Magnetic field coupling-eliminating magnetic bearing and manufacturing method thereof

A technology for magnetic bearings and magnetic field elimination, applied in the direction of magnetic bearings, bearings, bearing components, etc., can solve the problems of difficult guarantee, complicated manufacturing process, high concentricity, etc., and achieve the goal of improving control accuracy, simple manufacturing process, and reducing control difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

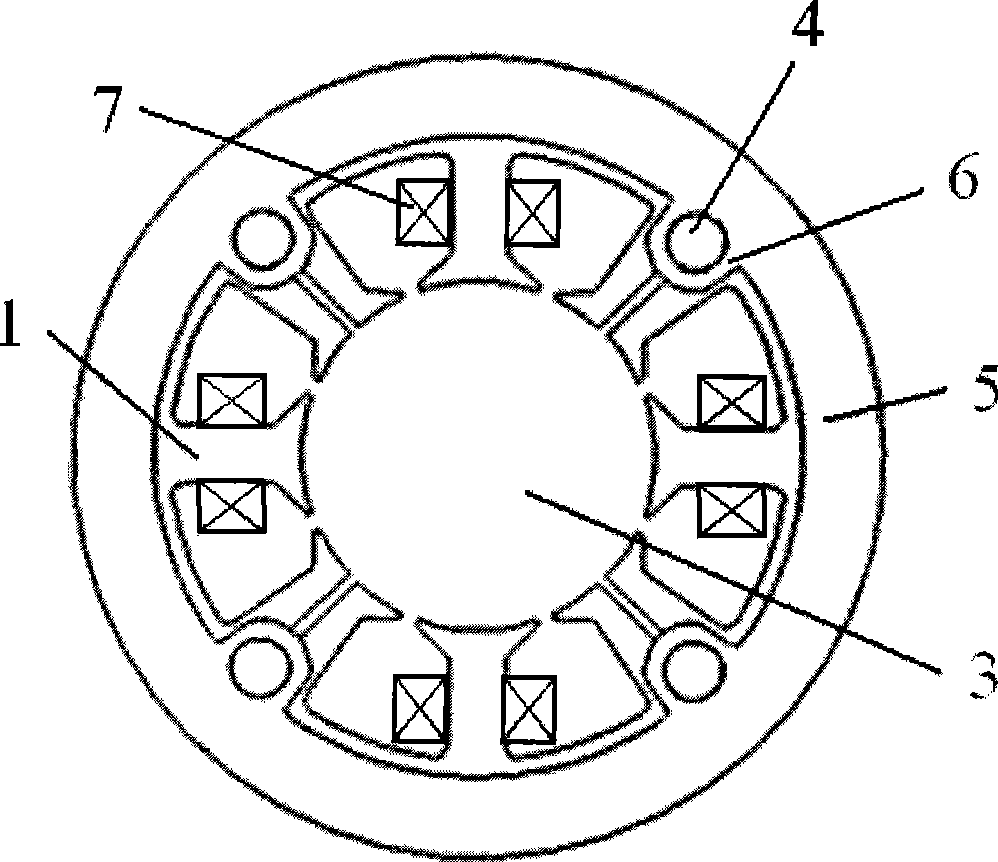

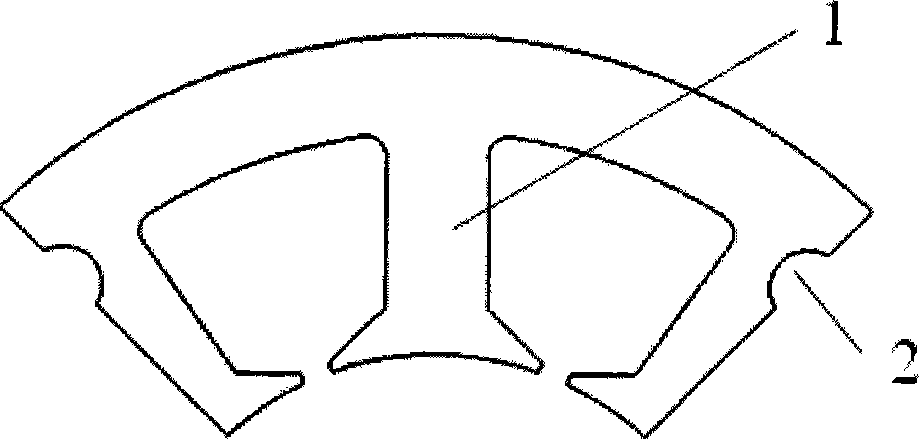

[0021] The magnetic force bearing that eliminates magnetic field coupling provided by the present invention has a structure such as figure 1 As shown: it is composed of four magnet cores 1, four coils 7, two magnetic isolation rings 5, and four rivets 4, and the four magnet cores 1 are all "E"-shaped structures. Among them: the two magnetic isolation rings are matched with the outer circle of the magnet core by using their spigots, and are respectively placed on both sides of the magnet core to clamp the magnet core, and the magnetic isolation ring and the magnet core are riveted together by rivets, each A coil 7 is wound with an enameled wire on the magnet core to form a whole magnetic bearing.

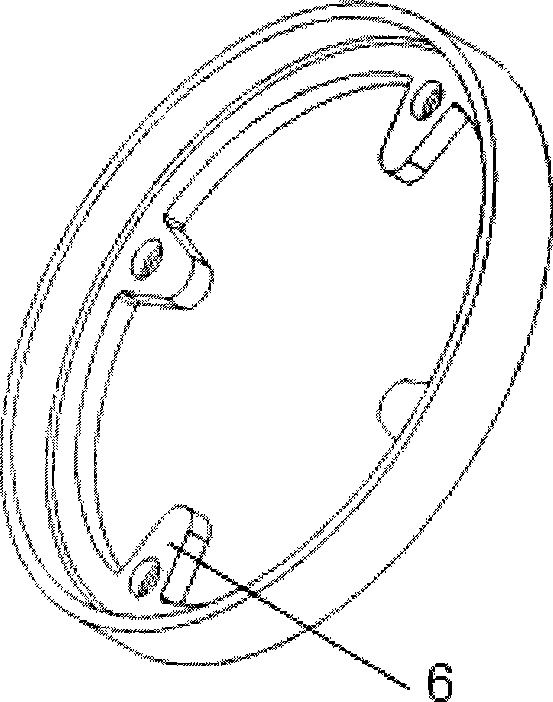

[0022] Described magnetic isolation ring 5 has a structure such as figure 2 As shown: four lugs 6 are evenly distributed on its inner circle, and each lug 6 has a round hole for rivet connection; Round fit spigot structure.

[0023] The magnetic isolation ring 5 and the rivet 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com