A method for simultaneously producing tar, phenol and water gas

A water gas and tar technology, applied in the field of coal chemical industry, can solve the problems of large heat consumption, heat loss, high organic impurity content, and achieve the effect of strengthening the vaporization process and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, a kind of anthracite lump coal is used as raw material, and the main composition is: 86% fixed carbon, 3% moisture, 6% volatile matter and 5% ash.

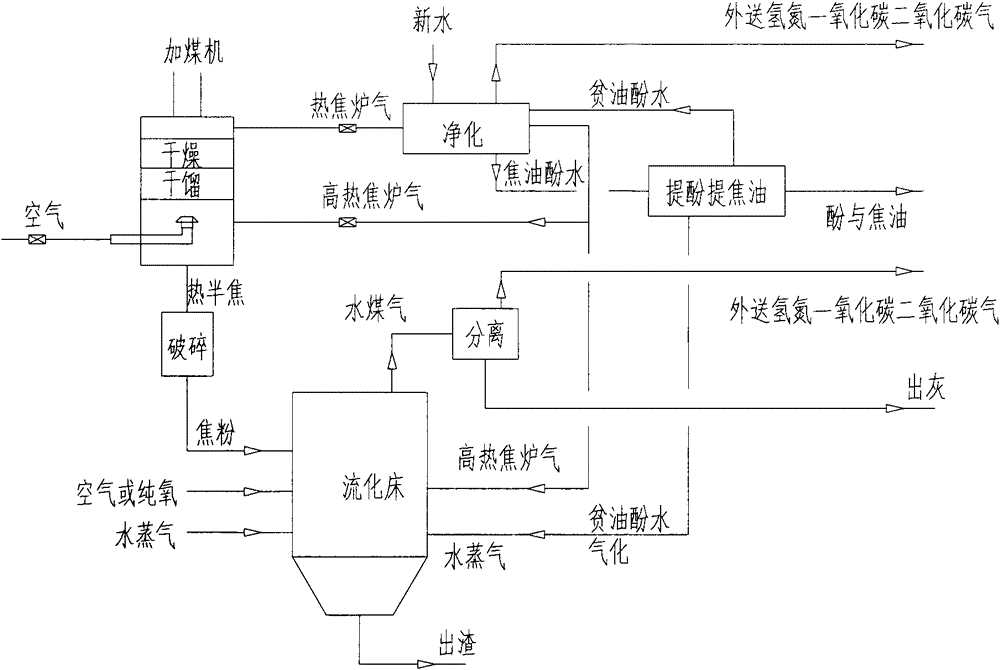

[0018] (1) Anthracite lump coal is dehydrated to less than 2% through the drying layer, and then enters the dry distillation layer to remove volatile matter to 5%, and simultaneously obtains hot coke oven gas and hot semi-coke. The hot coke oven gas passes through the washing equipment to obtain tar and phenol water, and then through the organic matter separation equipment to obtain coke oven gas with high calorific value and the mixed gas of hydrogen, nitrogen, carbon monoxide and carbon dioxide. The tar phenol water is obtained by extracting phenol and tar to obtain tar, phenol and Oil-poor phenol water, part of oil-poor phenol water is returned to the purification equipment as washing water, and part of oil-poor phenol water is vaporized and enters the fluidized bed as a gasification agent; part of the...

Embodiment 2

[0021] In this embodiment, a lignite lump coal is used as a raw material, and the main composition is: 28% fixed carbon, 40% moisture, 27% volatile matter, and 5% ash.

[0022] (1) The lignite lump coal is dehydrated to less than 5% through the drying layer; then enters the dry distillation layer to remove the volatile matter to 5%, and simultaneously obtains hot coke oven gas and hot semi-coke. The hot coke oven gas passes through the washing equipment to obtain tar and phenol water, and then through the organic matter separation equipment to obtain coke oven gas with high calorific value and the mixed gas of hydrogen, nitrogen, carbon monoxide and carbon dioxide. The tar phenol water is obtained by extracting phenol and tar to obtain tar, phenol and Oil-poor phenol water, part of oil-poor phenol water is returned to the purification equipment as washing water, and part of oil-poor phenol water is vaporized and enters the fluidized bed as a gasification agent; part of the high...

Embodiment 3

[0025] In this embodiment, a long-flame coal stick is used as a raw material, and the main composition is: 35% fixed carbon, 10% moisture, 46% volatile matter, and 9% ash.

[0026] (1) Long-flame coal coal sticks go through the drying layer to remove water to less than 2%, and then enter the dry distillation layer to remove volatile matter to 8%, and obtain hot coke oven gas and hot semi-coke at the same time. The hot coke oven gas passes through the washing equipment to obtain tar and phenol water, and then through the organic matter separation equipment to obtain coke oven gas with high calorific value and the mixed gas of hydrogen, nitrogen, carbon monoxide and carbon dioxide. The tar phenol water is obtained by extracting phenol and tar to obtain tar, phenol and Oil-poor phenol water, part of oil-poor phenol water is returned to the purification equipment as washing water, and part of oil-poor phenol water is vaporized and enters the fluidized bed as a gasification agent; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com