Preparation method of titanium dioxide loaded graphene base phase-change microcapsule

A technology of phase-change microcapsules and titanium dioxide, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., and can solve the problems of not being dispersed and easy agglomeration of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of titanium dioxide-supported graphene-based phase-change microcapsules, comprising the following steps:

[0028] (1) prepare a graphene oxide solution; get a certain amount of graphene oxide and dissolve it in an organic solvent, ultrasonically, and disperse;

[0029] (2) Preparation of fatty acid solution: Weigh 20g of phase change material and place it in a three-necked flask, then add 250ml of organic solvent and 5% surfactant, stir at a speed of 1200rpm to obtain an emulsion;

[0030] (3) Preparation of graphene oxide-coated phase change material: fix the above-mentioned three-necked flask in a constant temperature oil bath, set the reaction temperature to 60°C, add the solution in (1) into the three-necked flask, and add a catalyst at the same time to stir to oxidize Graphene attached to the surface of the phase change material droplet;

[0031] (4) Titanium dioxide deposition: cool down the above mixed solution, then treat it at a constant t...

Embodiment 2

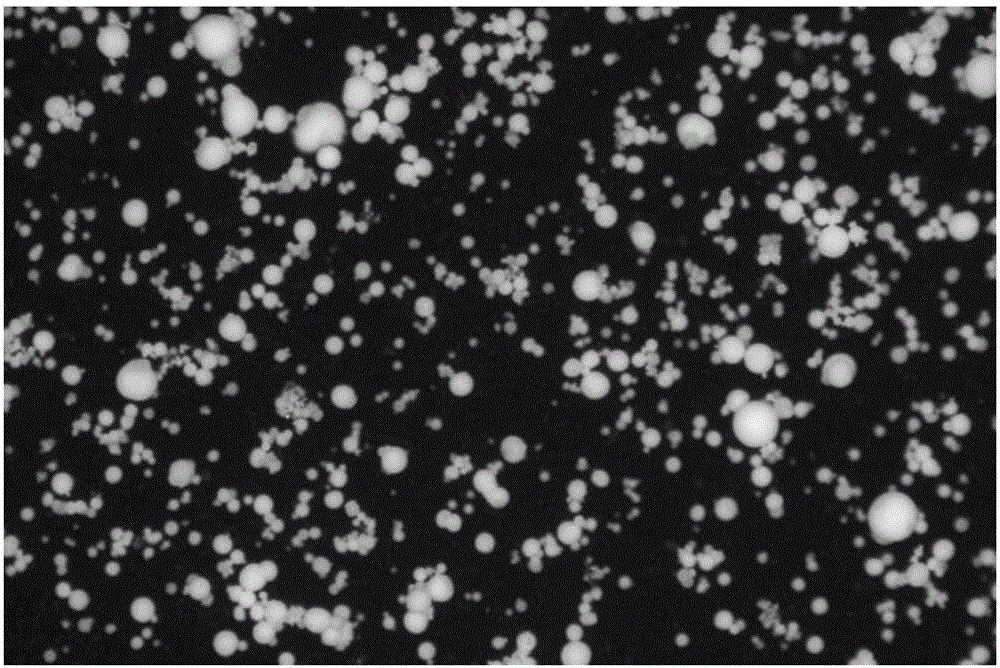

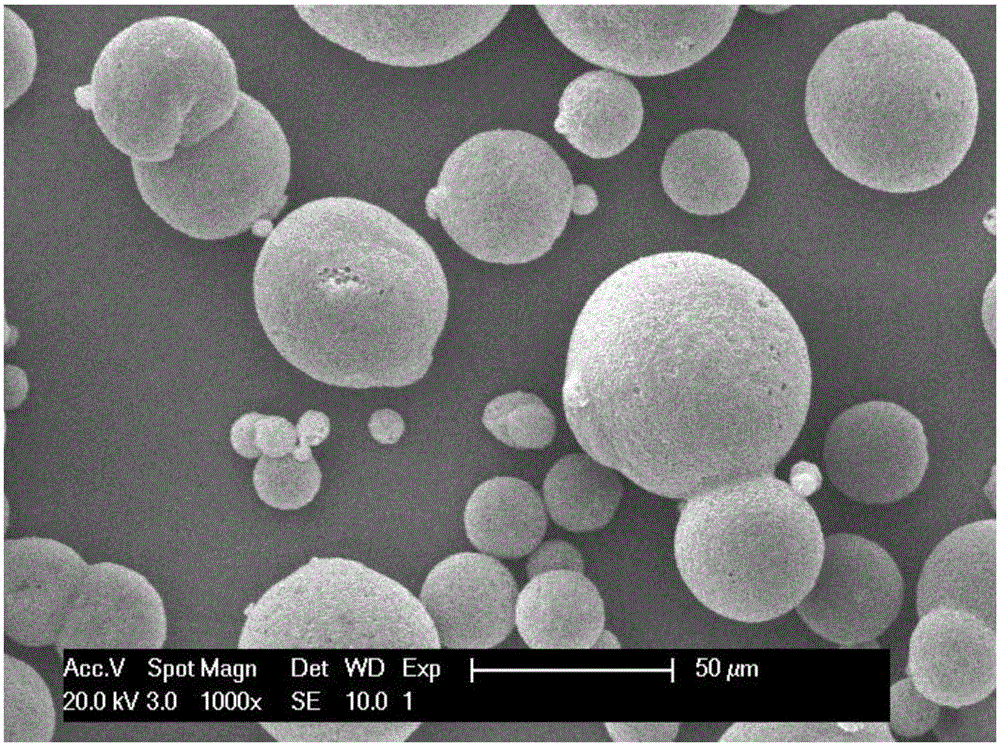

[0033] Such as figure 1 with 2 Shown, a kind of preparation method of titanium dioxide supported graphene-based phase change microcapsules, comprises the following steps:

[0034] (1) prepare a graphene oxide solution; get a certain amount of graphene oxide and dissolve it in an organic solvent, ultrasonically, and disperse;

[0035] (2) Preparation of paraffin wax solution: take 15g of phase change material and place it in a three-necked flask, then add 250ml of organic solvent and 5% surfactant, the surfactant is a compound Span-Tween emulsion, at a speed of 1000rpm Stir to obtain an emulsion;

[0036] (3) Preparation of graphene oxide-coated phase change material: fix the above-mentioned three-necked flask in a constant temperature oil bath, set the reaction temperature to 60°C, add the solution in (1) into the three-necked flask, and add a catalyst at the same time to stir to oxidize Graphene attached to the surface of the phase change material droplet;

[0037] (4) Ti...

Embodiment 3

[0039] A preparation method of titanium dioxide-supported graphene-based phase-change microcapsules, comprising the following steps:

[0040] (1) prepare a graphene oxide solution; get a certain amount of graphene oxide and dissolve it in an organic solvent, ultrasonically, and disperse;

[0041] (2) Preparation of paraffin wax solution: Weigh 20g of n-eicosane and place it in a three-necked flask, then add 250ml of organic solvent and 5% surfactant, the surfactant is sodium dodecylsulfonate, and carry out at a speed of 1100rpm stirring to obtain emulsion;

[0042] (3) Preparation of graphene oxide-coated phase change material: fix the above-mentioned three-necked flask in a constant temperature oil bath, set the reaction temperature to 60°C, add the solution in (1) into the three-necked flask, and add a catalyst at the same time to stir to oxidize Graphene attached to the surface of the phase change material droplet;

[0043] (4) Titanium dioxide deposition: lower the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com