Patents

Literature

39results about How to "Reduce cellulite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

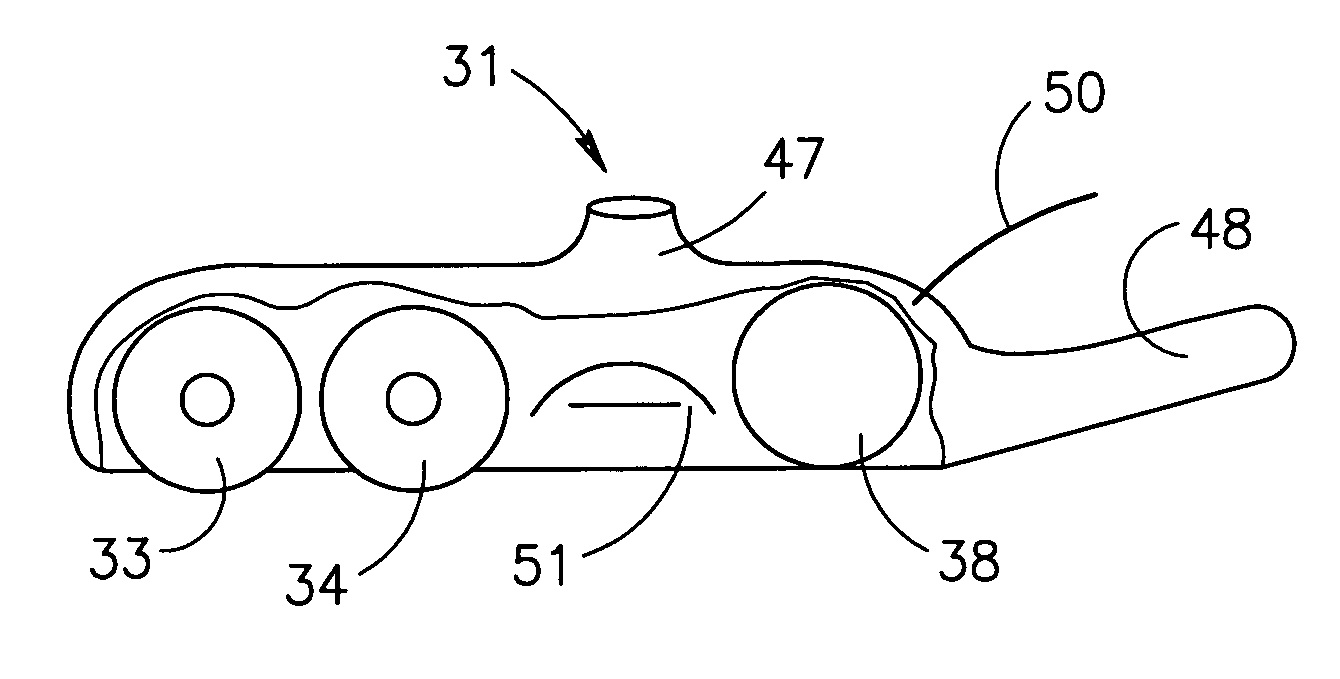

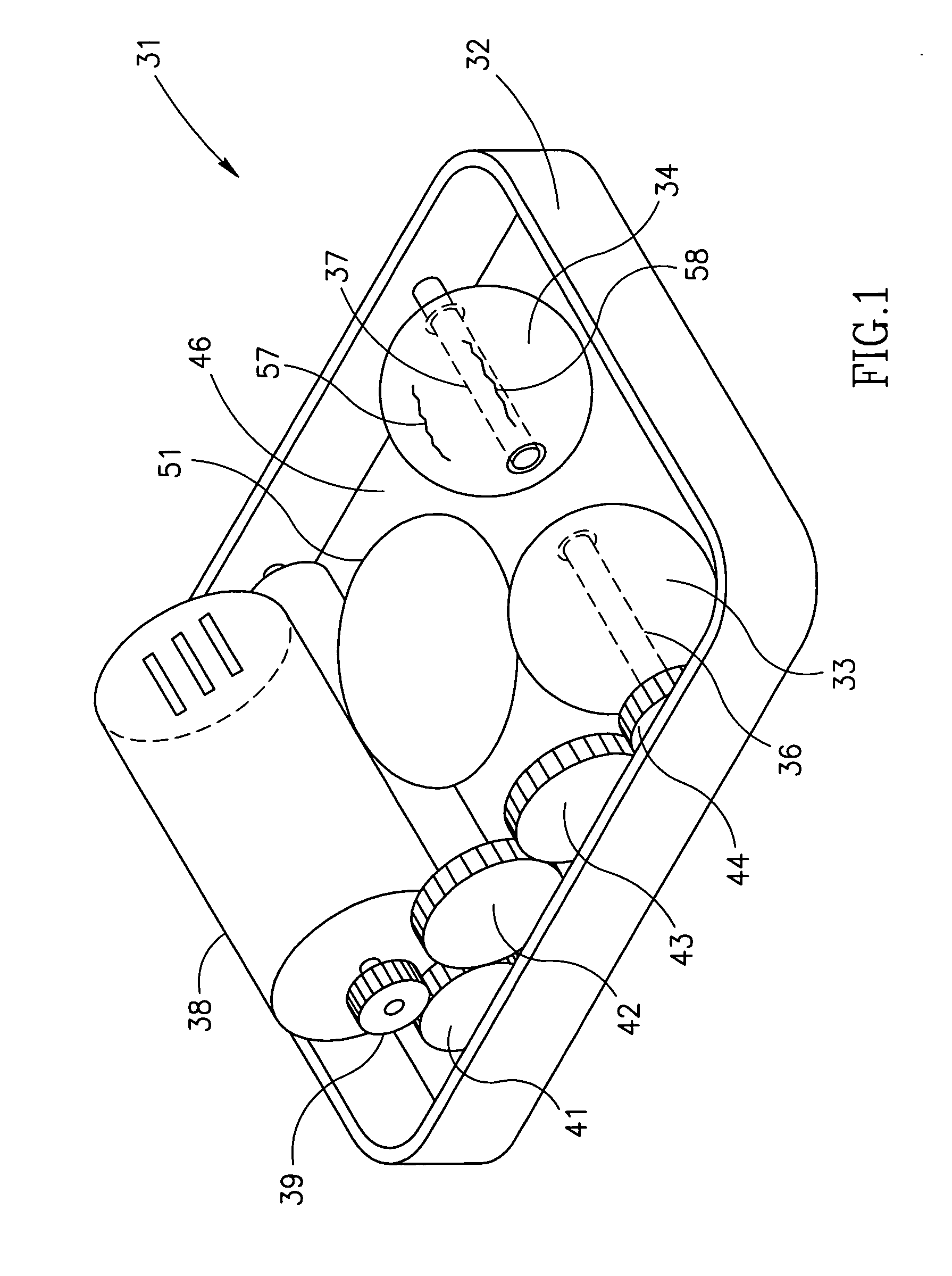

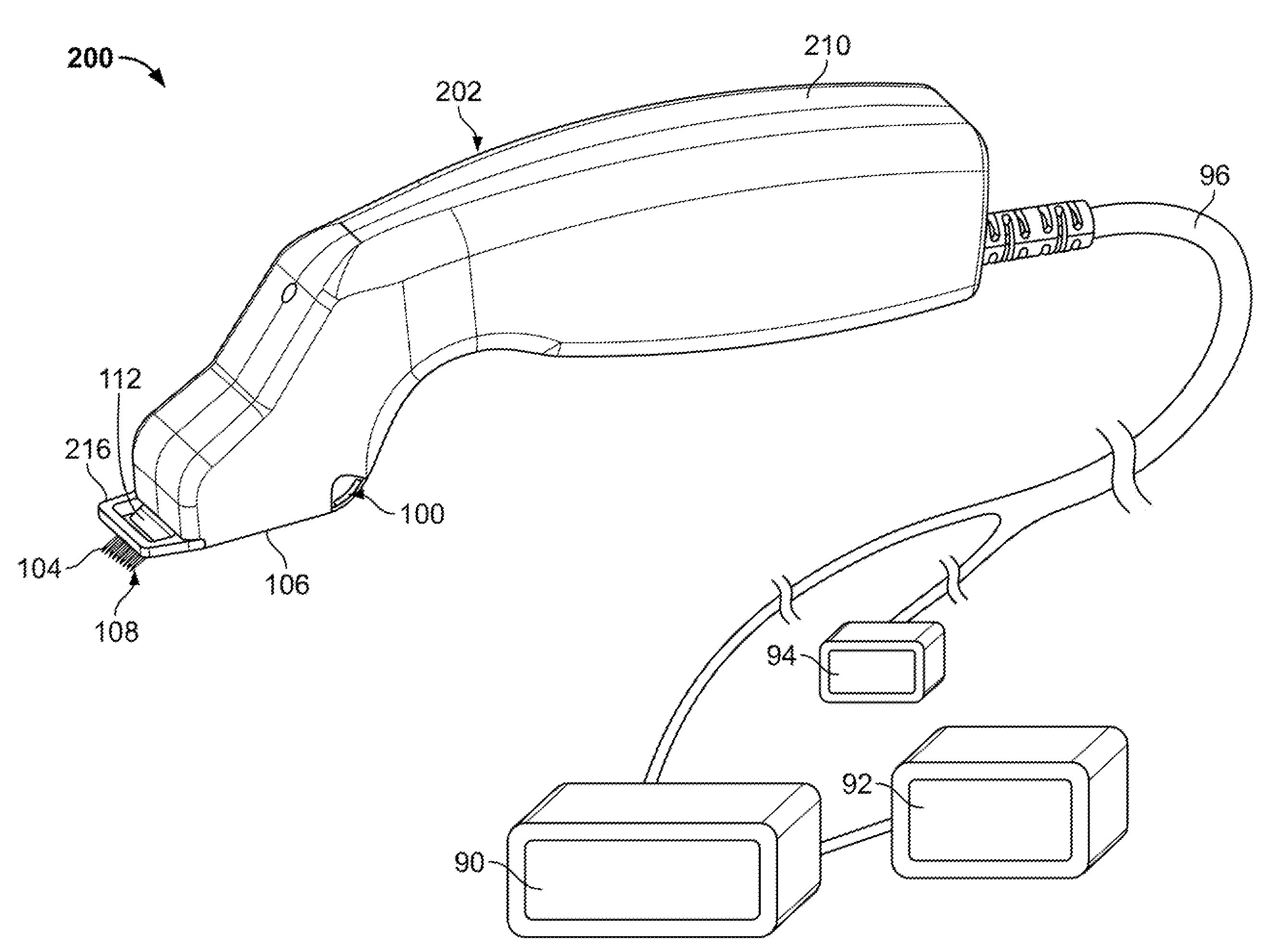

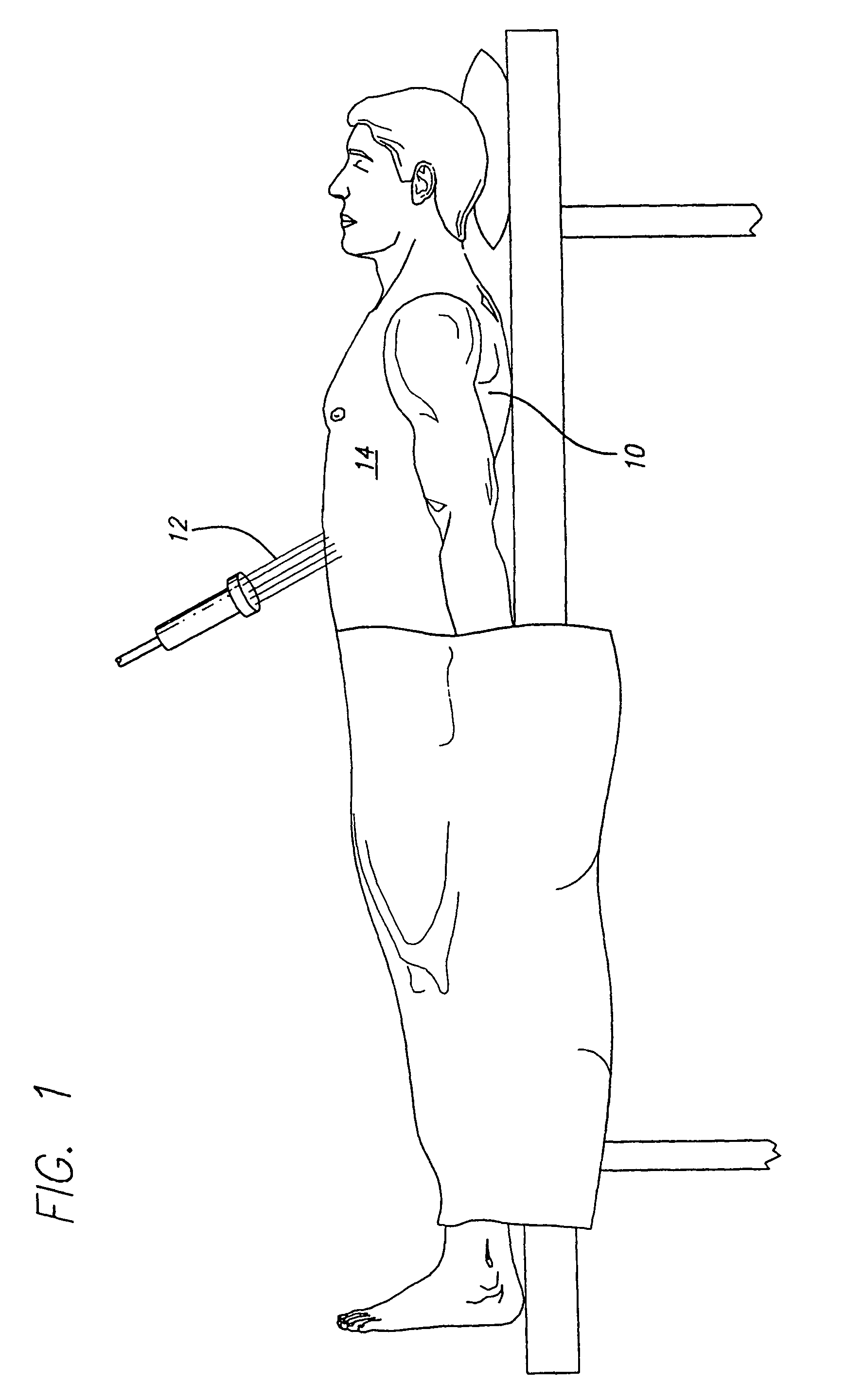

Method for reducing the appearance of skin cellulites using vacuum radiant heat and mechanical manipulation

InactiveUS6926683B1Effectively combat effectReducing and combating celluliteAnti-cellulite devicesPneumatic massageMedicineRadiant heat

A massaging apparatus that includes at least one massaging element in a housing and extending therefrom for use in manipulating a subject's tissue and further including a radiant heat source.

Owner:TENSOR TECH

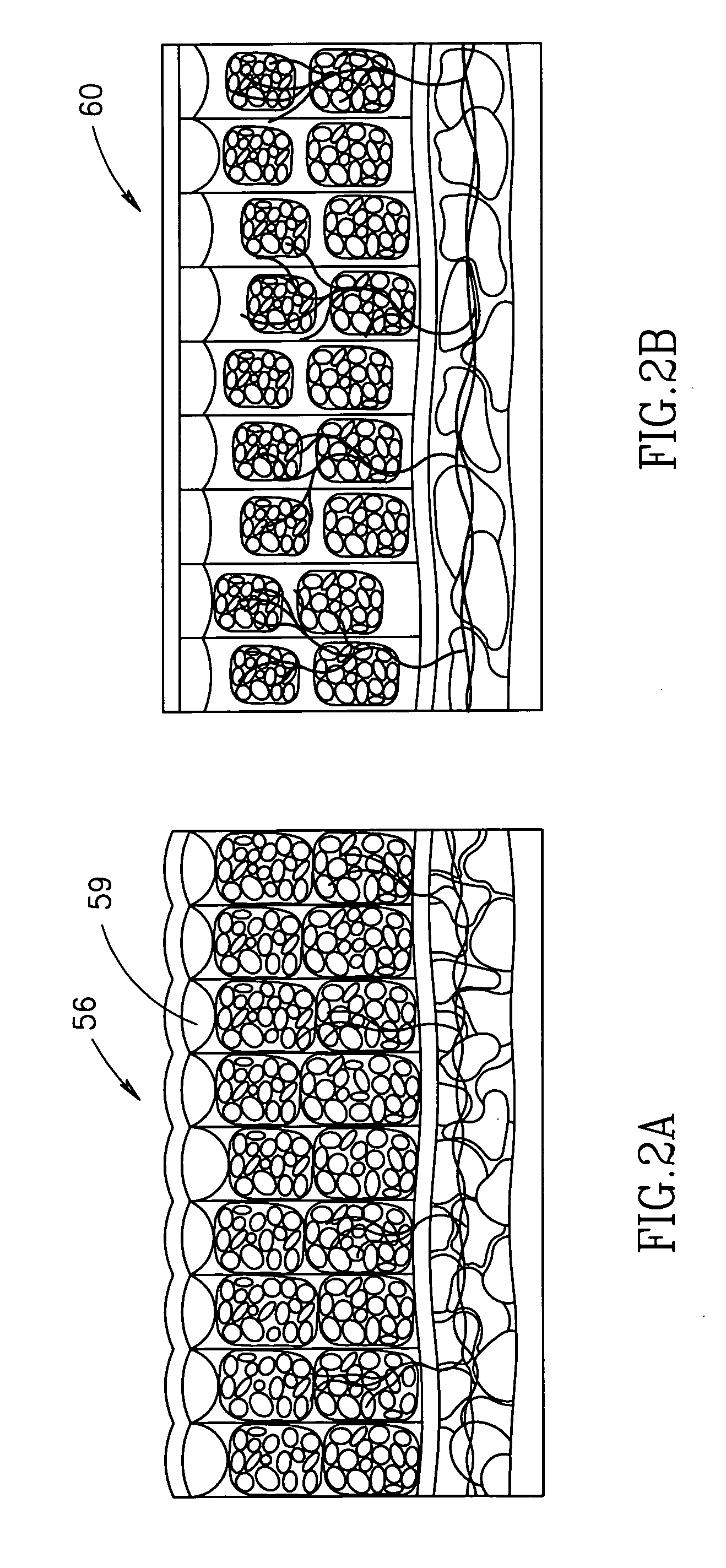

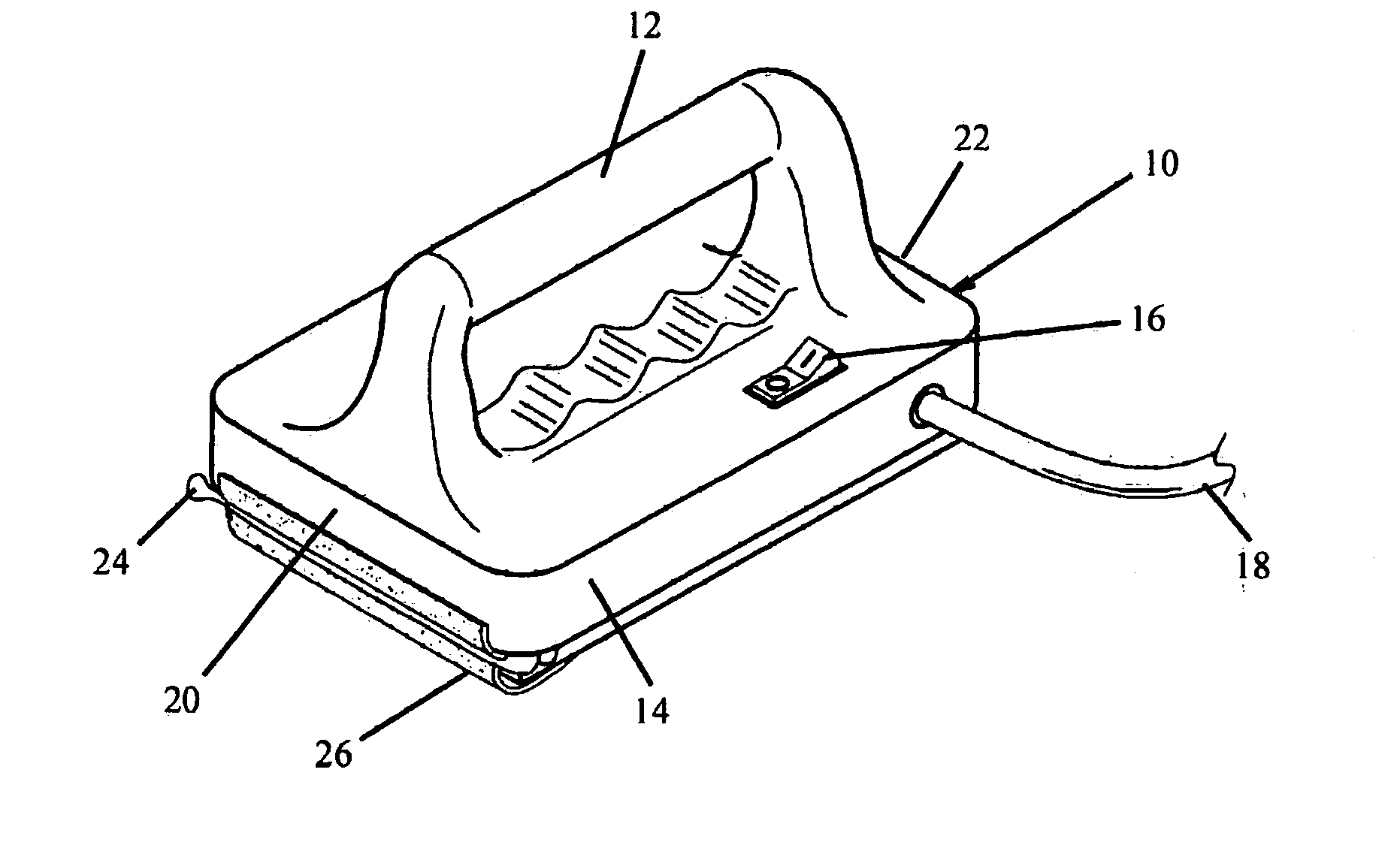

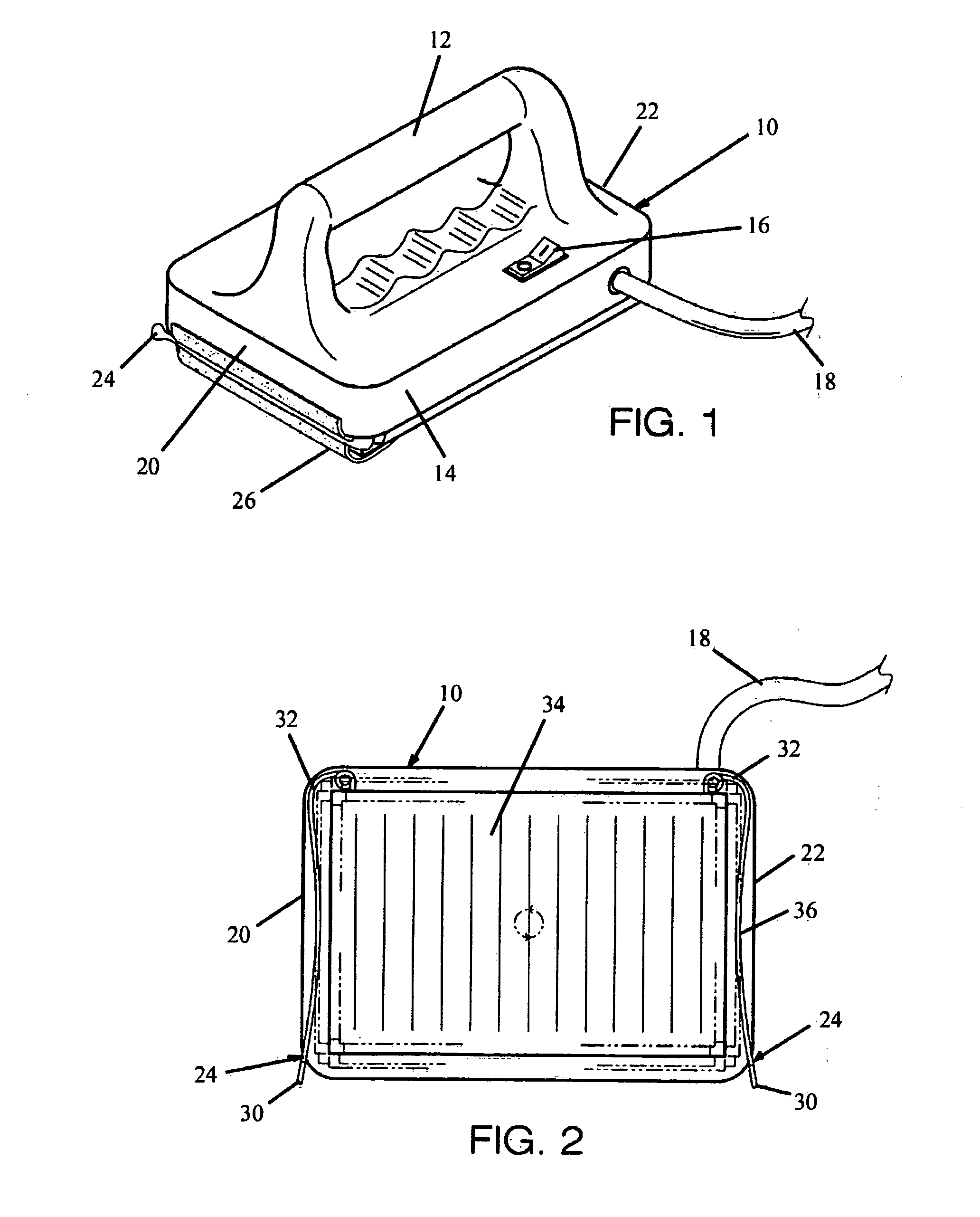

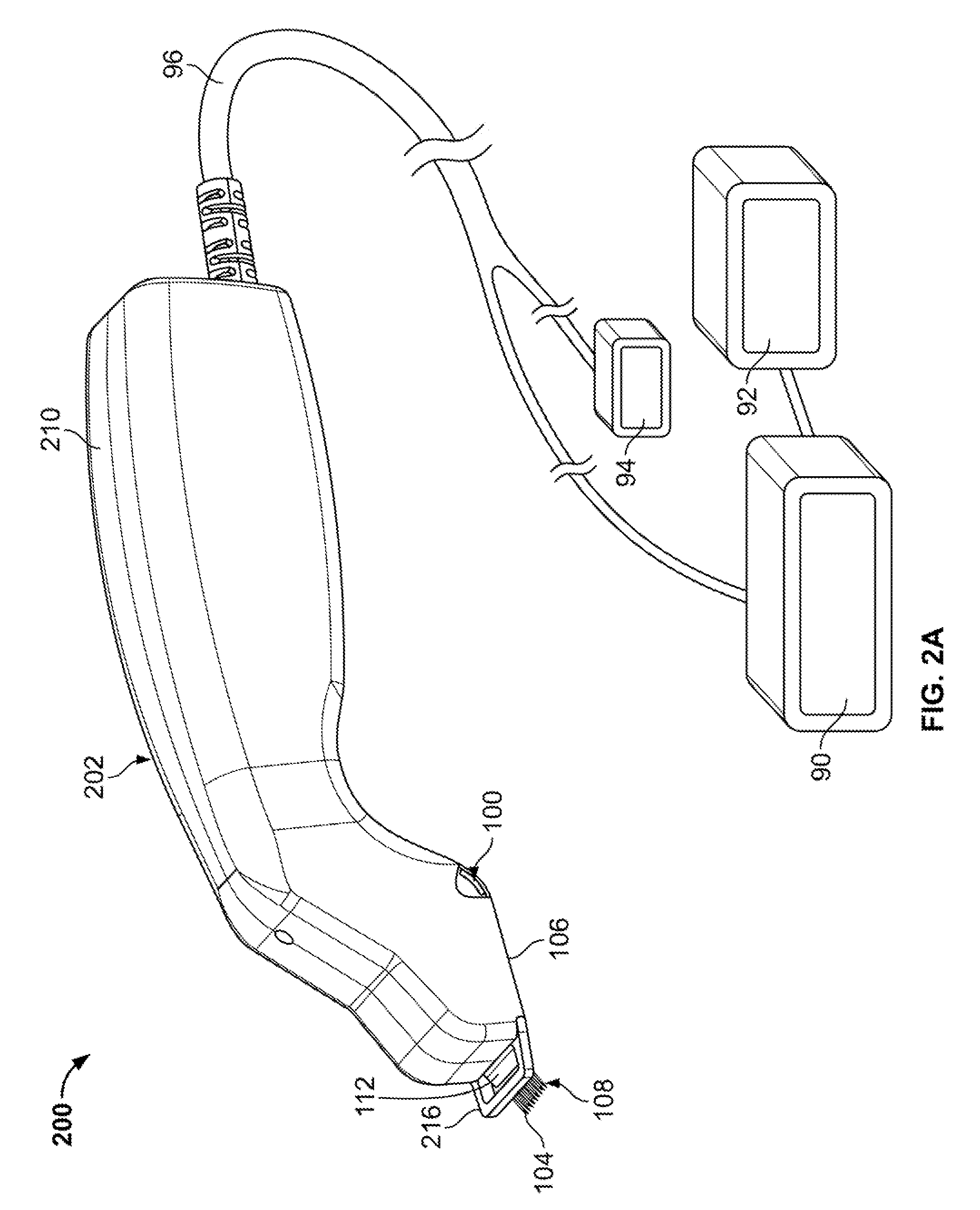

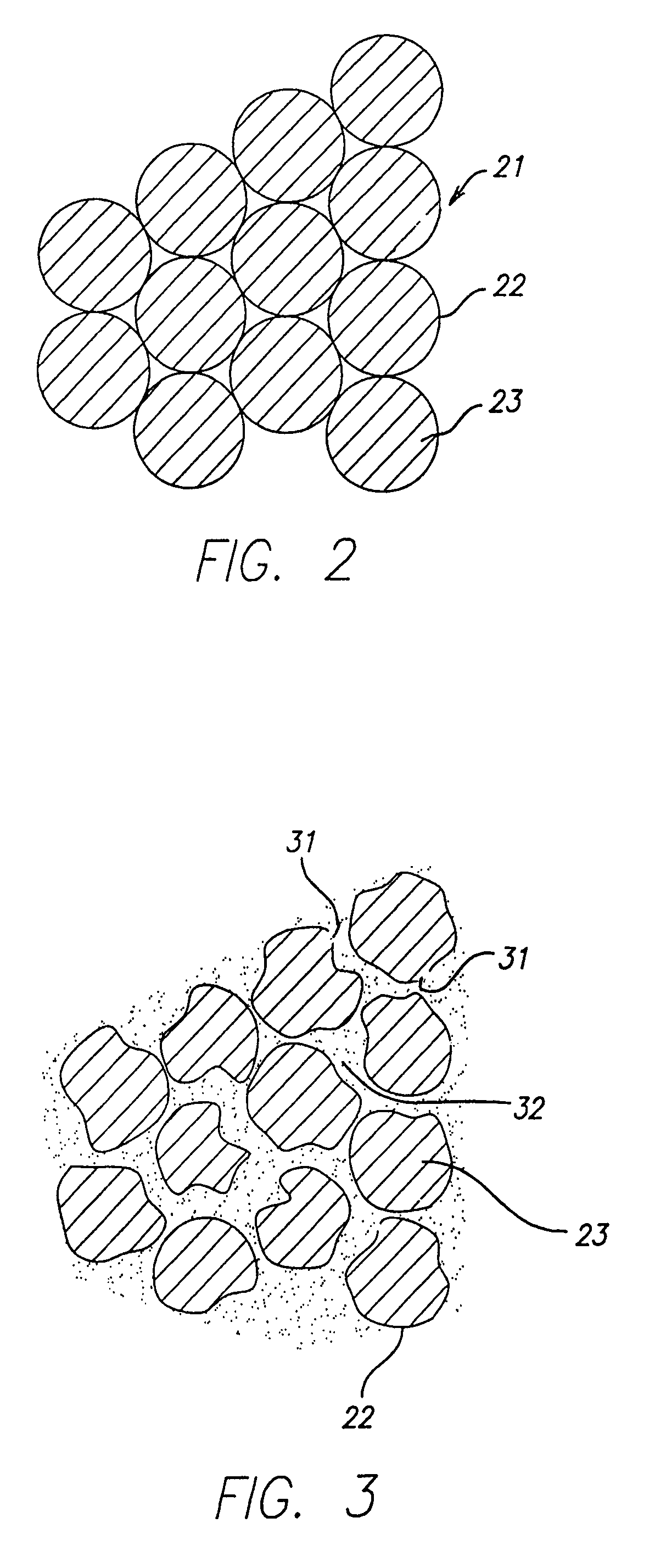

Skin treatment device and method for exfoliation and cellulite reduction

A novel device and method for use in providing multiple cosmetic treatments is disclosed, where a sanding tool is provided with sanding surfaces for use in imparting exfoliation, depilation, and cellulite treatments on the skin of a person. Select sanding surfaces are use for each of the exfoliation, depilation and cellulite treatments with the sanding action being generated by the orbital sanding effects of a palm sander. Specifically, a 100 grit (CAMI) sanding paper is used for exfoliation, a 180 grit (AMI) sanding paper is used for depilation, and the sander pad of the sanding tool of the present invention is used directly on the skin for cellulite reduction.

Owner:FERRARA JOELLA ANN

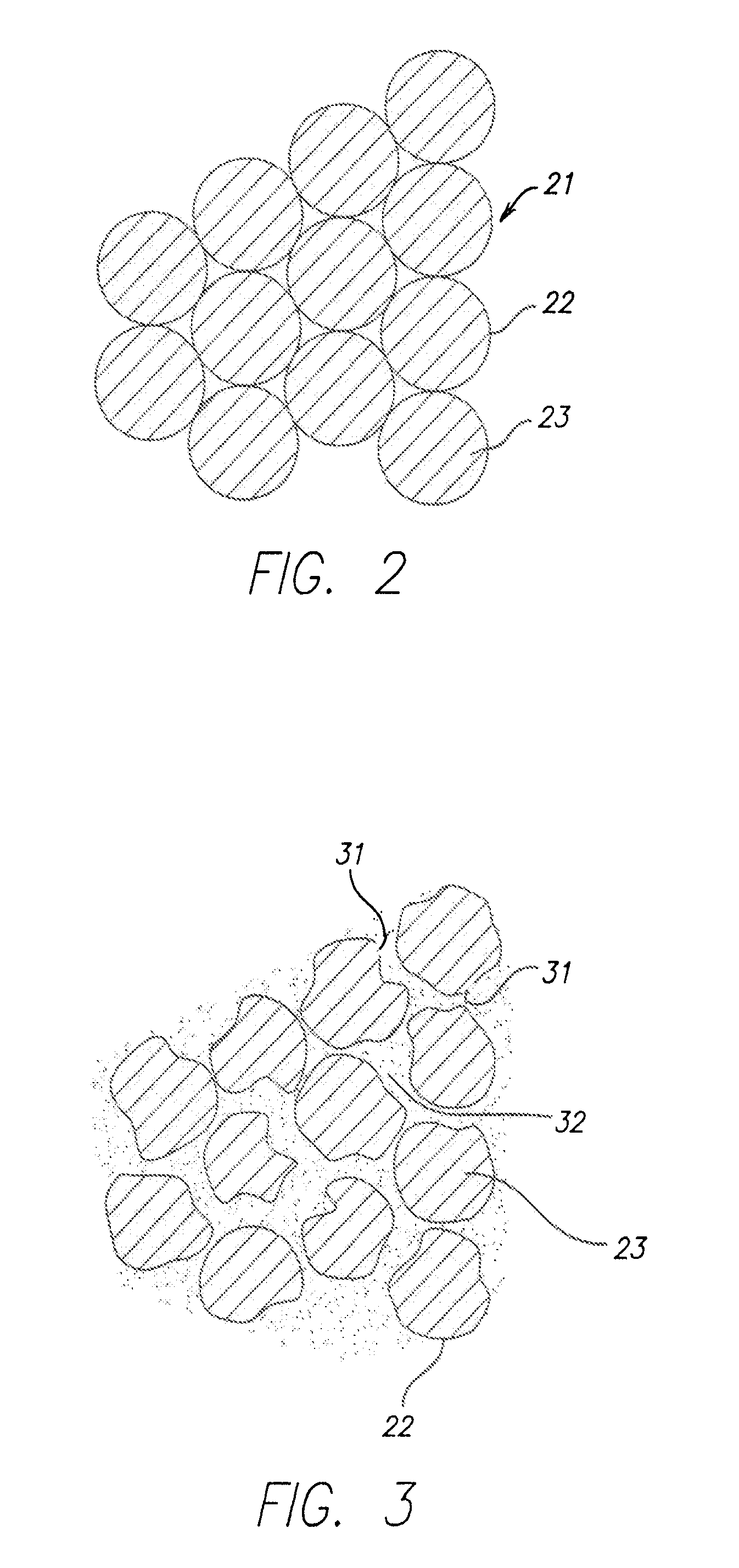

Microvesicles

InactiveUS20110014251A1Promote absorptionEasy to storeNervous disorderToilet preparationsInducerPopulation

A method of producing a population of differentiated cells comprising: a) inducing differentiation in a first population of cells by applying an inducer to said cells, b) harvesting microvesicles produced from first population of cells, and c) inducing differentiation in a second population of cells by applying said microvesicles or a derivative thereof to said second population of cells wherein, said first population of cells is autologous to said second population of cells and wherein the inducer applied to said first population of cells is not present in said second population of cells or is only present in trace amounts. Also related methods of producing microvesicles, methods of medical and / or cosmetic treatment and related products and uses.

Owner:LYDAC NEUROSCIENCE LTD

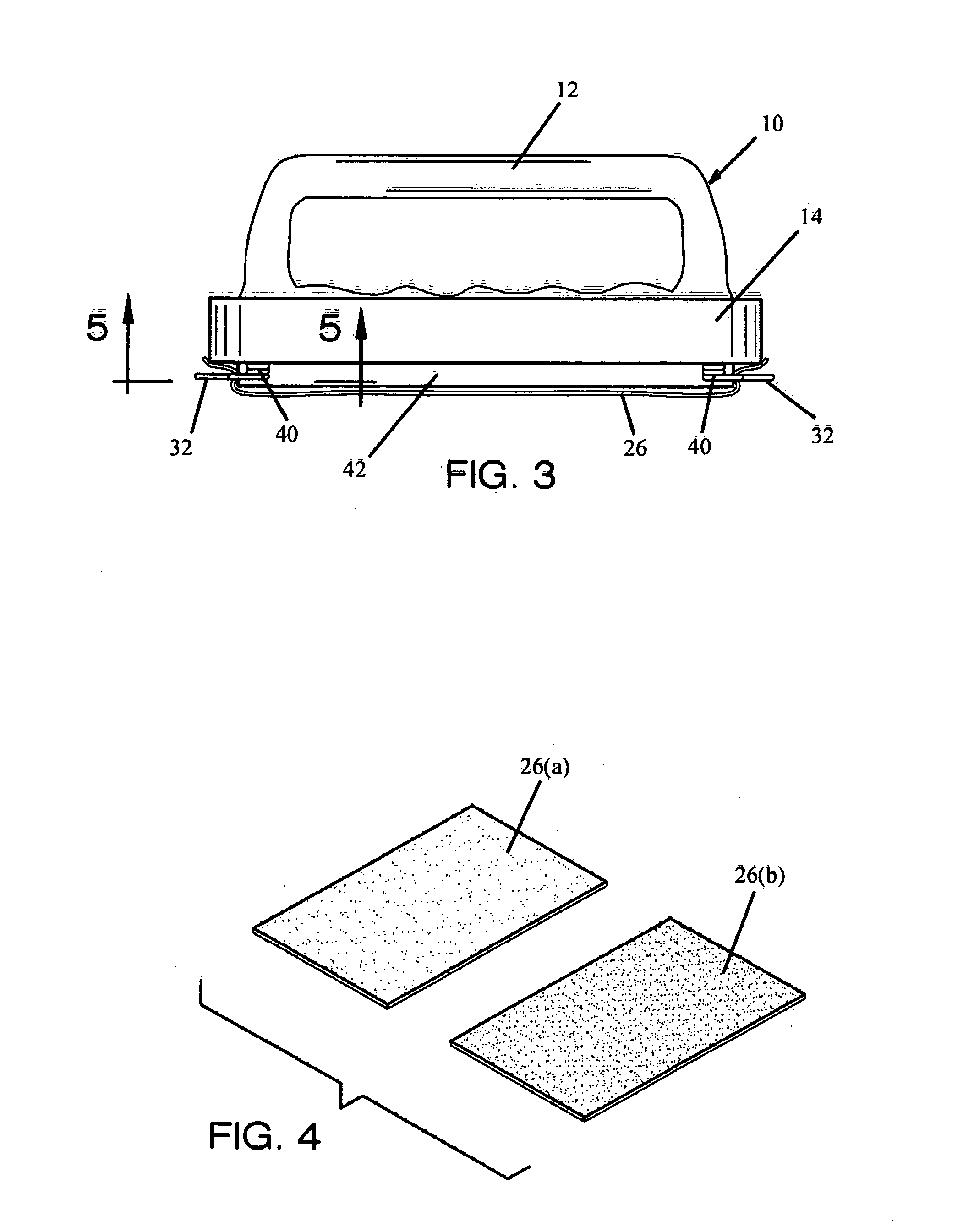

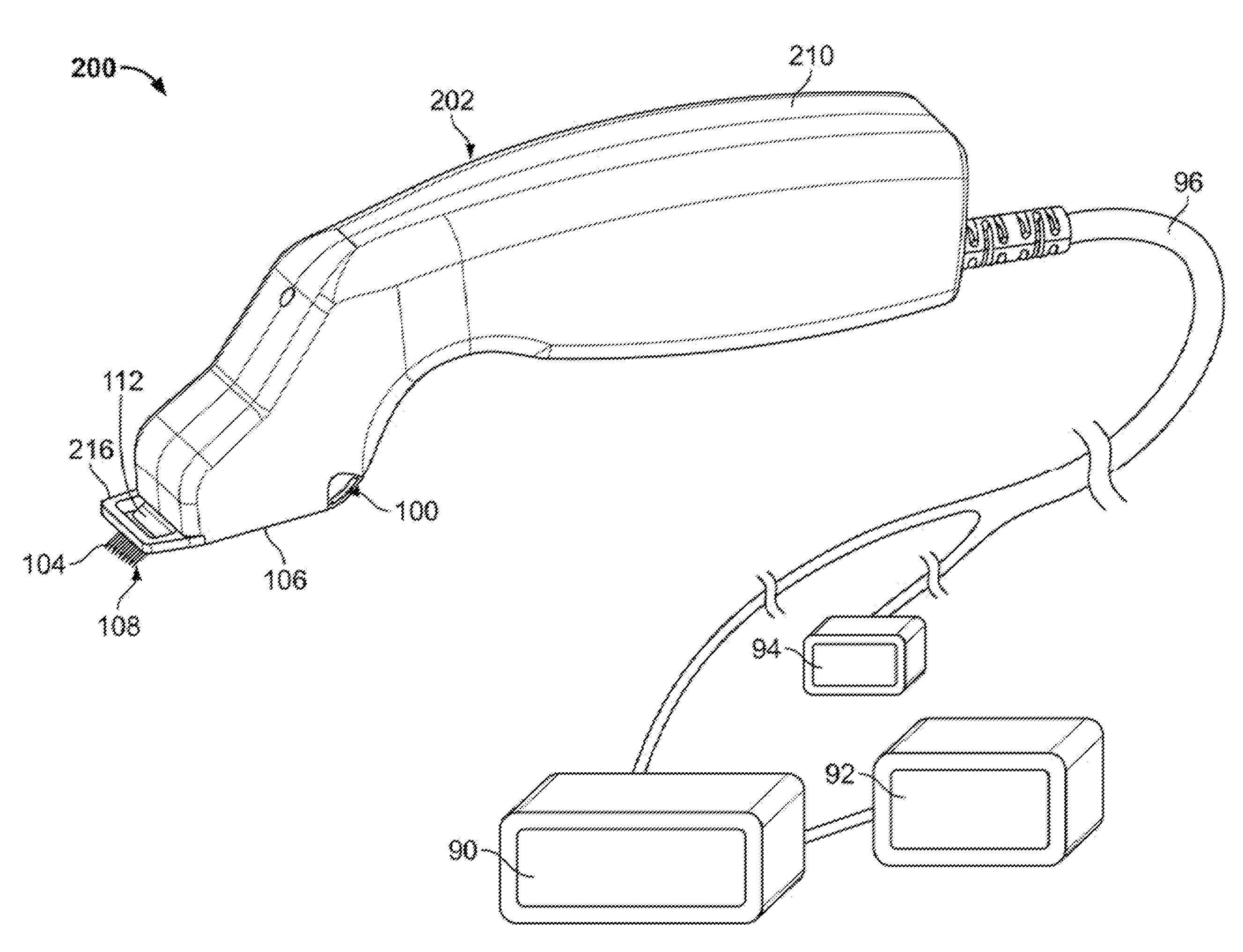

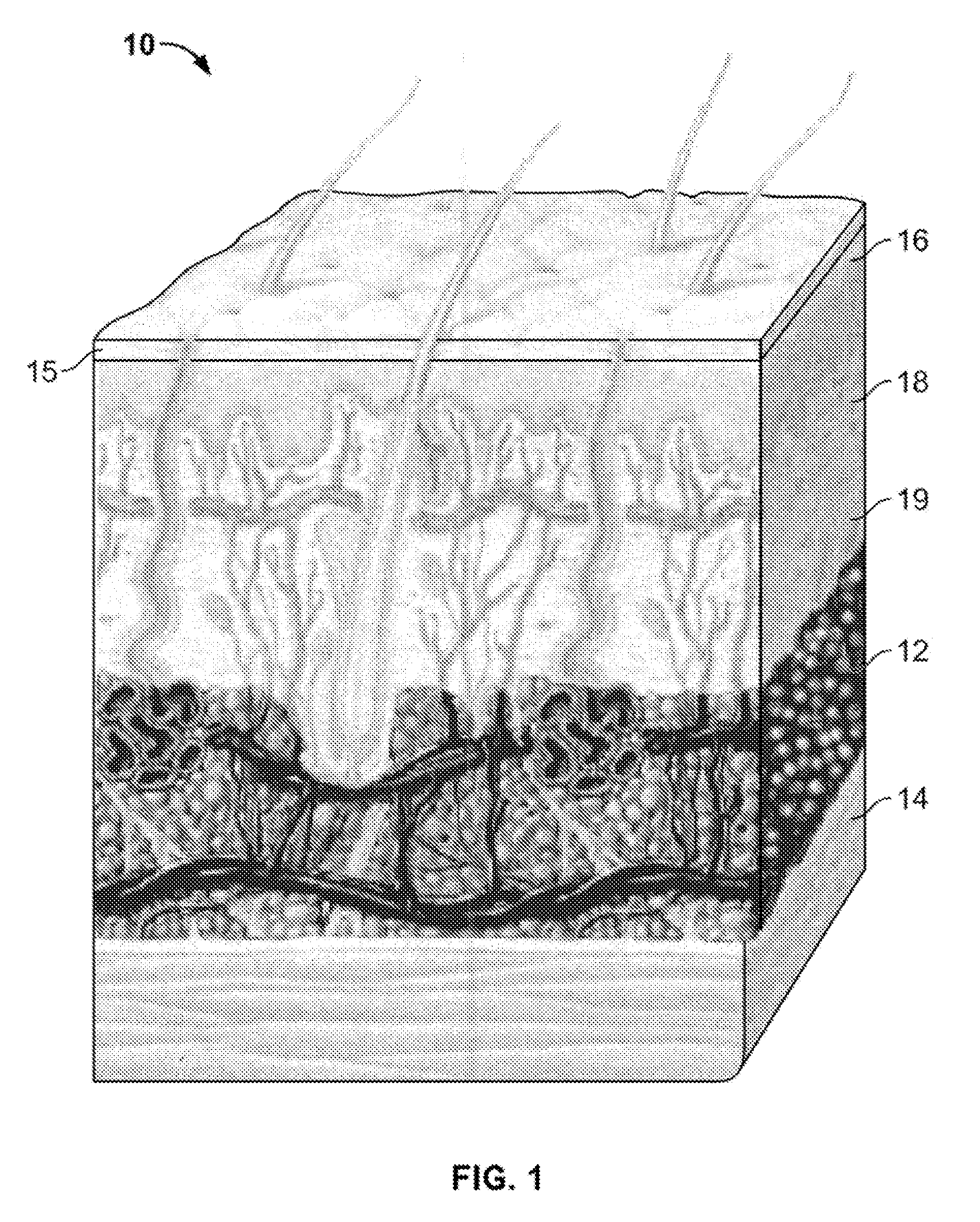

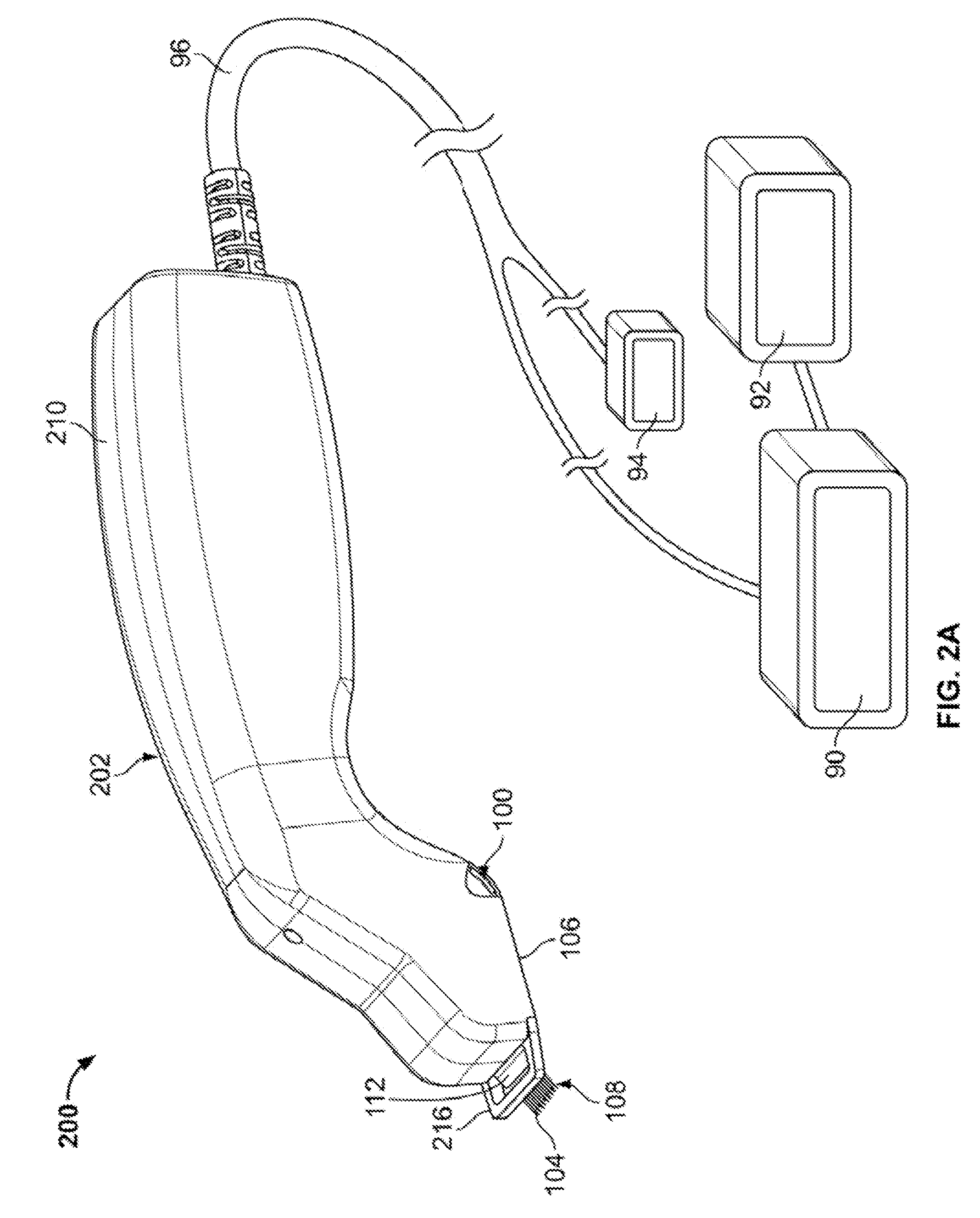

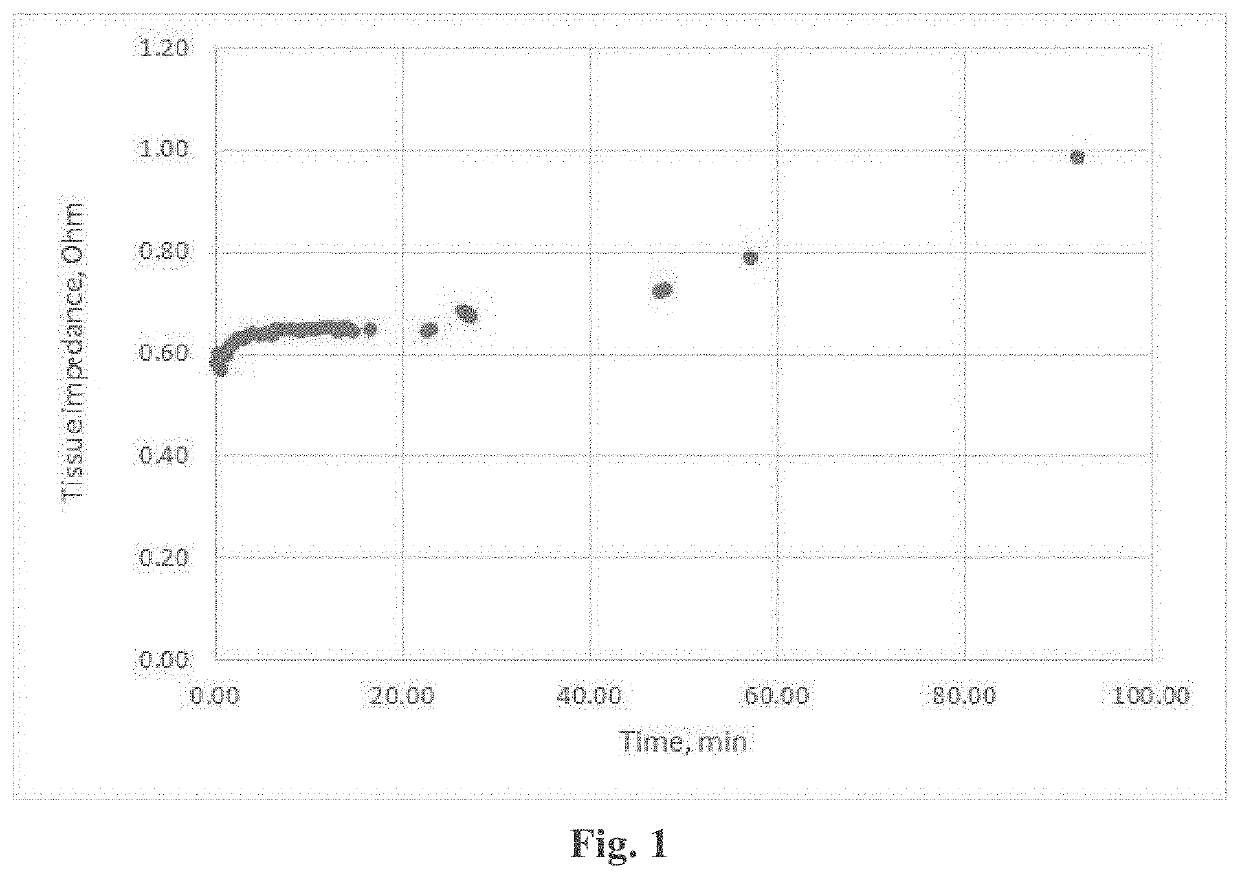

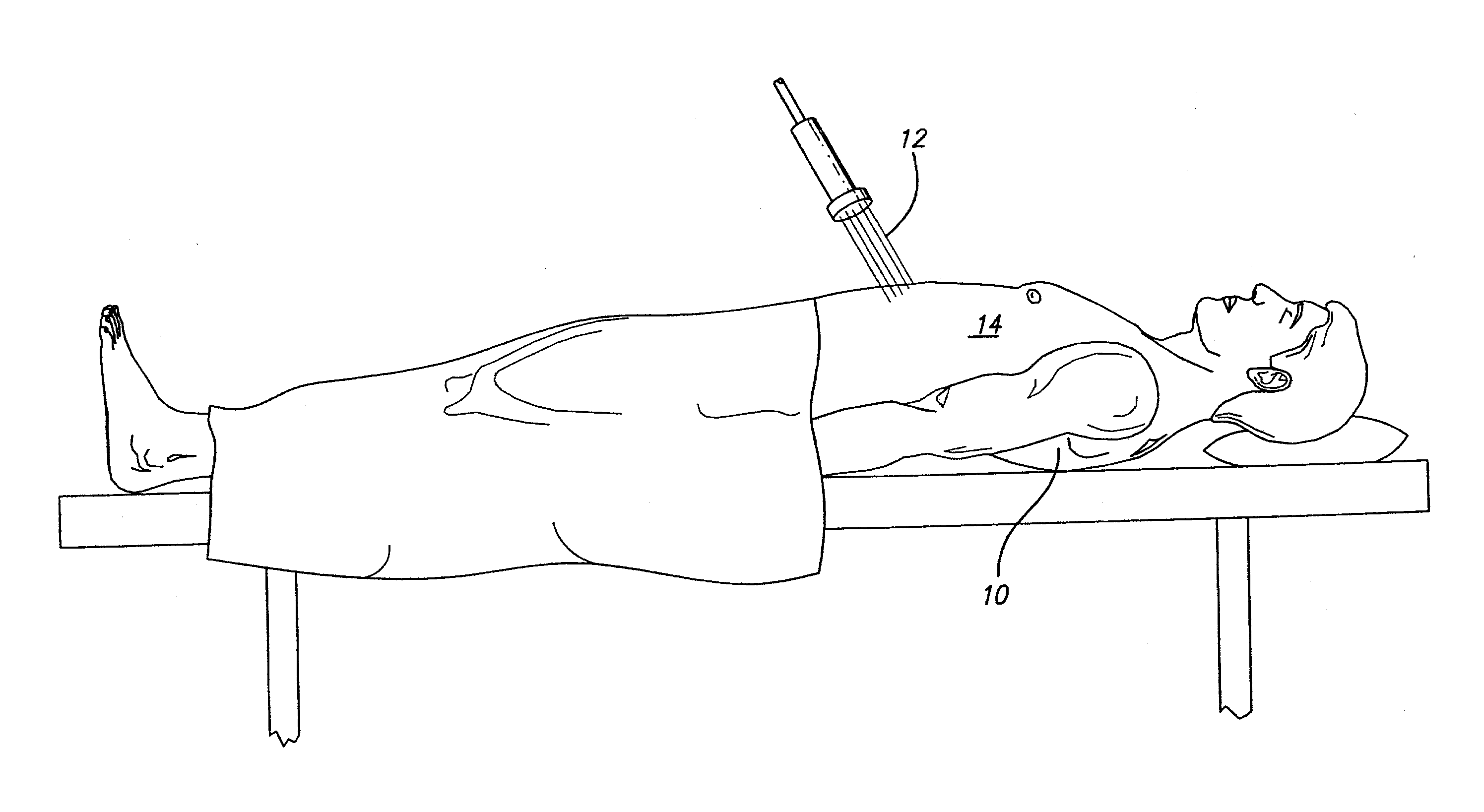

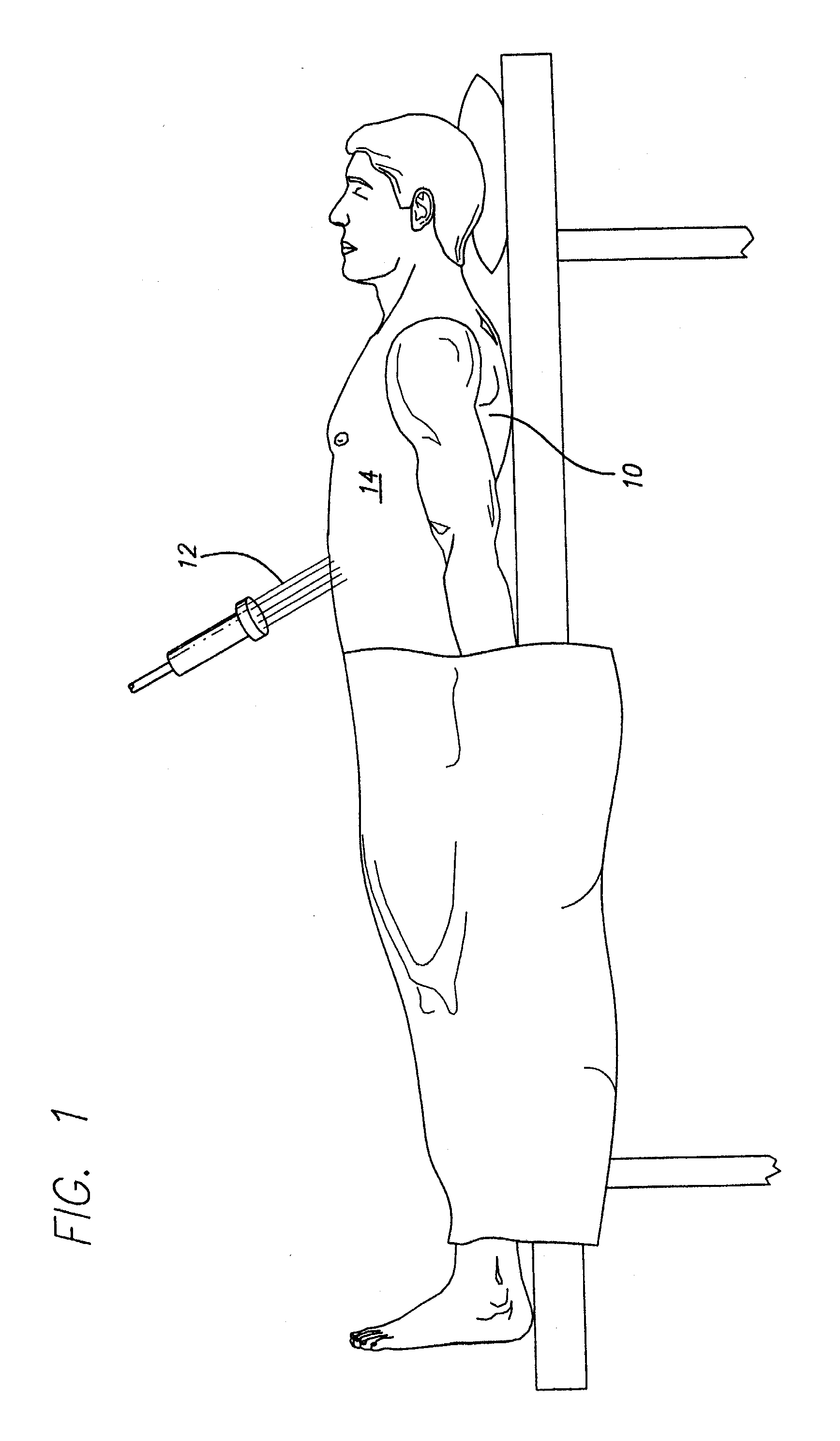

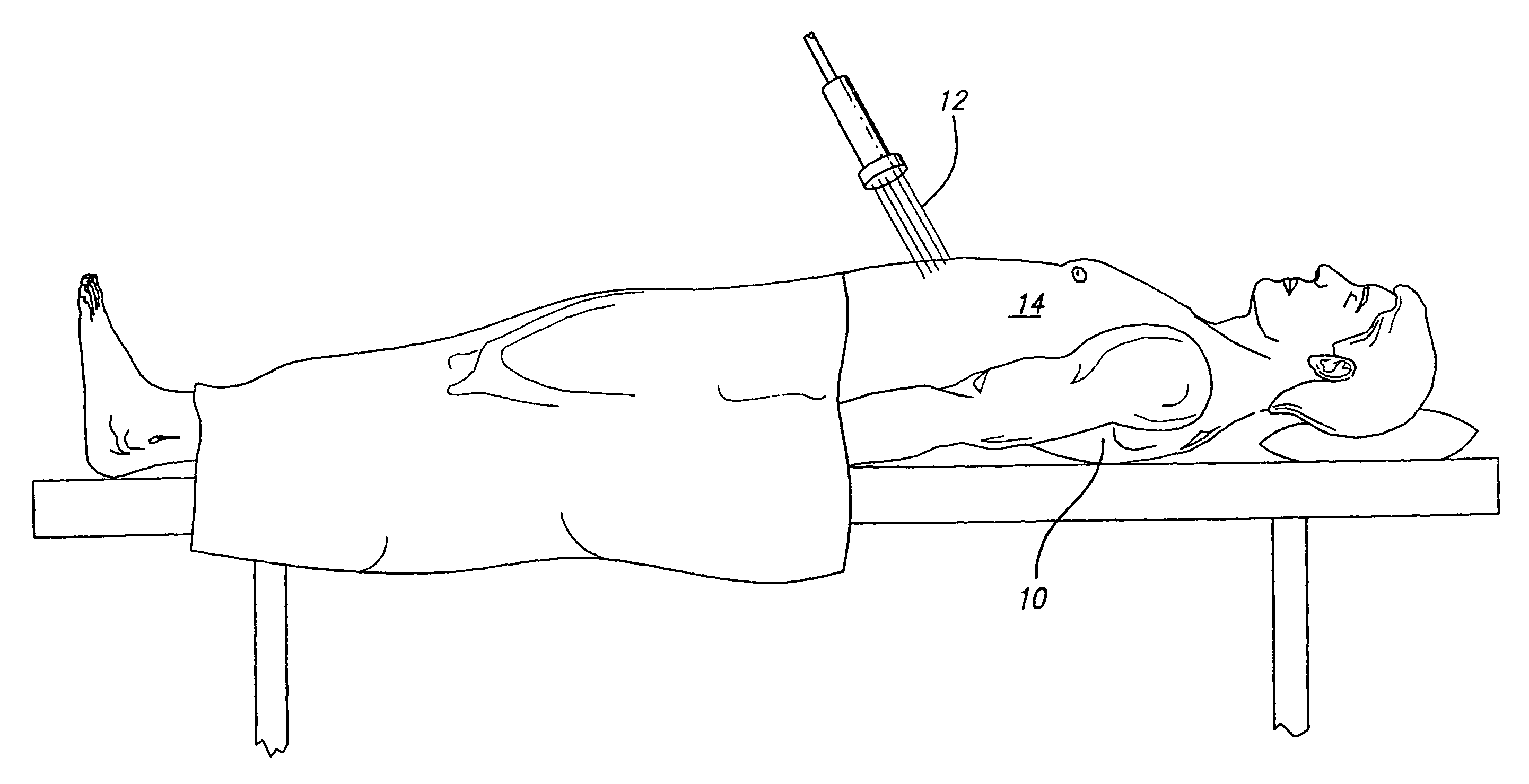

Devices and methods for percutaneous energy delivery

ActiveUS20100010486A1Avoid energyGood lookingUltrasound therapySurgical needlesEnergy minimizationBiomedical engineering

The invention provides a system and method for percutaneous energy delivery in an effective, manner using one or more probes. Additional variations of the system include array of probes configured to minimize the energy required to produce the desired effect.

Owner:SYNERON MEDICAL LTD

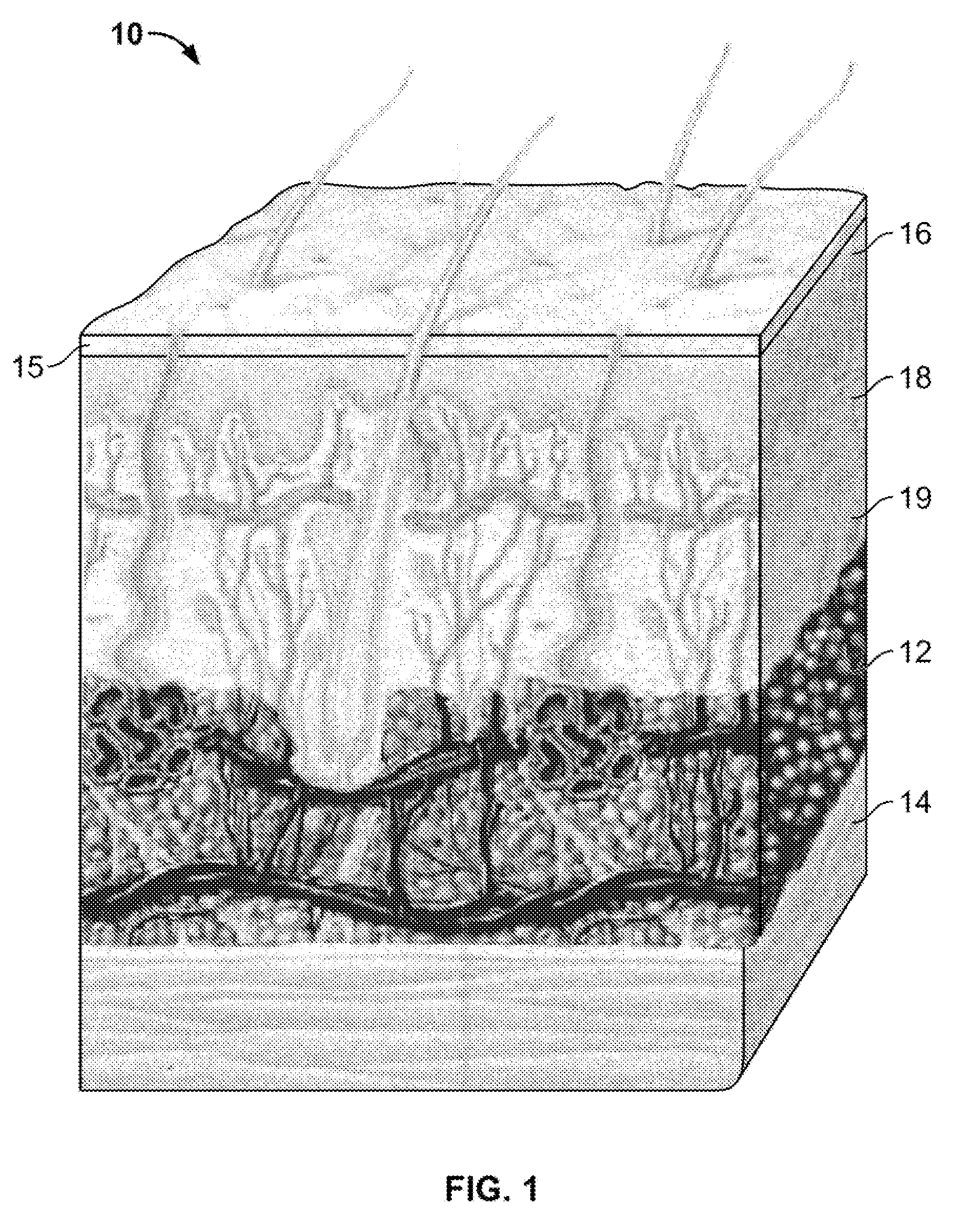

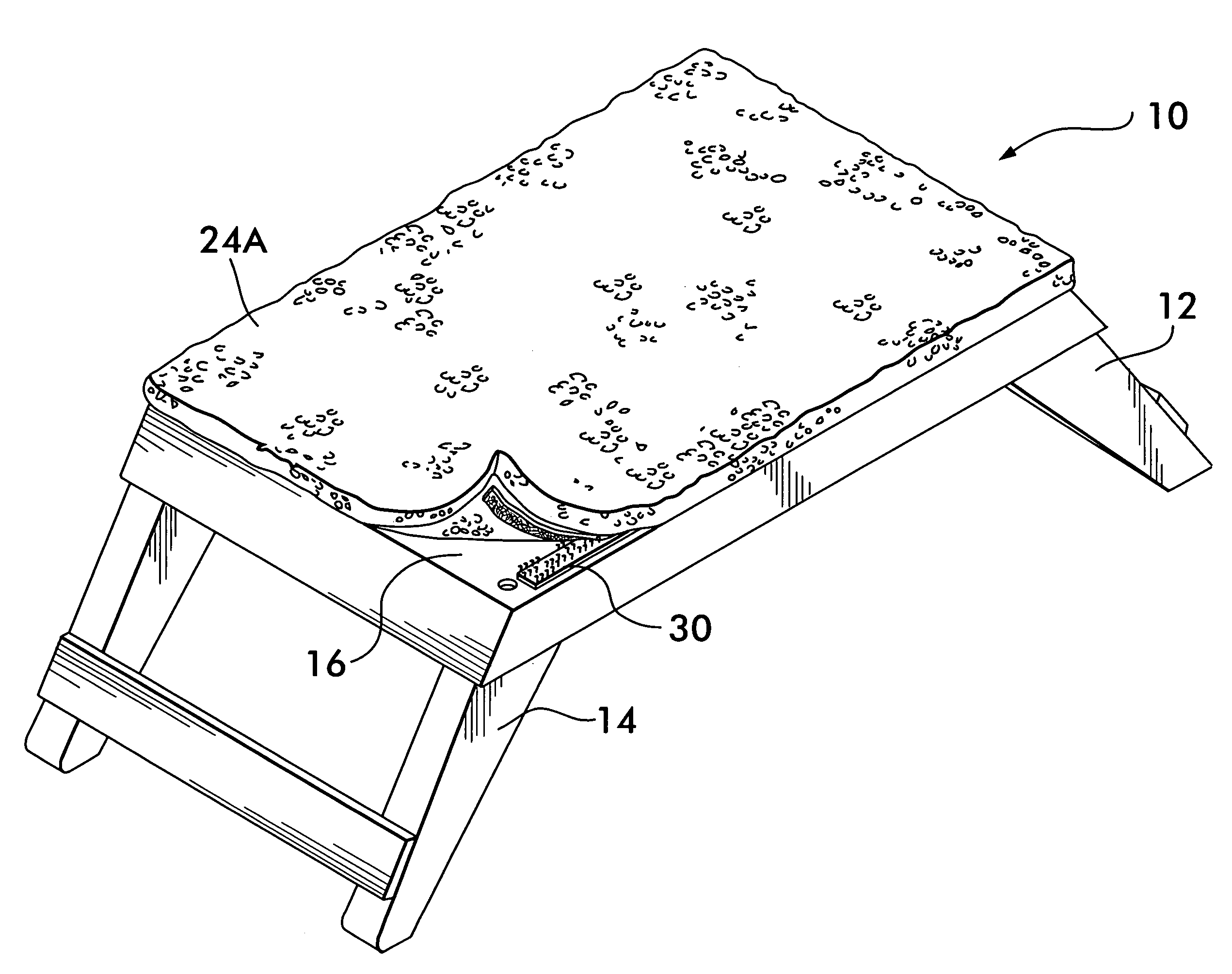

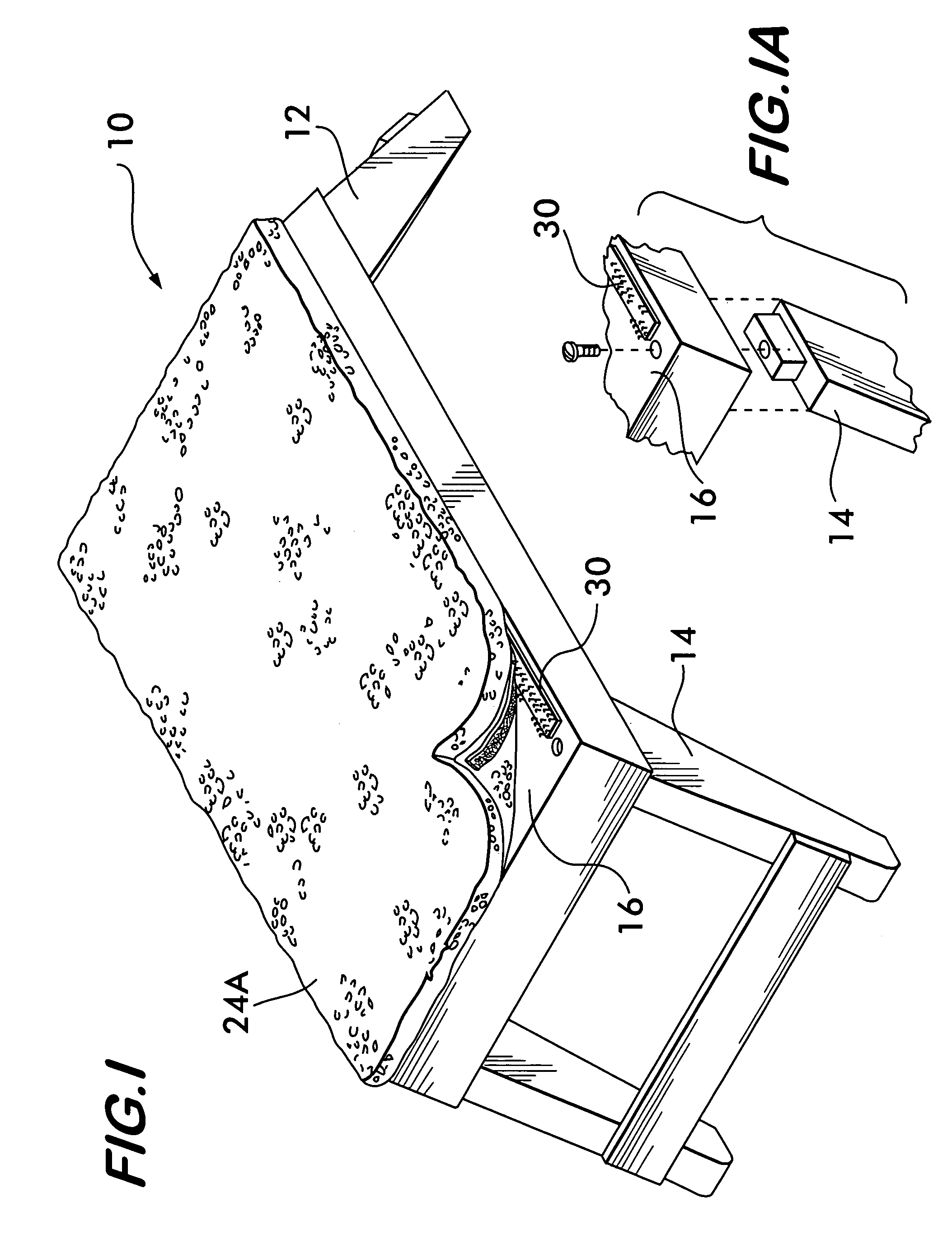

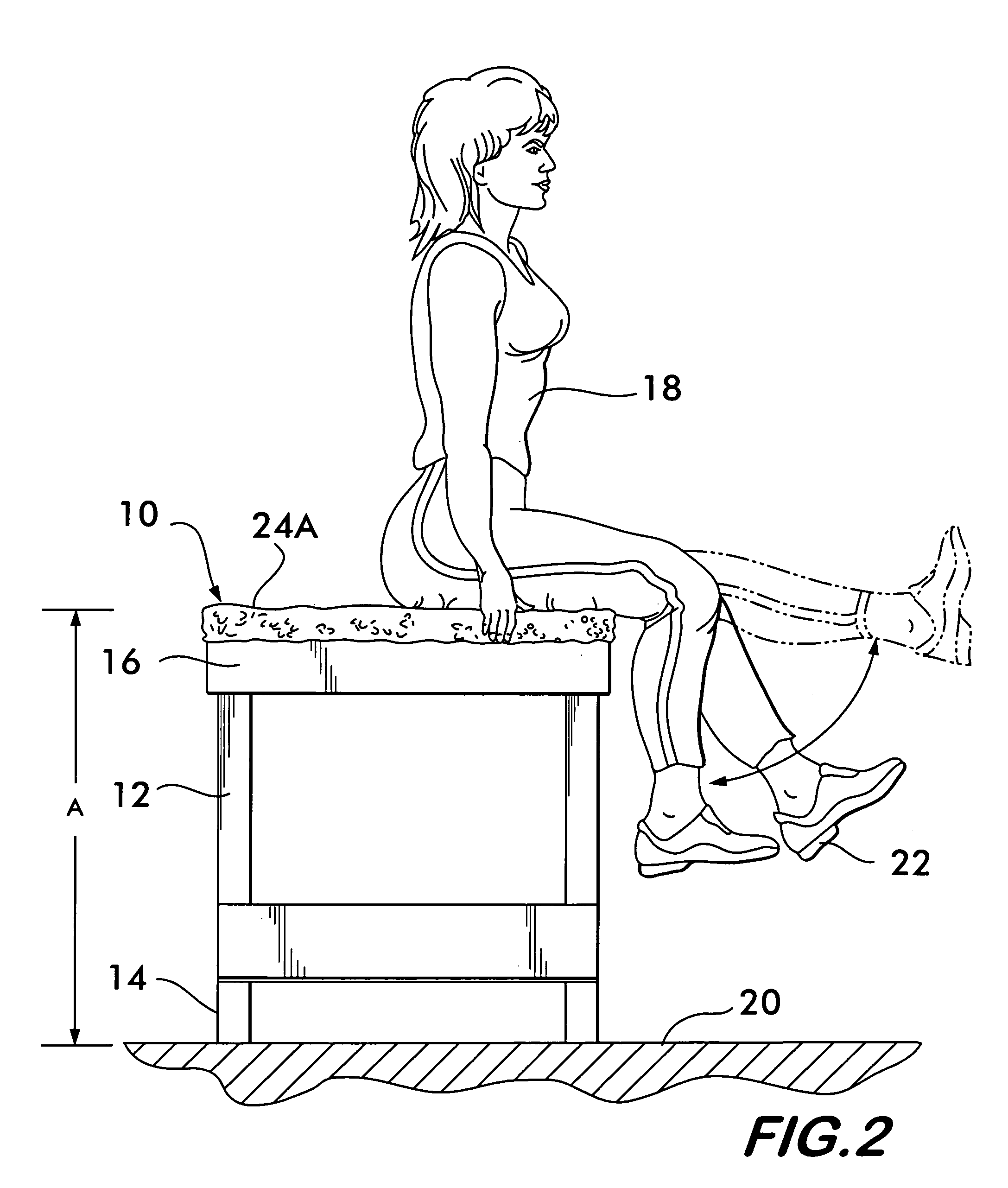

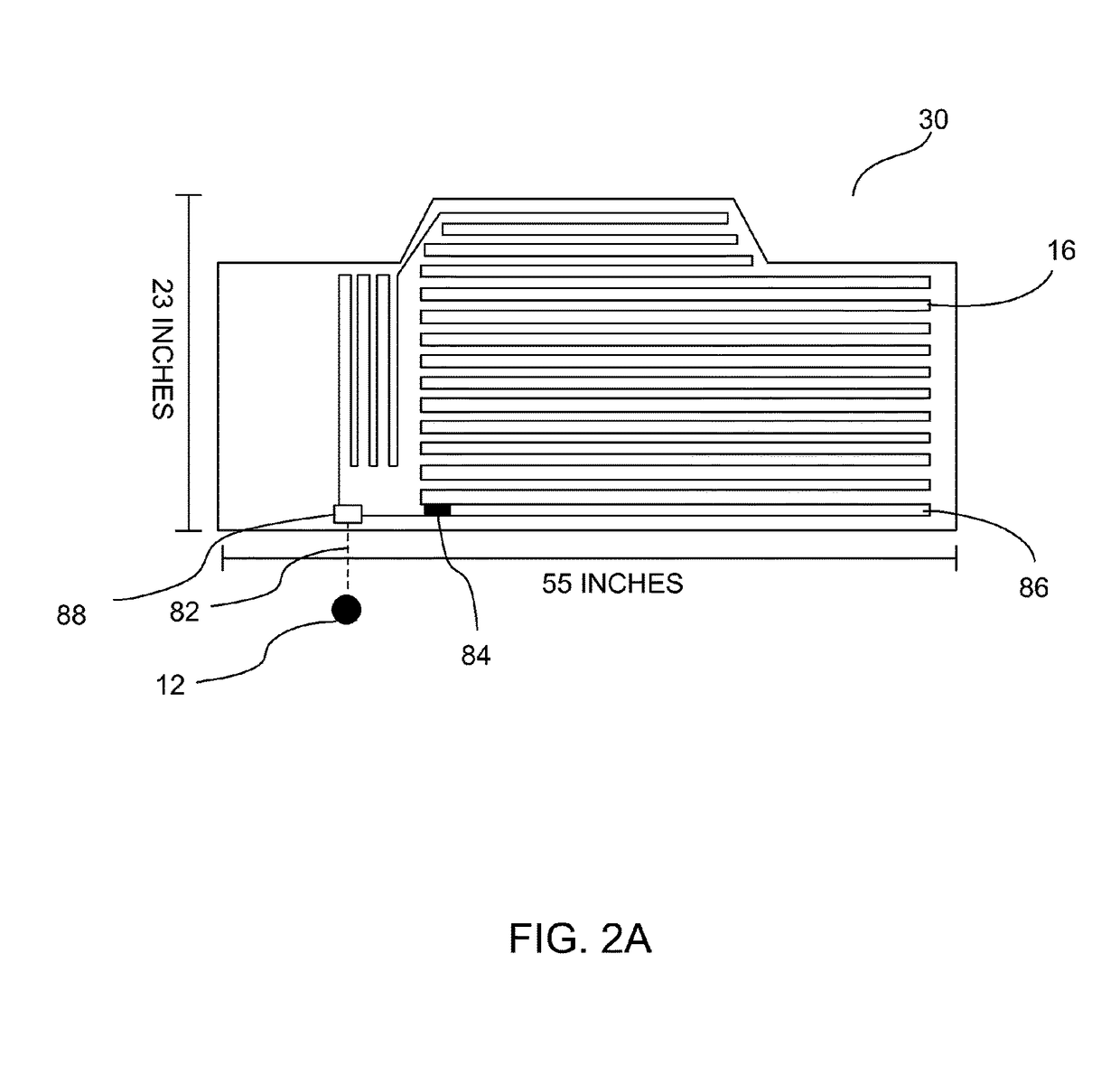

Cellulite reducing bench

InactiveUS6988979B1Decrease viscosityIncrease blood flowAnti-cellulite devicesChiropractic devicesPhysical exerciseEngineering

An exercise bench for performing exercises for the reduction of cellulite which includes a frame having legs and a seating surface attached to the frame to support a body of a user. The seating surface is located at a height above a floor upon which the frame is placed that is greater than about twenty inches such that an average user's feet do not fully touch the surface upon which the frame is placed. A textured surface on the seating surface has a sufficient quantity and height of protuberances to enable reduction of cellulite when skin of the user is placed on the surface, the skin is kept relatively fixed relative to the textured surface, and the body of the user is moved relative to the textured surface such that fat tissue is moved relative to the textured surface. A method of using the bench is also provided.

Owner:TRAINOR WENDI

Methods for applying energy to tissue using isolated energy sources

InactiveUS20100217254A1Avoid energyGood lookingUltrasound therapyDiagnosticsEnergy minimizationEngineering

The invention provides a system and method for percutaneous energy delivery in an effective, manner using one or more probes. Additional variations of the system include array of probes configured to minimize the energy required to produce the desired effect.

Owner:SYNERON MEDICAL LTD

Method for enhanced electro-muscle stimulation

ActiveUS20210283395A1Increase muscle strengthReduce celluliteElectrotherapyLight therapyElectro stimulationEngineering

Owner:INMODE LTD

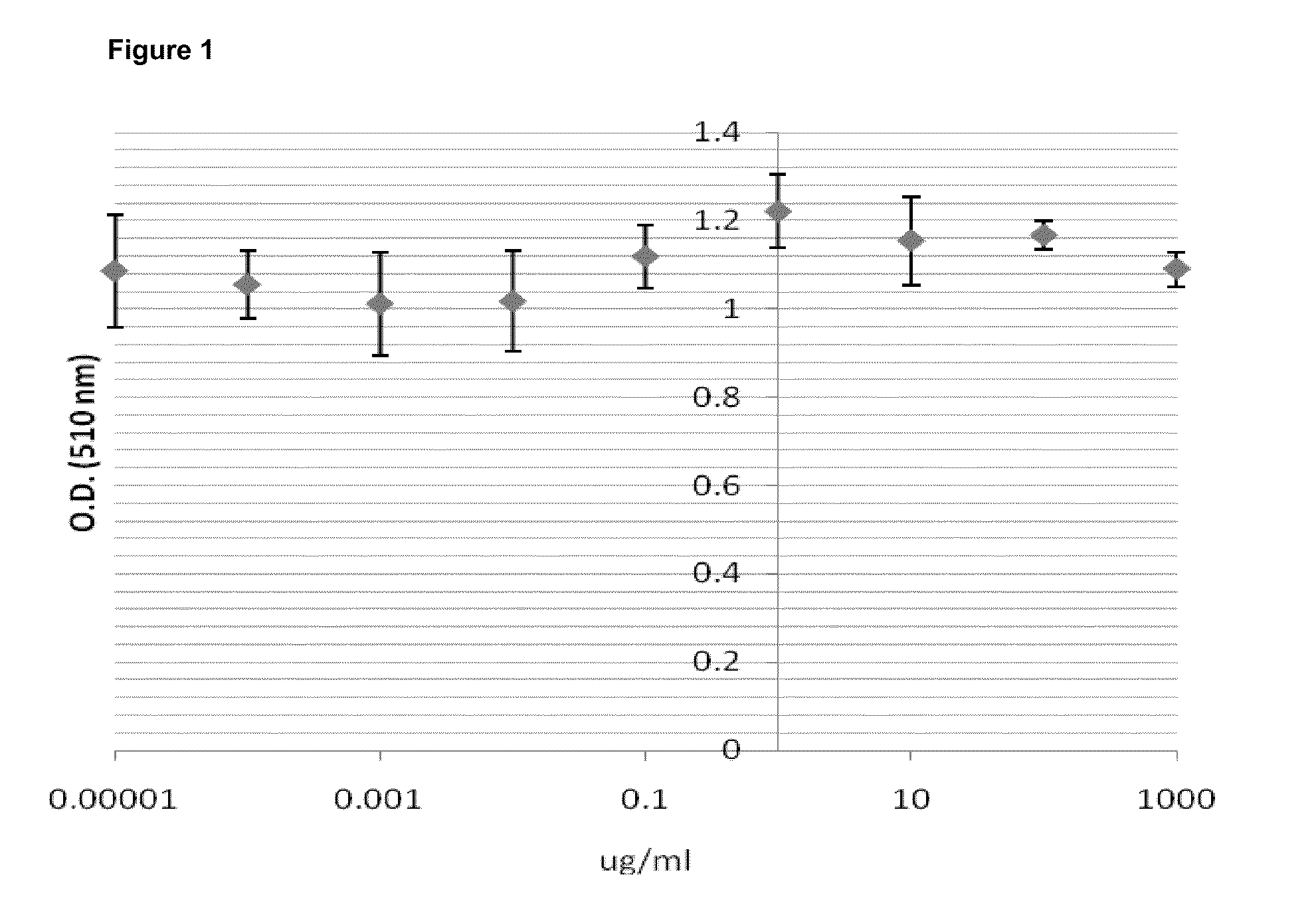

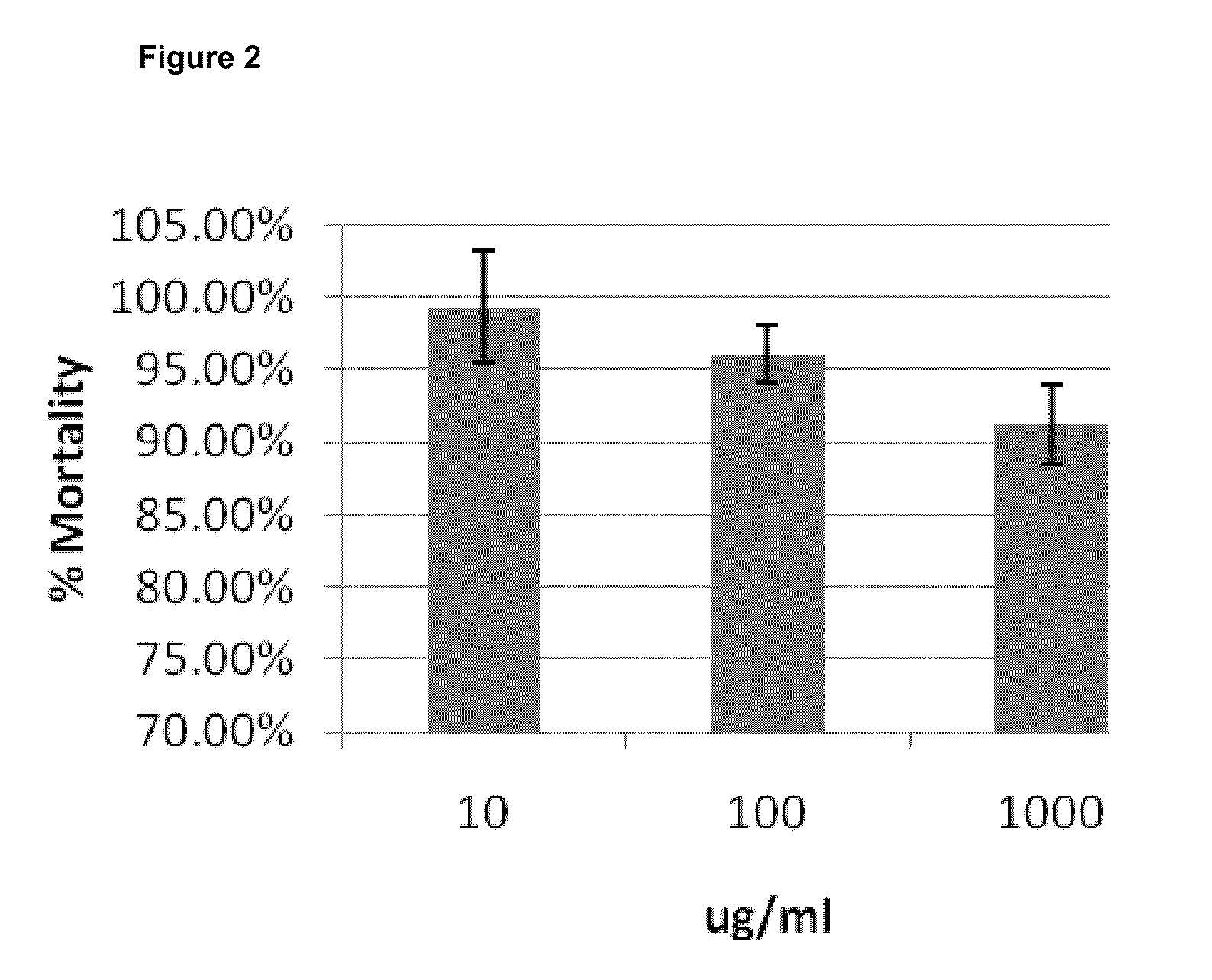

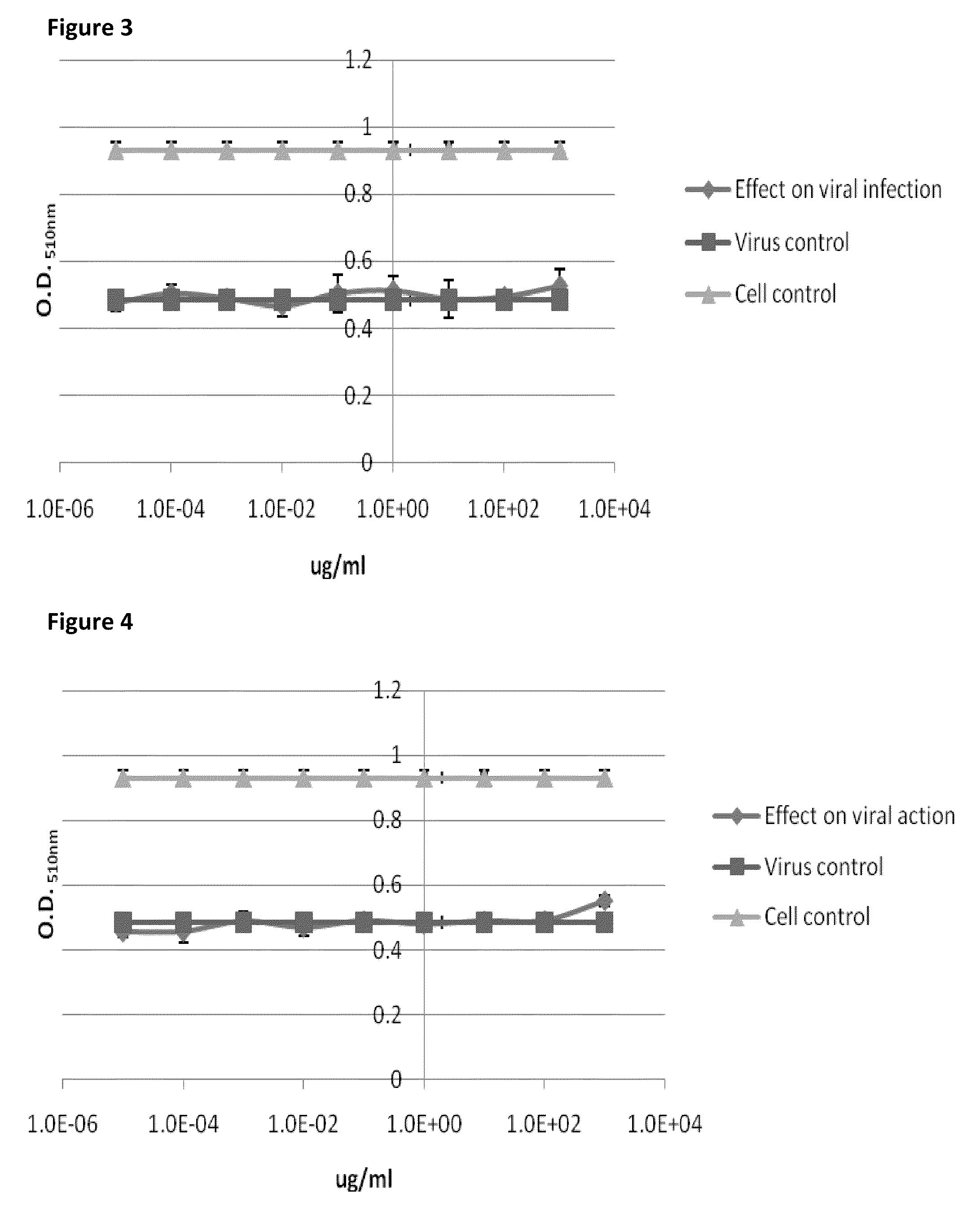

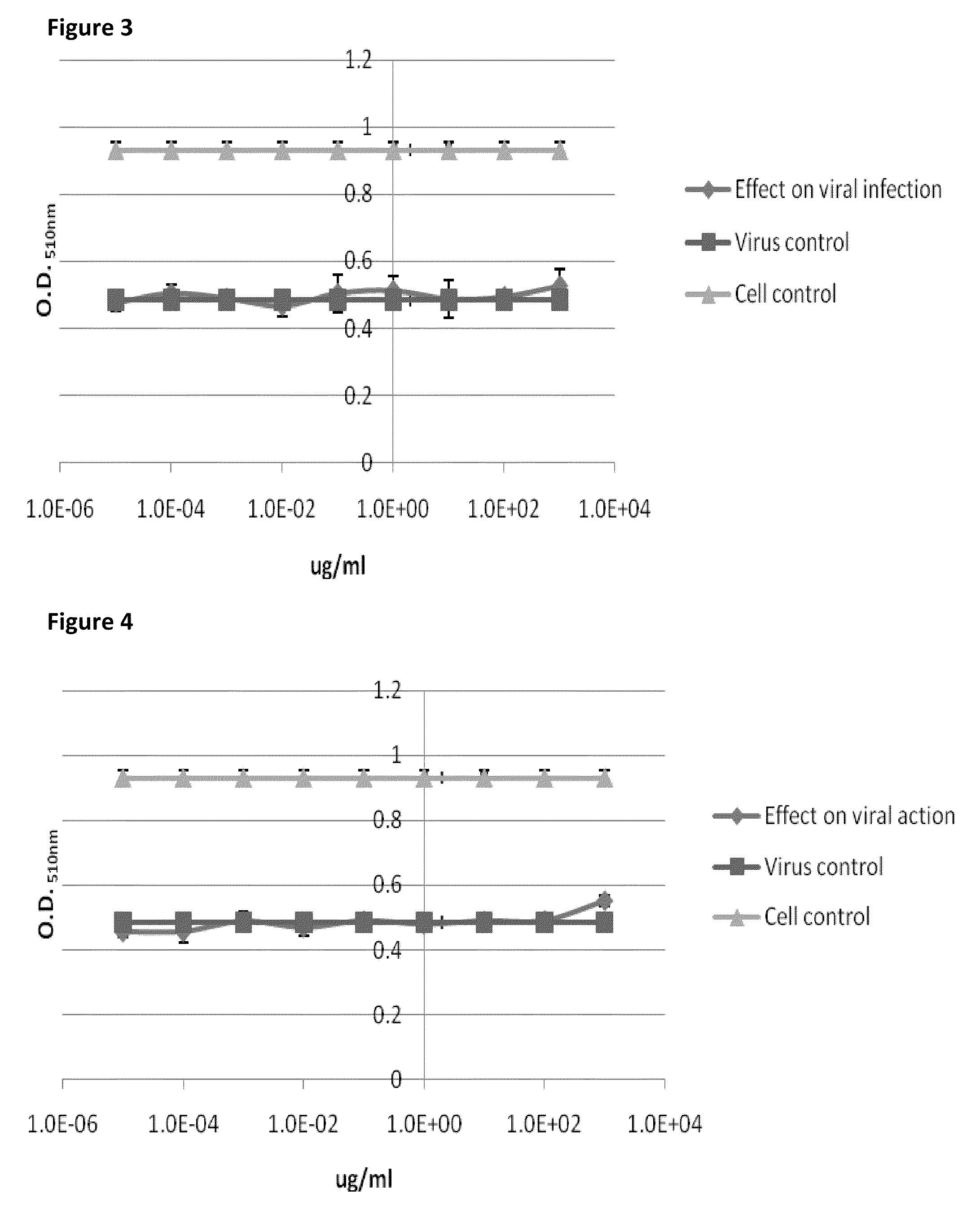

Compositions and methods of treating viral infections

ActiveUS20100190744A1Decreasing body fatQuality improvementBiocideHydroxy compound active ingredientsAstragalus polysaccharideSulfated polysaccharides

The present invention relates to the field of nutraceuticals, and in particular to nutraceuticals comprising sulfated polysaccharides, Astragalus polysaccharides, resveratrol, and combinations thereof. These compositions find use in inducing physiological responses such, decreasing body fat, increasing lean body mass, alleviating the symptoms of colds, preventing the onset of colds, increasing energy, increasing the feeling of well-being in subjects, and improving skin tone and appearance.

Owner:LIFE SCI NUTRITION AS

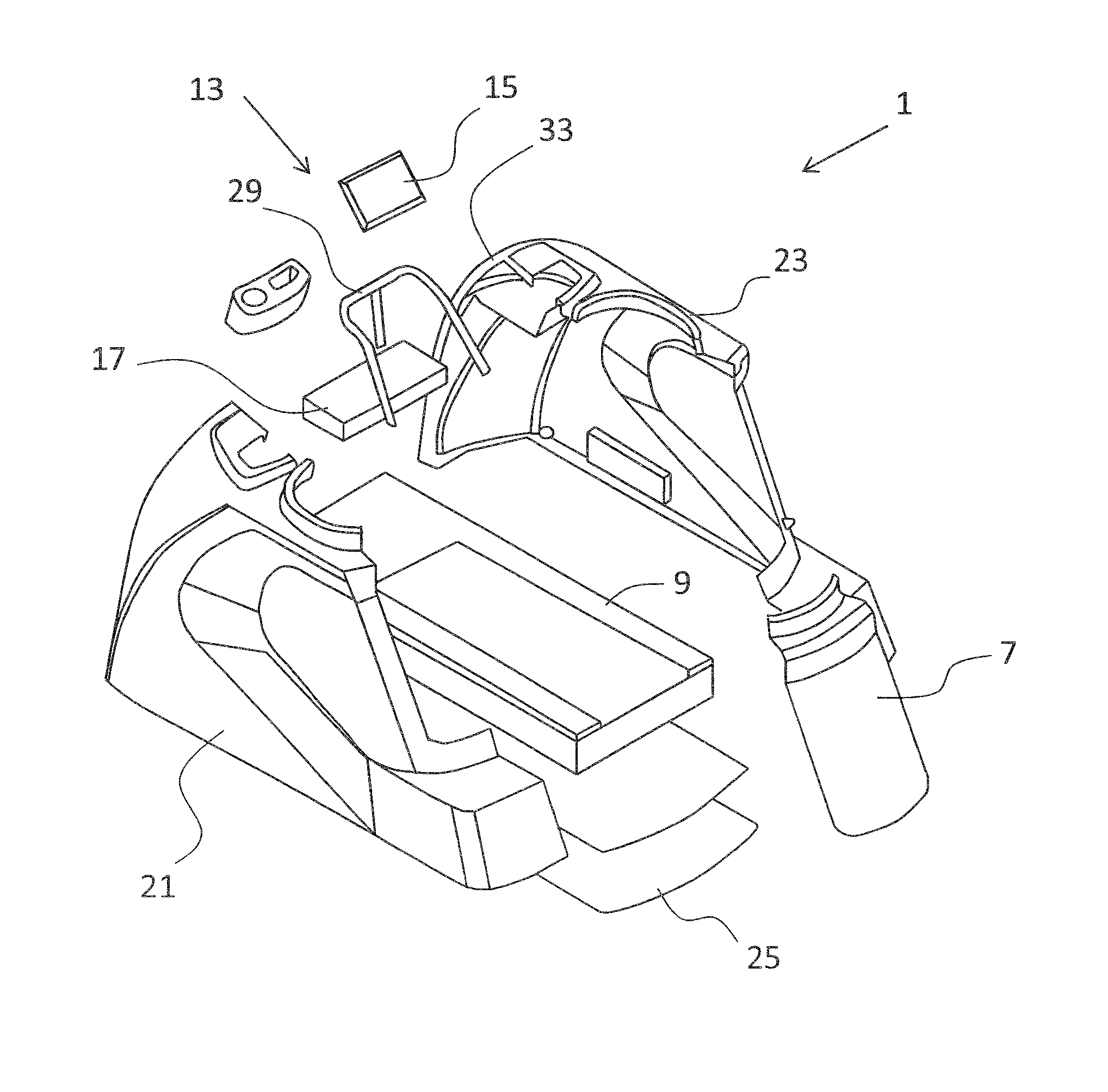

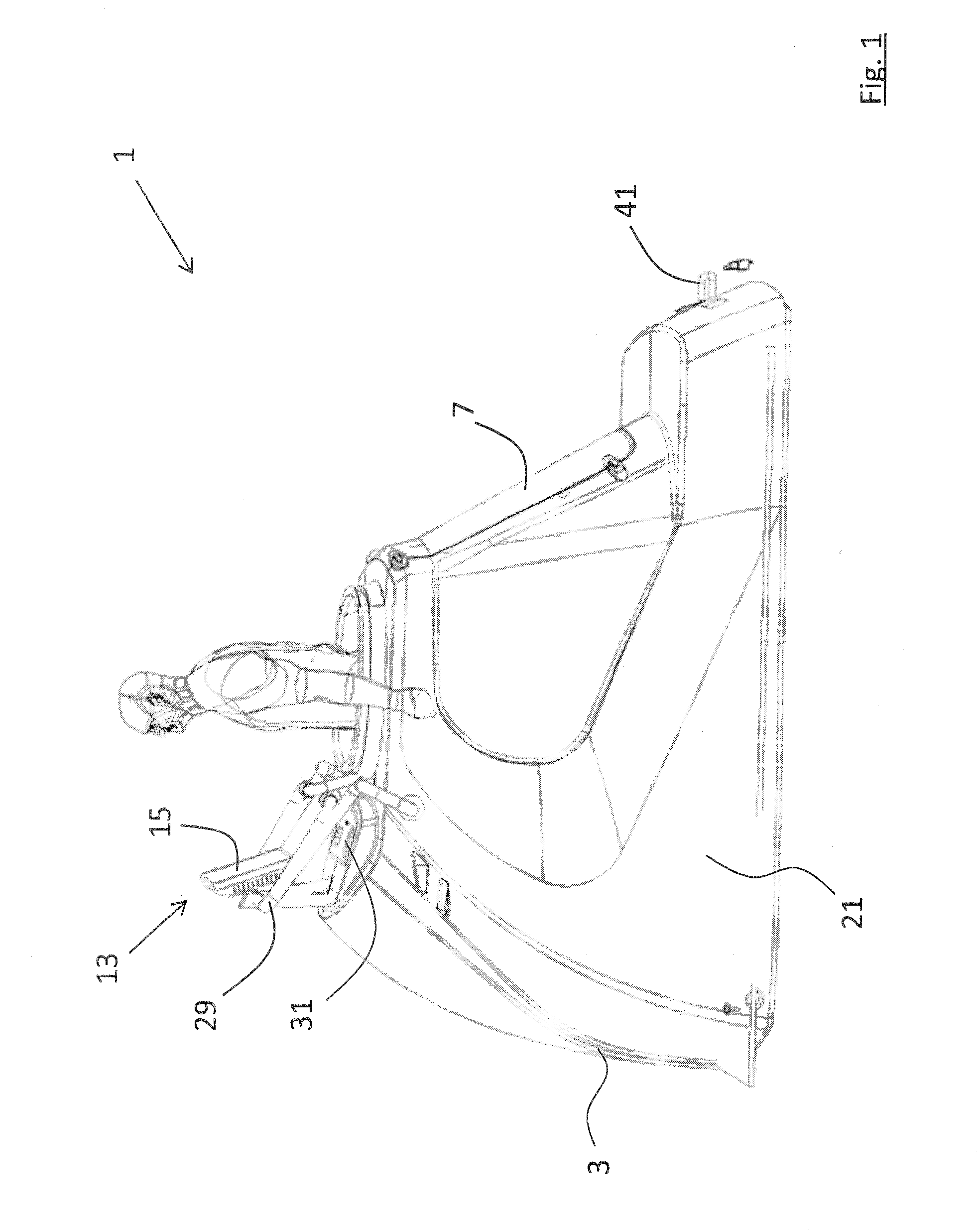

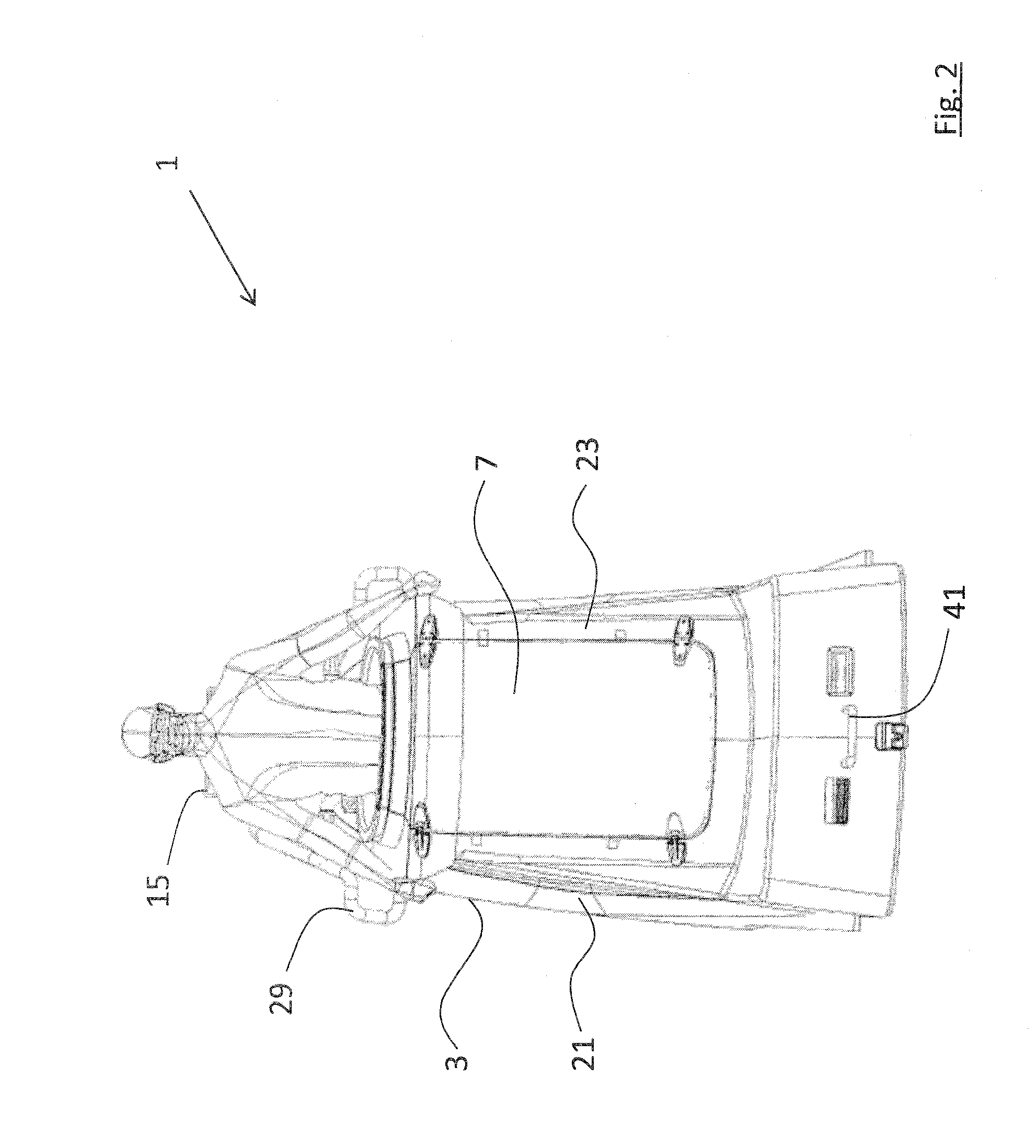

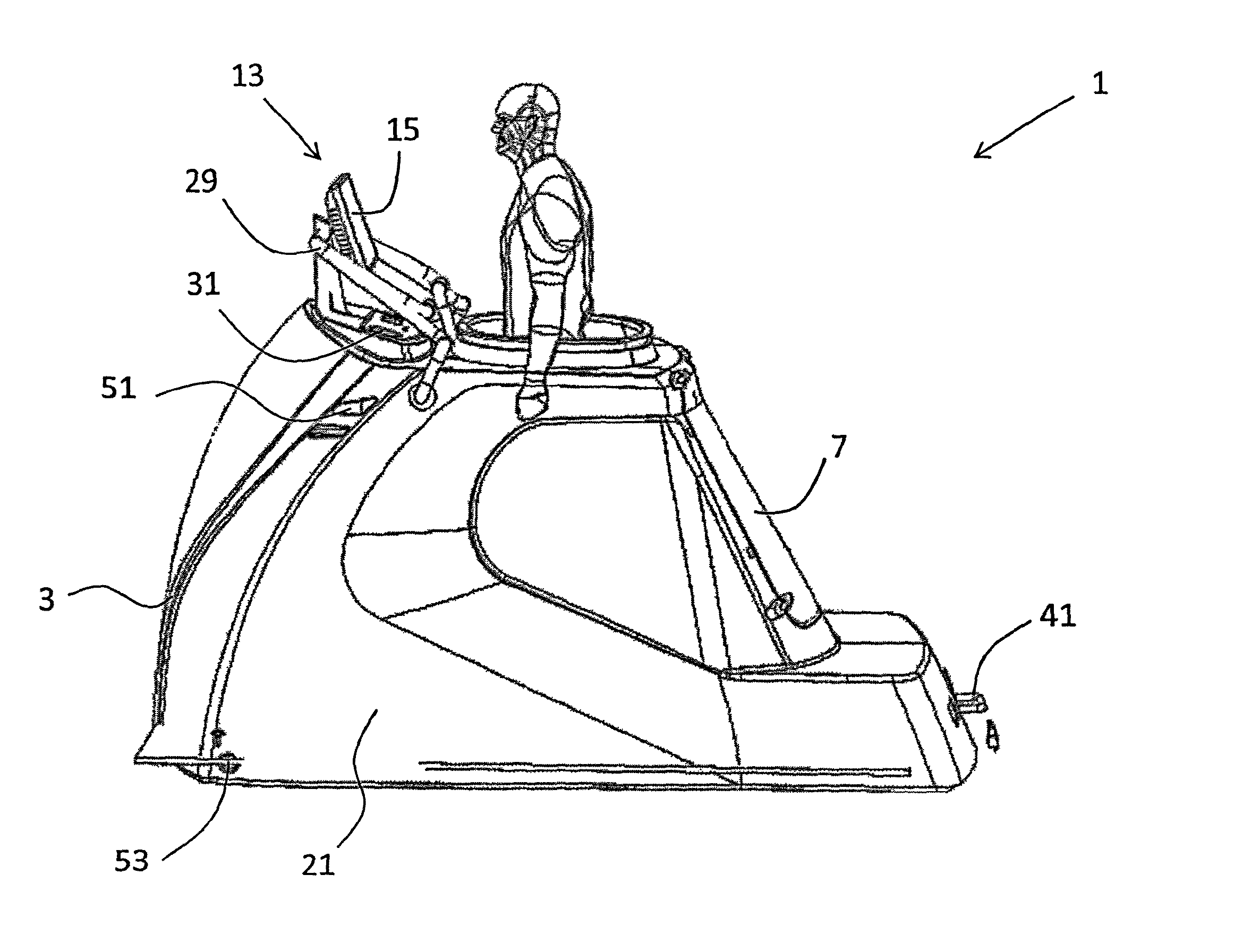

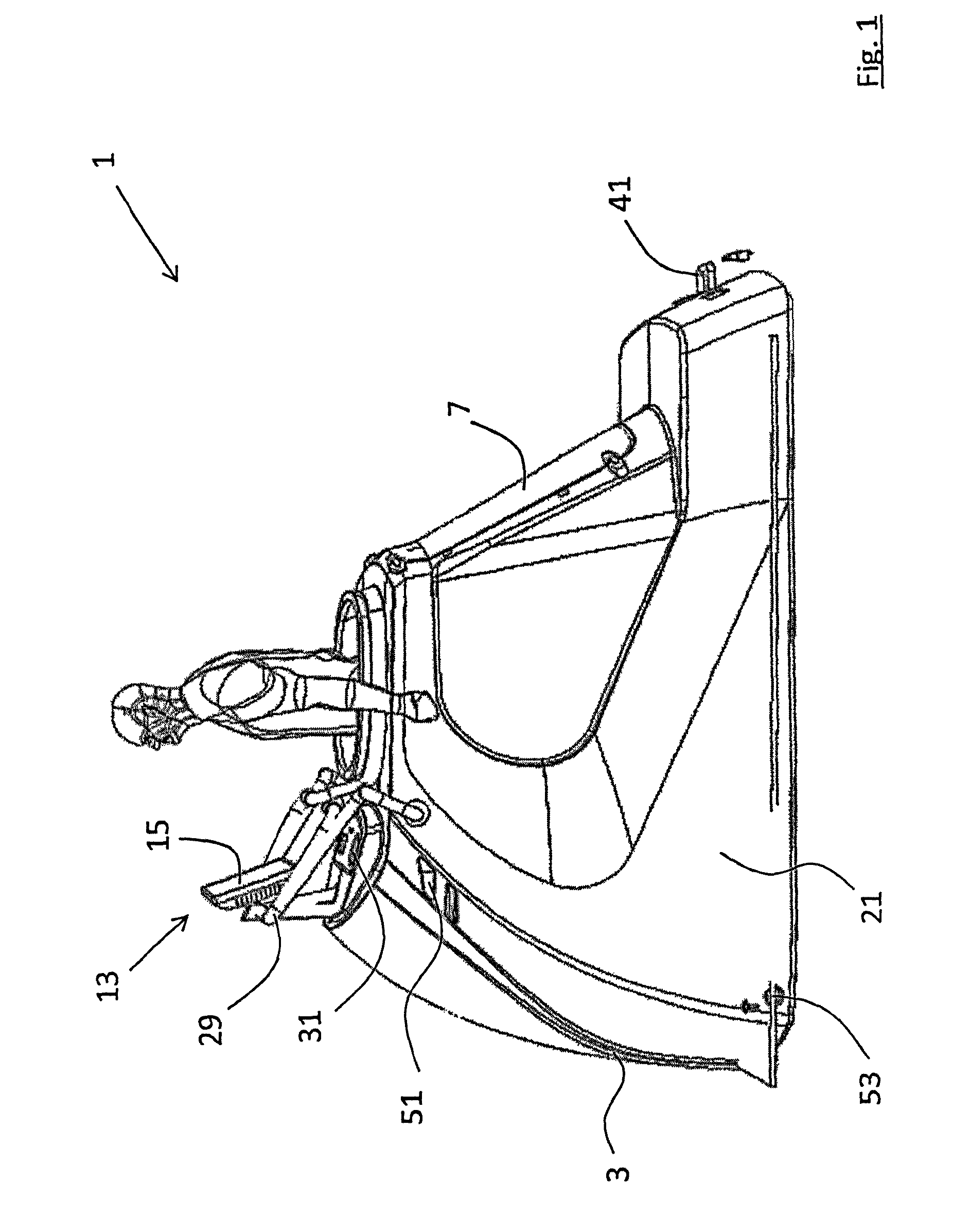

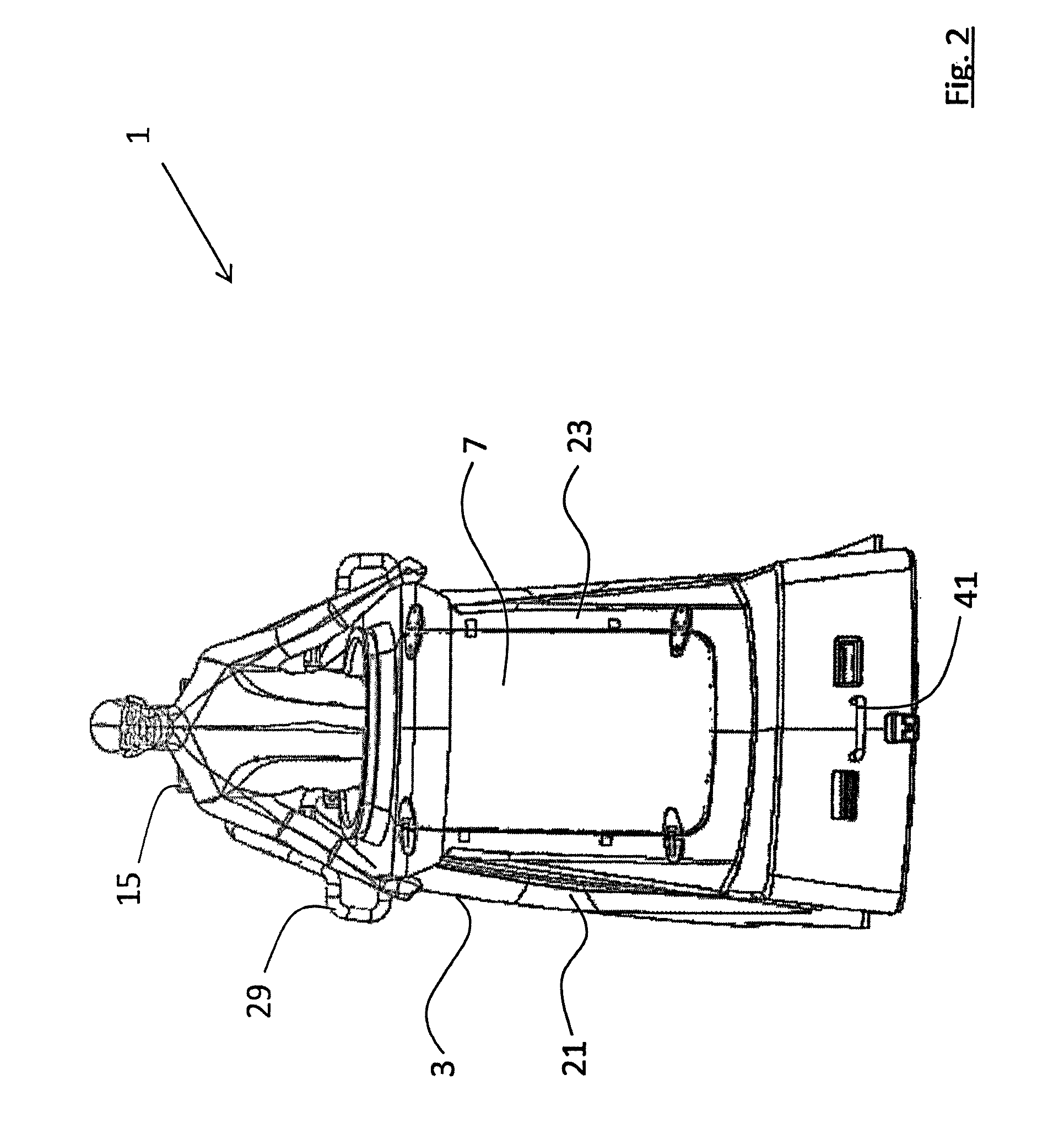

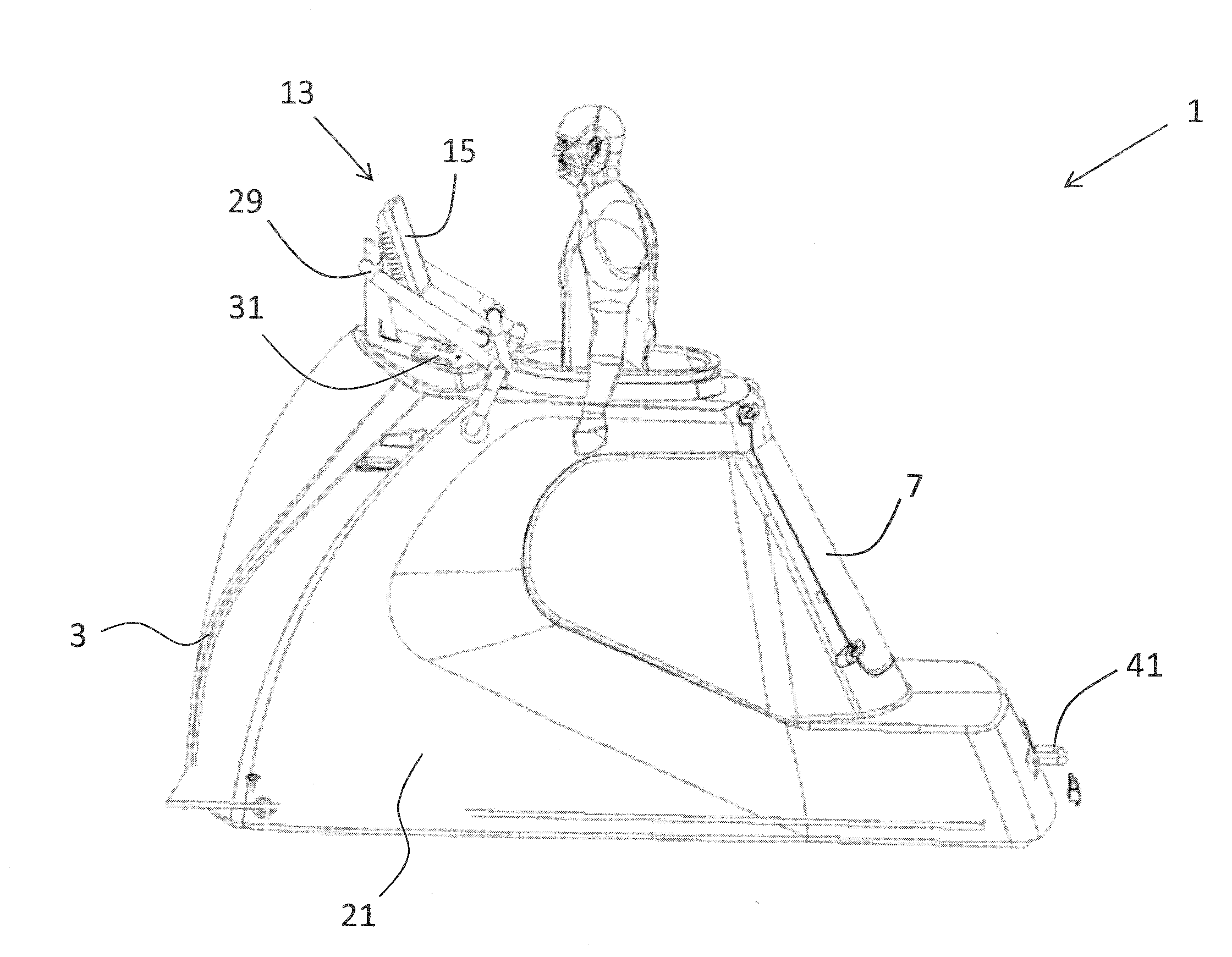

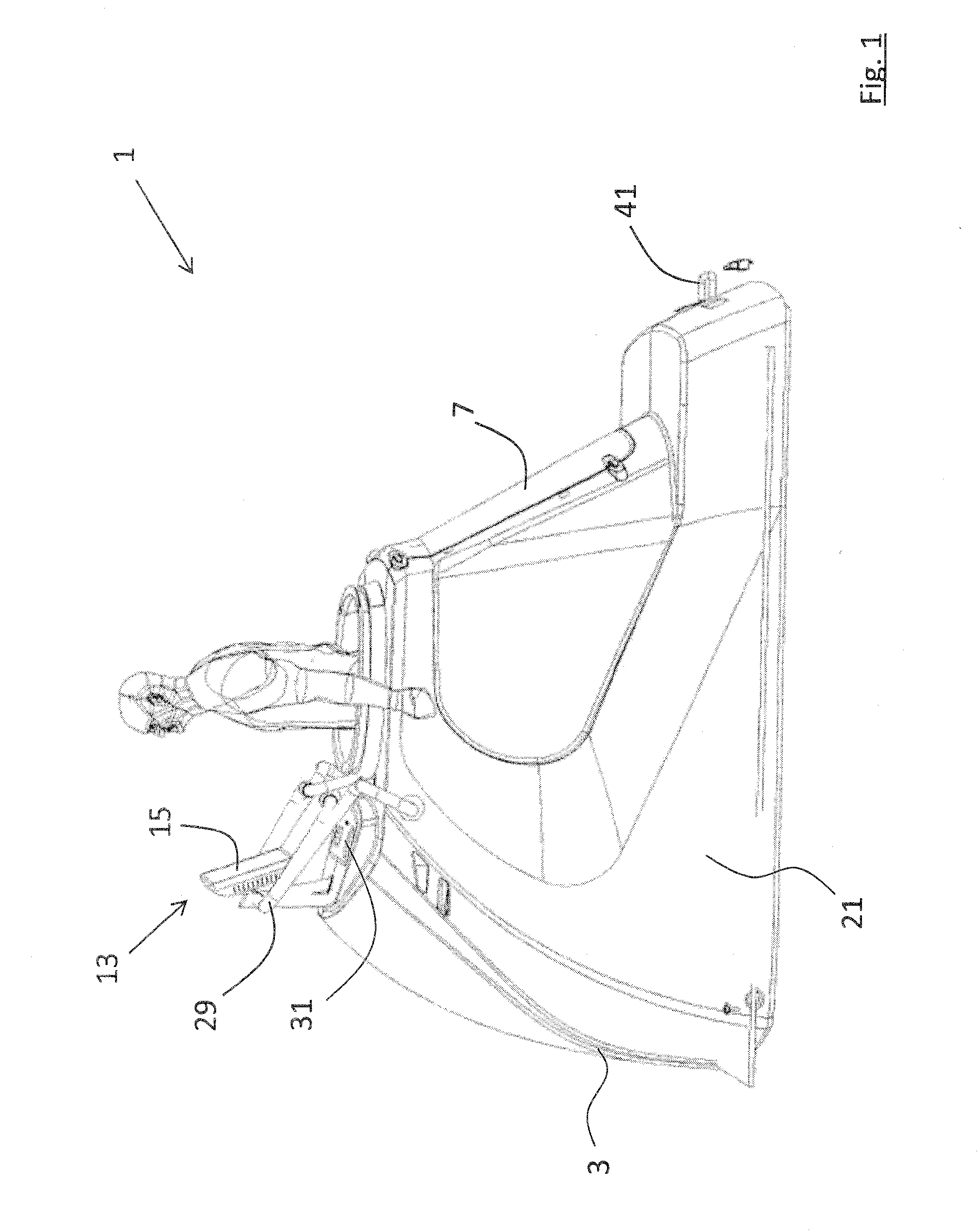

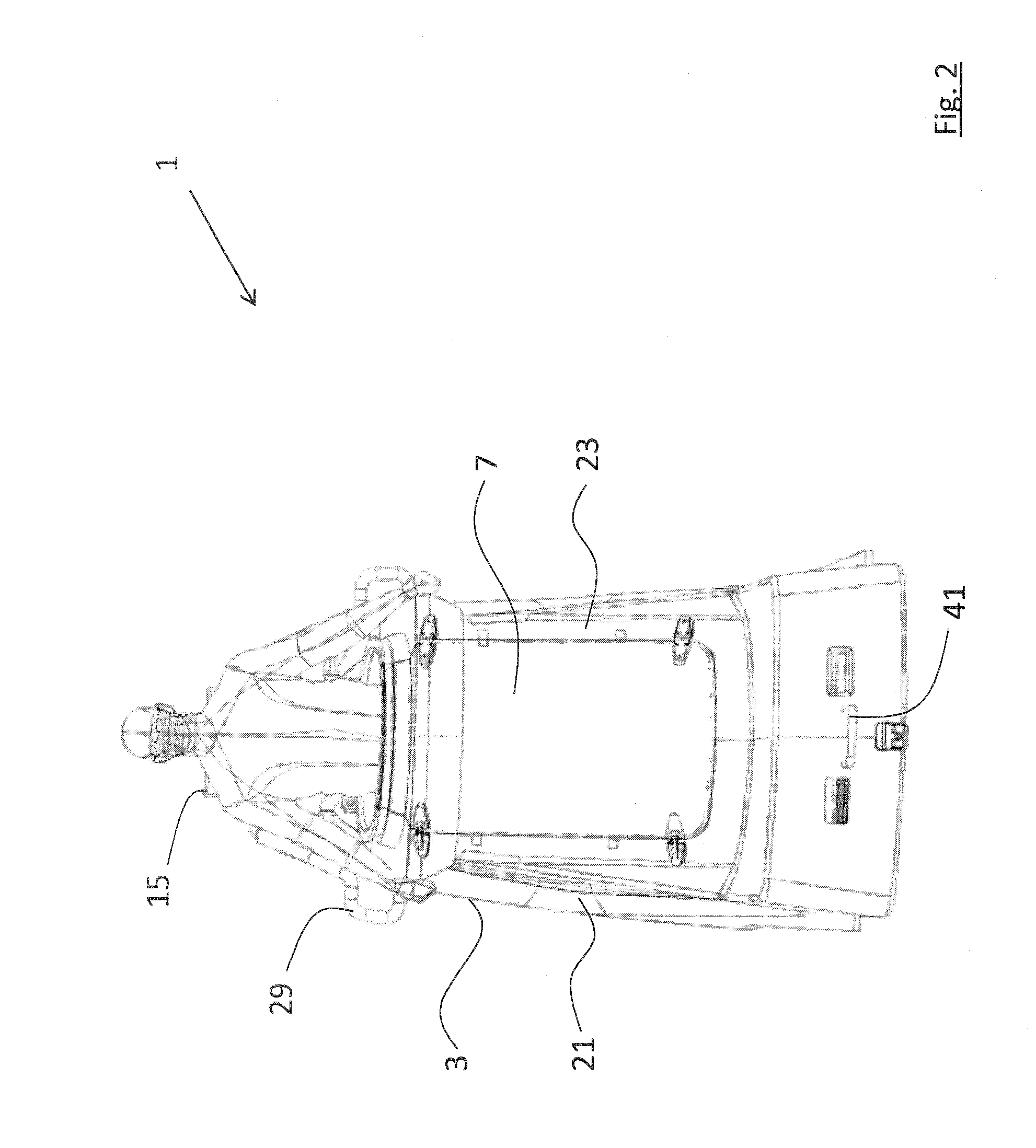

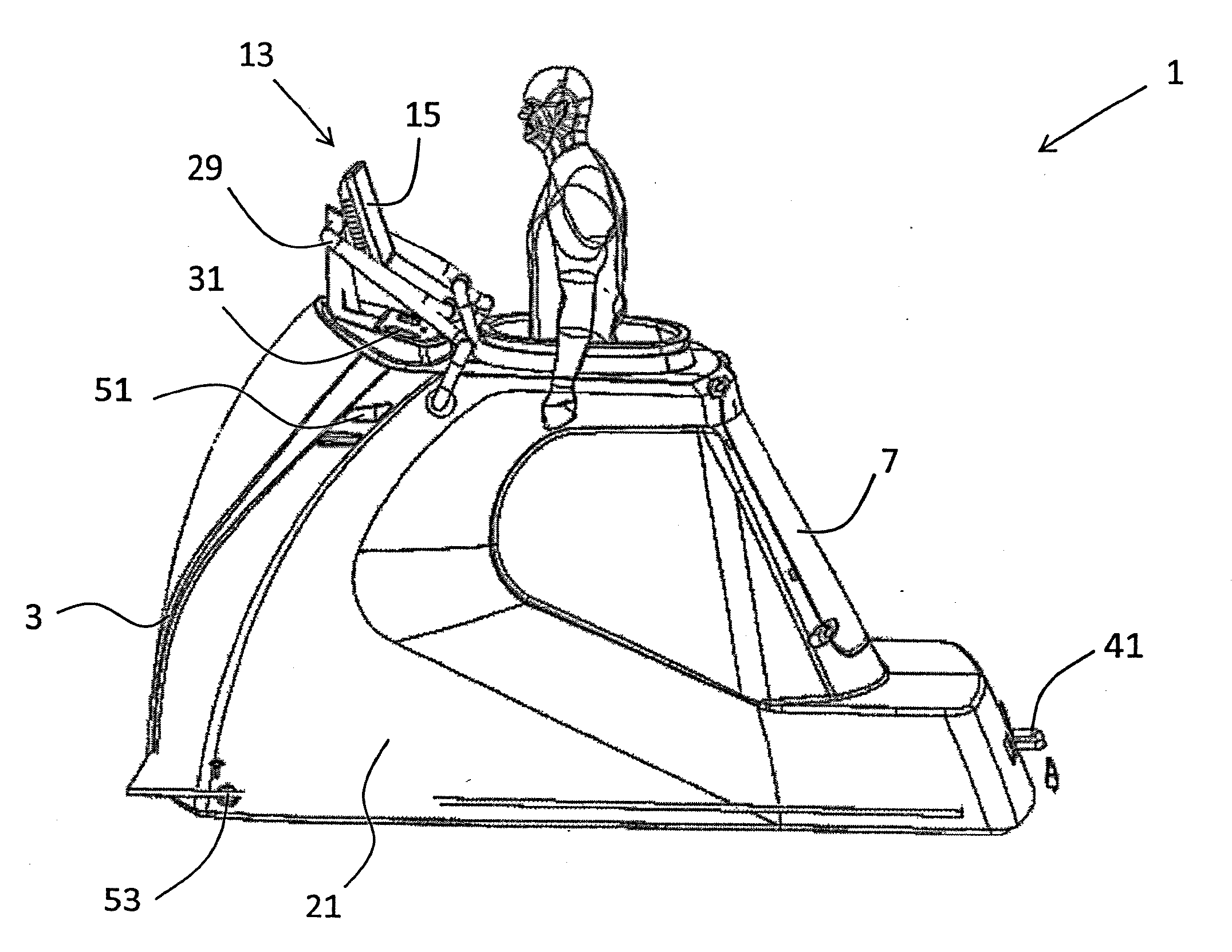

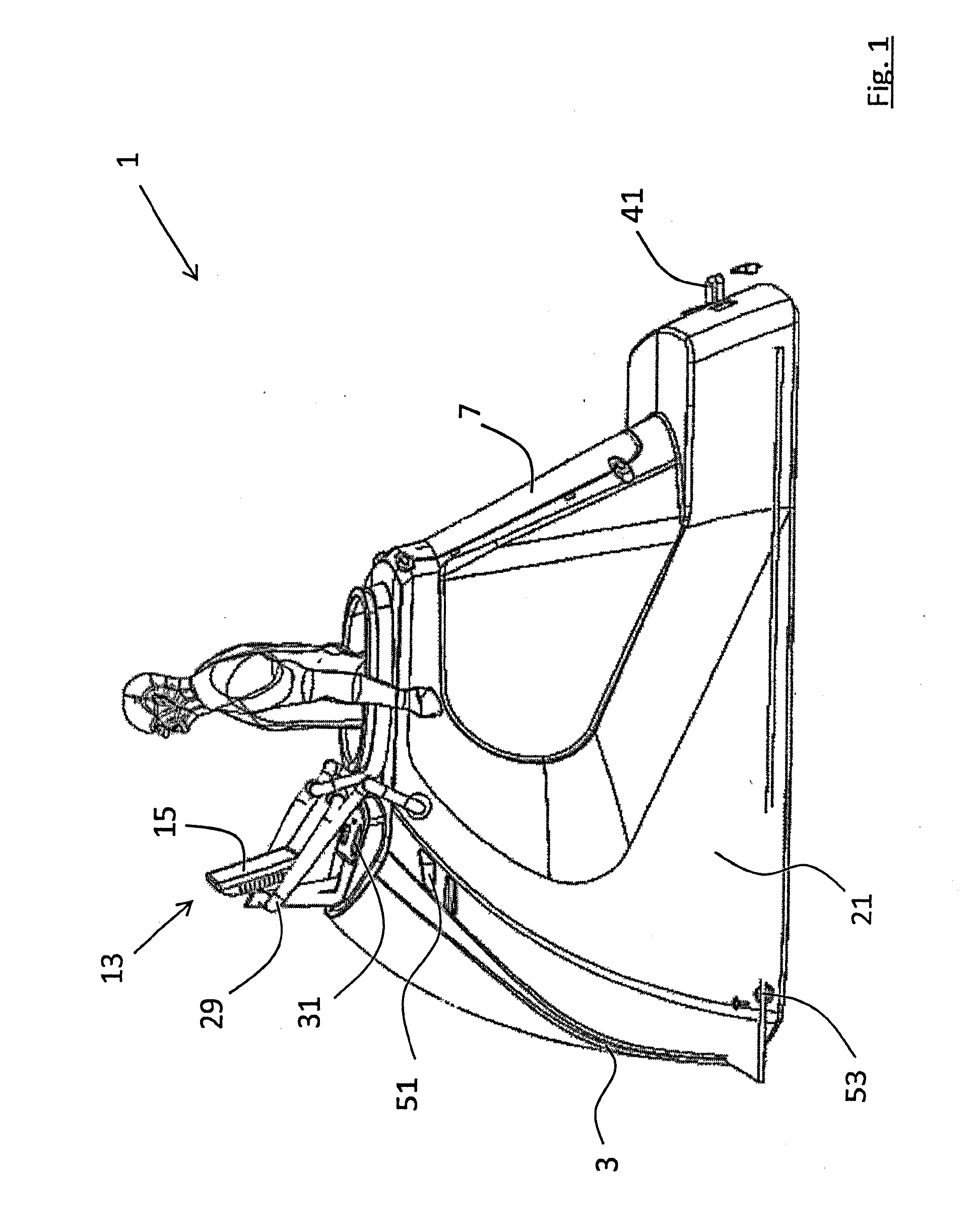

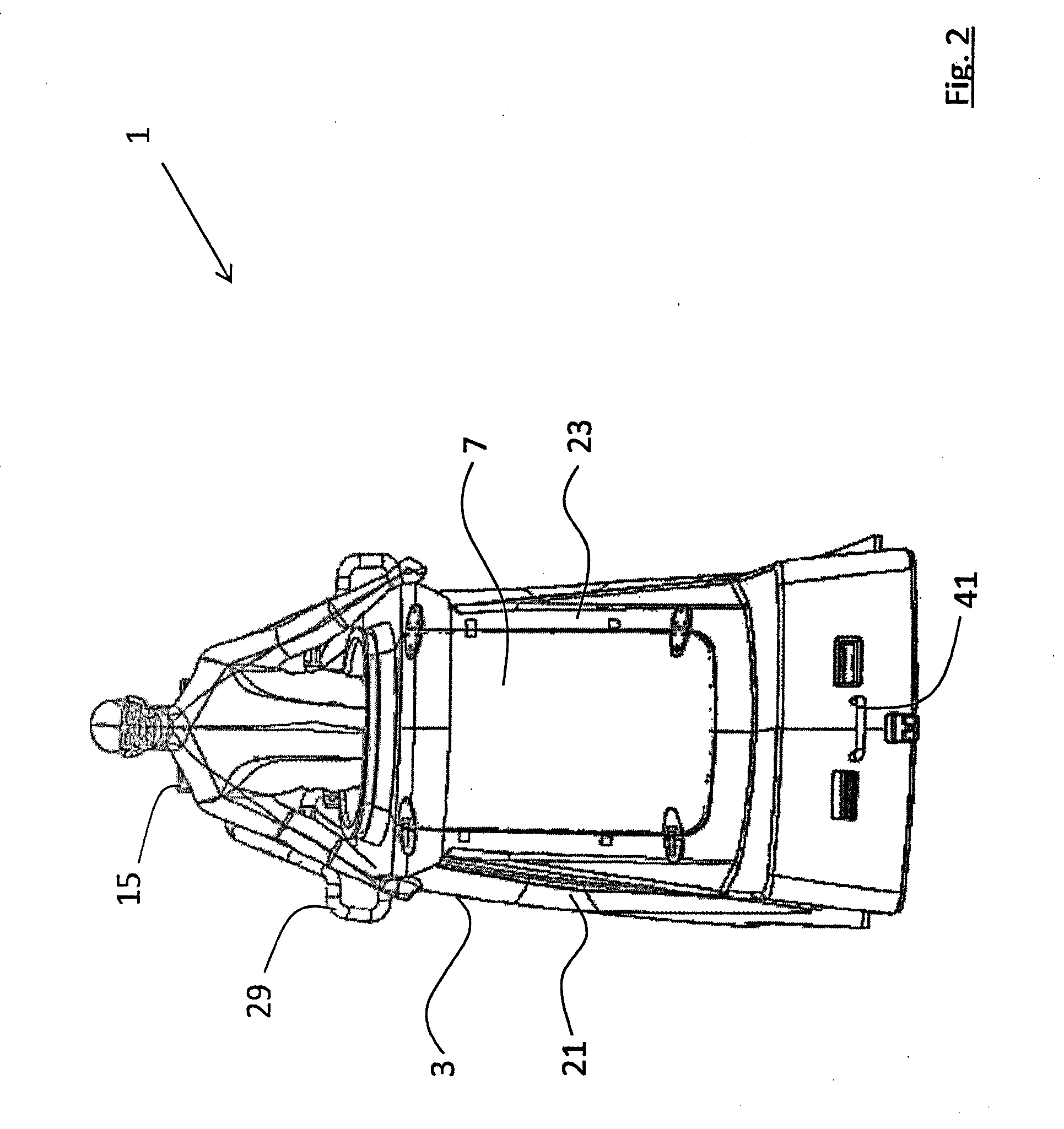

Exercise device

ActiveUS9272175B2Quality improvementIncrease intensitySpace saving gamesMuscle exercising devicesEngineeringPhysical exercise

Owner:EGAN

Exercise device

InactiveUS8900098B2Quality improvementIncrease intensityBreathing protectionClubsCost effectivenessEngineering

This invention relates to an exercise device and more particularly to an exercise device of the type that allows the user of the exercise device to exercise with part of their body in a negative pressure environment. These devices are becoming increasingly popular however the known devices are prone to frequent failure. The present invention provides a construction of exercise device that reduces the incidences of failure caused by failure of the electronics panel. The electronics panel being mounted in a separate dedicated enclosure internal the chamber with the negative pressure environment, the interior of the dedicated enclosure is isolated from the negative pressure conditions and atmosphere in the remainder of the chamber. The exercise device will be more reliable and cost effective to run. Furthermore, the construction of the present invention permits easier access to the interior of the casing for maintenance when maintenance is required.

Owner:EGAN

Exercise device

ActiveUS20140113775A1Quality improvementIncrease intensitySpace saving gamesMuscle exercising devicesEngineeringPhysical exercise

Owner:EGAN

Stable water in oil aminophylline emulsions

InactiveUS20030050318A1Alleviate the conditionUndesirable crystal growth is preventedCosmetic preparationsBiocideTheophyllineWater in oil emulsion

A water in oil emulsion system and a process for preparing such a emulsion has been provided for topically applying aminophylline for reducing cellulite conditions.

Owner:WESTERN HLDG

Fat Reduction Using External Laser Radiation and Niacin

InactiveUS20110295187A1Reduce fatReduce celluliteElectrotherapyTreatment involving filtrationPresent methodRadiology

The present invention is a non-invasive method for reducing fat or cellulite in a patient by administering a therapeutically effective amount of niacin and applying laser energy to targeted external regions of a patient's body. The present method helps create smooth contours.

Owner:ERCHONIA CORP

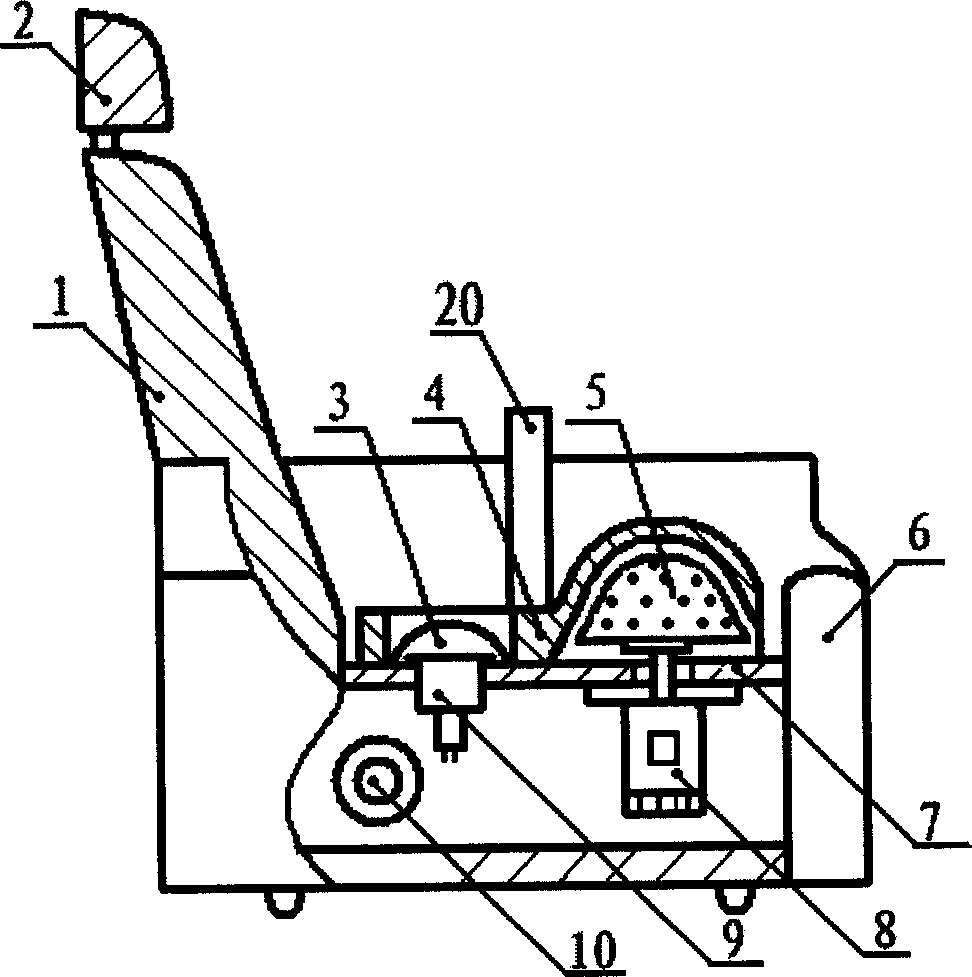

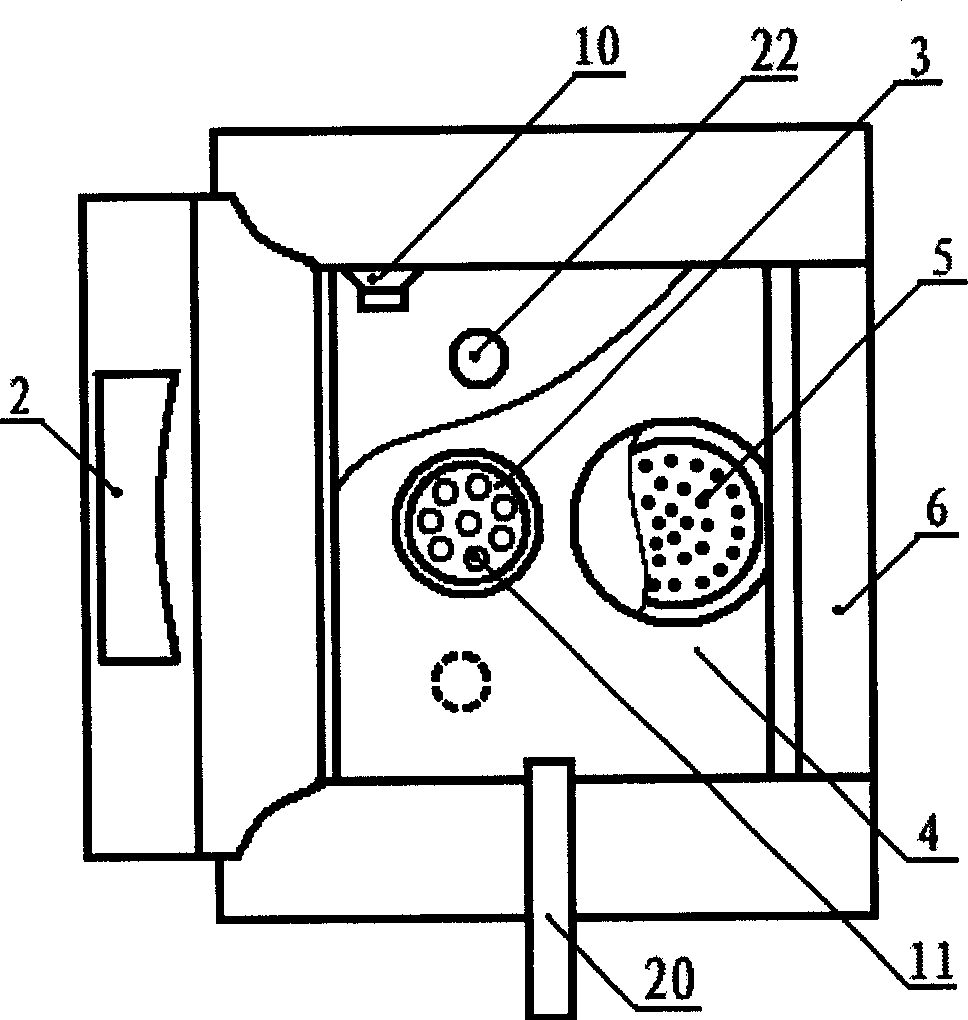

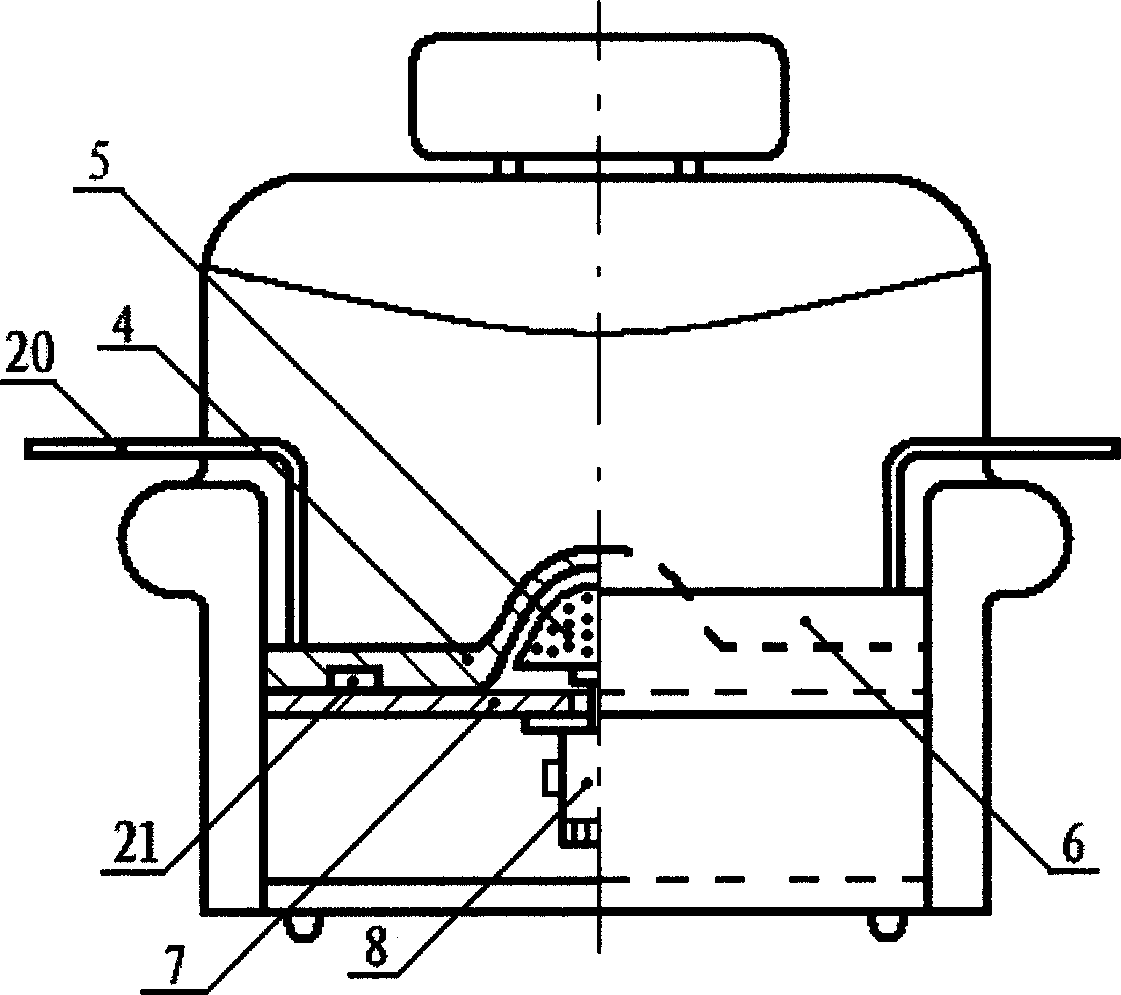

Colorful lighted highly frequency spiral massaging chair

InactiveCN1729958AReduce belly fatPromote Qi and blood circulation and smooth flowDevices for pressing relfex pointsVibration massageLeg cushionLoudspeaker

The invention discloses a colorful high-frequency vibration massage chair, for operting the light therapy and the massage on the human perineal acupiont, vai the method of accelerating the inner gas and blood circulation of human body, to realize the improved ability of disease-resistant, improved quality of life, retarded apolexis and prolonged life. The invention comprises a chair, a colorful light, a magnet, a loudspeaker, and a high-frequency spiral massage prepared long charcoal cushion. Wherein, the colorful light is mounted on the back part of chair plate while its lower part has a color-intonation converter, its upper part has a transparent lamp shade and its two sides have magnets; the sides or the face of chair has been mounted with loudspeaker; the motor of high-frequency spiral massager device is mounted under the chair plate; the vibration cap is mounted on the head of eccentric axis of motor; the soft cushion with round holes and prepared long charcoal is mounted on the faces of transparent lamp shade and the vibration cap while its two sides have remote infrared abdominal belt; and a leg cushion is arranged at the front of chair plate. Said invention can be used for health care and treating variable diseases.

Owner:陈朝阳

Fat reduction using external laser radiation and niacin

InactiveUS7993382B2Reduce fatReduce celluliteElectrotherapyTreatment involving filtrationNiacinNon invasive

Owner:ERCHONIA CORP

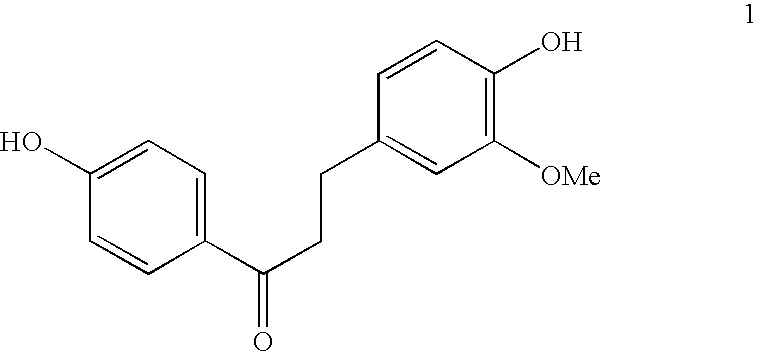

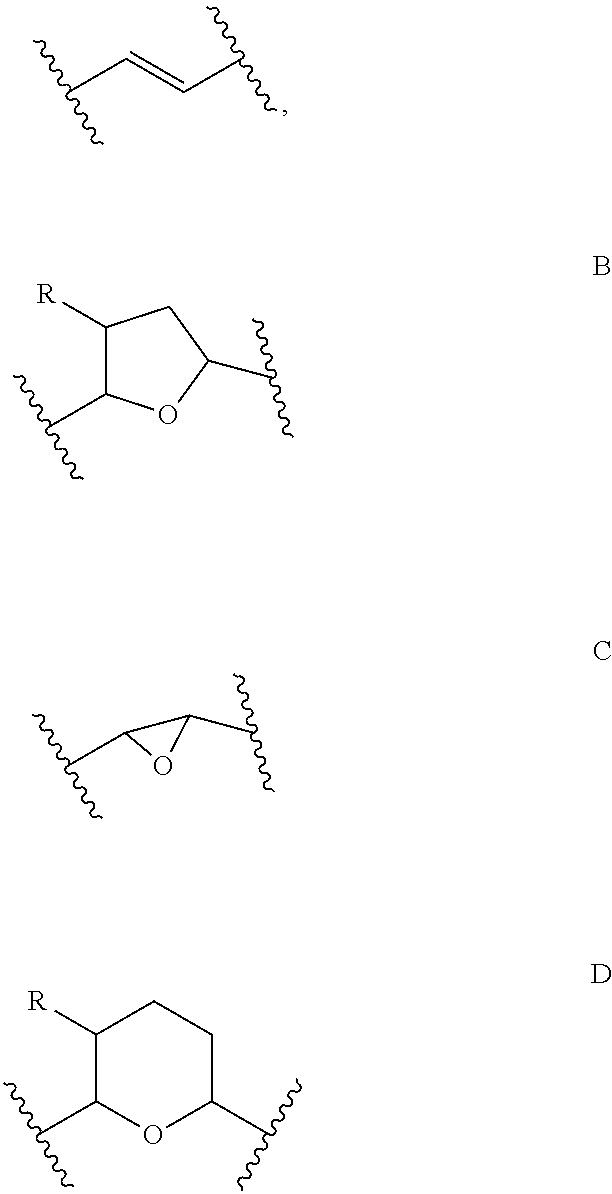

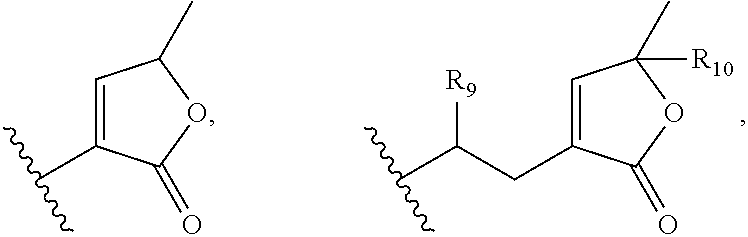

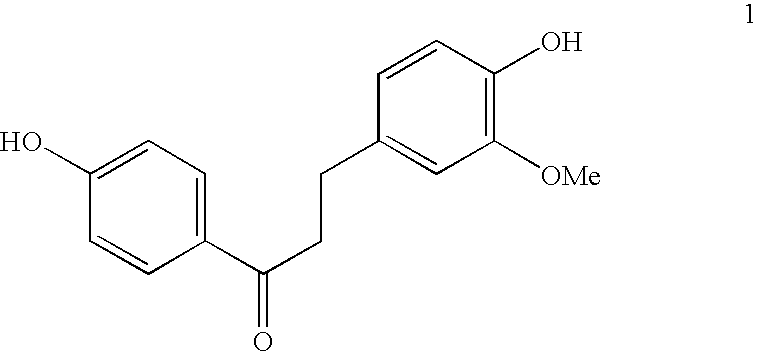

Use of 3-(4-hydroxy-3-methoxyphenyl)-1-(4-hydroxyphenyl) propane-1-one for improved skin contouring or against cellulite

InactiveUS20090209651A1Easy to tightenAvoid disadvantagesBiocideCosmetic preparationsSkin surfaceKetone

A cosmetic or dermatological preparation which is suitable for application to skin and comprises 3-(4-hydroxy-3-methoxyphenyl)-1-(4-hydroxyphenyl)-propane-1-one in a concentration which is effective for at least one of increasing skin moisture content, moisturizing skin, improving the surface structure of the skin, reducing cellulite, increasing the resilience and elasticity of skin, strengthening the connective tissue of skin, and reducing stretch marks on skin. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:BEIERSDORF AG

Powder spraying process

ActiveCN113265191AImprove adhesionTightly bondedLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyPowder Spray

The invention discloses a powder spraying process which comprises the following steps: S1, spraying bottom powder on the surface of a workpiece to obtain a bottom powder coating; s2, spraying surface powder on the surface of the bottom powder coating in the S1; and s3, baking the surface of the workpiece obtained through spraying in the S2, and solidifying the base powder and the surface powder; the base powder mainly comprises epoxy resin, polyurethane resin, a sand texture agent and an auxiliary agent; the surface powder mainly comprises polyurethane resin, a sand streak agent and an auxiliary agent; and the percentage content of the sand streak agent in the bottom powder in the total mass of the bottom powder is smaller than the percentage content of the sand streak agent in the surface powder in the total mass of the surface powder. The base powder and the surface powder both contain the sand streak agent, the sand streak agent in the surface powder accounts for a large percentage content of the total mass of the surface powder, the surface powder coating is firstly heated and cured, convex and concave sand streaks are formed on the interface of the surface powder and the base powder, and the interface area of the base powder and the surface powder is larger than the coating area, so that the adhesive force between the base powder coating and the surface powder coating is increased; and the adhesion between the coatings is tighter, and meanwhile, the orange peel phenomenon is reduced.

Owner:江苏耀坤液压股份有限公司

Exercise device

InactiveUS20140106935A1Overcome problemsQuality improvementPneumatic massageTreatment roomsCost effectivenessEngineering

This invention relates to an exercise device and more particularly to an exercise device of the type that allows the user of the exercise device to exercise with part of their body in a negative pressure environment. These devices are becoming increasingly popular however the known devices are prone to frequent failure. The present invention provides a construction of exercise device that reduces the incidences of failure caused by failure of the electronics panel. The electronics panel being mounted in a separate dedicated enclosure internal the chamber with the negative pressure environment, the interior of the dedicated enclosure is isolated from the negative pressure conditions and atmosphere in the remainder of the chamber. The exercise device will be more reliable and cost effective to run. Furthermore, the construction of the present invention permits easier access to the interior of the casing for maintenance when maintenance is required.

Owner:EGAN

Method of reducing fatty tissue using lymphatic massage

InactiveUS20050192521A1Reduce celluliteGenitals massageSuction-kneading massageLymphatic massageMassage

A method for reducing fatty tissue using lymphatic massage is disclosed that includes the steps of evaluating body regions of a patient to determine at least one massage area, massaging in a first session the at least one massage area, the first session massage going in the direction of muscle attachment and the lymphatic system and including an application of a first pressure by balls of fingers of a massage therapist, massaging in a second session the at least one massage area, the second session massage including an application of a second pressure greater than the first pressure, and applying a reducing cream and an almond oil.

Owner:HINCAPIE GLORIA

Skin Care Compositions and Methods of Use Thereof

ActiveUS20160263013A1Improve firmnessImprove skinCosmetic preparationsToilet preparationsRosmarinusGerontology

Owner:UNIGEN

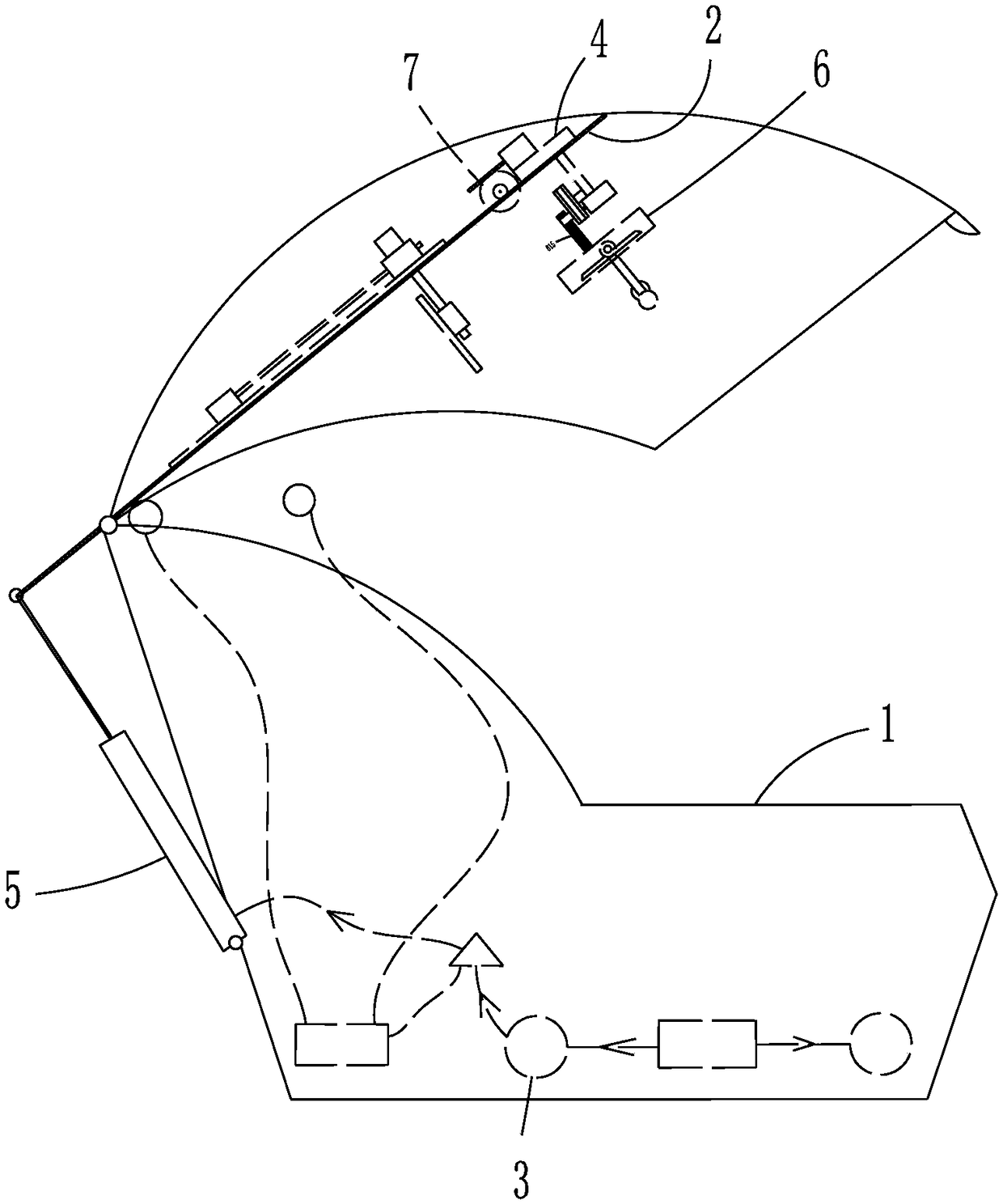

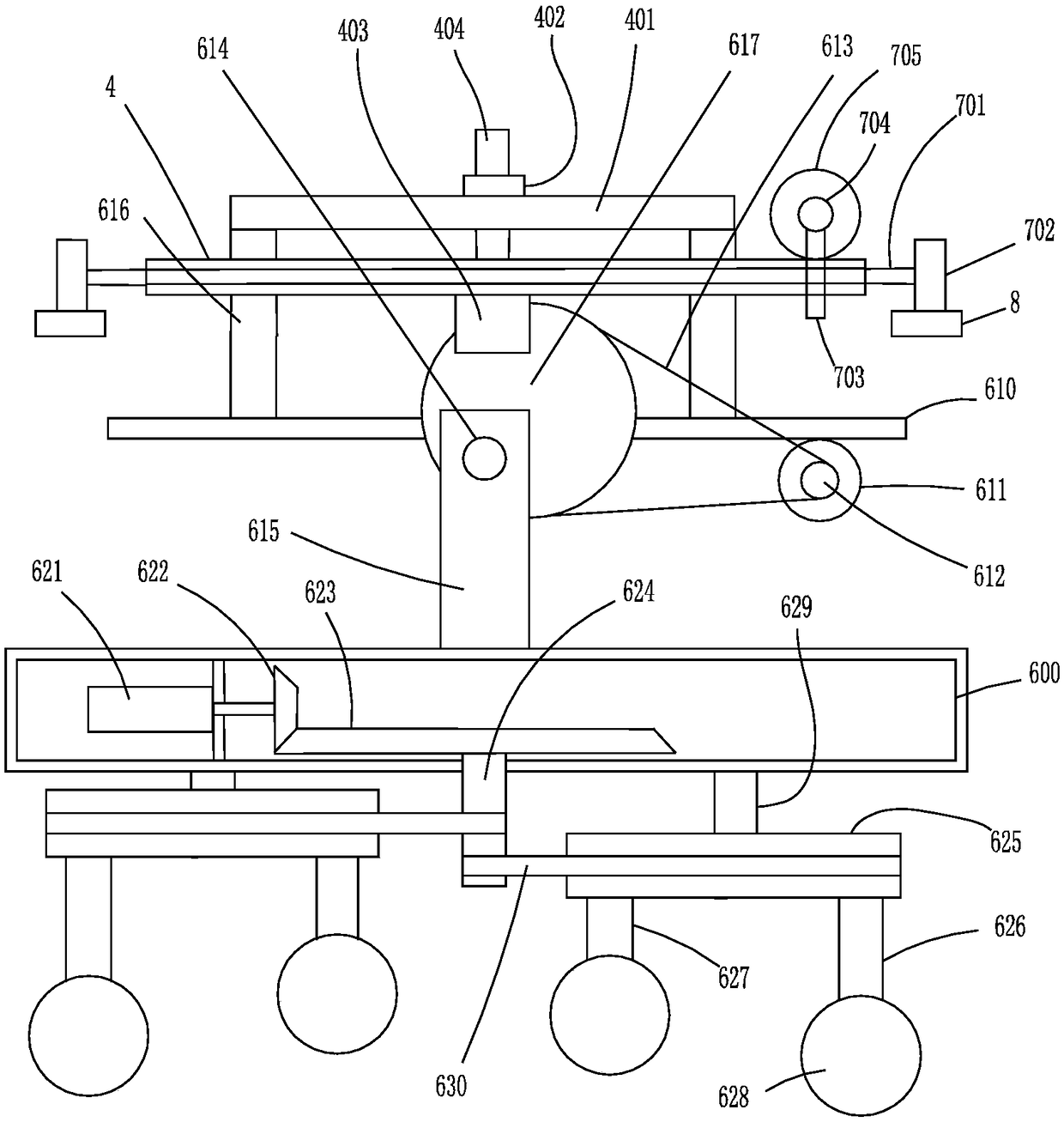

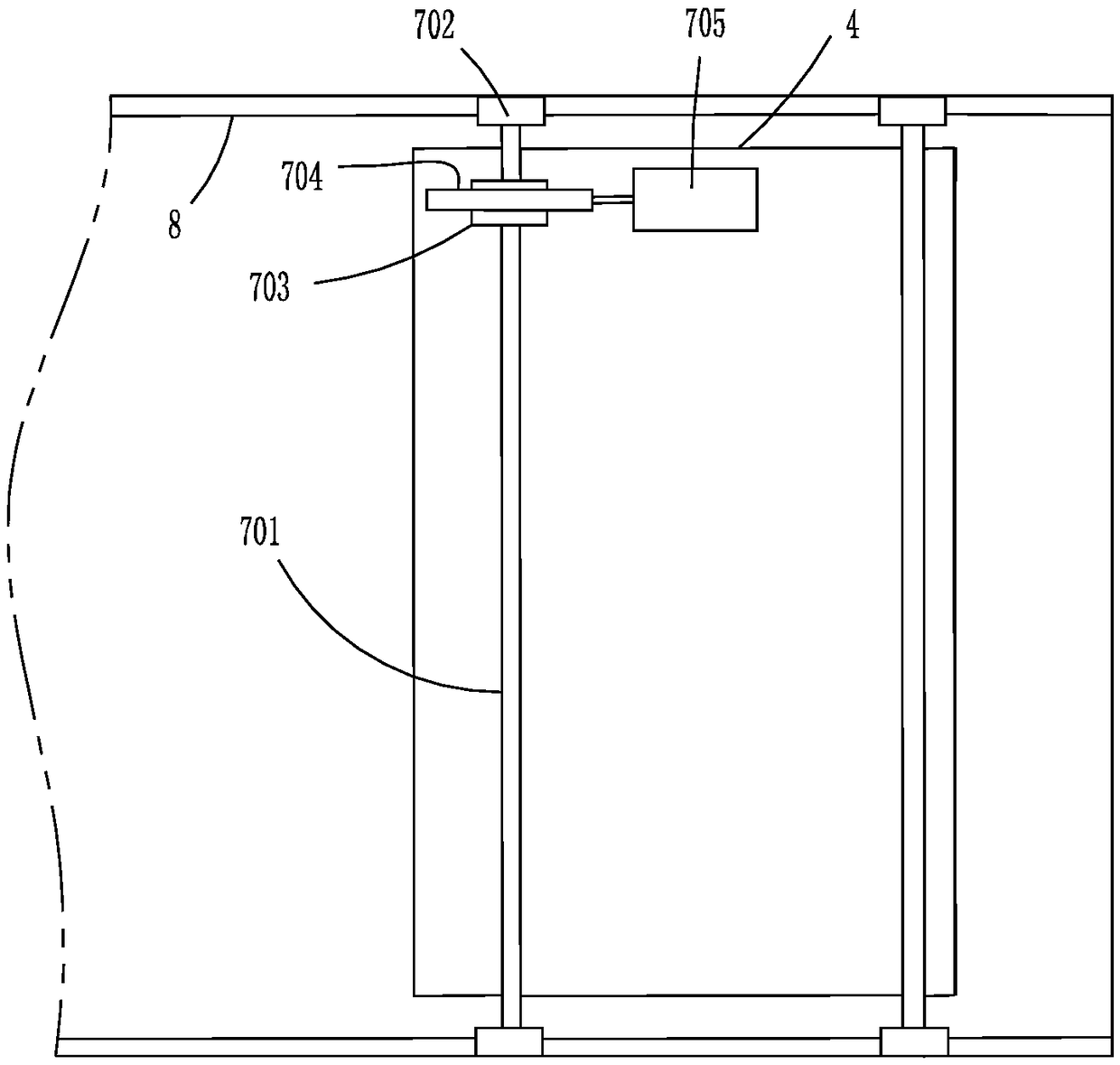

Abdominal massage chair

ActiveCN109124977APromote digestionReduce celluliteBreathing protectionTreatment roomsGastric digestionSomatosensory system

The invention discloses an abdominal massage chair, comprising a main body (1), a frame (2) is hinged on the top of the main body (1), a rotating device (5) connected with the frame (2) is arranged onthe rear side of the main body (1), rack (8) is arranged on both sides of the frame (2), rack (8) is connected with a traveling frame (4) through a traveling mechanism (7), and a 3D abdominal massagemachine (6) is connected with the traveling frame (4). The present invention has the following advantages: 1. It can promote intestinal peristalsis, improve gastric digestion and reduce abdominal redundancy; 2, that quality of the user's rest or sleep is effectively guarantee; 3, the user is comfortable when massaging on the massage chair and oxygen therapy; 4, that user can not quickly tire theeyes of the user when watching the movies and TV plays on the invention, and the effect of the user watching the movies and TV plays is good; In addition, the invention also has the advantages of adapting to a wide range of users and good safety.

Owner:浙江荣泰健康电器有限公司

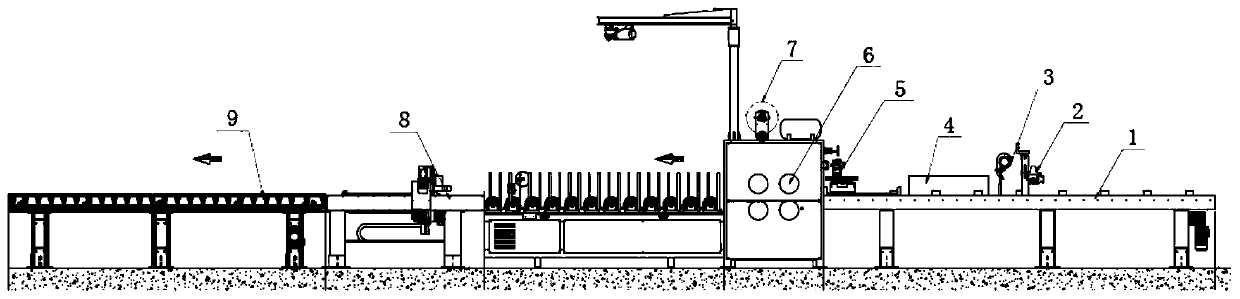

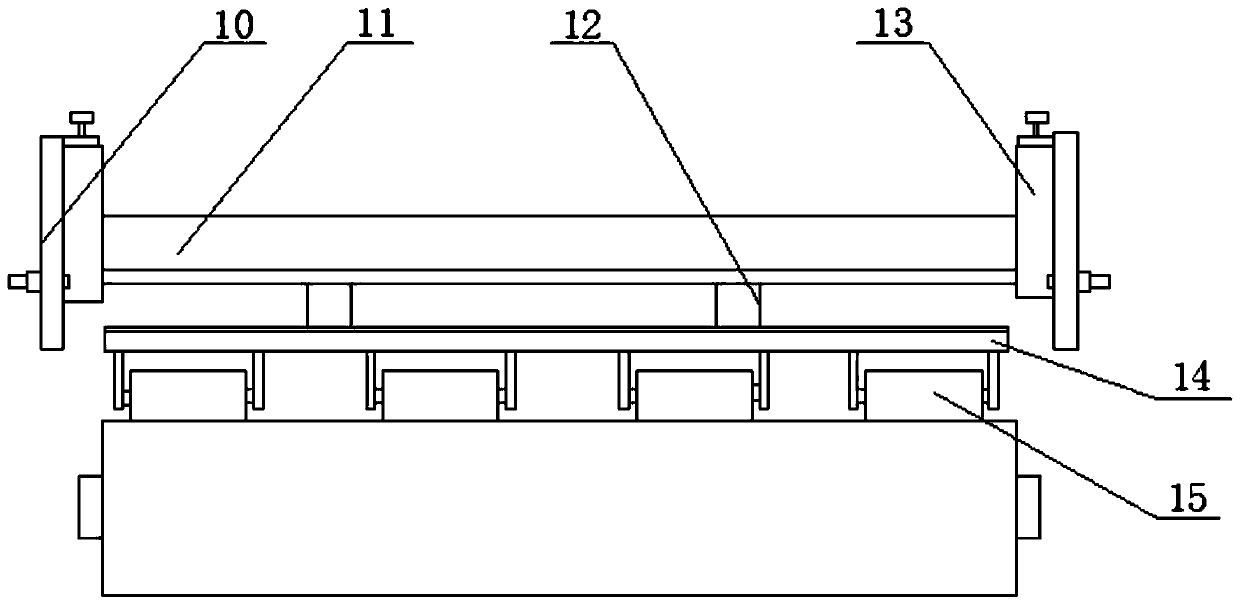

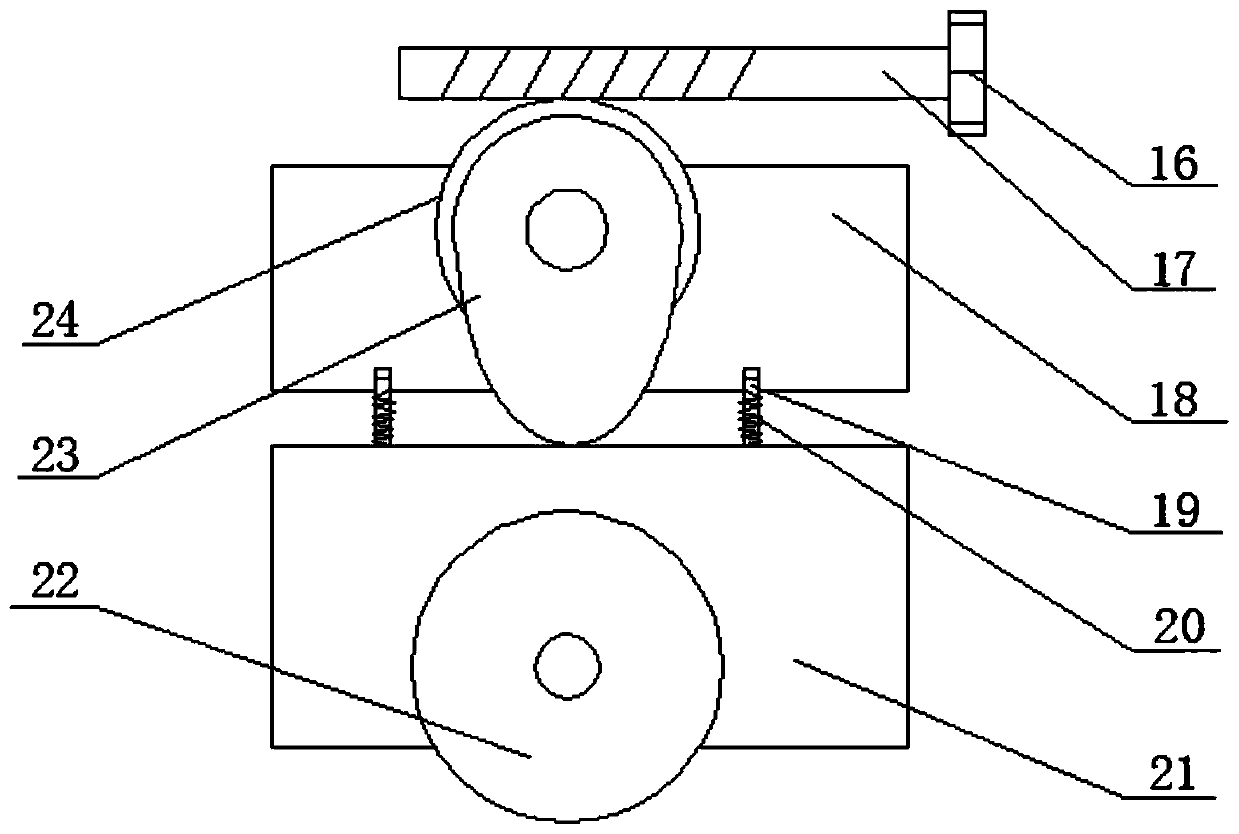

Ultra-light fiberboard compounding process and compounding device

PendingCN111591006AFlat surfaceReduce surface blemishesLamination ancillary operationsLaminationDust controlMechanical engineering

The invention discloses an ultra-light fiberboard compounding process and a compounding device. A fiberboard is placed in a coating machine, the fiberboard and a coating film are pressed and formed after being heated, then coating is conducted, the heating temperature is 100-130 DEG C, the workshop environment temperature is 15-25 DEG C, the humidity is 30% + / -2%, the pressure during pressing is set to be 15-20 MPa, and the pressing time is not shorter than 35 s. According to the invention, the fiberboard and the coating film can be compounded through low-temperature setting; the coating machine is provided with a liftable and movable hairbrush dust removal device, so that the dust removal effect of fiberboards with different thicknesses can be met; and a gluing device is provided with a gap adjusting device, so that the distance between glue rollers can be slightly and accurately adjusted to adapt to gluing of fiberboards with different thicknesses. The compounding device is uniform in gluing, thorough in dust removal, suitable for compounding fiberboards with different thicknesses, good in finished product quality, not prone to product edge warping and the like.

Owner:绍兴欣亚行汽车配件有限公司

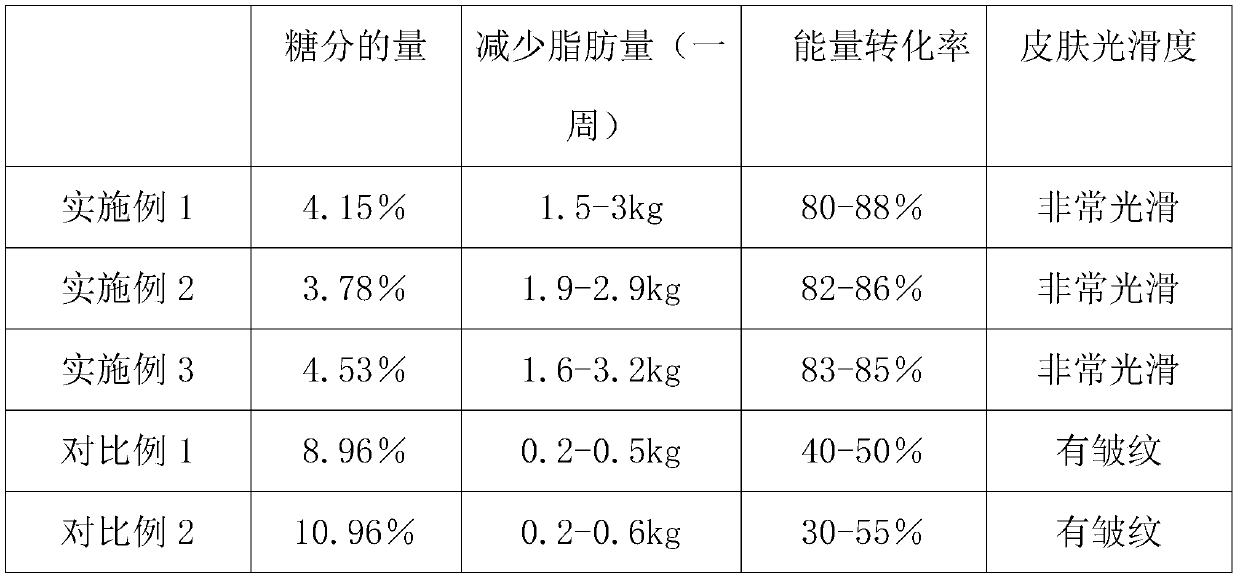

Auxiliary whitening anti-glycation beverage and preparation method thereof

PendingCN111357894ALow in sugarHigh energy conversion rateFood ingredient as taste affecting agentBiotechnology'Orange peel' skin

The invention relates to the technical field of food processing, in particular to an auxiliary whitening anti-glycation beverage. The beverage comprises the following components in percentage by weight: 55 to 65 percent of collagen, 23 to 30 percent of blueberry fruit powder, 11 to 15 percent of acerola cherry powder, 0.5 to 1.5 percent of chrysanthemum flower powder and 0.05 to 0.2 percent of stevioside. The auxiliary whitening anti-glycation beverage prepared by the invention is low in sugar content, capable of reducing more fat within one week and high in energy conversion rate, and the skin is smooth after the beverage is used for a period of time. The collagen can improve the compactness and elasticity of human skin, stimulate metabolism of collagen, proteoglycan and elastin, improveskin smoothness, reduce skin wrinkles, improve cellulite and reduce fat mass; the acerola cherry powder not only has an antioxidant effect, but also contains a blood-enriching component, namely iron,and can avoid dark yellow skin and color spots; the chrysanthemum flower powder has the effects of dispelling wind, clearing heat, calming the liver and improving eyesight; and the stevioside has thecharacteristics of high sweetness, low calorie and no obvious toxic or side effect.

Owner:山东国和堂制药有限公司

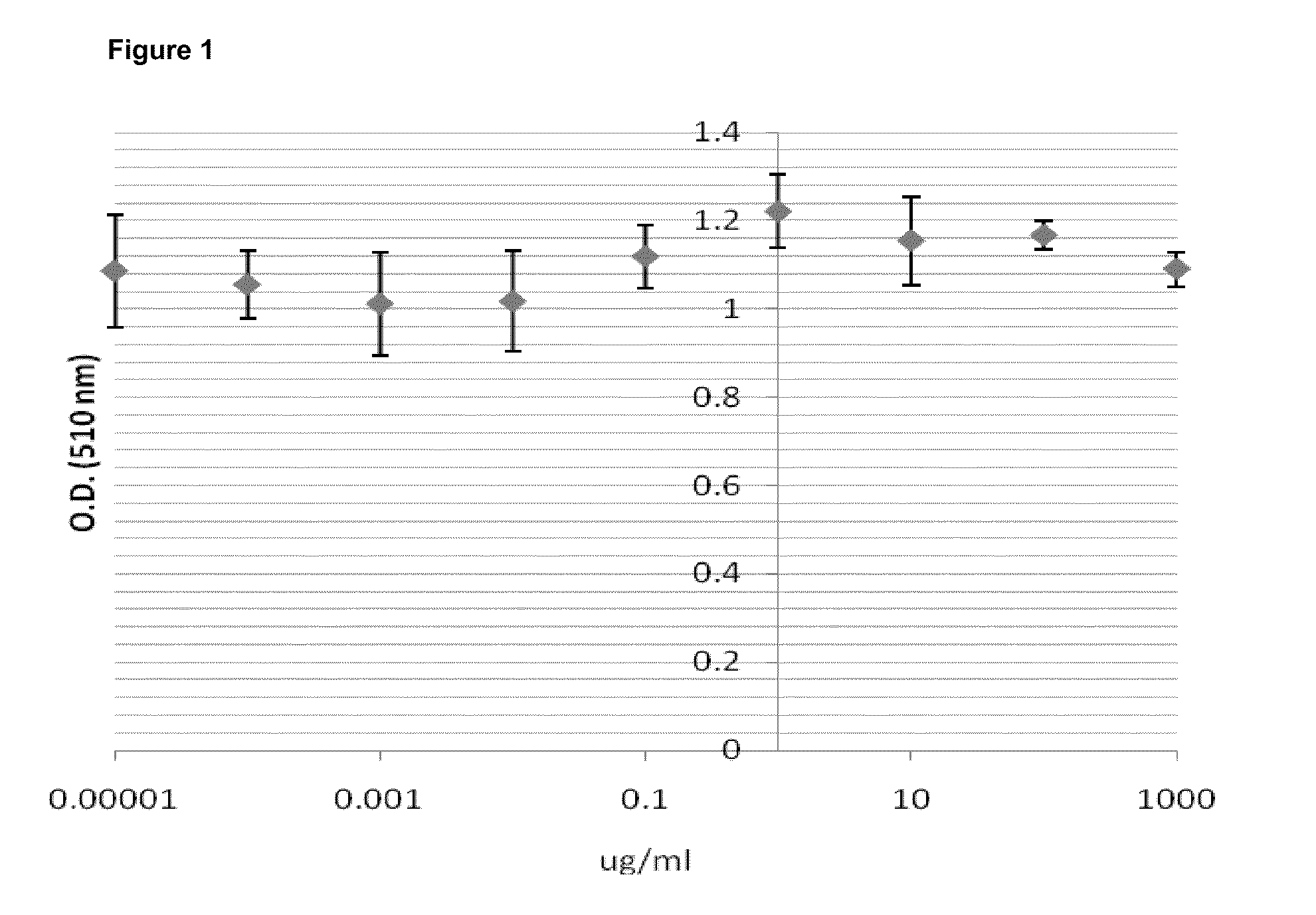

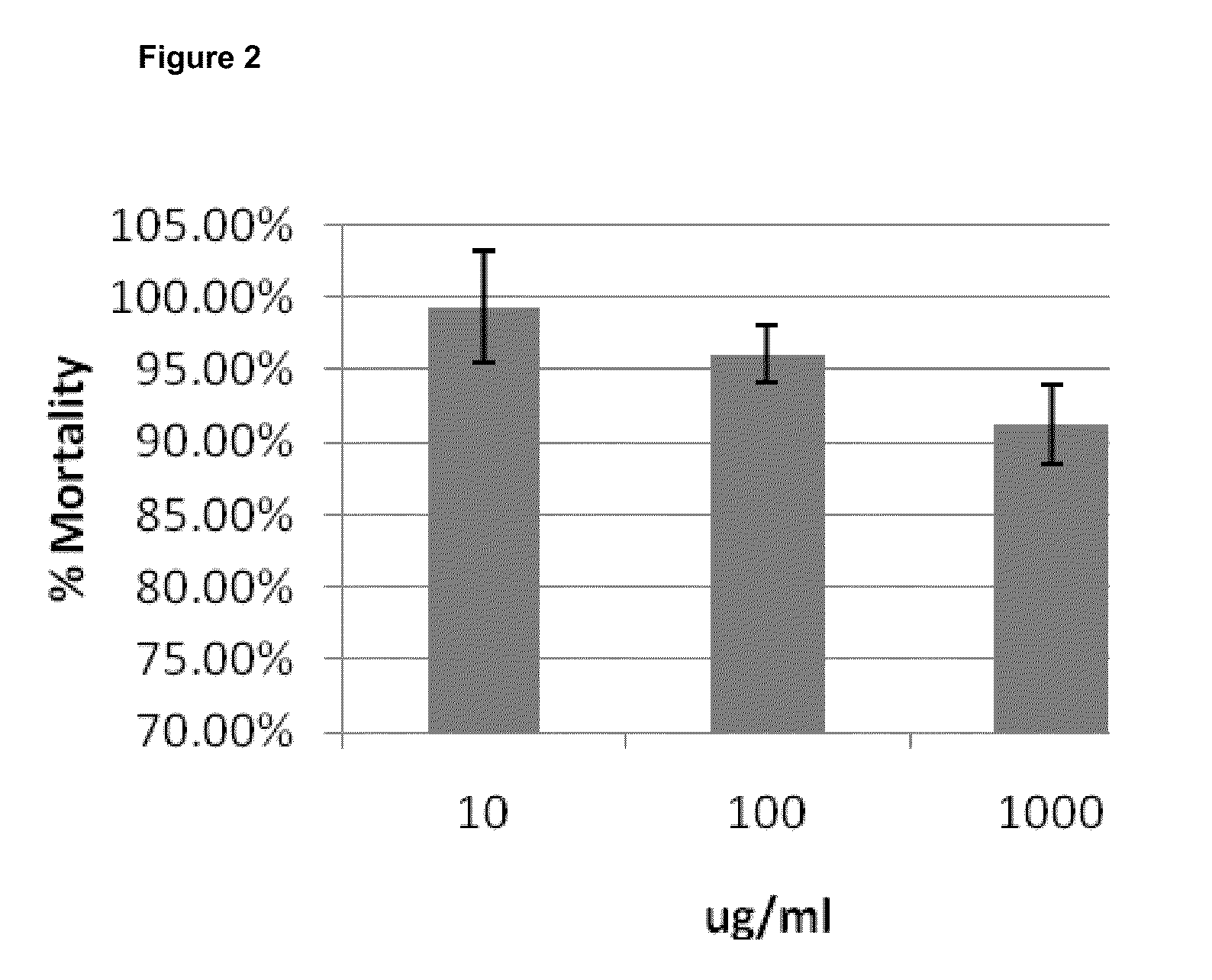

Compositions and methods of treating viral infections

ActiveUS8697670B2Decreasing body fatQuality improvementBiocideHydroxy compound active ingredientsSulfated polysaccharidesMedicine

The present invention relates to the field of nutraceuticals, and in particular to nutraceuticals comprising sulfated polysaccharides, Astragalus polysaccharides, resveratrol, and combinations thereof. These compositions find use in inducing physiological responses such, decreasing body fat, increasing lean body mass, alleviating the symptoms of colds, preventing the onset of colds, increasing energy, increasing the feeling of well-being in subjects, and improving skin tone and appearance.

Owner:LIFE SCI NUTRITION AS

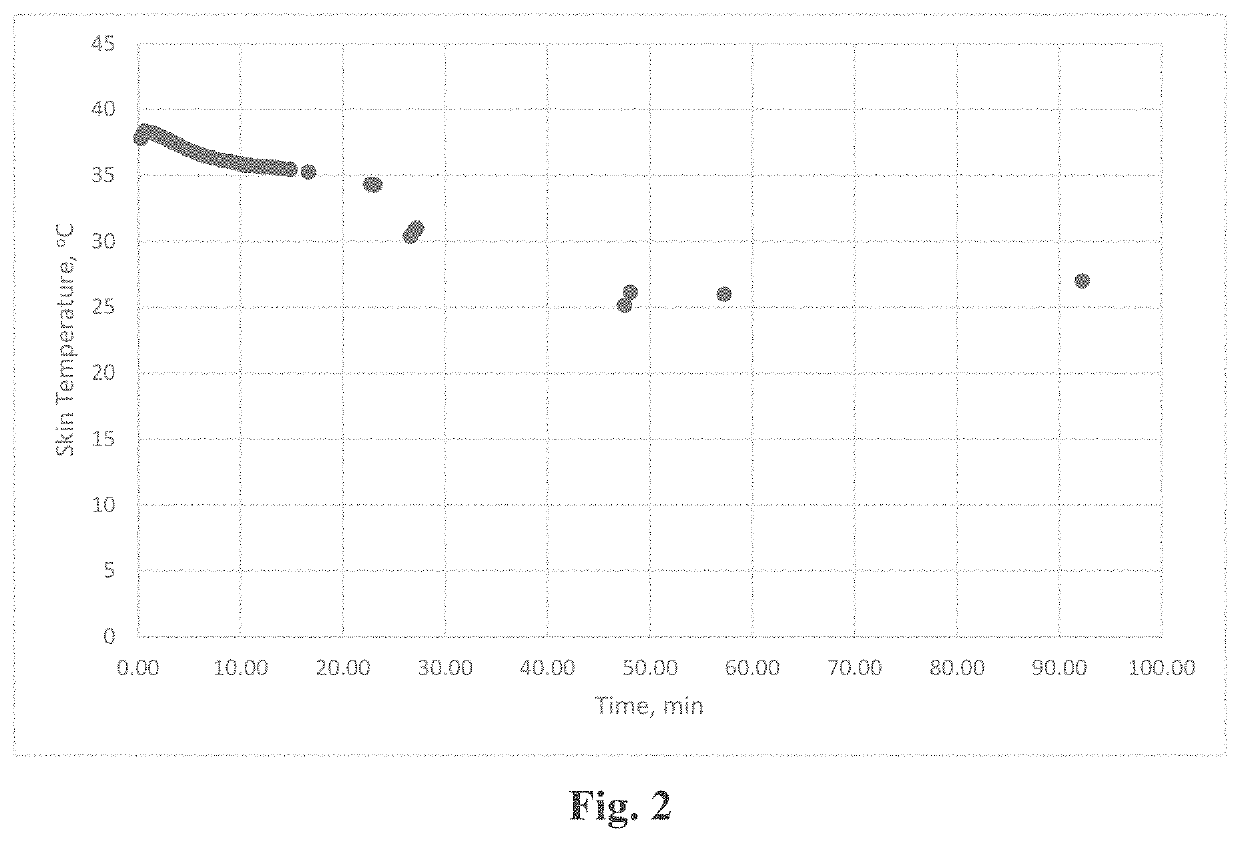

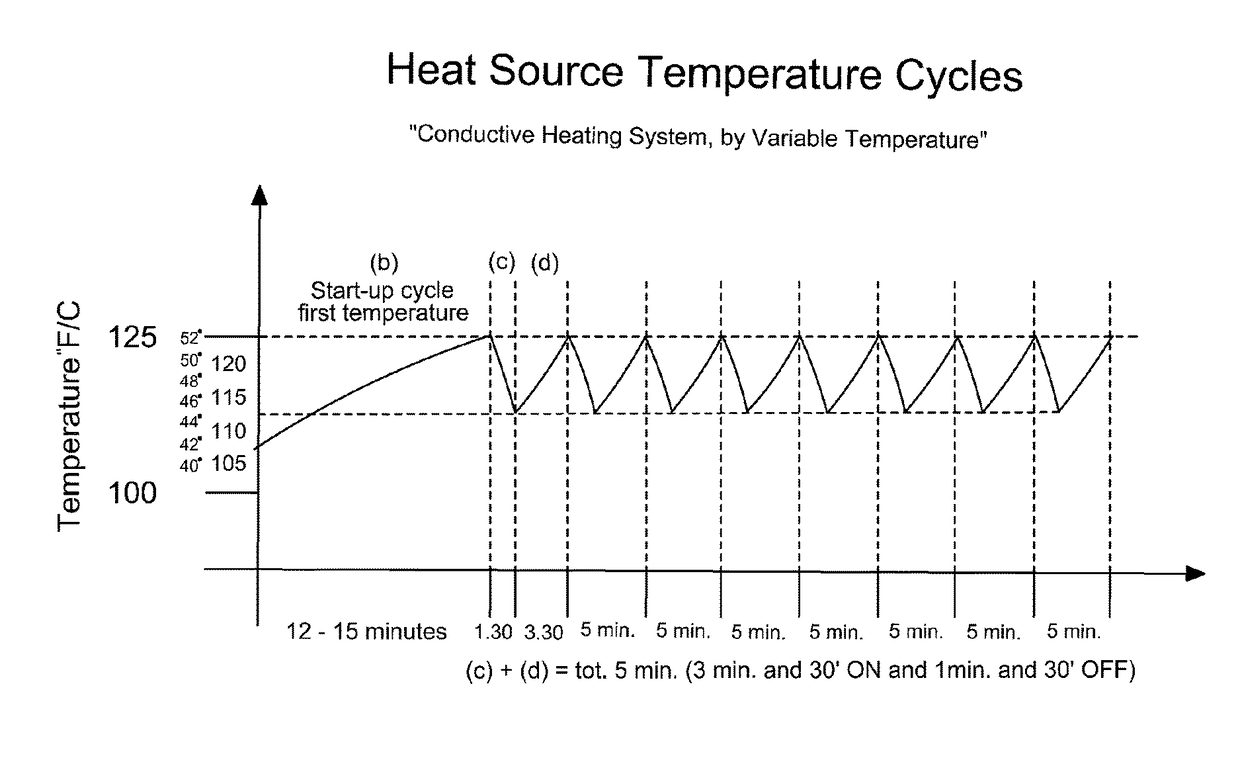

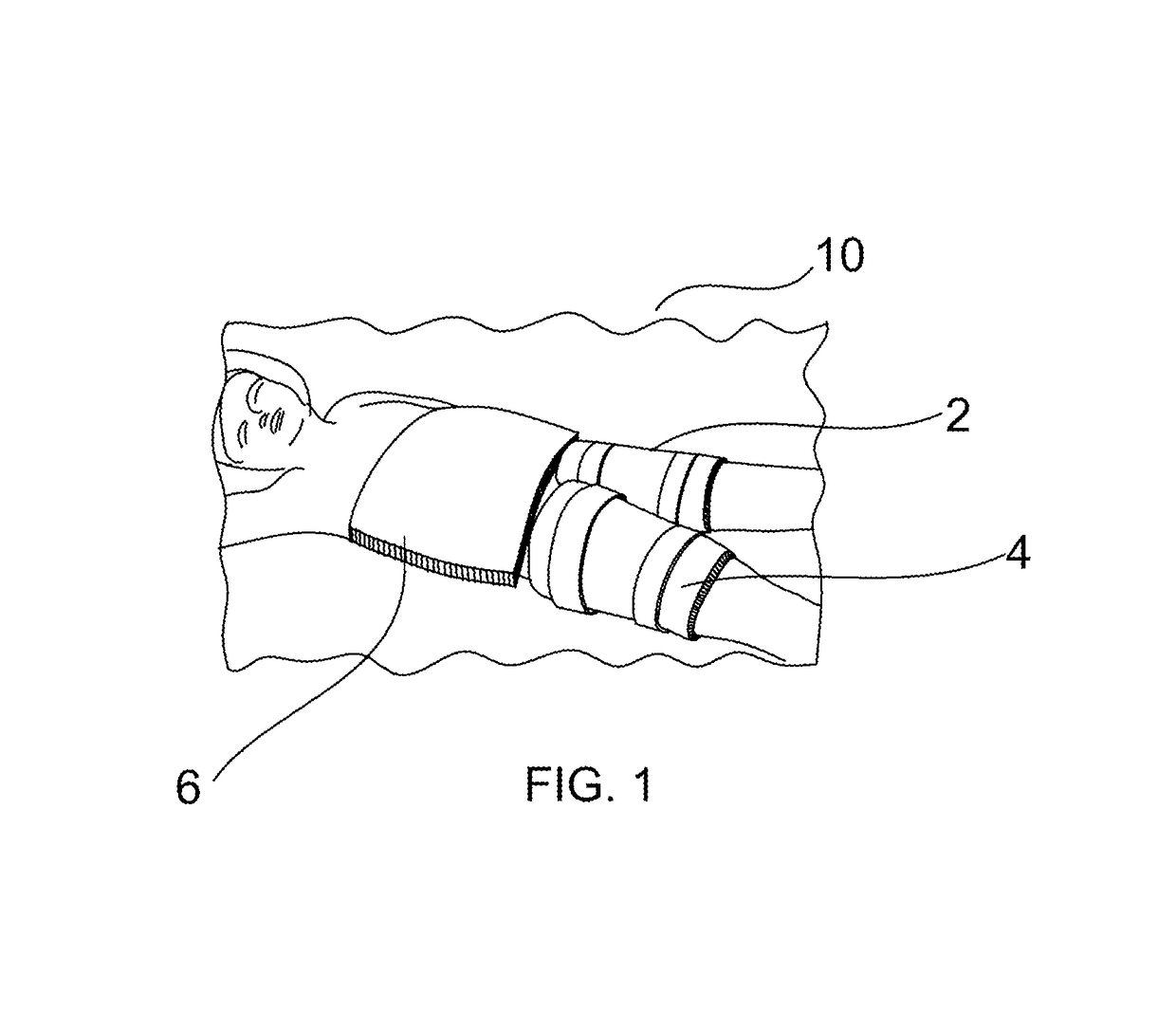

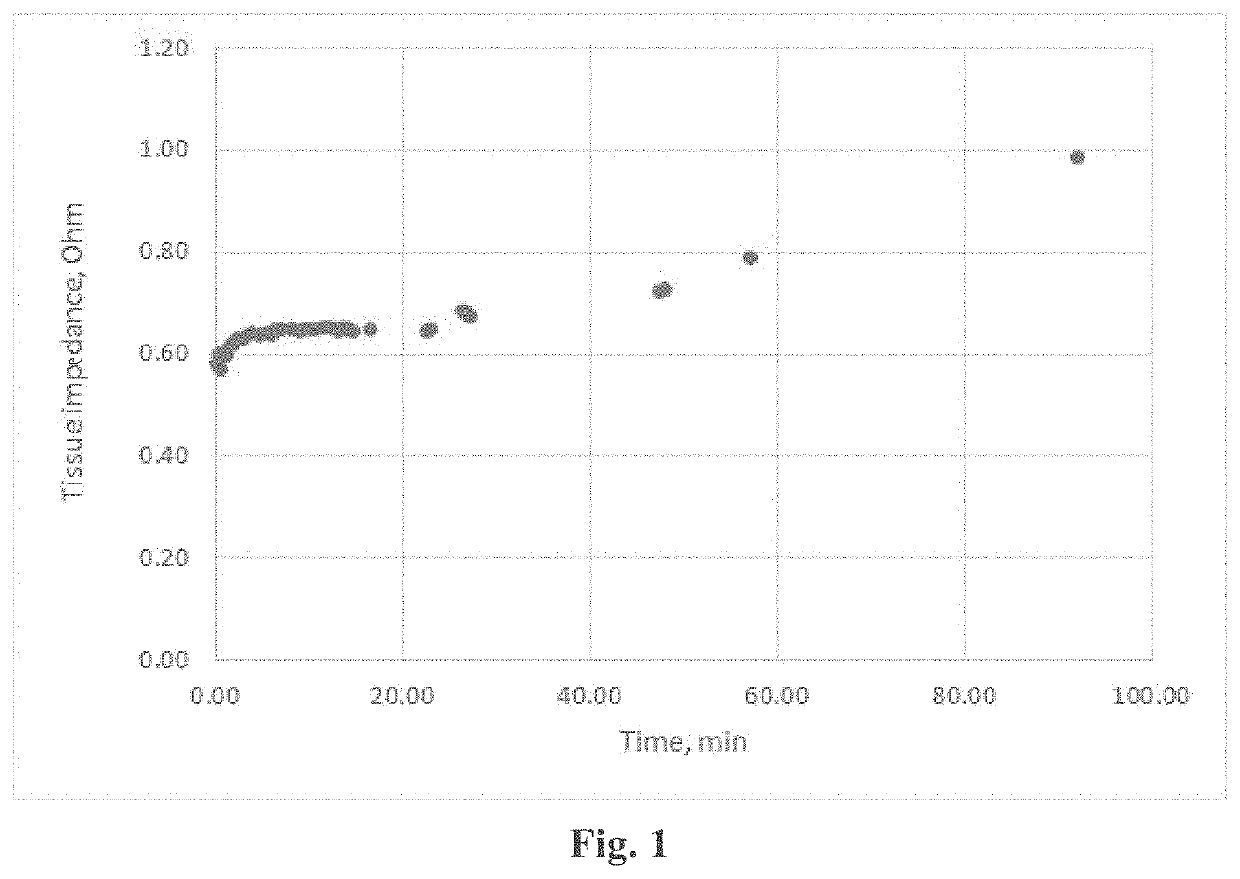

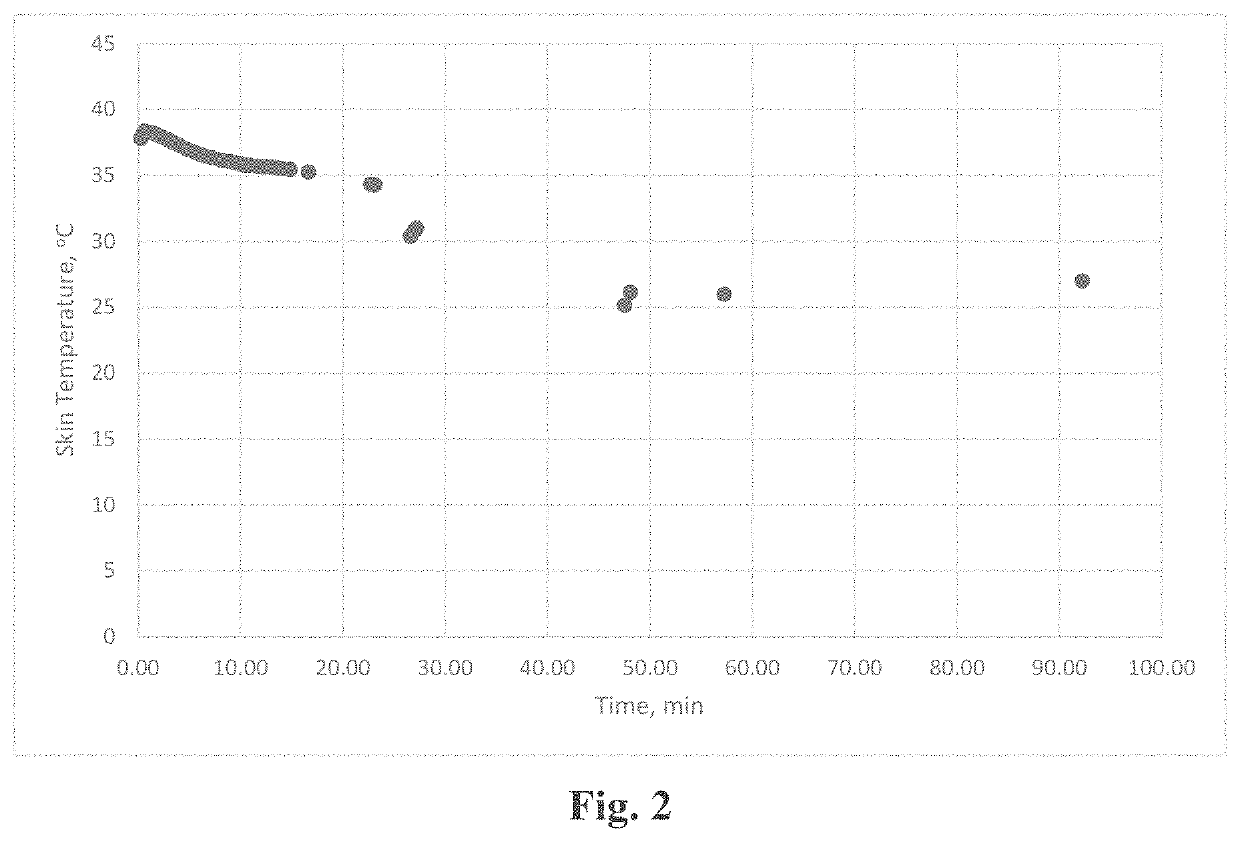

Non-invasive thermal wrap method for inducing calorie burning and weight loss

ActiveUS9597225B1Lower the volumePromote circulationEducational modelsTherapeutic coolingPolyesterWhole body

A method for reducing cellulite, local or generalized fat comprising applying thermal body wraps, which are cycled in temperature, is provided. Based on a body composition test, suggested targets for body fat percentage, total weight, fat weight, lean weight, weight to lose, body water percentage and basal metabolic rate are calculated. The thermal body wraps are described and may comprise layers of synthetic material, such as polyurethane and polyester fabric. The body wraps may have a heating circuit including a coaxially arranged heating cable, and a control loop including a negative temperature coefficient thermistor. The heating cable may have a protection wire, coaxially surrounding and insulated from a heating wire, so that if a break in the heating wire is detected, current flow to the heating wire is suspended. A thermostat in the wrap provides additional safety.

Owner:GUERRIERI MASSIMO

Use of 3-(4-hydroxy-3-methoxyphenyl)-1-(4-hydroxyphenyl) propane-1-one for improved skin contouring or against cellulite

InactiveUS8236859B2Increase moisture contentImprove surface structureCosmetic preparationsBiocideSkin surfaceConnective tissue

A cosmetic or dermatological preparation which is suitable for application to skin and comprises 3-(4-hydroxy-3-methoxyphenyl)-1-(4-hydroxyphenyl)-propane-1-one in a concentration which is effective for at least one of increasing skin moisture content, moisturizing skin, improving the surface structure of the skin, reducing cellulite, increasing the resilience and elasticity of skin, strengthening the connective tissue of skin, and reducing stretch marks on skin. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:BEIERSDORF AG

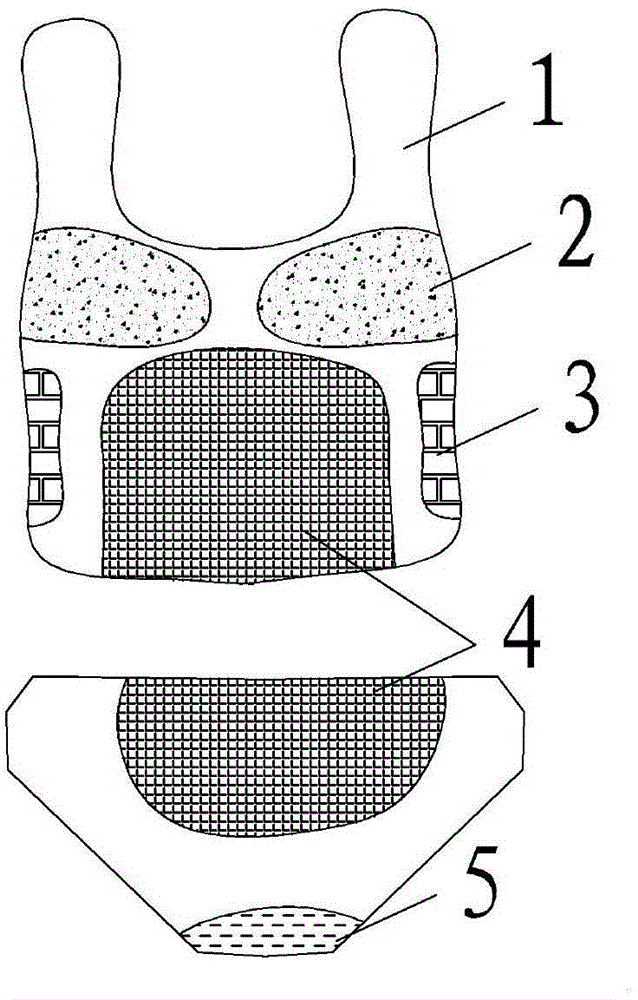

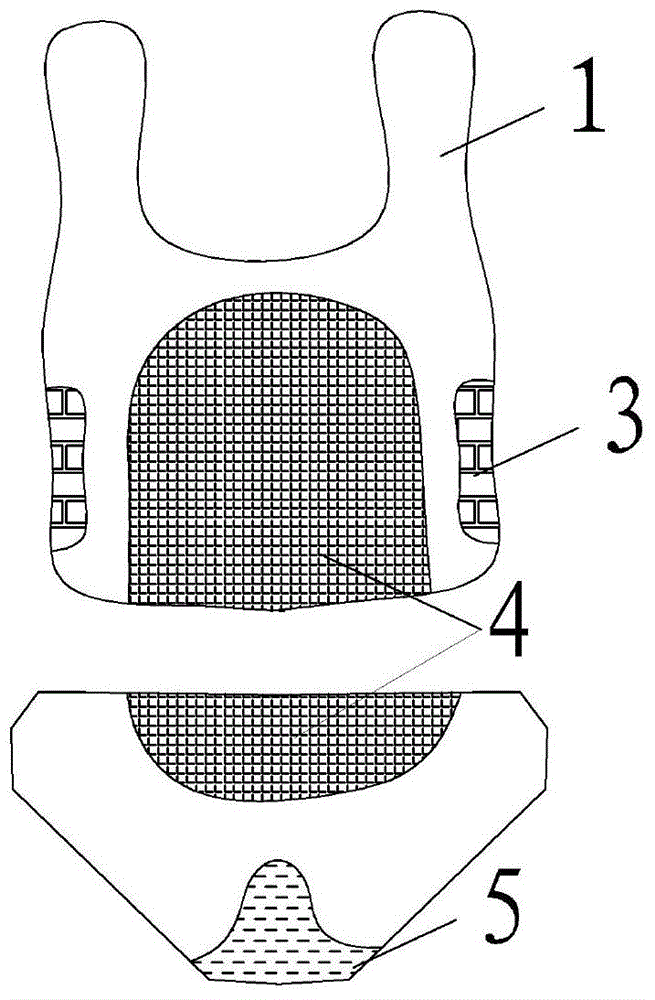

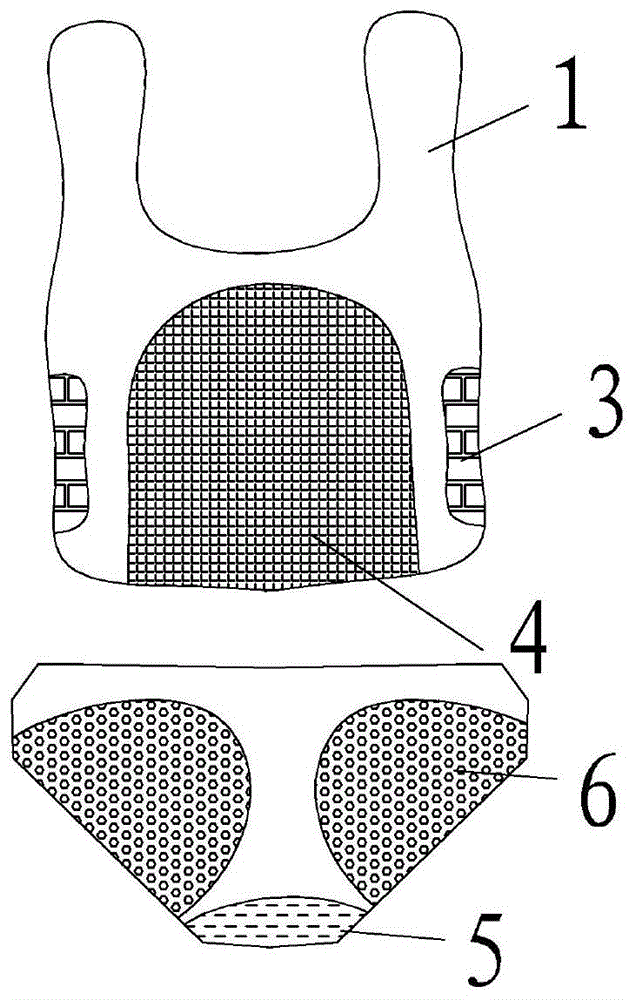

Health care underwear containing silks

InactiveCN104957785AGood moisture absorption and releaseGood heat dissipation and warmth retentionUndergarmentsBody shapeMedicine

The invention provides health care underwear containing silks. Main raw materials of the health care underwear are silks, according to different properties of all parts of the underwear, fabric surface structures are changed through weave structures such as honeycombs, cord weaves and through hole weaves, and the health care underwear with the higher pertinence is obtained; as the raw materials of the underwear are the silks, the problems of irritability and the like can be effectively prevented, and the health care underwear has the beneficial effects of moisture and air permeability, softness, comfort, light and thin character and the like; in addition, suture lines are arranged on the outer side of the underwear, so that discomfortableness caused by friction between the suture lines and the skin is reduced. By means of the health care underwear containing the silks, the good characteristic of the silks and the surface structure of the fabric are combined, so that moisture and air permeability, comfort and softness of a dresser are achieved; and the body shaping, massage and health care effect on different parts can be achieved.

Owner:SUZHOU WILDER IND & TRADE

Method for enhanced electro-muscle stimulation

ActiveUS11464970B2Increase muscle strengthReduce celluliteLight therapyExternal electrodesElectro stimulationPhysical therapy

Owner:INMODE LTD

Traditional Chinese medicine composition

InactiveCN105998800ASymptoms improvedGastroenteritis reliefDigestive systemAntinoxious agentsBiotechnologyVegetable oil

The invention relates to traditional Chinese medicine composition and belongs to the technical field of traditional Chinese medicines. The composition is prepared from the components in parts by weight as follows: 2-7 parts of dandelions, 2-9 parts of dark plums, 6-15 parts of heartleaf houttuynia herbs, 6-15 parts of mulberry fruits, 3-15 parts of polygonatum, 2-8 parts of fructus lycii, 6-15 parts of Chinese angelica, 3-15 parts of corn stigma, 2-8 parts of wax gourd peel, 2-6 parts of panax pseudoginseng and 2-10 parts of vegetable oil. The traditional Chinese medicine composition has no toxic or side effects, is mild, safe and reliable, can effectively clear away toxin in gastrointestinal tracts, plays a role in protection of intestinal mucosa, realizes both functions at the same time and has remarkable treatment effect on various gastrointestinal diseases.

Owner:佛山煜新科技有限公司

Water-clarifying liver-protecting compound preparation for tilapia aquiculture

The invention discloses a water-clarifying liver-protecting compound preparation for tilapia aquiculture, belonging to the technical field of aquiculture. The water-clarifying liver-protecting compound preparation comprises the following components in parts by weight: 15-20 parts of neutral protease, 0.5-2 parts of lipase, 3-5 parts of amylase, 8-15 parts of oriental wormwood powder, 15-20 parts of oriental water plantain powder, 5-10 parts of semen cassiae powder, 0.5-2 parts of chlorogenic acid, 0.1-2 parts of garlicin, 5-8 parts of trimethylglycine trimethylglycocoll, 0.2-2 parts of vitamin C and 25-50 parts of bentonite. After the raw materials are weighed according to the parts by weight, the raw materials are evenly mixed, are split-packaged and are finally packaged and warehoused. The water-clarifying liver-protecting compound preparation for tilapia aquiculture has the advantages that the effect is stable, the preparation can be directly spread and is convenient to use, the bioavailability is high and the efficacy is not influenced by environmental conditions; and after the preparation is used, the aquiculture water environment and the body internal environment of tilapia can be rapidly remedied, and the efficacies of clarifying the water, protecting the tilapia liver, building the body, preventing diseases and promoting the growth are taken.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com