Arrangement of components in a fluid energy machine and assembly method

a technology of fluid energy machines and components, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as harboring the risk of damage, damage to adjacent components, and damage to adjacent parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]All directional statements such as axial, radial, tangential or circumferential direction always relate—unless stated otherwise—to the longitudinal axis X of the rotor. The longitudinal axis X of the rotor R corresponds to the axis of rotation of the rotor R during operation. The central longitudinal axes of the impellers, of the inner bundle IB, of an outer housing OC, of a cover COV, of a low-pressure insert LPU and of a collector COL run in substantially coincident fashion, aside from planned or unplanned deviations which are not relevant in the context of the invention.

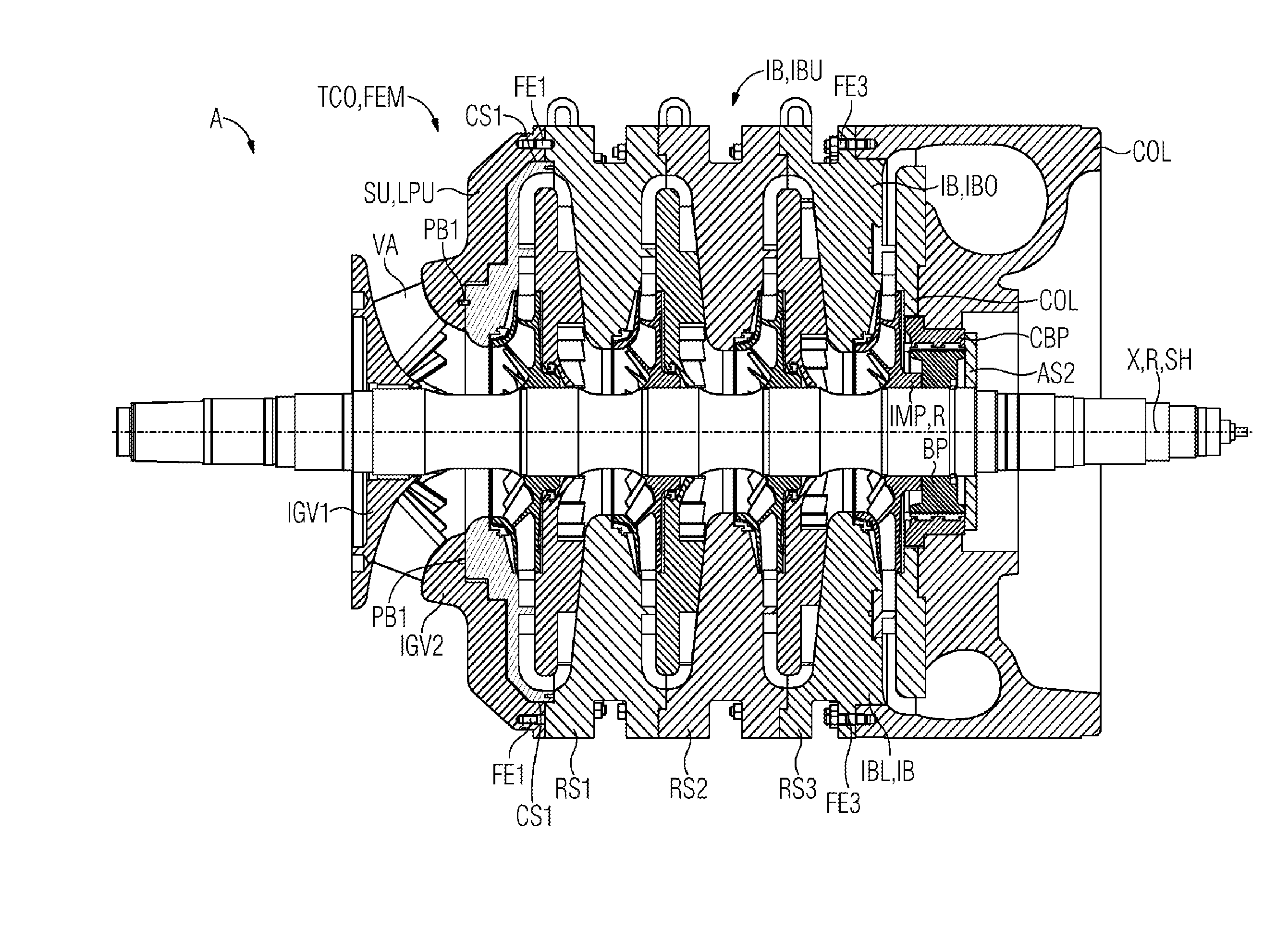

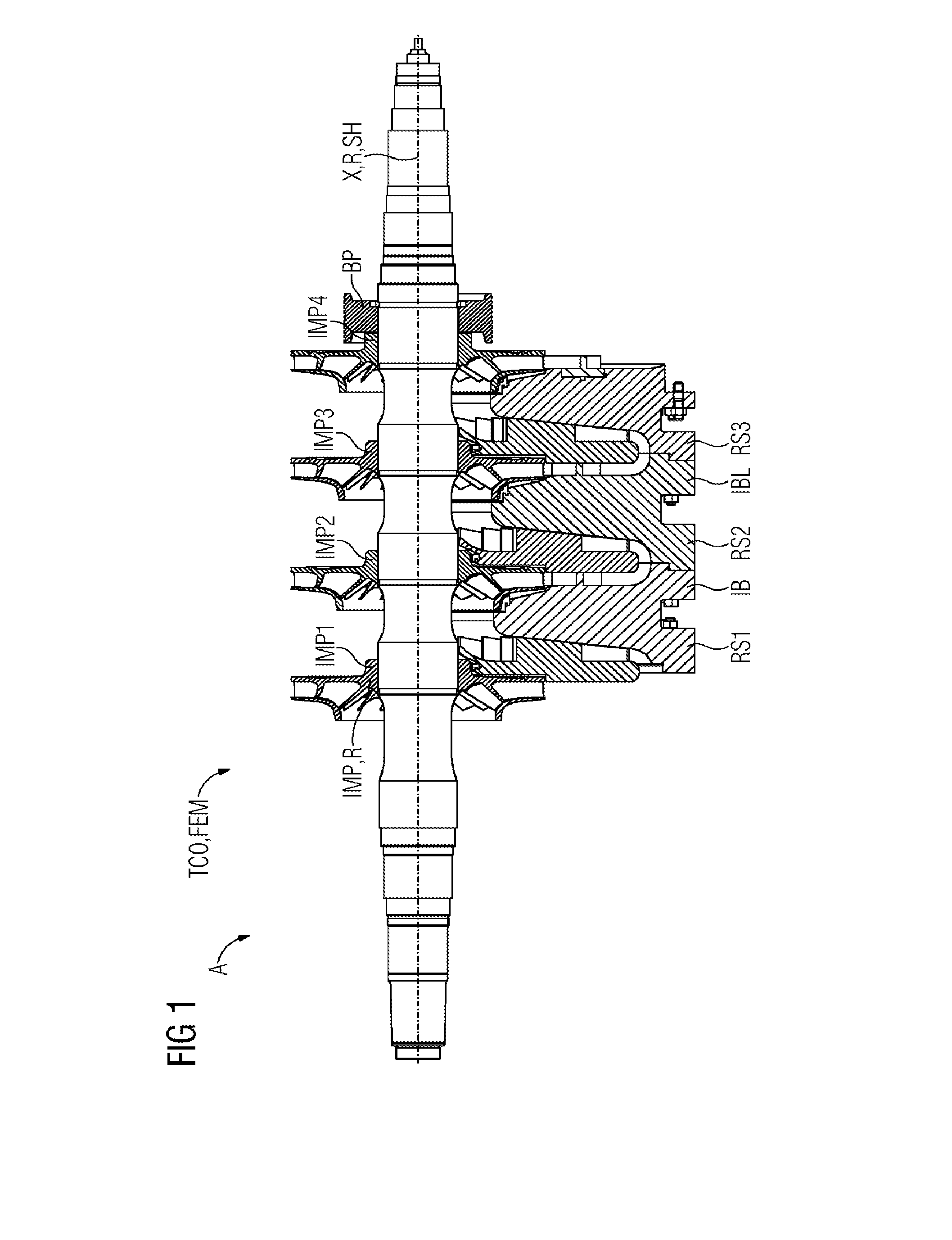

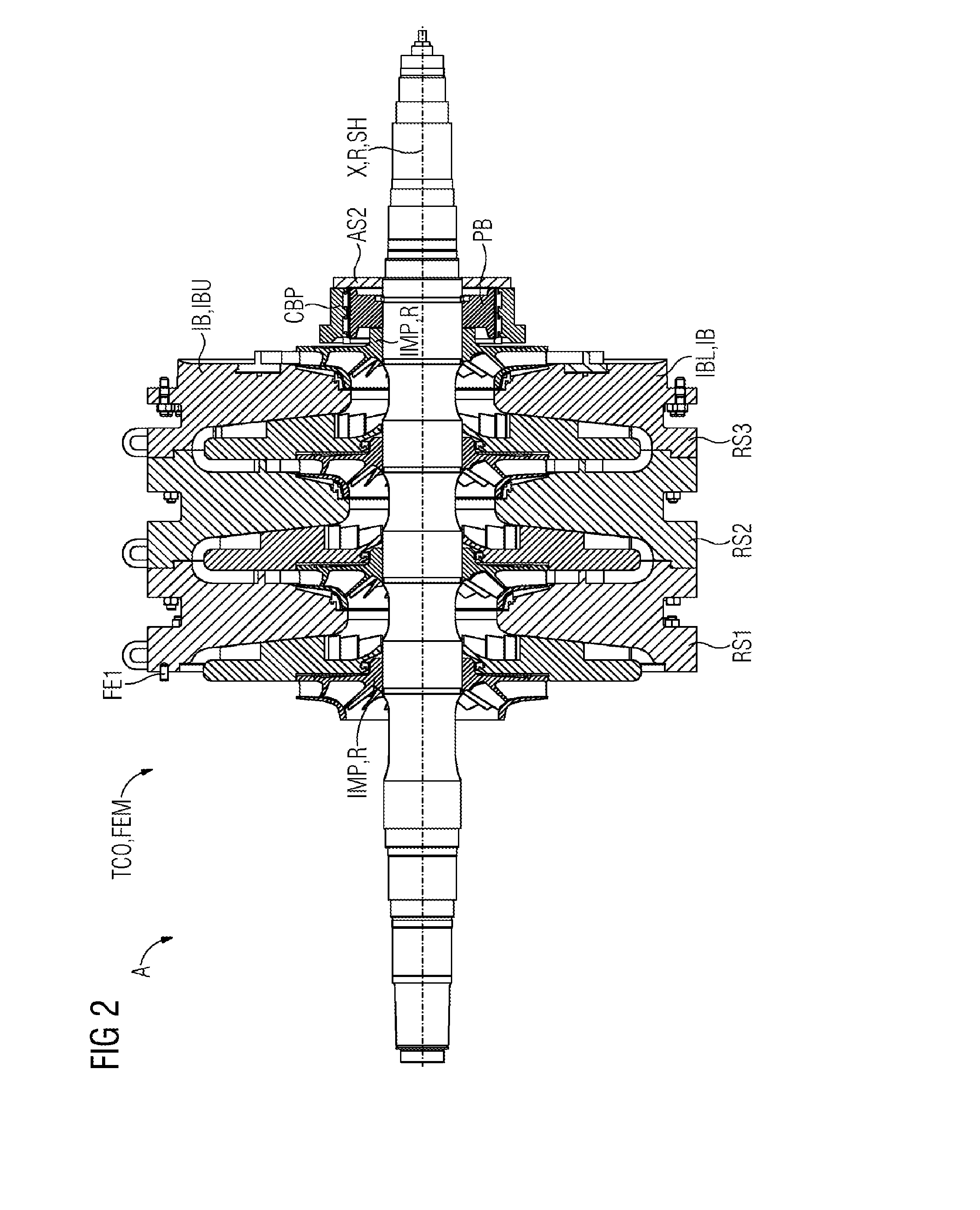

[0042]FIGS. 1-5 show, in each case in an illustration of a longitudinal section, an arrangement A comprising components of a fluid energy machine FEM, specifically of a turbocompressor TCO, with a longitudinal axis X. Here, FIGS. 1-5 show different stages of the assembly of the components in the context of an assembly process in successive steps, wherein FIG. 1 illustrates the smallest number of components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com