Ultra-light fiberboard compounding process and compounding device

A composite device and composite process technology, which is applied in the production field of automotive interior materials, can solve problems such as difficult product warping, and achieve the effects of difficult product warping, good finished product quality, and reduction of surface spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, the heating temperature is 100°C, the ambient temperature of the workshop is 25°C, the humidity is 30%, the pressure during pressing is set to 20Mpa, the pressing time is 45s, the thickness of PVC film is 0.08mm, the thickness of GMT board is 0.4mm, fiberboard and The covering films are bonded by hot melt adhesive. The weight of the finished product after compounding is 1425 ± 3% g / m 2 , Lighter than traditional plates, maximum deformation ≤ 15mm, tensile strength ≥ 85MPa, flexural modulus ≥ 4000 MPa, impact strength ≥ 700J / m, the performance results of each test are far higher than the technical standards.

Embodiment 2

[0026] Example 2, the heating temperature is 130°C, the ambient temperature of the workshop is 15°C, the humidity is 28%, the pressure during pressing is set to 15Mpa, the pressing time is 50s, the thickness of PVC film is 0.15mm, the thickness of GMT board is 0.6mm, fiberboard and The covering films are bonded by hot melt adhesive. The weight of the finished product after compounding is 1680 ± 4% g / m 2 , Lighter than traditional plates, maximum deformation ≤ 14mm, tensile strength ≥ 102MPa, flexural modulus ≥ 5000 MPa, impact strength ≥ 800J / m, the test performance results are far higher than the technical standards.

Embodiment 3

[0027] Example 3, the heating temperature is 115°C, the ambient temperature of the workshop is 20°C, the humidity is 32%, the pressure during pressing is set to 18Mpa, the pressing time is 40s, the thickness of PVC film is 0.16mm, the thickness of GMT board is 0.5mm, fiberboard and The covering films are bonded by hot melt adhesive. The weight of the finished product after compounding is 1550 ± 3% g / m 2 , Lighter than traditional plates, maximum deformation 15mm, tensile strength ≥ 95MPa, flexural modulus ≥ 4500 MPa, impact strength ≥ 750J / m, the test performance results are far higher than the technical standards.

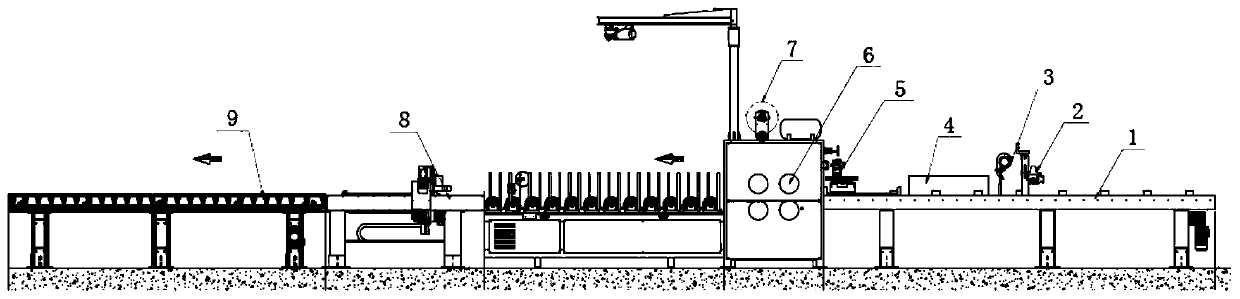

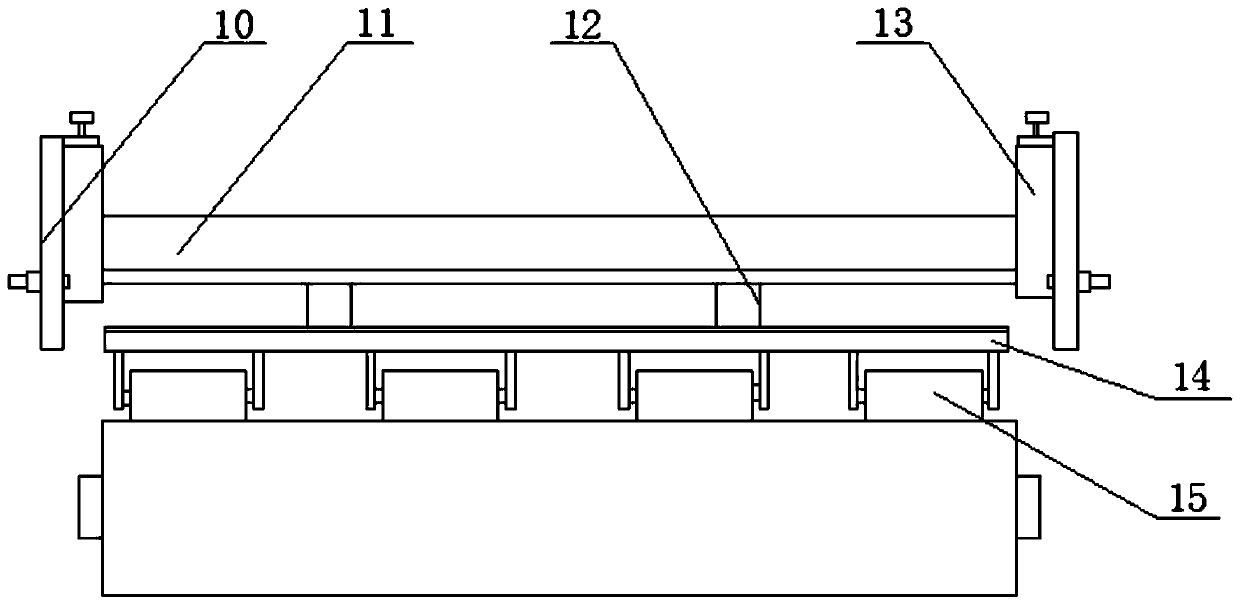

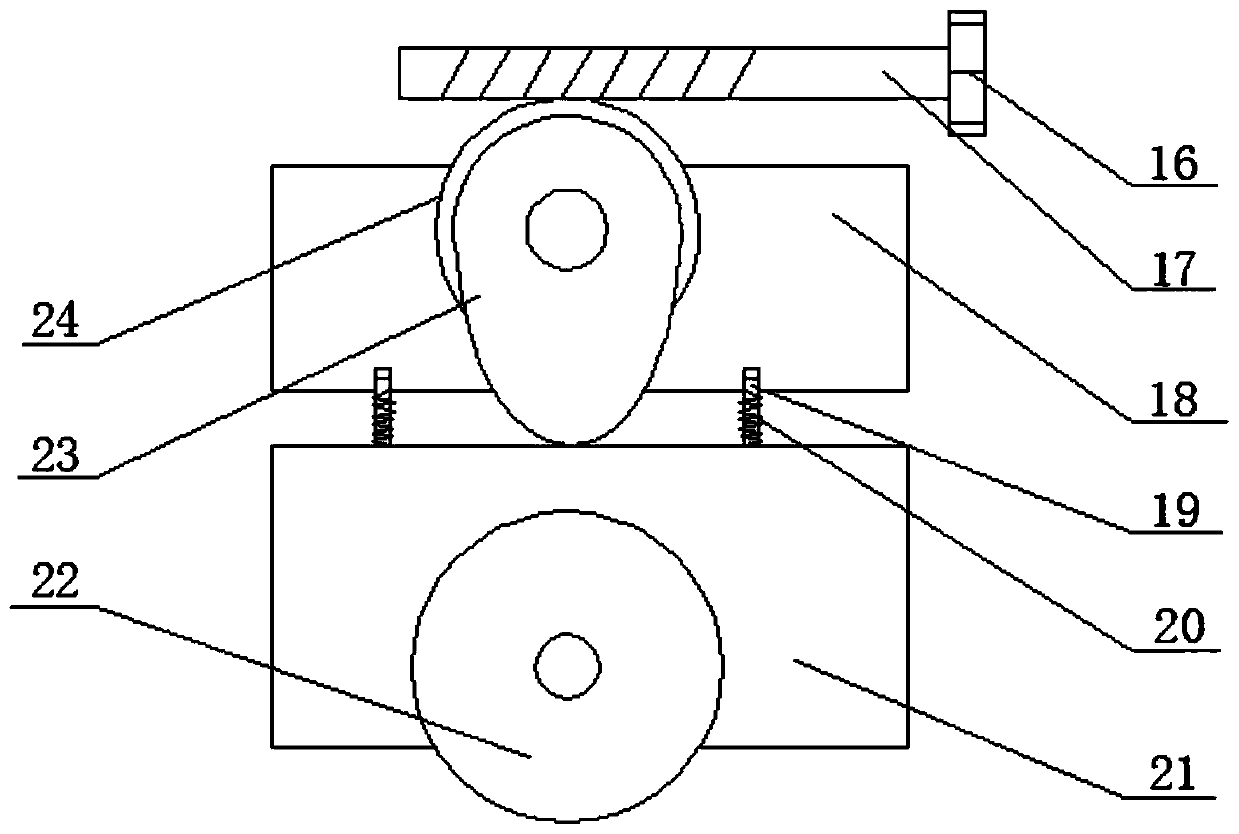

[0028]An ultra-light fiberboard composite device, the cladding machine includes a frame, along which a conveying device 1, a dust removal device, a heating device 4, a gluing device 5, a pressing device 6 and an online Cutting device 8. The fiber board automatically passes through the machine through the conveying device 1, and the surface of the fiber board is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com