A method for preparing a high-performance nitrogen-doped porous carbon-supported PtNi alloy particle methanol fuel cell catalyst

A nitrogen-doped porous carbon, methanol fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of high preparation cost, low output, complex process, etc. Cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

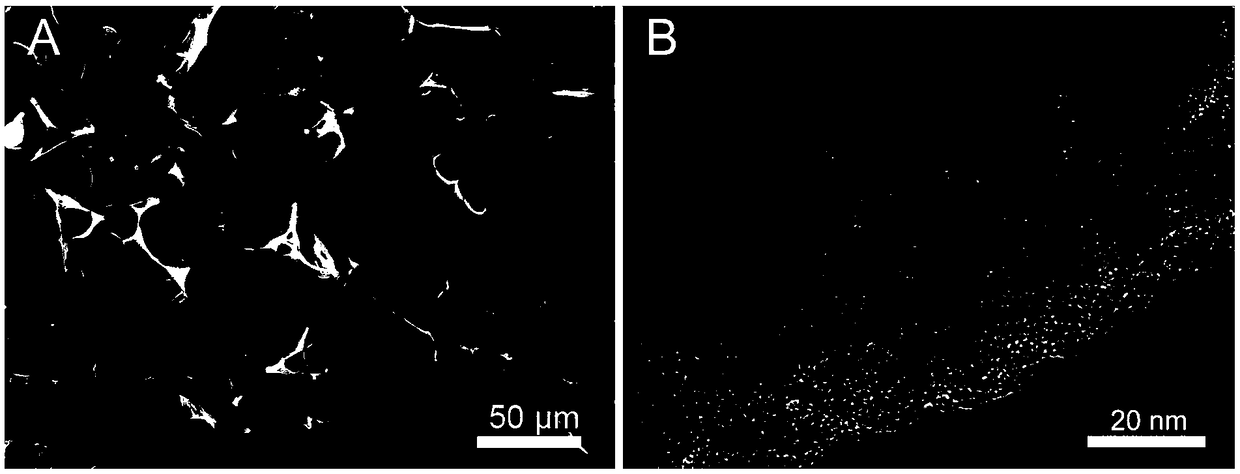

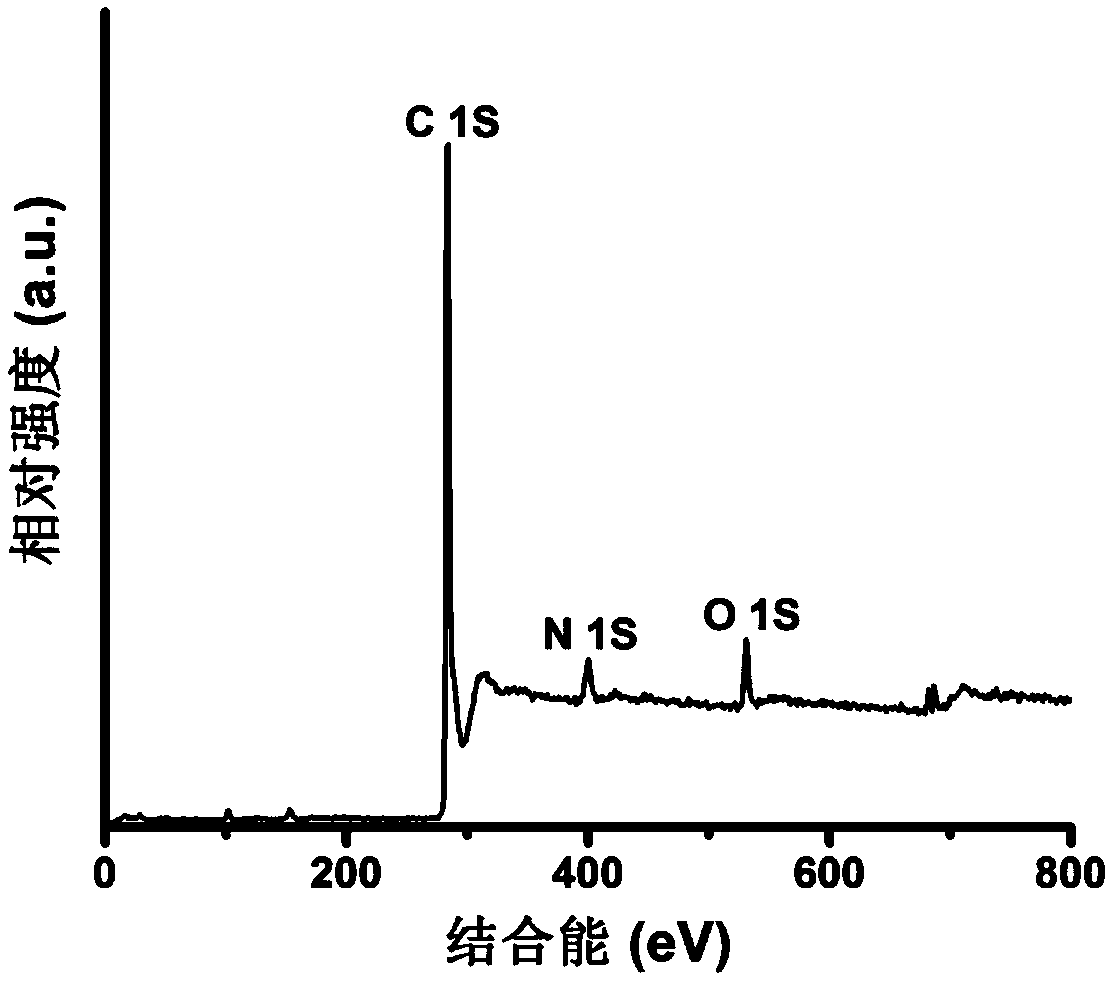

[0033] Step 1: Take 2g of the cigarette butt filter element and put it into a spice grinder to make a fluffy filter element with a tap density of about 0.02gcm -3 .

[0034] Step 2: Take 2g of the filter element and 20g of deionized water for hydrothermal reaction in a stainless steel reactor, raise the temperature to 250°C at a rate of 5°C / min, and keep the temperature for 2h. Then cool to room temperature at 5°C / min. The produced carbon material was dried at 112°C.

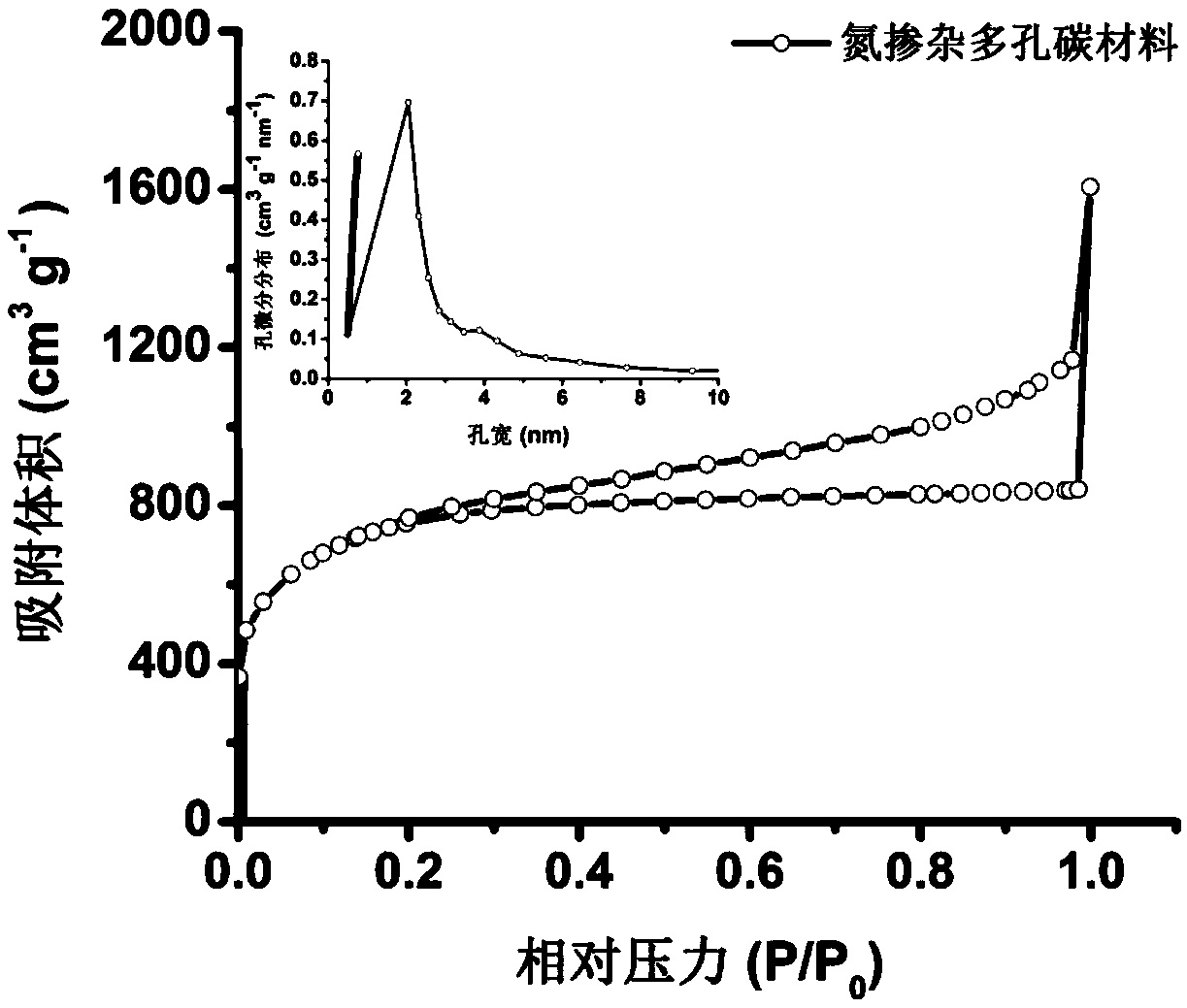

[0035] Step 3: Obtain 1.5g of carbonaceous substance, get 6g KOH and carbonaceous material. After grinding evenly, add alumina porcelain boat, heat to 800°C at 3°C / min under nitrogen protection, keep warm for 1h and then cool under nitrogen protection.

[0036] Step 4: the gac obtained is at 2mol L -1 Stirring recovery cleaning under the HCl solution, and then cleaning with deionized water until the pH is neutral. The obtained samples were dried in an oven at 112°C for use.

[0037]Step 5: Take 16 mg of th...

Embodiment 2

[0045] The preparation steps of the PtNi / N-HPC catalyst are the same as in Example 1, except that the holding temperature is 700°C when the carbon material is activated in the third step.

Embodiment 3

[0047] The preparation steps of the PtNi / N-HPC catalyst are the same as those in Example 1, except that the holding temperature is 900°C when the carbon material is activated in Step 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com