Moreover, compared with the traditional production process of organic cotton, the cultivation method provided by the invention is simple in operation and easy to grasp for farmers, and the labor productivity can be improved.

Owner:SINKIANG YIDA AGRI TECH +1

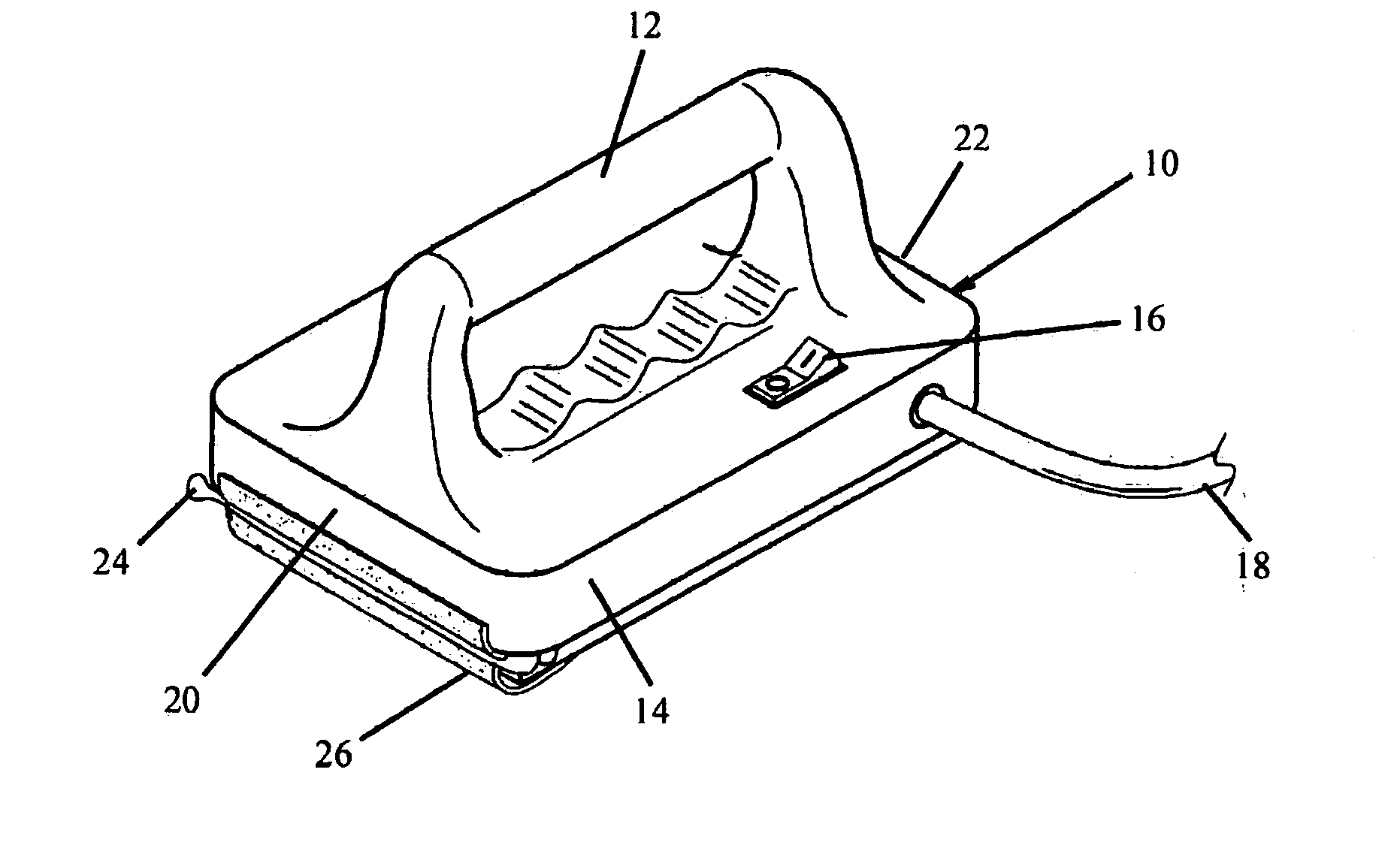

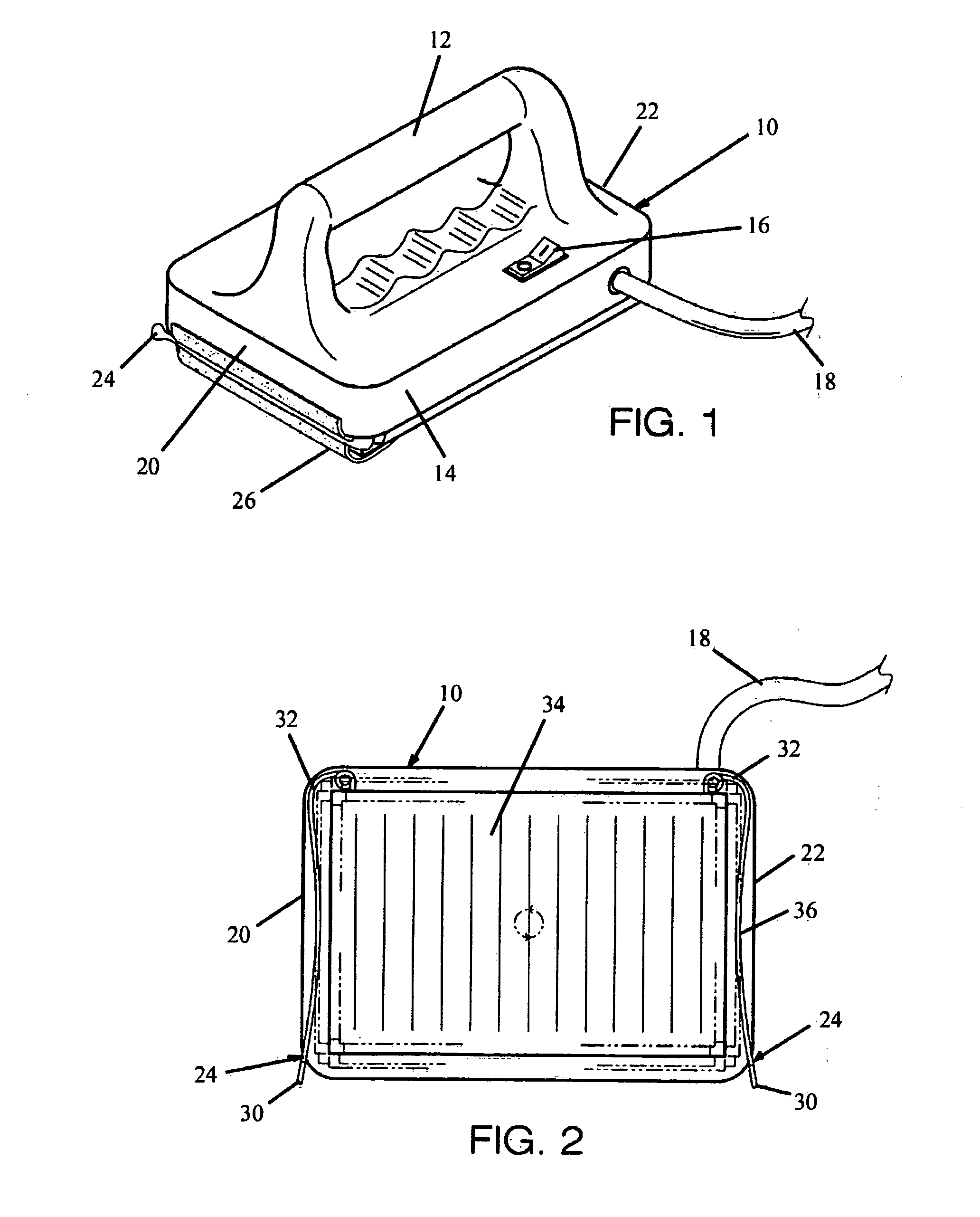

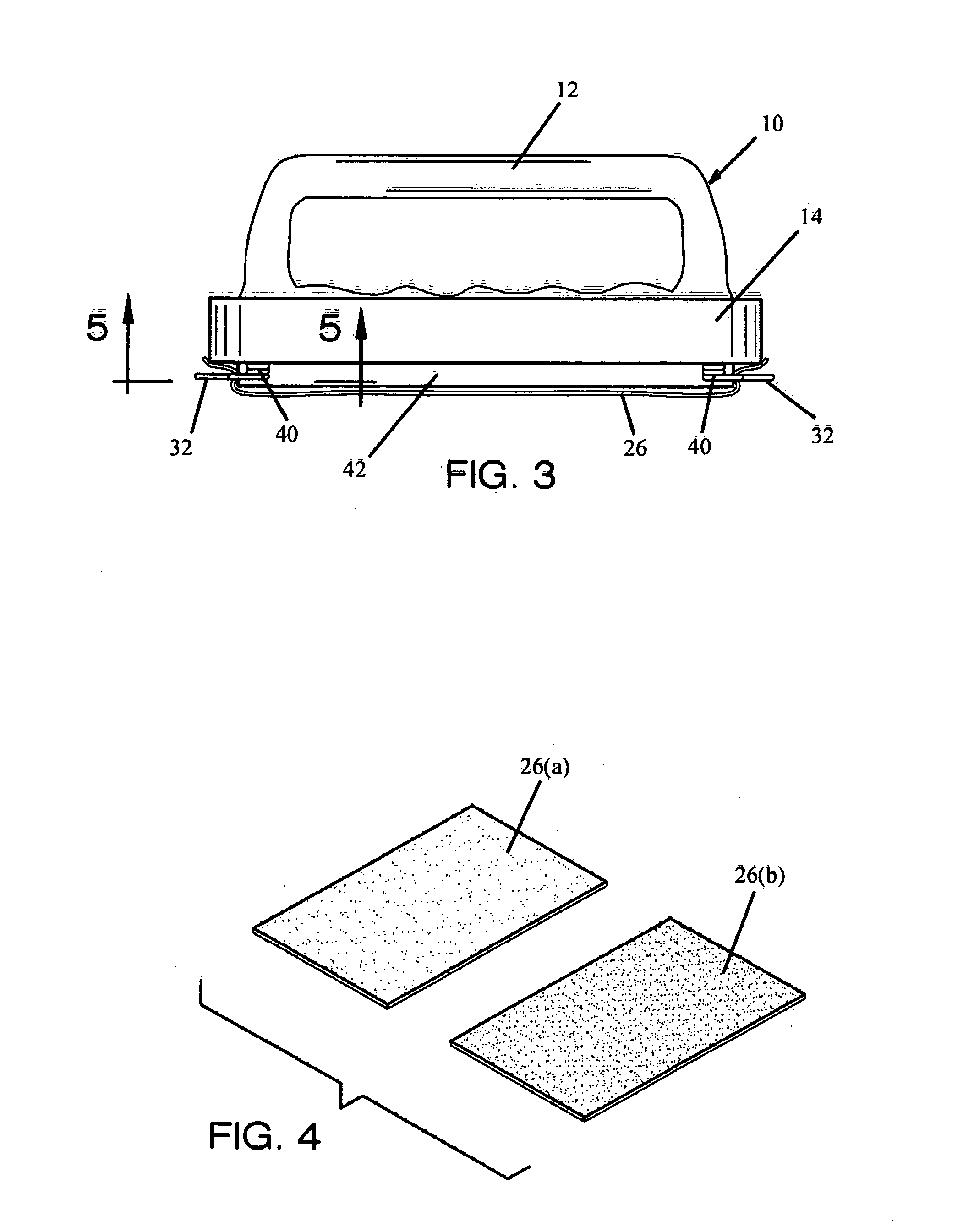

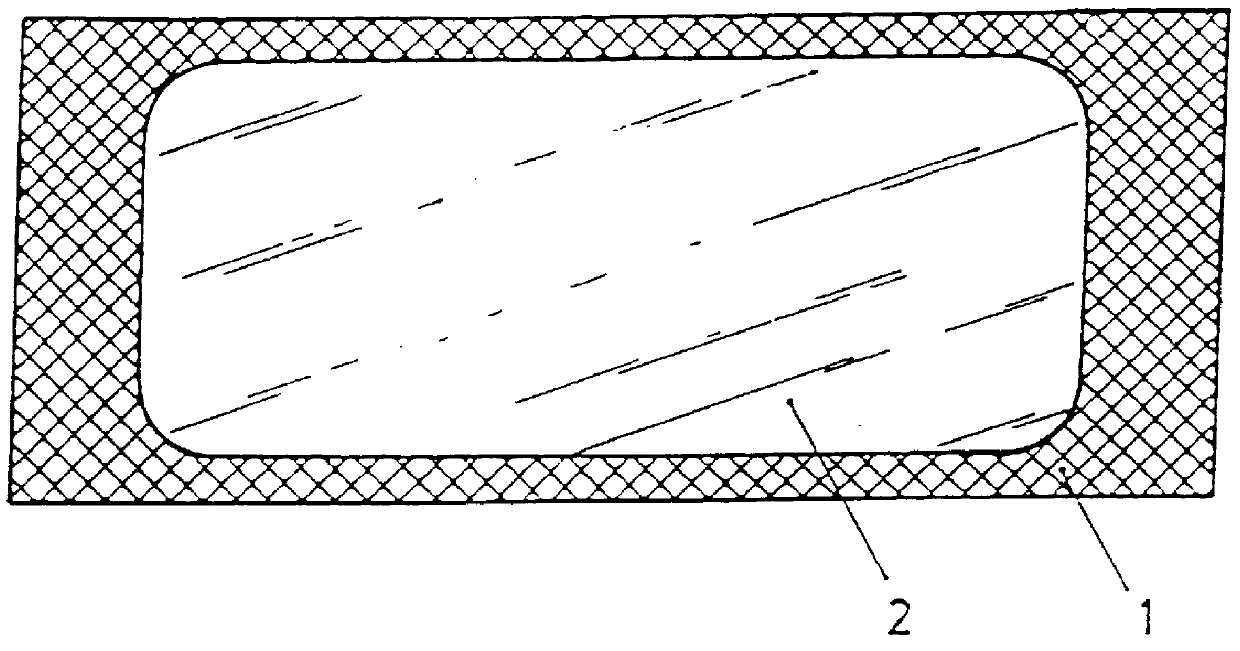

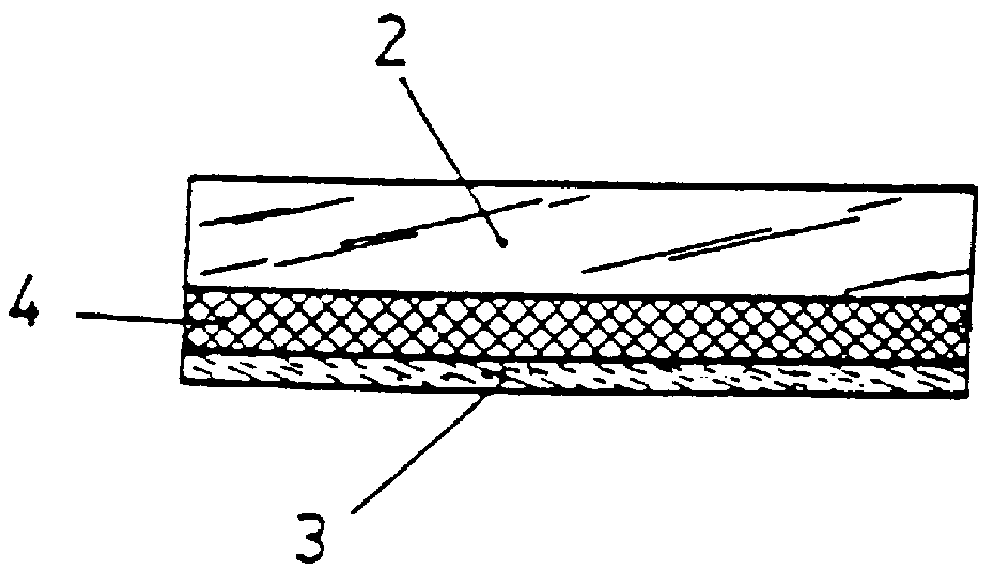

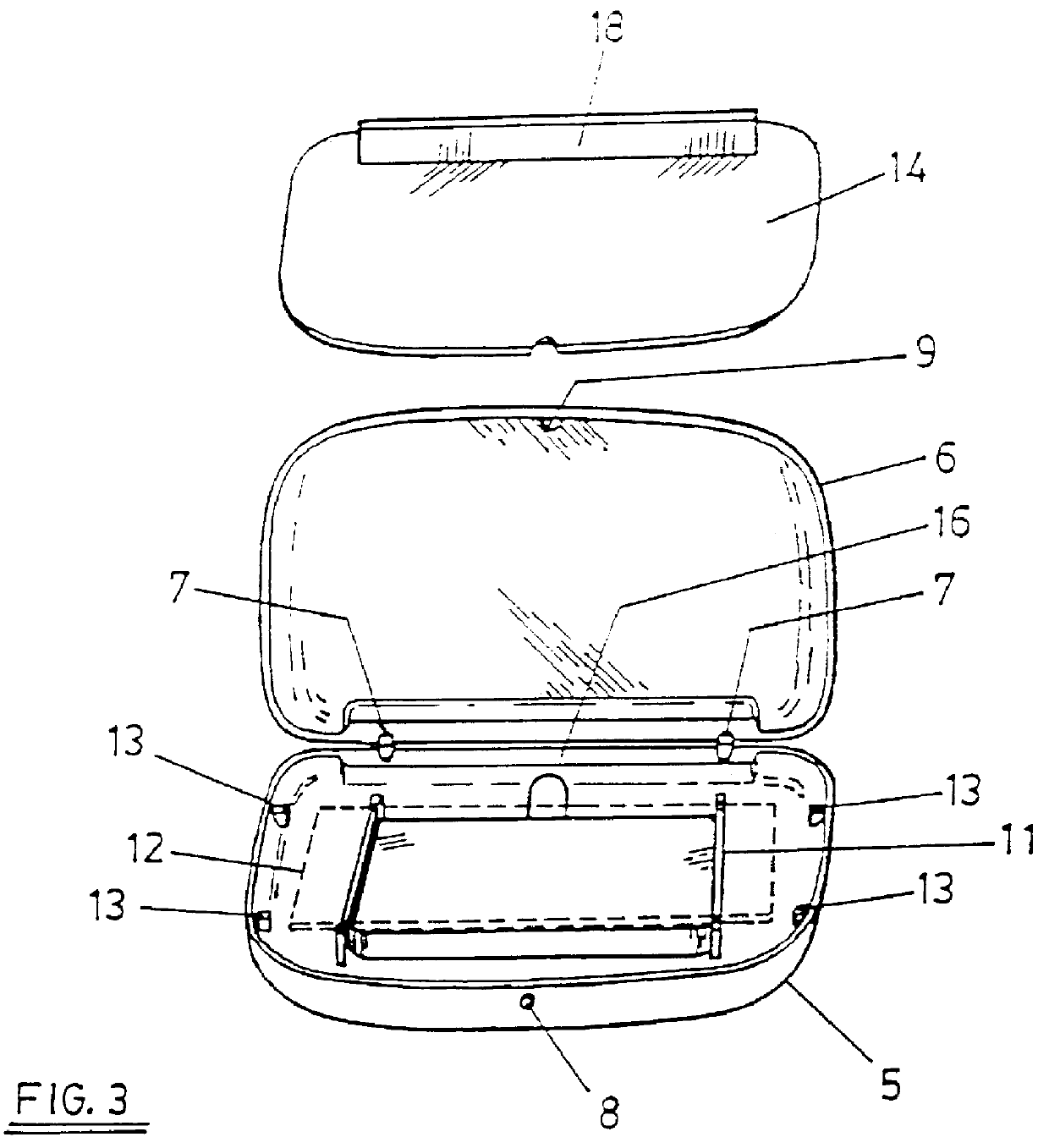

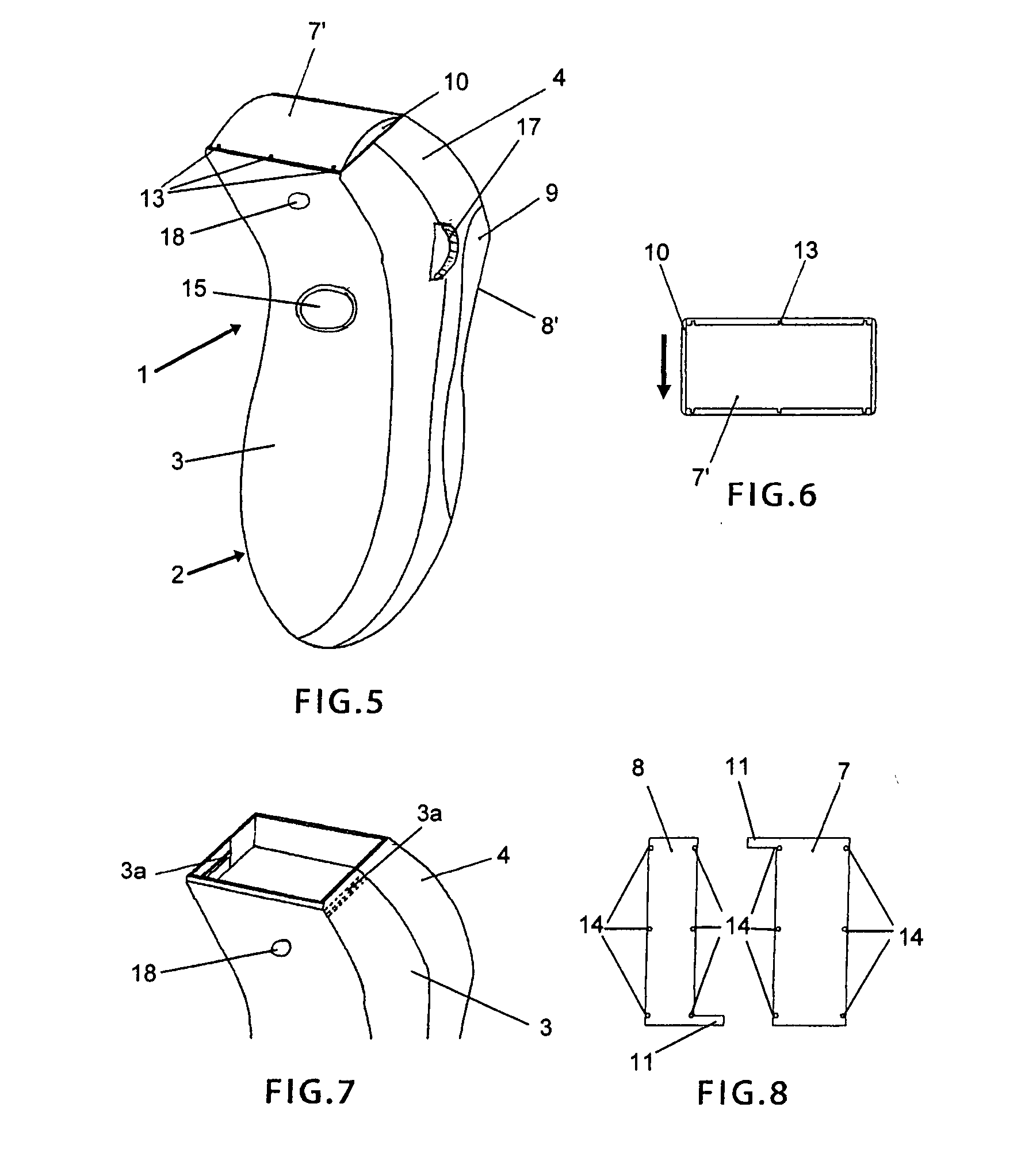

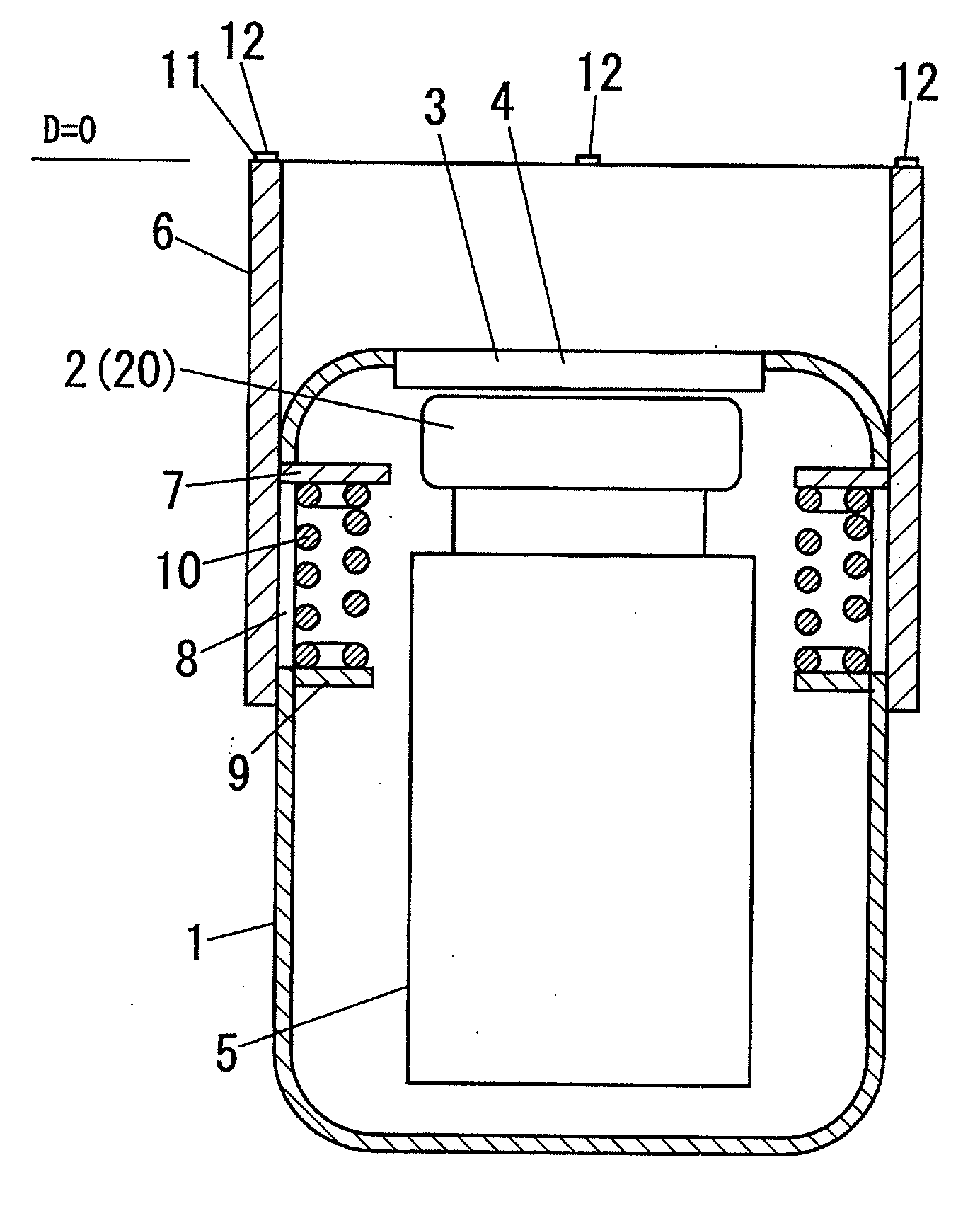

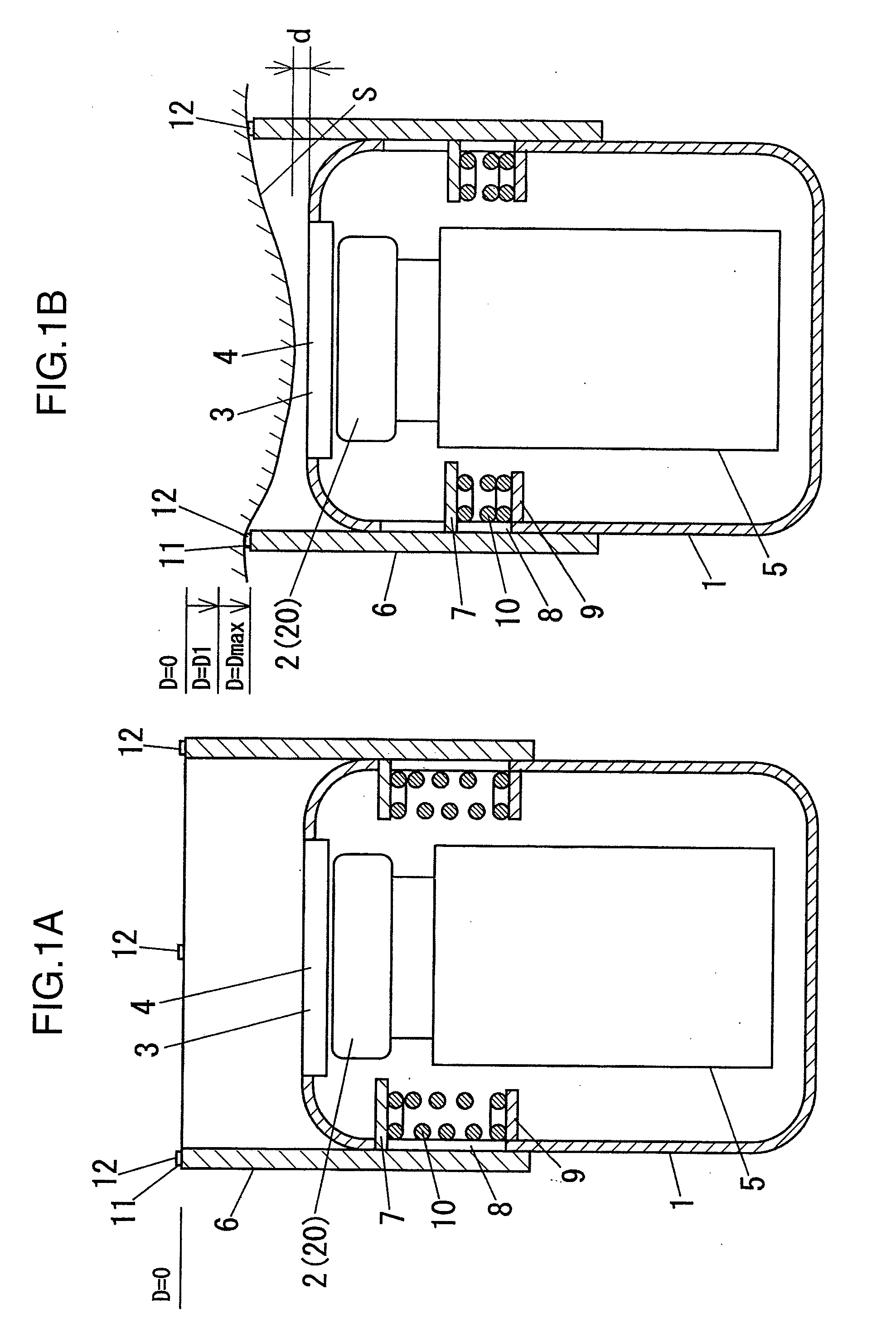

Wax band for depilation and device for its use

InactiveUS6027513ALose consistencyLose stabilityHair-singeingSurgeryWaxElectrical resistance and conductance

PCT No. PCT / ES97 / 00040 Sec. 371 Date Oct. 20, 1997 Sec. 102(e) Date Oct. 20, 1997 PCT Filed Feb. 20, 1997 PCT Pub. No. WO97 / 30608 PCT Pub. Date Aug. 28, 1997The invention relates to a wax band which presents a support strip (1) conformed by two sheets (3 and 4) interconnected in back-to-back relationship; the sheet (3) is made of plastic material and the sheet (4), on which is deposited a wax layer (2), is made of a cellulose web. For the application of said wax band, a heating device is used which is comprised of two bodies (5 and 6), hinged to each other. The body (5) houses a heating plate (12) provided with an electric resistance and a plate (14) on which are placed the wax bands to be heated. This invention applies to the fabrication of products and apparatuses intended to the aesthetics of the human body and more particularly to depilation.

Owner:CERABOMA

Terylene comfortable cotton velvet woolen blanket and preparing method thereof

The invention relates to a comfortable cotton velvet blanket and the technical field of the manufacturing method. The polyester comfortable cotton velvet blanket of the invention adopts the DTY polyester yarns of 0.39 to 3.12dtex and the FDY polyester yarns of 55 to 167dtex, and after warp knitting fabric manufacture, the polyester comfortable cotton velvet blanket is manufactured by that the grey cloth is sequentially treated with slitting, combing, ironing and shearing, heat setting, printing or dyeing, post treatment, back fuzzing sorting, and napping typing. The invention selects suitable materials, preparation procedures and equipment, the finished products of the polyester comfortable cotton velvet blanket have stable gram weight and strong stereoscopic impression of the hair side, and the hair height reaches ideal feeling; the suede of the blanket is like cotton, which has soft hand feeling and is fluffy; and the blanket also has very good hydroscopic property and no depilation phenomenon, is mould proofing and moth proofing, is bright in color, and can directly touch the skin, thus being sure to obtain the favour of the people.

Owner:徐建平

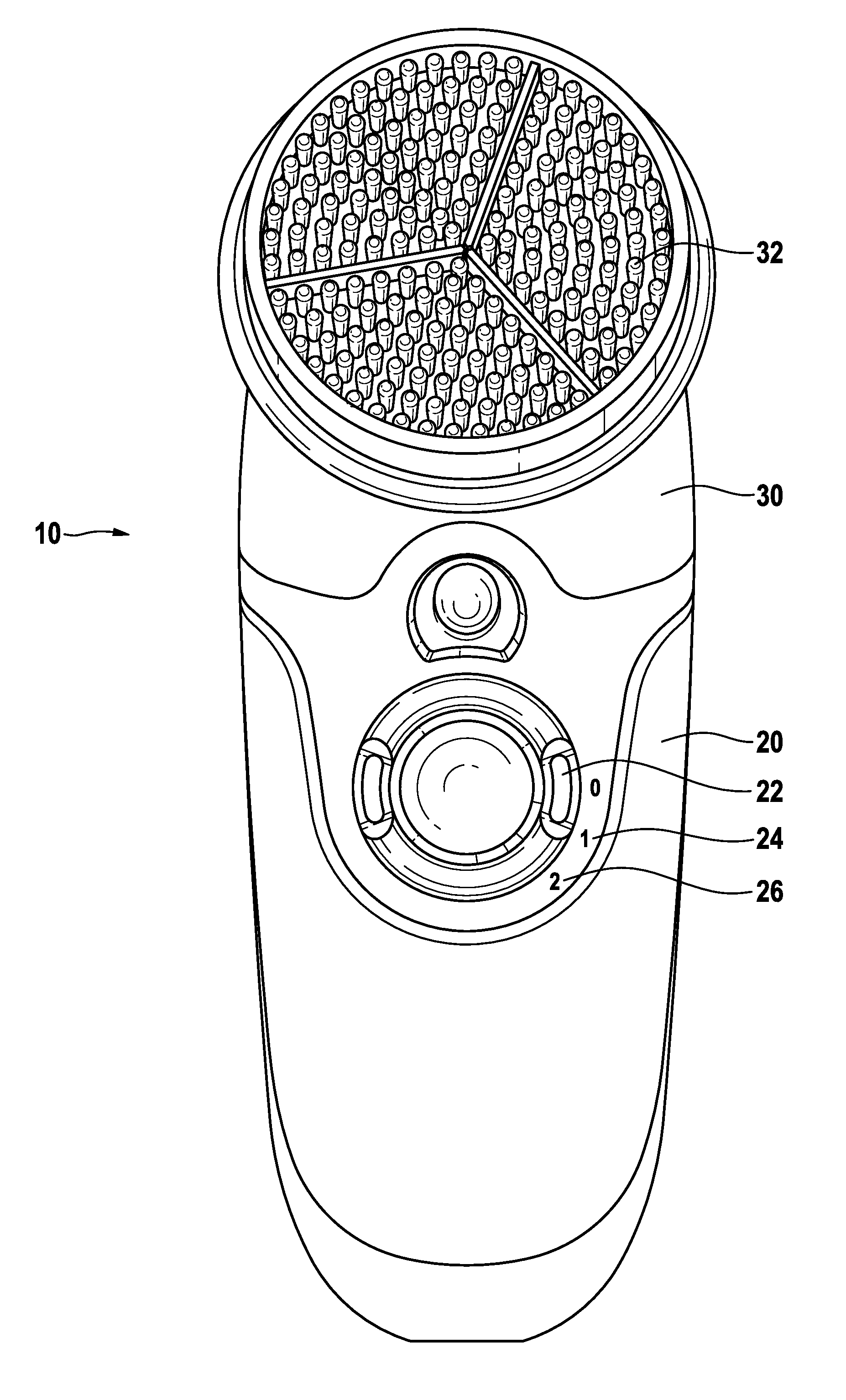

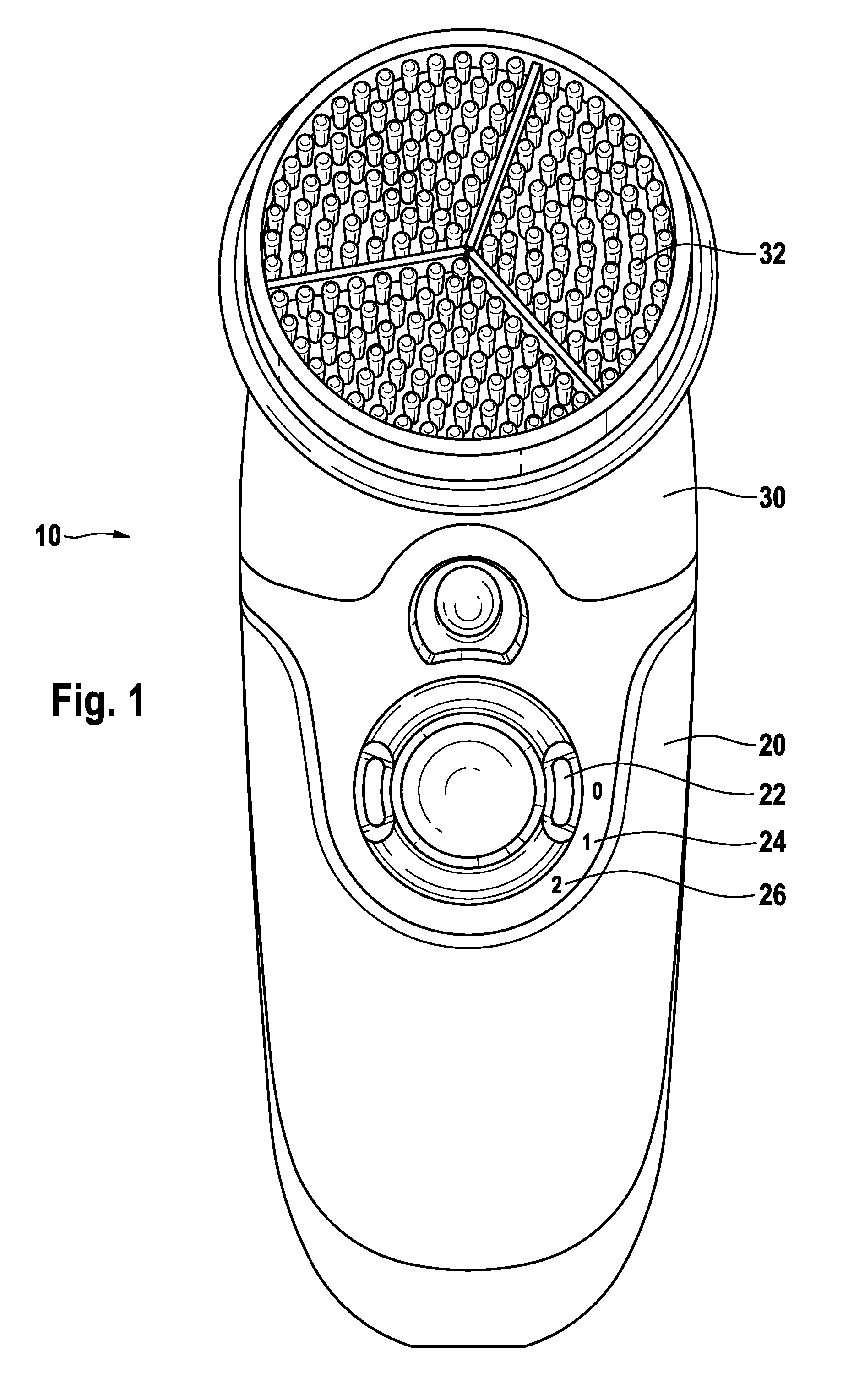

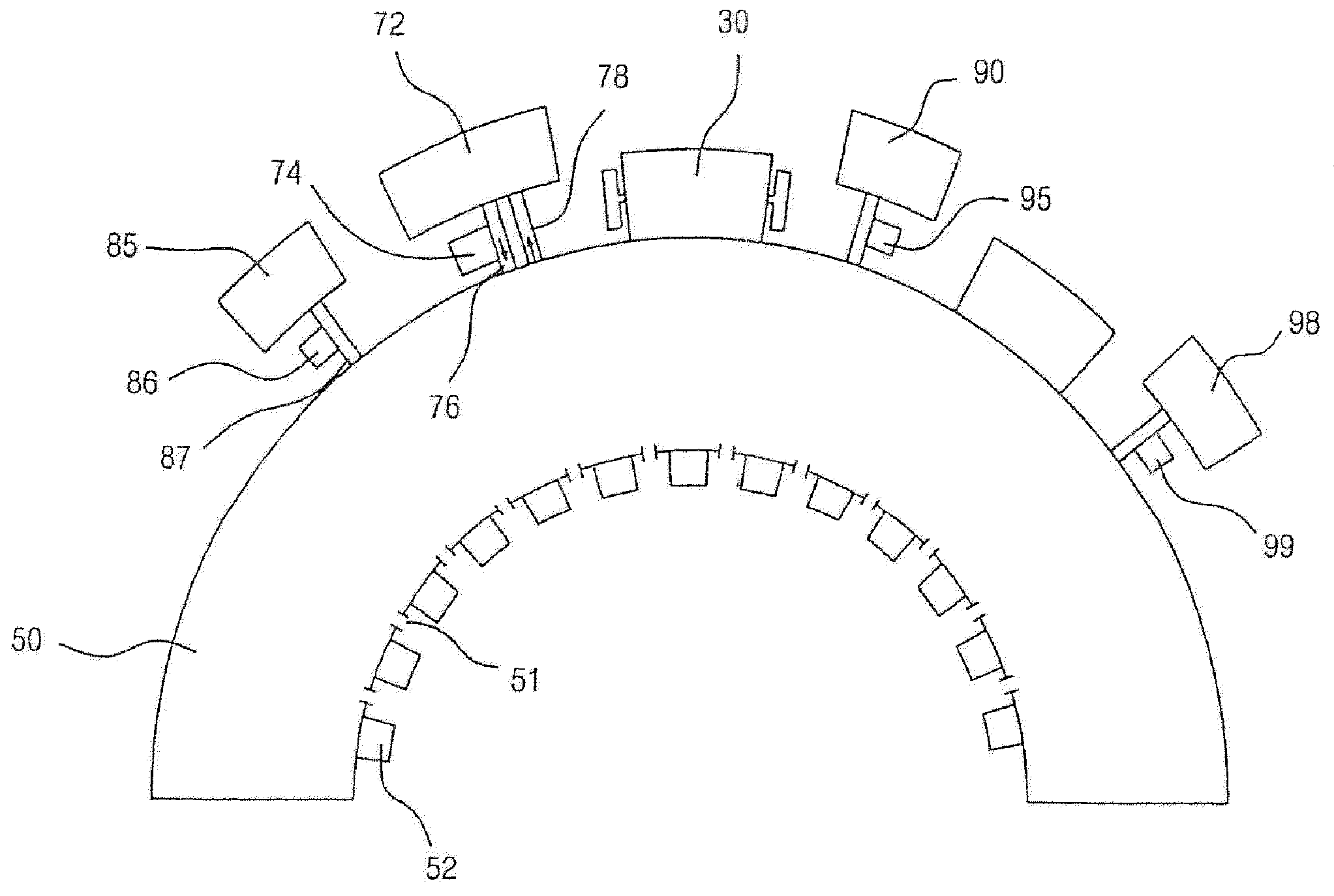

Skin treatment device

InactiveUS20130023901A1Cleansing and refreshing skinHair-singeingBrush bodiesSkin treatmentsGear wheel

The present invention concerns a skin treatment device for professional and private use. In particular the present invention concerns a skin treatment device comprising a drive unit and a first attachment and a second attachment, the first attachment comprising a brush, the second attachment comprising an epilation or a depilation unit, wherein the first attachment comprises a gear box and the second attachment comprises a gear box and the gear box comprises by the second attachment provides a gear reduction of at least 1.25 to 4.

Owner:BRAUN GMBH

Preparation method of dried salted duck

The invention discloses a preparation method of dried salted duck, which is characterized in that: a duck is electrically shocked and killed and then is completely depilated through a complete depilation process combining an ironing process and a secondary ironing process, chest of the duck is cleared, the duck with feet, wings and head being removed is salted, then the duck is immersed in saltwater brine, and finally the dried salted duck product is obtained through a dehydration process combining the baking dehydration and the natural air drying. The preparation process of the dried salted duck is free from being influenced by the weather, the duck is thoroughly depilated, and at the same time the prepared dried salted duck has strong cured flavor and good taste.

Owner:阜南县郜台板鸭厂

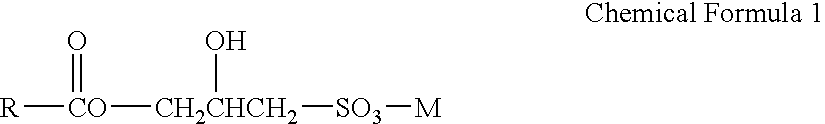

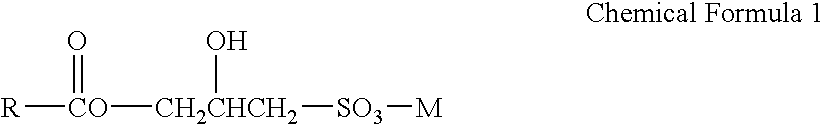

Manufacturing method of monoglyceride sulfonate, toilet soap composition using the same, and manufacturing method of toilet soap composition comprising salt

InactiveUS20050215456A1Economically and easily preparingImprove machinabilityCosmetic preparationsSurface-active detergent compositionsSulfonateMonoglyceride

The present invention relates to a method for preparing monoglyceride sulfonate that is useful for a cleansing agent for a human body, economically in a large amount, from an inexpensive fatty acid using a convenient manufacturing unit. The present invention also provides a soft soap composition comprising monoglyceride sulfonate and a fatty acid soap, which has superior molding and stamping workability, softness, smoothness, foamability, and moisturizing ability. The present invention also provides a method for preparing a salt-containing soft soap using the fatty acid used for preparation of the monoglyceride sulfonate, which contains a lot of salt, so that is softens skin, easily removes waste materials, prevents irritation, promotes blood circulation, and prevents depilation and dandruff.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

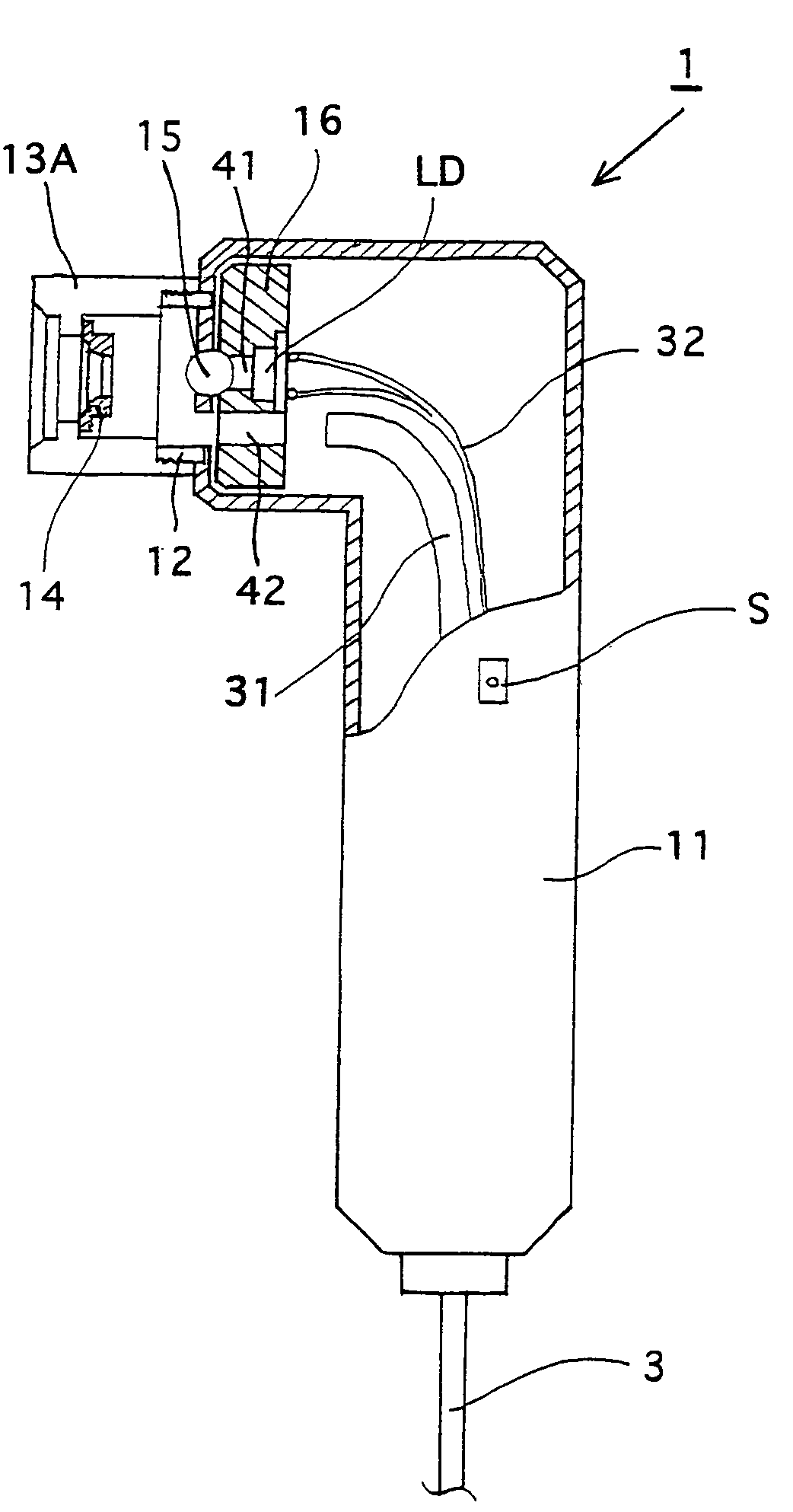

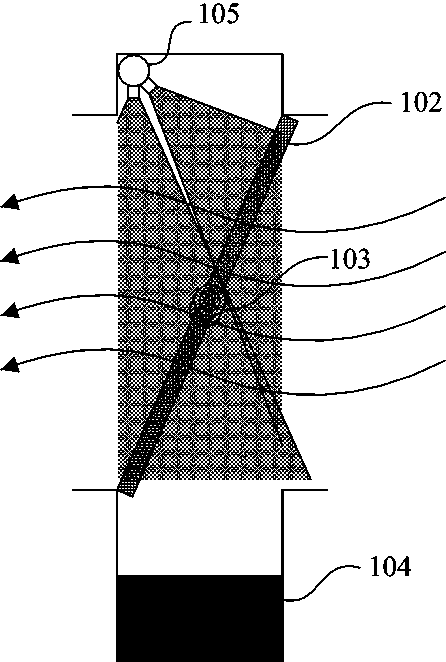

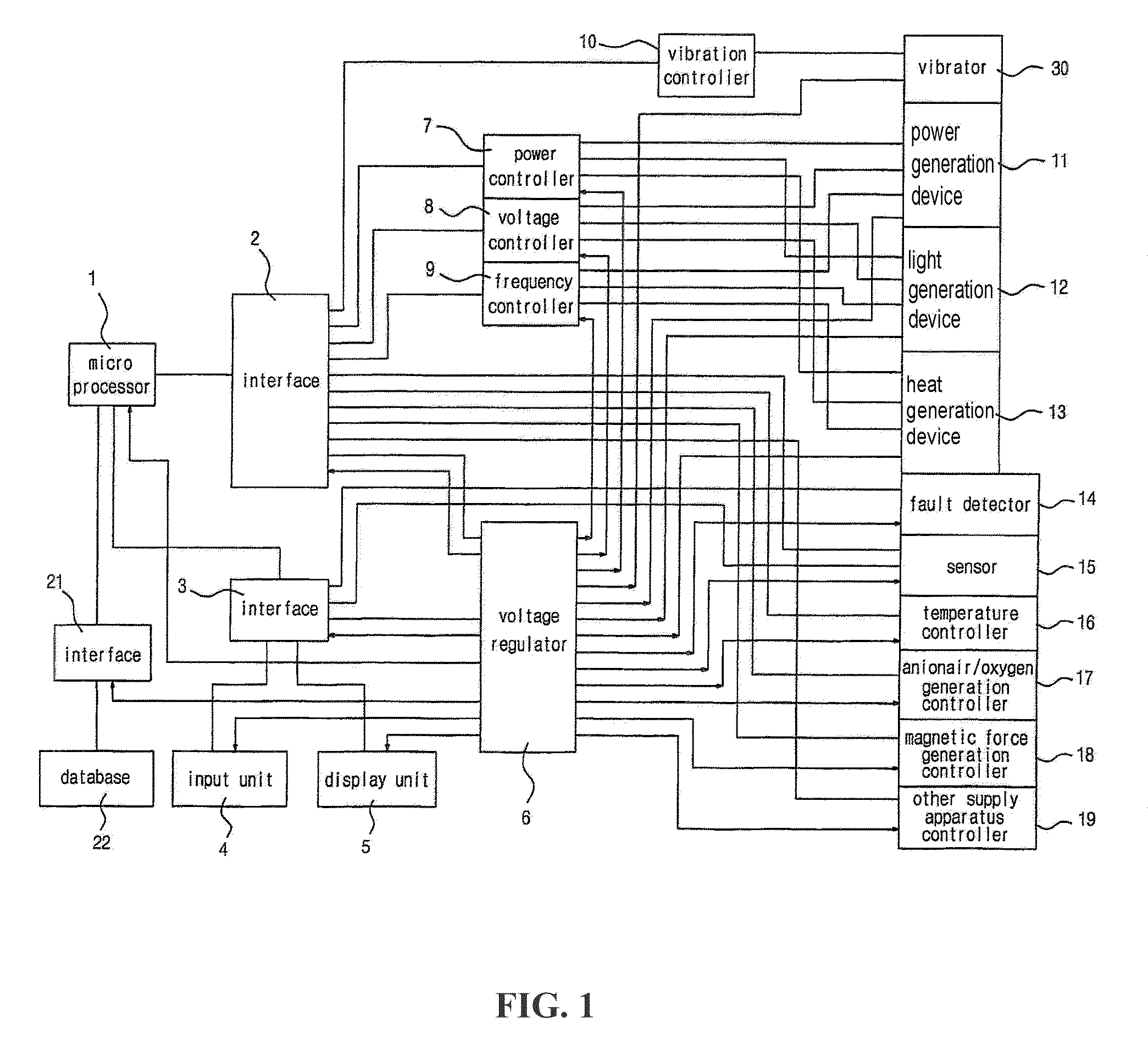

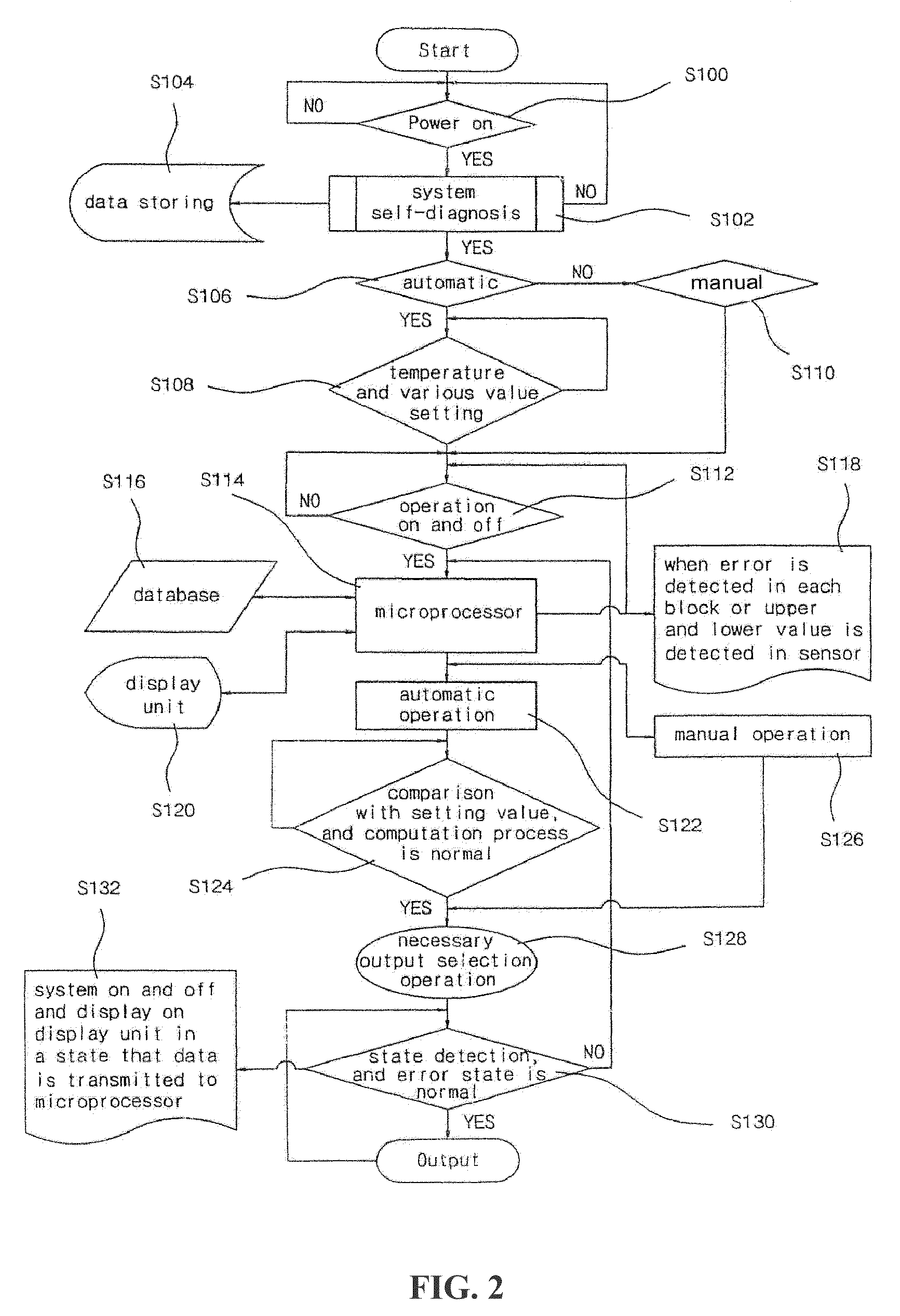

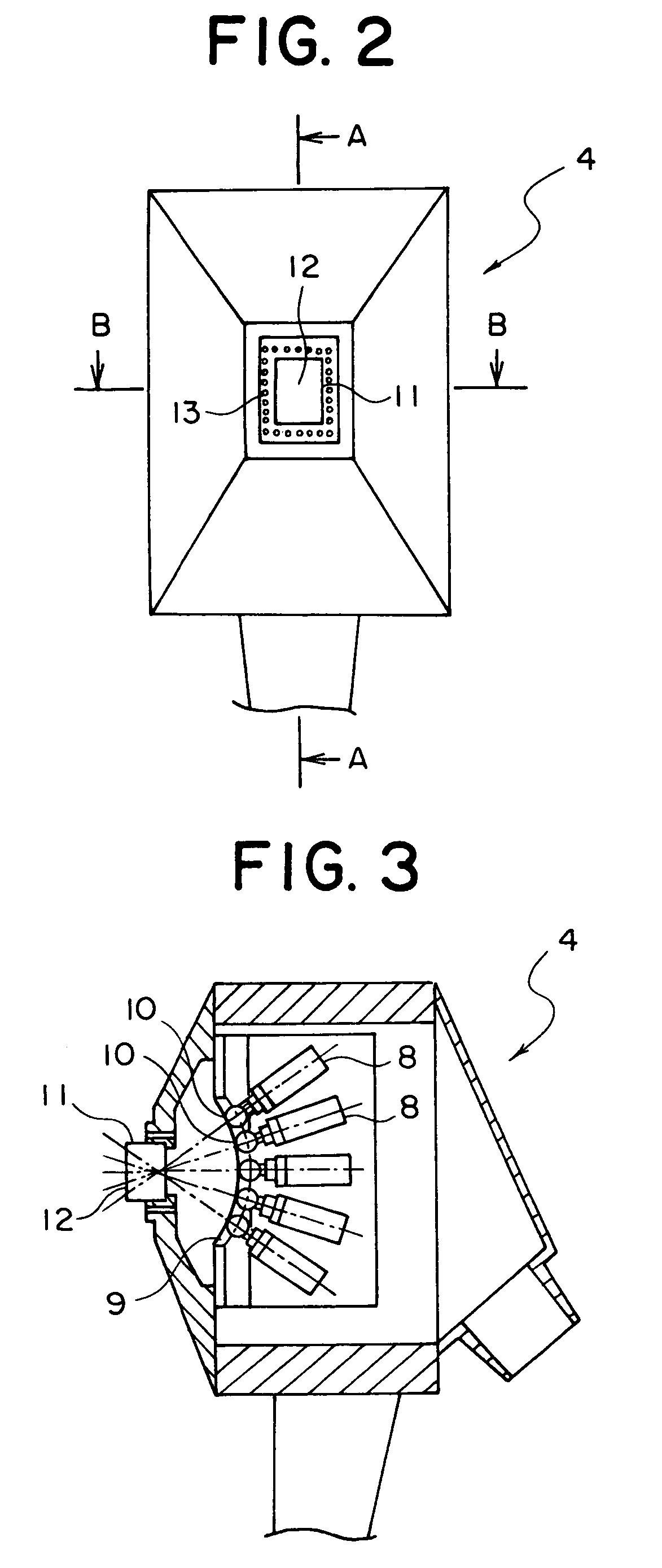

Apparatus for laser depilation

InactiveUS7329252B1Prevent hair growthAppropriate energy levelSurgical instrument detailsLight therapyLight beamPeak value

An apparatus for laser depilation according to the present invention uses a semiconductor laser diode, which is controlled in respect of its energy level, thereby permitting an economical, effective and safe cosmetic treatment. The power output of light of the semiconductor laser diode ranges from 5 to 1500 mW, and the peak wavelength ranges from 600 to 1600 nm. The controller of the semiconductor laser diode comprises pulsating power output control means and radiation period control means for setting a desired length of time for radiation. With these control means the energy level of the beam of light from the laser may be so controlled that a strong beam of light may be thrown for a relatively short time, or that a weak beam of light may be thrown for a relatively long time. Thus, hairs of different thickness and colors can be removed.

Owner:YA MAN LTD

Sodium sulfide-free, lime-free depilation caustic dip method for lining leather of high-grade pig leather shoes

The invention relates to a depilation caustic dipping method of the lining leather of high quality pigskin shoes without using sodium sulfide and lime, which is characterized in that the method can greatly reduce the pollution of S and waste residue in waste water caused by sodium sulfide, sodium sulfhydrate and the lime in the process of traditional leather manufacturing process, and the discharge amount of the waste water is reduced by 40% and is easy to treat compared with the conventional depilation liming working procedure. Meanwhile, a non-ammonia dealkalization method is adopted to greatly reduce the content of NH3-N in the waste water. Compared with the traditional technique, the method can shorten the production period, save materials and reduce the comprehensive cost of production.

Owner:湖南省怀其皮革集团制革有限公司

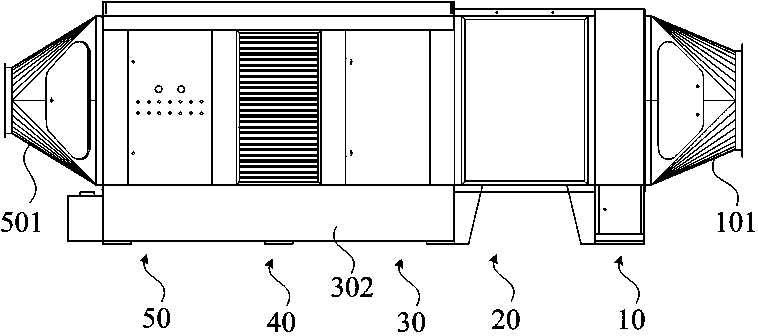

Physical purification device for boarding machine oil smoke

An embodiment of the invention discloses a physical purification device for boarding machine oil smoke. The device comprises a depilation system, a cooling system, an emulsification spray system, a de-watering and demisting system and a static purification system. The depilation system comprises a filter screen for filtering cloth wool impurities; an airway of the cooling system is provided with heat-conducting fins for cooling the gas; an airway of the de-watering and demisting system is provided with a baffling and demisting plate for carrying out water blocking and filtering treatment on the water-laden gas; and an airway of the static purification system is provided with a plurality of nested adsorption cylinders and high-pressure discharge needles. Through filtering, cooling, spraying, demisting and static adsorption treatment on the exhaust gas, the discharged gas is smoke-free, odor-free and dust-free, so as to avoid environmental pollution.

Owner:李川凌

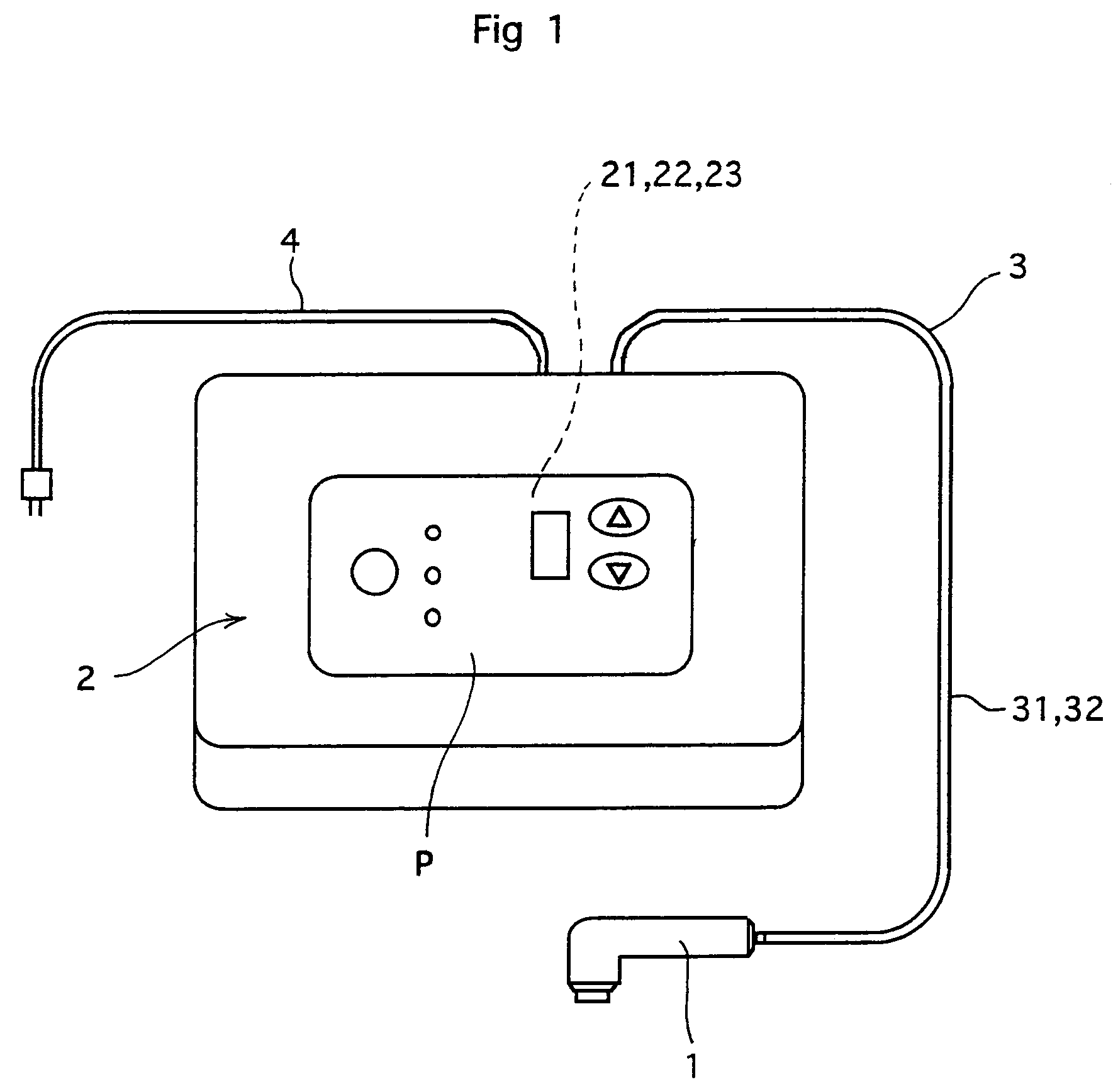

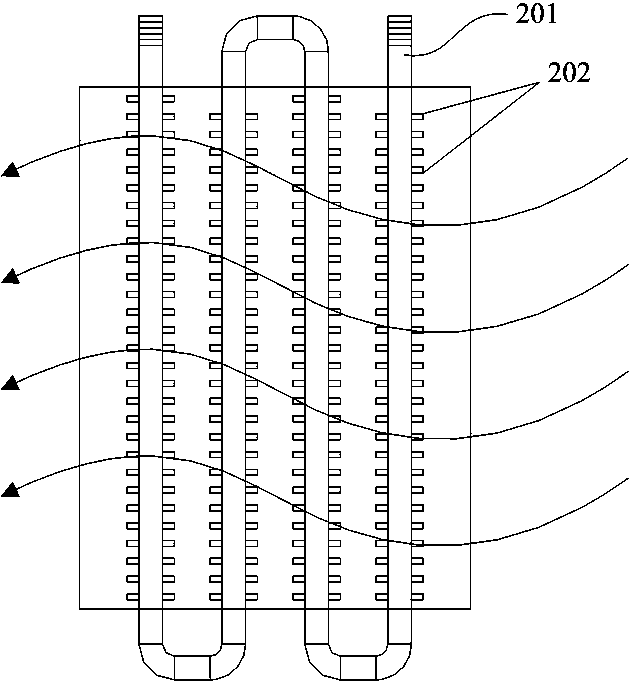

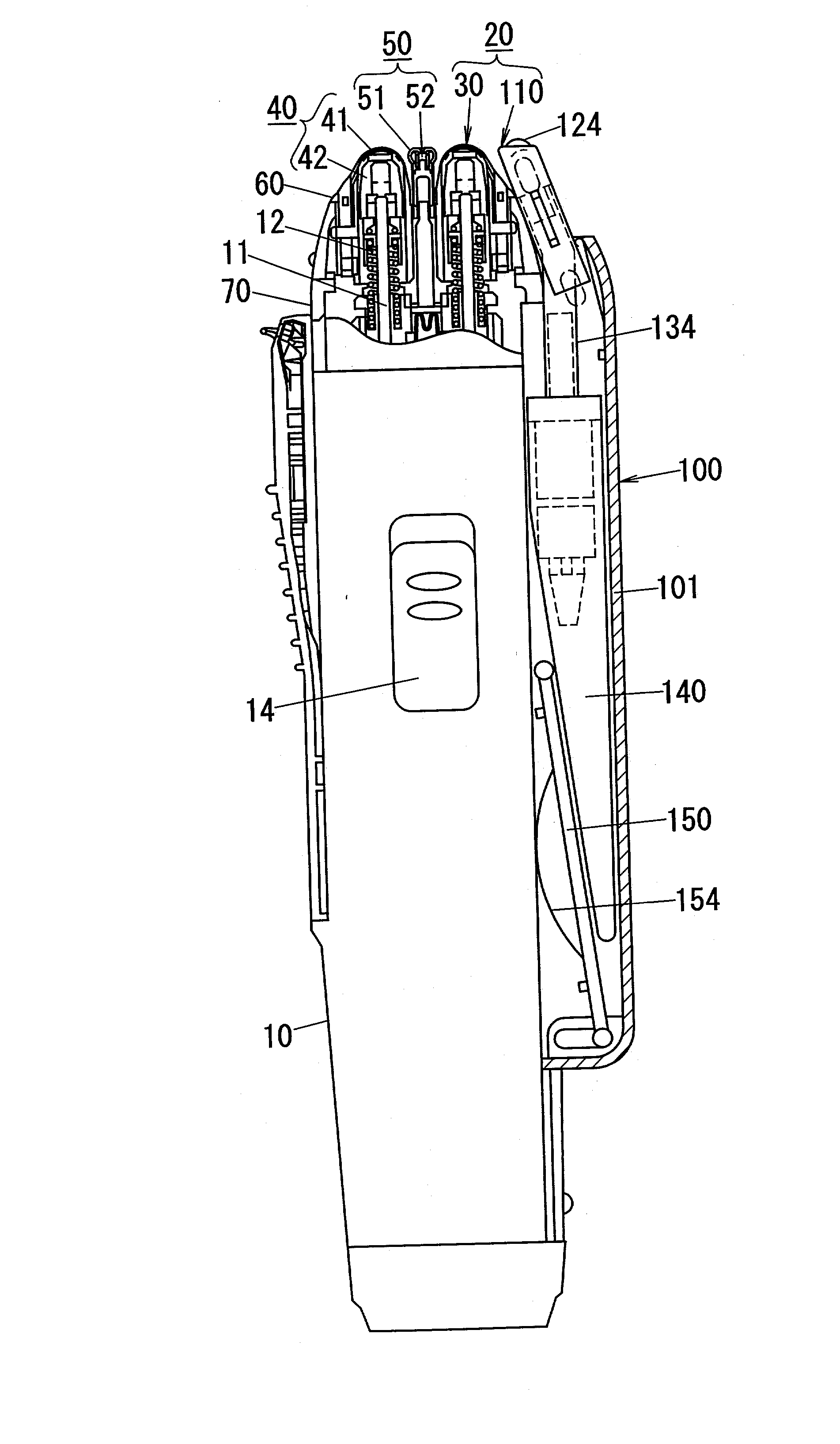

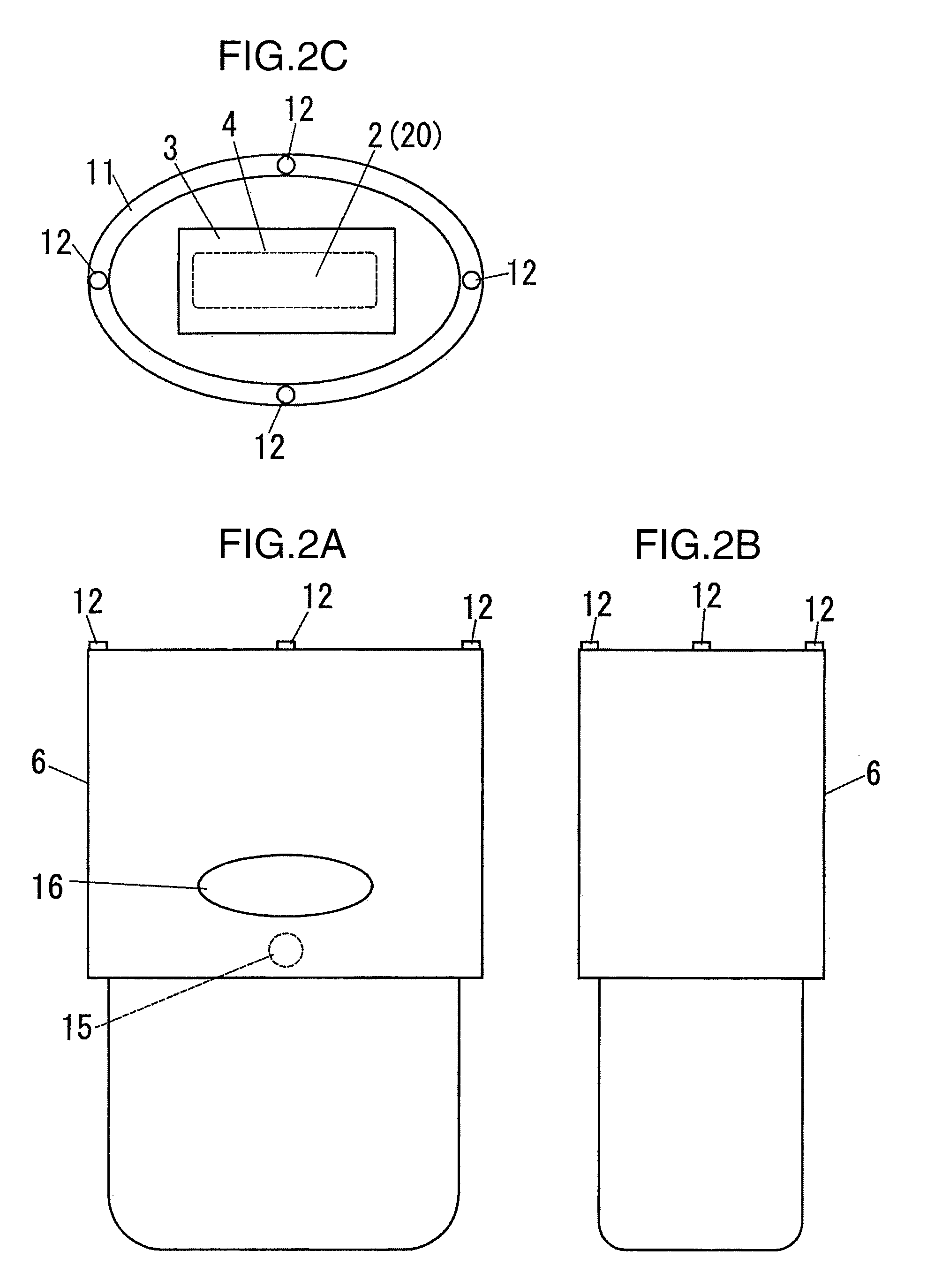

Optical depilation apparatus

InactiveUS20100152719A1Improve securityEasy maintenanceDiagnosticsSurgical instrument detailsSkin contactOptoelectronics

An optical depilation apparatus of high safety is provided, in which the light irradiating the skin during the depilation treatment can be prevented from leaking and entering the eyes, maintenance can be facilitated, and the light for depilation can be prevented from being emitted at an unintended time and entering the eyes. The apparatus for performing depilation by irradiating the skin with light includes: an apparatus body; a light source unit provided at the apparatus body and capable of emitting the light for irradiating the skin; a light shielding pipe having a skin contact surface at an end surface on the side opposite to the apparatus body in the axial direction of the light shielding pipe and is attached detachably to the apparatus body so as to surround a portion of the apparatus body which radiates light emitted from the light source unit; and a control circuit that disables the emission of light from the light source unit in a state in which the light shielding pipe is not attached to the apparatus body.

Owner:PANASONIC CORP

Electrolytic depilation device

InactiveUS20070239152A1Amplifier modifications to reduce non-linear distortionModulated-carrier systemsElectricityElectrolysis

Owner:TREZON MICHEL

Hair growth apparatus

Owner:WHANG HA UK

Preparation method of cartilage regeneration scaffold material

The invention provides a preparation method of a cartilage regeneration scaffold material. The preparation method is characterized in that fresh skin at back, face or buttock of a dead animal is taken as a raw material and is subjected to treatment processes such as deep and low-temperature treatment, depilation, inactivation of virus, decellularization, structure remodeling, crosslinkage, freeze-drying, re-modification and sterilization, thus obtaining a finished product. The cartilage regeneration scaffold material prepared by the method disclosed by the invention can be used for promoting adhesion and growth of cartilage cells and promoting healing of articular cartilage injuries. The product belongs to a natural extracellular matrix ingredient which is beneficial to adsorption, proliferation and differentiation of the cells, also has a certain mechanical strength, can exist in the body for a long time in the form of a tissue filler, also has good tissue affinity and compatibility, and can be used for inducing cartilage cells to grow therein so as to rebuild the cartilage, promote the adhesion and growth of the cartilage cells, promote the healing of the articular cartilage injuries and restore articular defects, so the cartilage regeneration scaffold material is a novel regeneration scaffold material for effectively restoring articular cartilage defects.

Owner:北京科健生物技术有限公司

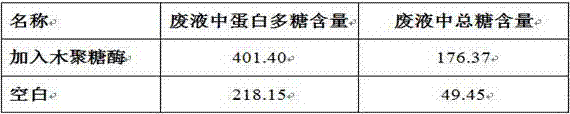

Animal hide fiber loosening method based on xylanase effect

ActiveCN107312896AReduce dosageReduce processing difficultyPre-tanning chemical treatmentFiberDepilations

The invention discloses an animal hide fiber loosening method based on the xylanase effect and relates to the field of production of leather and fur leather. The method is characterized in that xylanase is added as a hide fiber loosening additive during the steps such as water soaking, depilation, softening and pickling of leather making or during the steps such as water soaking, softening and pickling of fur leather making. By means of the method, the components such as proteoglycan and glycosaminoglycan, which have a cohesive effect on hide fiber, in the animal hide can be efficiently and specifically destroyed. Hide protein ingredients cannot be destructed. The method has wide applicability and is suitable for the manufacturing process of all-purpose leather or fur leather with various kinds of animal hides as raw materials. The effects of promoting loosening of hide fiber and improving the softness, hand feeling and physical and mechanical properties of finished leather products are achieved. Through the method in the leather making process, pollutants such as lime and sodium sulfide are reduced, and the depilation effect is improved.

Owner:SICHUAN UNIV

Ashless and alkali sulfide free depilation liming treatment method for preparing leather from raw sheep skin

InactiveCN101265505AEasy to handleReduce pollutionPre-tanning chemical treatmentWater savingSodium bisulfide

The invention relates to an alkali depilation liming method of currying and processing goatskin without generating dust and vulcanization. The method is characterized in that sodium sulfide, sodium bisulfide and lime are not used; lime precipitate and residua do not appear to ensure the drained waste water to be more easily processed; the pollution to the environment in the currying process is greatly reduced. The dust skin washing which is a highest water cost working procedure is eliminated, and the saved water is about 20 percent to 40 percent of the total draining quantity of waster water. The damage to finished leather quality is reduced because of mechanical effect; the loose surface rate caused by mechanical effect is greatly reduced; the production period is also shortened; various materials are saved and the production combined cost is reduced.

Owner:SICHUAN UNIV

Pet food for preventing depilation

The invention discloses a pet food for preventing depilation. The pet food provided by the invention is composed of a main component and an auxiliary component. The main component comprises the following ingredients: by weight, 20-50% of bean flour, 20-30% of corn flour, 2-10% of seaweed meal, 1-3% of protein powder, 2-10% of vegetable, 10-30% of meat and 1-5% of vitamin B. the auxiliary component comprises the following ingredients: by weight, 0.5-1.5% of oil, 0.3-0.8% of essence, 0.5-0.8% of salt, and 5-10% of a seasoning. The pet food for preventing depilation has advantages of reasonable allocation, balanced nutrients, simple technology and unique taste, and can enrich pet food kinds and meet requirements of people who keep pets. By adding seaweed meal into the pet food for preventing depilation, trichoxerosis and trichomadesis can be prevented, growth of new fur is promoted, and morbidity of dermatosis is minimized. In addition, pets can be treated at home without the need of going to pet hospital.

Owner:XUZHOU JINPAI PHARMA

Hair removing device with a lotion applicator

A hair removing device capable of feeding a lotion in association with a hair removing operation. The device has a treatment head that is mounted on a housing and includes a hair removing unit for hair depilation or hair epilation and an applicator for supplying a lotion on a user's skin. Also included in the device is a tank holding the lotion and a lotion supply mechanism for supplying the lotion from the tank to the applicator. The treatment head is formed with an actuator which acknowledges an even of the treatment head coming into an operative condition with the skin and activates a lotion supply mechanism to supply the lotion from the tank to the applicator when such event is acknowledged.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Optical depilation apparatus

InactiveUS20100152718A1Reliably prevent light leakSatisfy safety performance requirementsHair-singeingDiagnosticsLight irradiationDepilations

An optical depilation apparatus is used for performing depilation by irradiating skin with light. The apparatus has: a light source unit; a light irradiation port; and an apparatus body emitting light from the light source unit through the light irradiation port; a light shielding part disposed so as to surround the light irradiation port of the apparatus body; and a support part that supports the light shielding part so as to allow the light shielding part to move in the light irradiation direction with respect to the apparatus body. The support part has a receiving portion provided at the apparatus body, a convex portion provided at the light shielding part, and a spring member disposed between the receiving part and the convex part.

Owner:PANASONIC CORP

A kind of preparation method of black-bone chicken feed

InactiveCN102258133AFast growthGood disease prevention performanceFood processingAnimal feeding stuffDiseaseNutritional deficiency

A preparation method of black-bone chicken feed, which is composed of: corn flour, bran powder, bean cake powder, apple powder, bitter gourd powder, pine needle powder, pineapple powder, pumpkin powder, loofah powder, garlic powder, hawthorn powder, salt, almond powder , walnut powder, safflower powder, asparagus powder, bellflower powder, malt powder, tangerine peel powder, and the percentages described are percentages by weight; effectively overcome some breeders and large-scale breeding farms when black-bone chickens are raised due to lack of nutrition. Pecking hair, dull coat color, slow growth, small size, light weight, loose feathers, less activity, easy to get sick, easy to die.

Owner:刘学顺

Laser depilating method and laser depilating apparatus

InactiveUS7214222B2Irradiation range can be expandedSpeed up treatmentSurgical instrument detailsLight therapyDepilationsEnergy density

A laser depilating method for depilating treatment by irradiating a skin surface with a laser beam emitted from a semiconductor laser. A treatment region of the skin surface is treated with a semiconductor laser beam for an irradiation time of 100 msec or more per irradiation while controlling the laser beam so that the energy density when irradiating the skin surface may be in a range of 0.01–1 J / mm2. Irradiation of the skin surface with a semiconductor laser beam under such a condition provides a more secure and efficient treatment effect of laser depilation. A plurality of semiconductor laser beams are used as necessary to irradiate a wider area of skin surface at a time.

Owner:YA MAN LTD

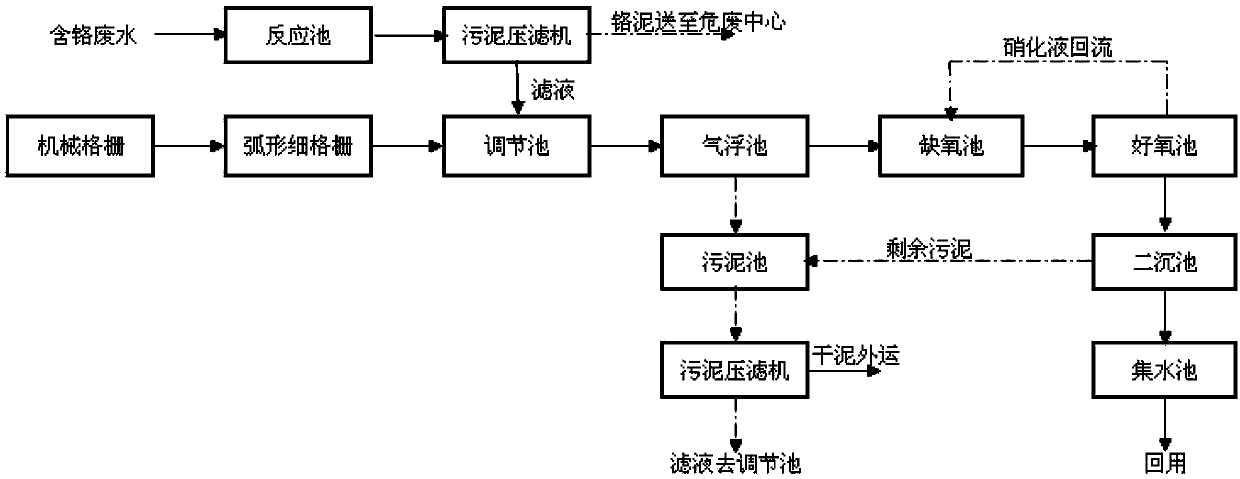

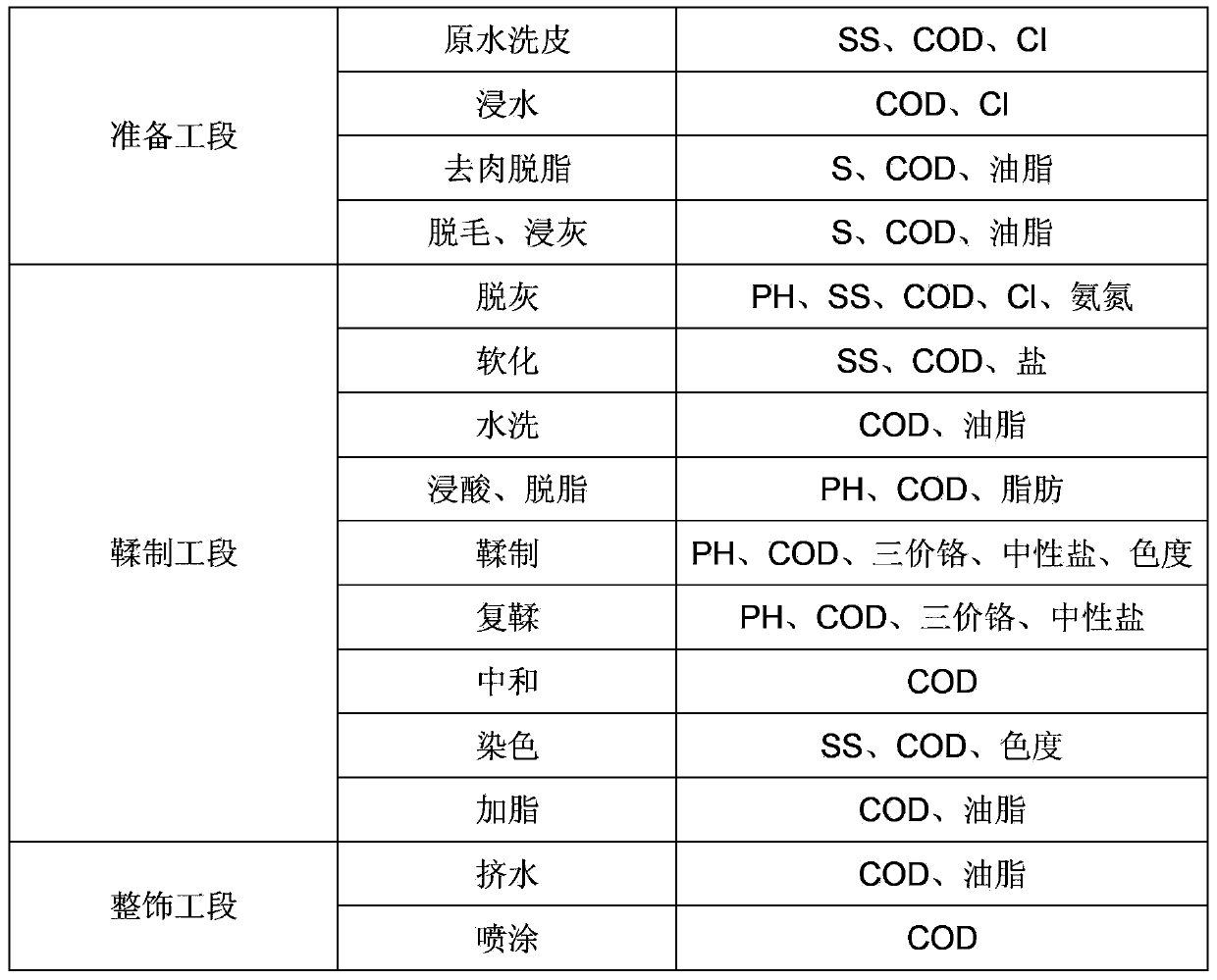

Leather wastewater treating method

InactiveCN103387310AOvercome intractable difficultiesAvoid poisoningSludge treatment by de-watering/drying/thickeningWater contaminantsHigh concentrationOil and grease

The invention discloses a leather wastewater treating method, comprising the following steps: (1) allowing chromium-containing wastewater to enter into a reaction tank for a reaction, subjecting settled sludge to press filtration with a filter press, separating chromium mud for separate treatment and allowing an obtained filtrate to enter into a regulating tank; (2) filtering rest wastewater (raw hide and skin washing water containing high-concentration Cl, alkaline depilation liming wastewater containing calcium and sulfur and degreasing wastewater containing grease and other saponified matters) with gratings and then allowing the rest wastewater to enter into the regulating tank; (3) adjusting the wastewater in the regulating tank (to a pH value of 7 to 8) and delivering the wastewater to an air floatation tank; (4) removing grease in the air floatation tank through air floatation, delivering obtained sludge to a sludge tank and allowing obtained liquid to enter into an anoxic tank for treatment; (5) allowing wastewater treated in the anoxic tank to enter into an aerobic tank; and (6) allowing wastewater treated in the aerobic tank to enter into a secondary sedimentation tank for treatment so as to obtain wastewater according with emission standards. With the method, the wastewater reaches national emission standards.

Owner:SANDA FILM SCI & TECH XIAMEN

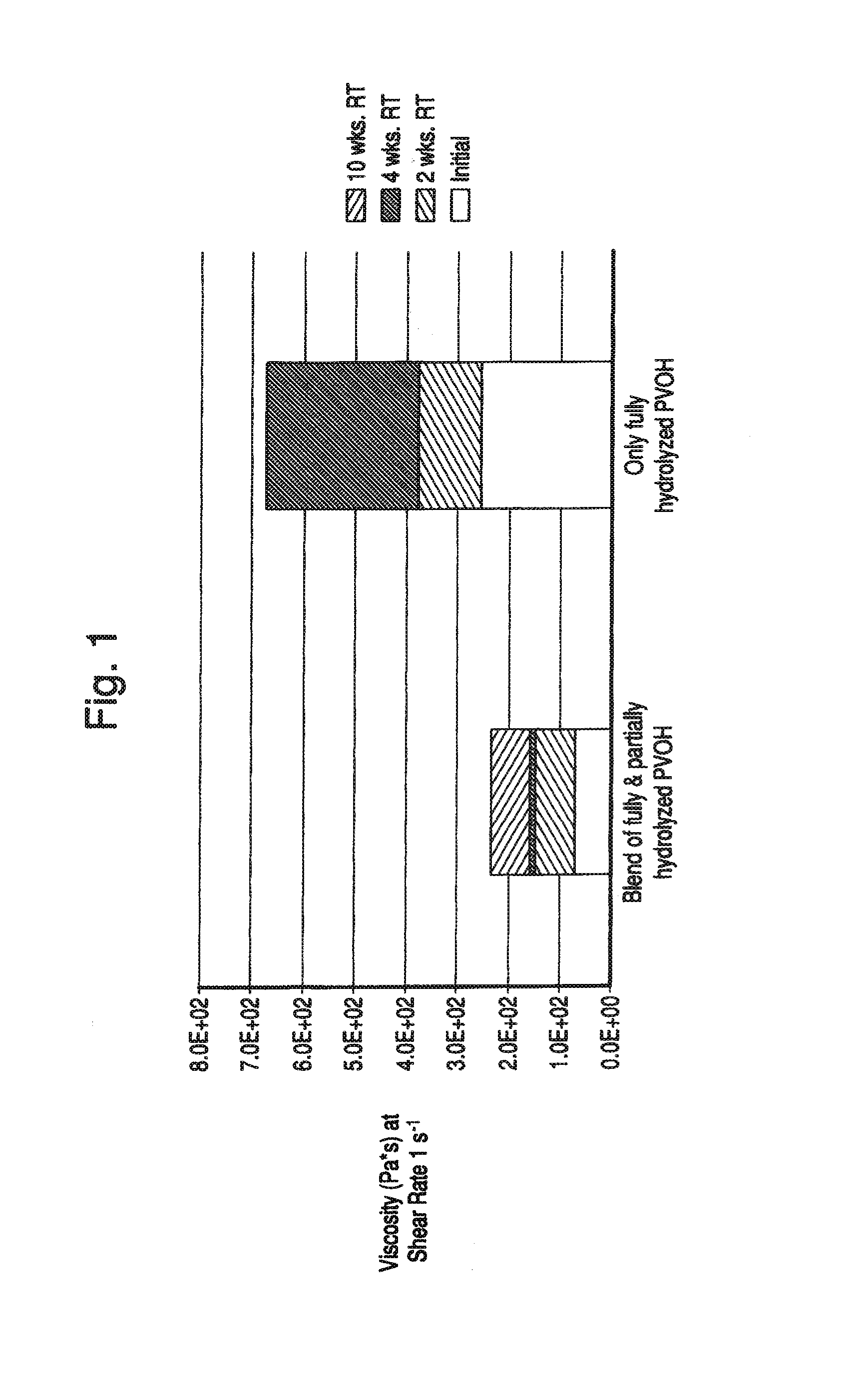

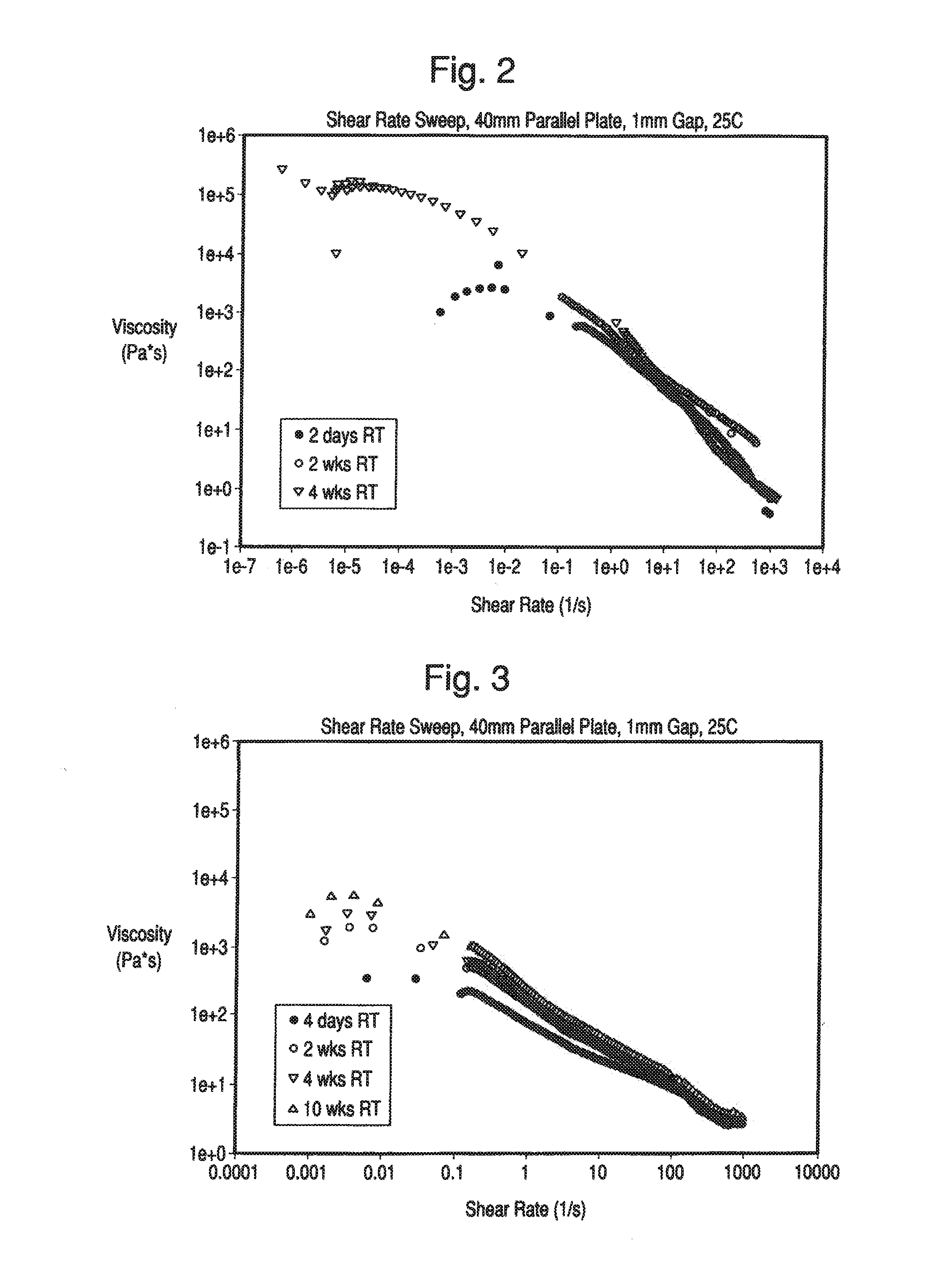

Single phase depilatory composition

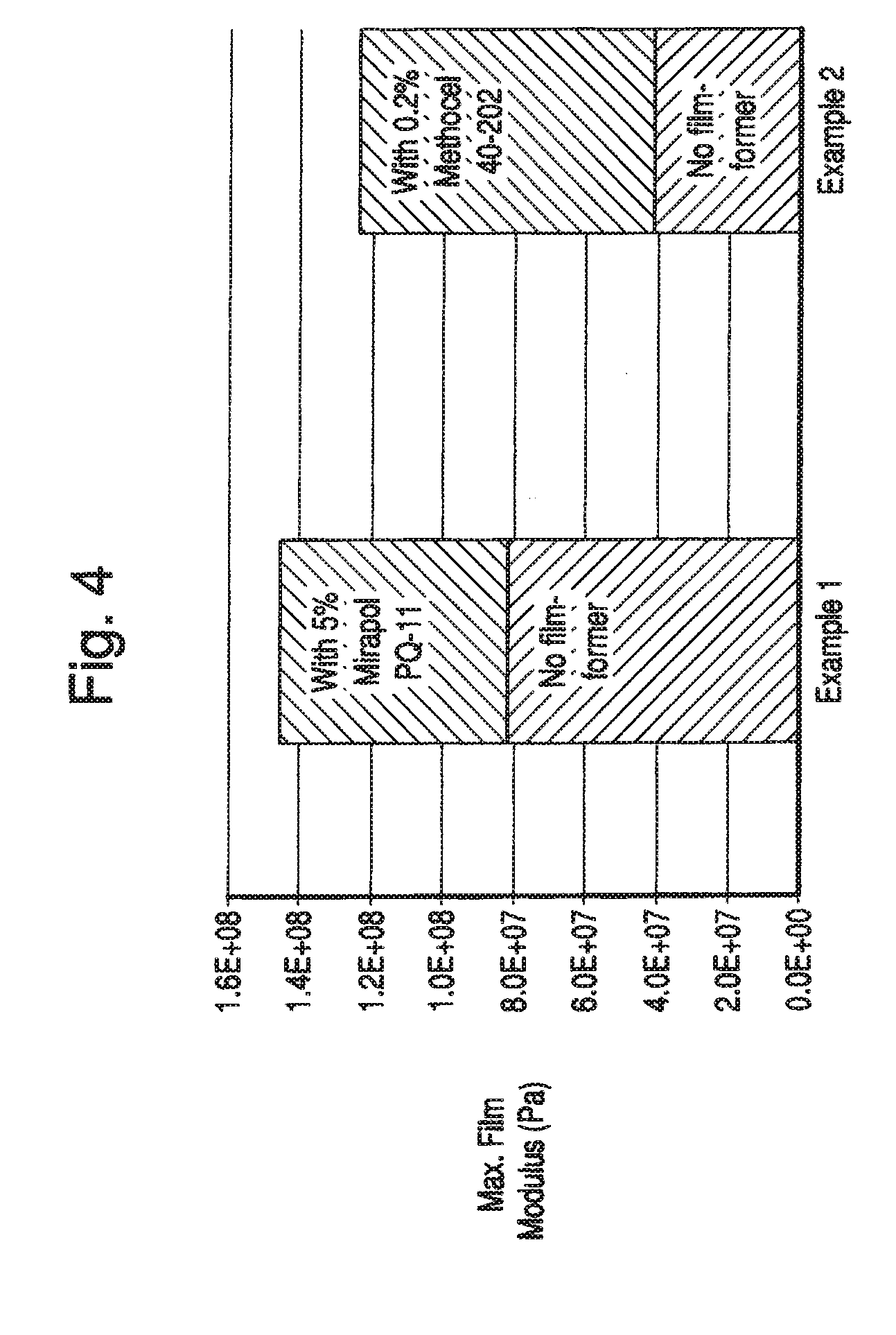

A depilatory composition, and a method of using a depilatory composition, where the present invention is a depilatory composition comprising: (1) a film-forming polymer; (2) depilatory active ingredients; and (3) a solvent system, wherein the depilation composition forms a peelable film after drying. The depilation composition of the present invention uses a blend of fully and partially hydrolyzed poly(vinyl alcohol).

Owner:CHURCH & DWIGHT CO INC

Method for leather-making with Co2 supercritical fluid as medium

InactiveCN1673394AContinuous operationSimple processPre-tanning chemical treatmentDepilationsMachining process

The present invention provides one kind of tanning method with supercritical CO2 fluid as medium, and the tanning method adopts supercritical CO2 fluid as medium for at least one step of degreasing, enzyme depilation, softening, tanning, dyeing, fatting, etc. During the said operation, no entrainer is sued basically, and the treating course with supercritical CO2 fluid can lower the temperature to 33 deg.c, lower the pressure to 7.4 MPa, shorten the treating period to 60 min and decrease power consumption.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com