Leather wastewater treating method

A treatment method and technology for leather wastewater, which can be used in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of thick odor, high chroma, and high oil content of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

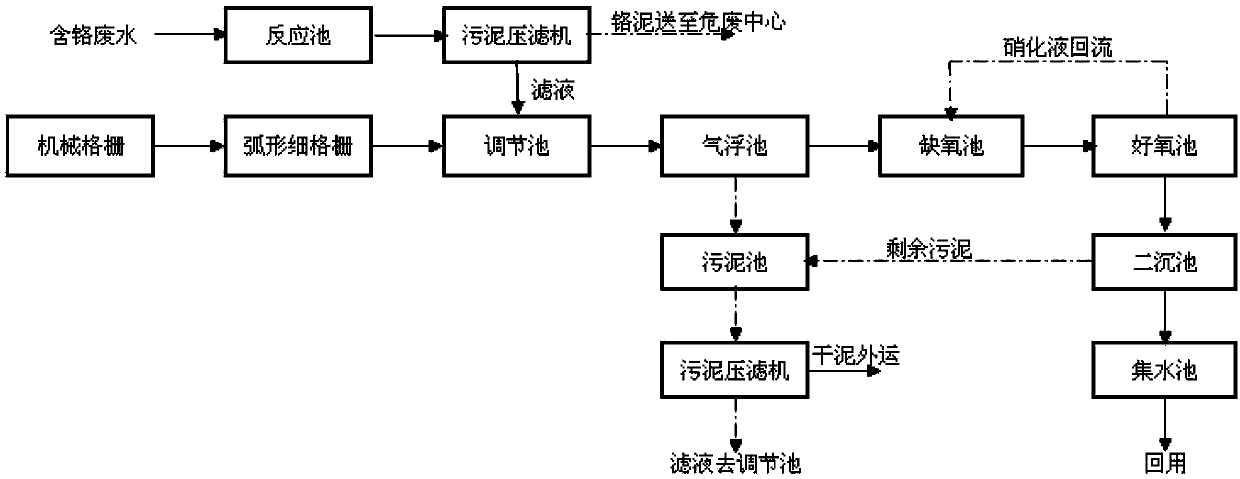

[0022] Concrete embodiment of the present invention, its flow process refers to figure 1 .

[0023] The reaction tank is used to precipitate chromium, and the total chromium content in the effluent is controlled below 1.5mg / L by using the reduction precipitation method (adding sodium sulfite and caustic soda)

[0024] The wastewater from the reaction tank is sent to the sludge filter press. After the filter press, the filtrate is sent to the adjustment tank, and the chrome sludge is sent to the hazardous waste center for treatment.

[0025] The grid pool is used to intercept sundries, minced meat, fur and so on. It can be set that the distance between the first level mechanical grille should not exceed 40mm. The second-level curved fine grid is not greater than 10mm.

[0026] The regulating pool is used to adjust the water quantity and quality, and the PH value of the incoming water is adjusted to 7-8.

[0027] The air flotation tank is used for oil treatment in wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com