Animal hide fiber loosening method based on xylanase effect

A technology of animal skin fiber and xylanase, applied in the field of leather or fur leather processing, can solve the problems of fiber looseness, achieve the effects of reducing pollution, excellent physical and mechanical properties, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1—yellow cow sofa leather soaked in water

[0043] 100kg of wet salted hide of yellow cattle, after washing, pre-soaking and removing meat, add to the drum, add 200kg of water, adjust the temperature to about 22°C, add 0.1kg of xylanase (Kunming Aikete Biotechnology Co., Ltd.), and turn 60 Minutes later, add 0.5kg of soda ash, 0.2kg of osmotic agent JFC, and 0.2kg of bactericide, and rotate for 60 minutes, intermittently, 5 minutes per hour, and the total immersion time is about 22 hours.

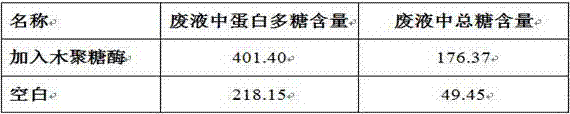

[0044] The results of proteoglycans and total sugars in the waste liquid after soaking in water are shown in Table 1. The proteoglycans and total sugars removed in the yellow cowhide soaked with xylanase were significantly higher than those in the blank group. The experimental results showed that the fiber loosening degree of the group added with xylanase was better.

[0045] Table 1 Proteoglycan and total sugar content in soaking wastewater (mg / L)

[0046]

Embodiment 2

[0047] Embodiment 2—cowhide upper leather depilation

[0048] Add 100kg of cowhide soaked in water to the drum, add 50kg of water, adjust the temperature to about 25°C, adjust the pH value of the hide to 6-7, and add 0.1kg of xylanase (Shandong Longkete Enzyme Preparation Co., Ltd.), after 4 hours of rotation , add 0.15 kg of 1398 protease, rotate for 3 hours, until only small hairs are left, add 1 kg of lime, rotate for 40 minutes, add 0.5 kg of sodium sulfide, rotate for 40 minutes, add expansion agent CAS (Sichuan Dawei Technology Co., Ltd.) 0.25 kg after hair removal , water 30kg, turn for 20min and stop for 20min, add CAS 0.25kg, water 25kg, turn for 20min and stop for 20min, add water 50kg, turn for 30min and stop the drum overnight. After the delimed bare leather is peeled and delimed, it does not need to be softened by enzymes, and directly enters the pickling process, and then proceeds according to the conventional shoe upper leather process.

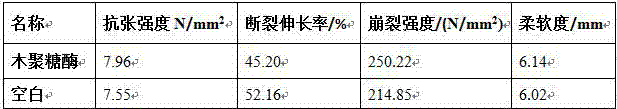

[0049] The properties ...

Embodiment 3

[0053] Example 3 - softening of pigskin garment leather

[0054] According to the conventional process, 100kg of naked pig hides are added to the drum after liming and peeling. After deliming, add 40kg of water, adjust the temperature to 35°C, add softening enzyme DOWELLZYMBM (protease, Sichuan Dawei Technology Co., Ltd.) 1.5kg and wood poly Carbohydrase (Shandong Longkete Enzyme Preparation Co., Ltd.) 0.05kg, rotate for 90 minutes, then intermittently rotate for 5 minutes every 30 minutes, for a total of 4 hours.

[0055] The skins treated above are then subjected to follow-up operations according to the conventional process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com