Patents

Literature

75results about How to "Accurate concentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

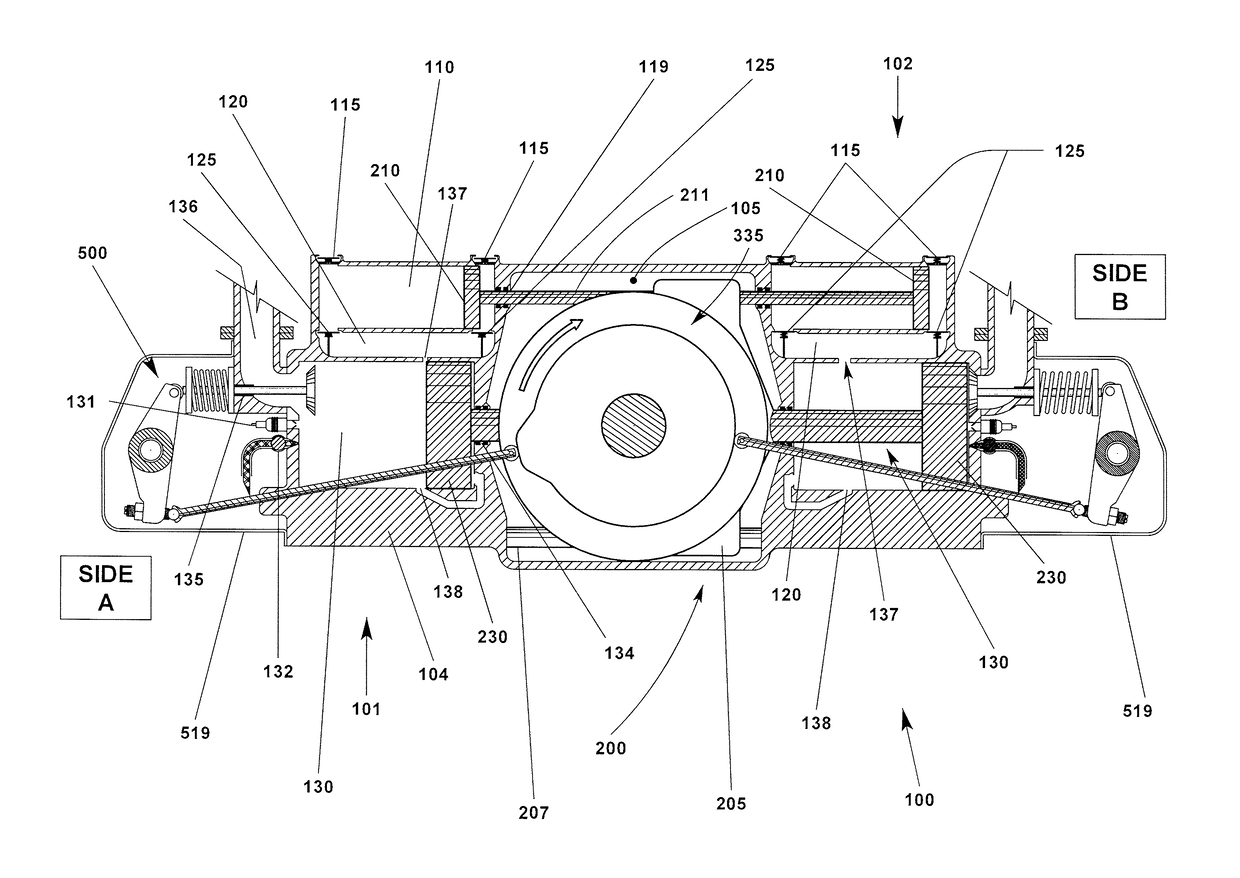

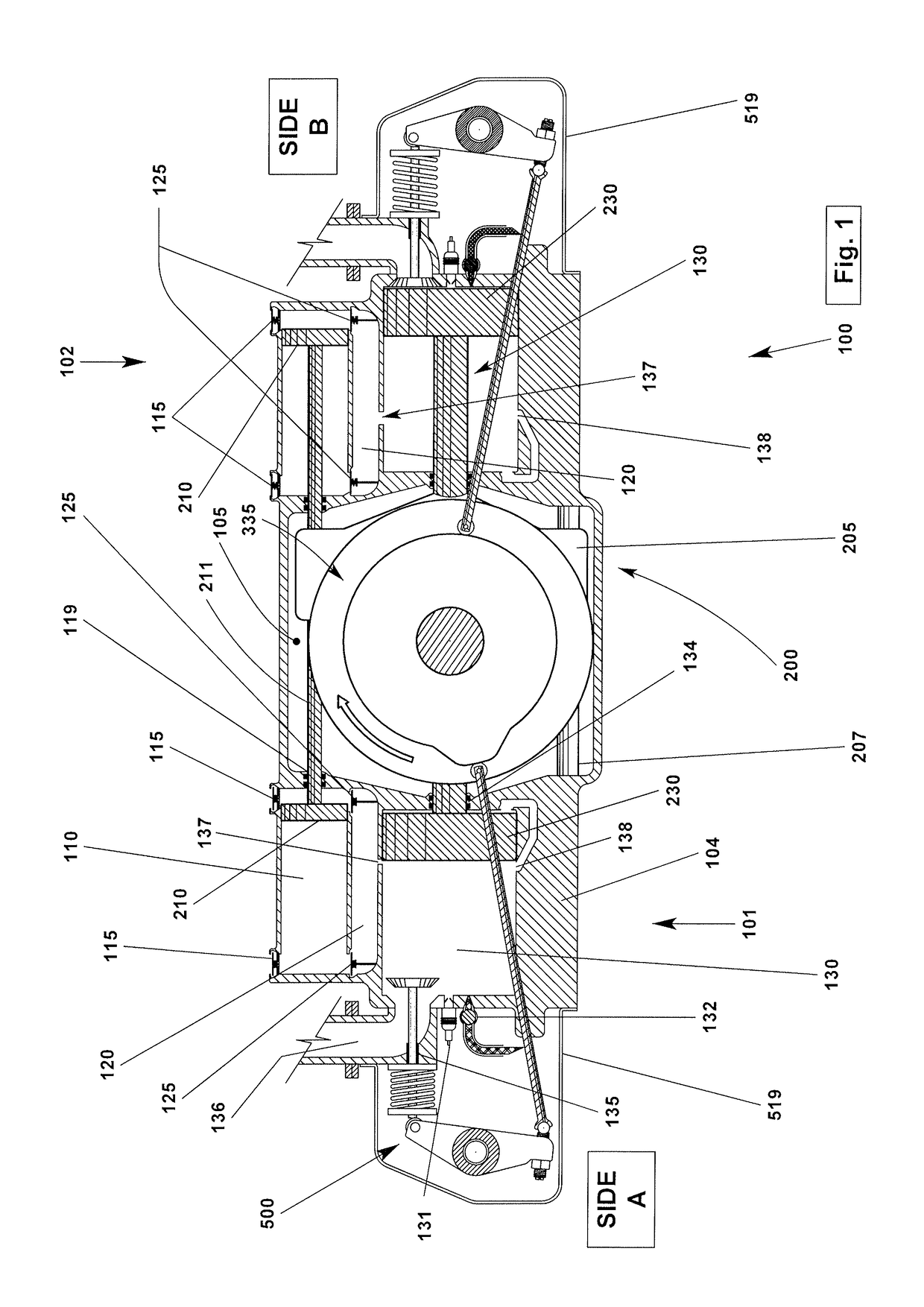

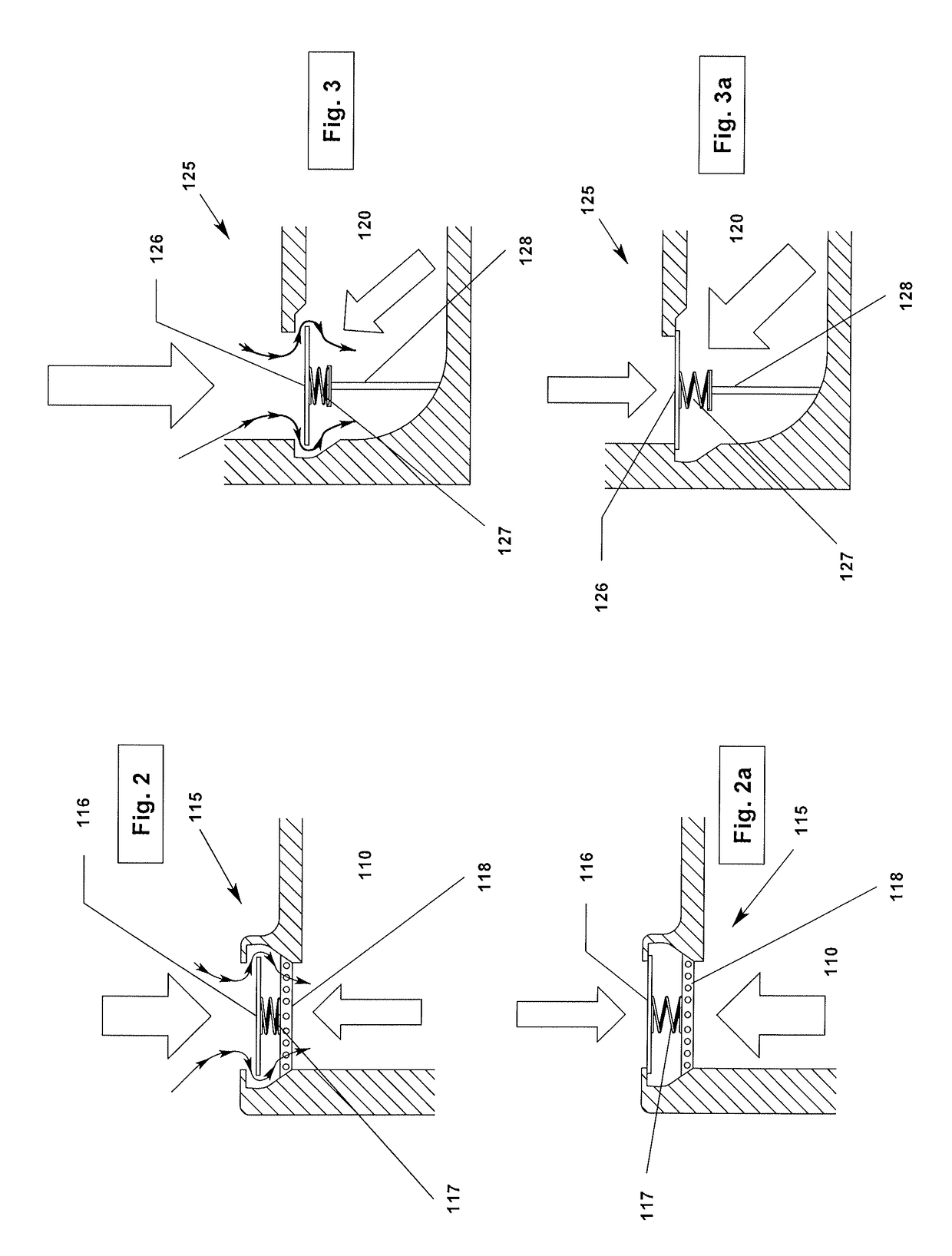

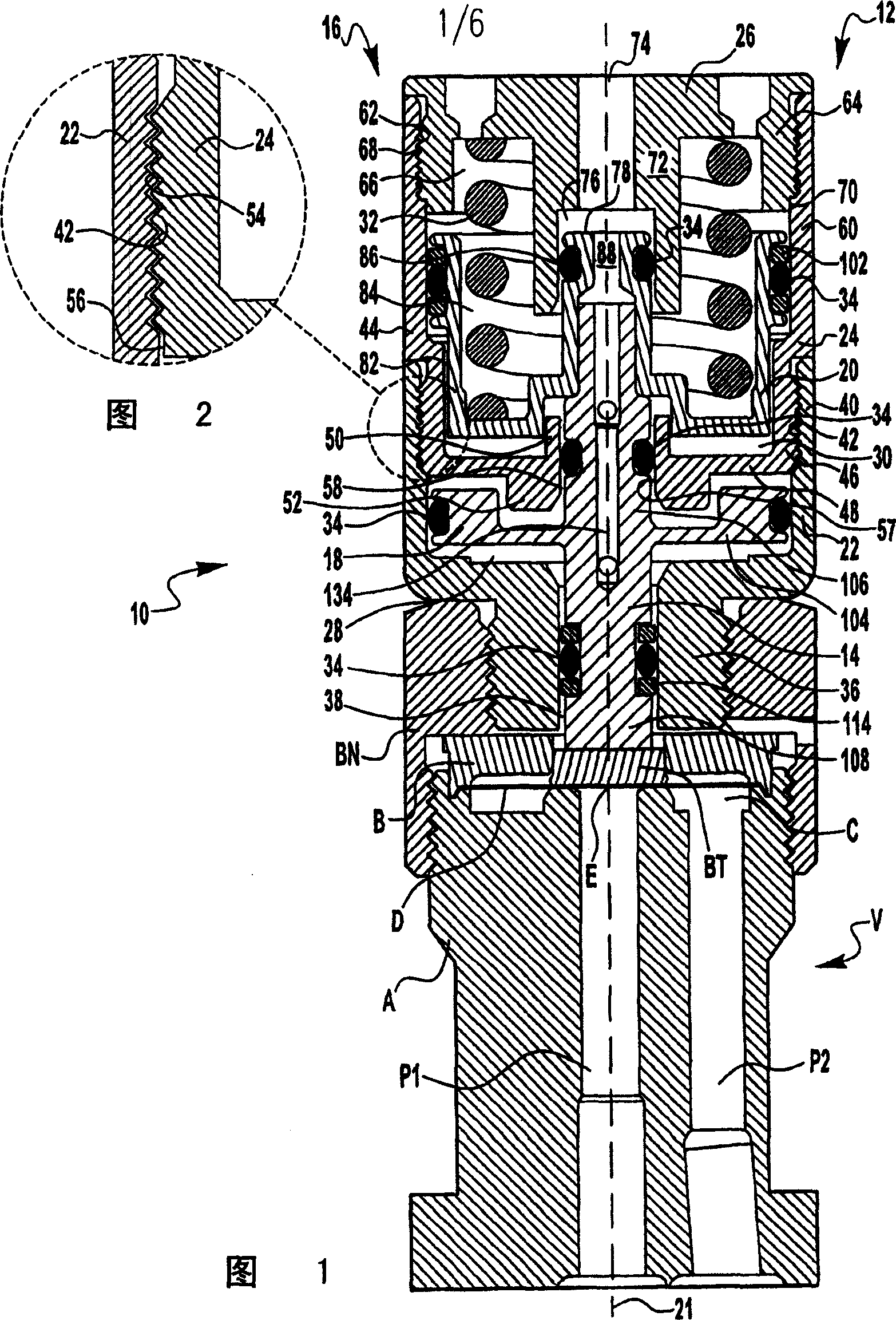

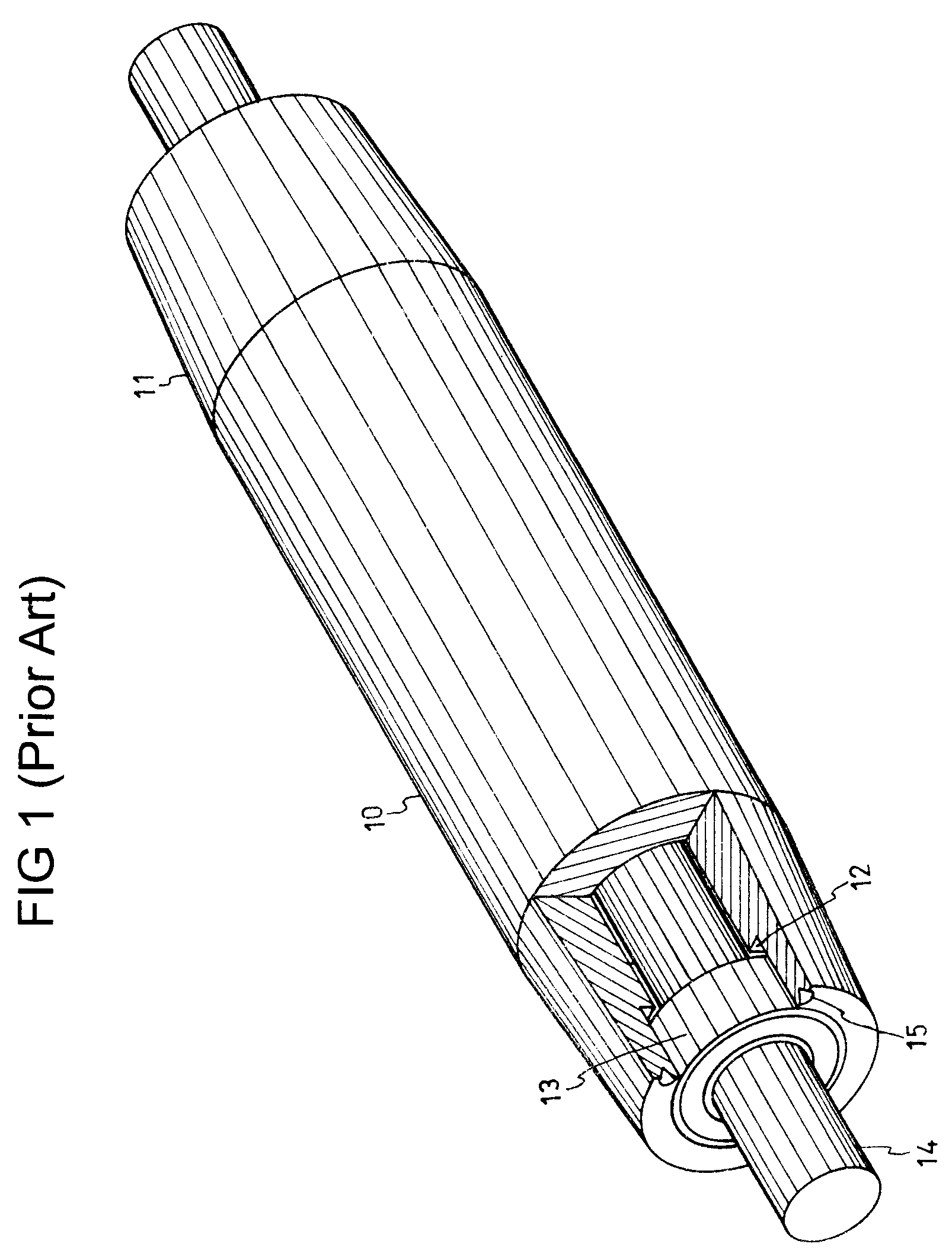

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

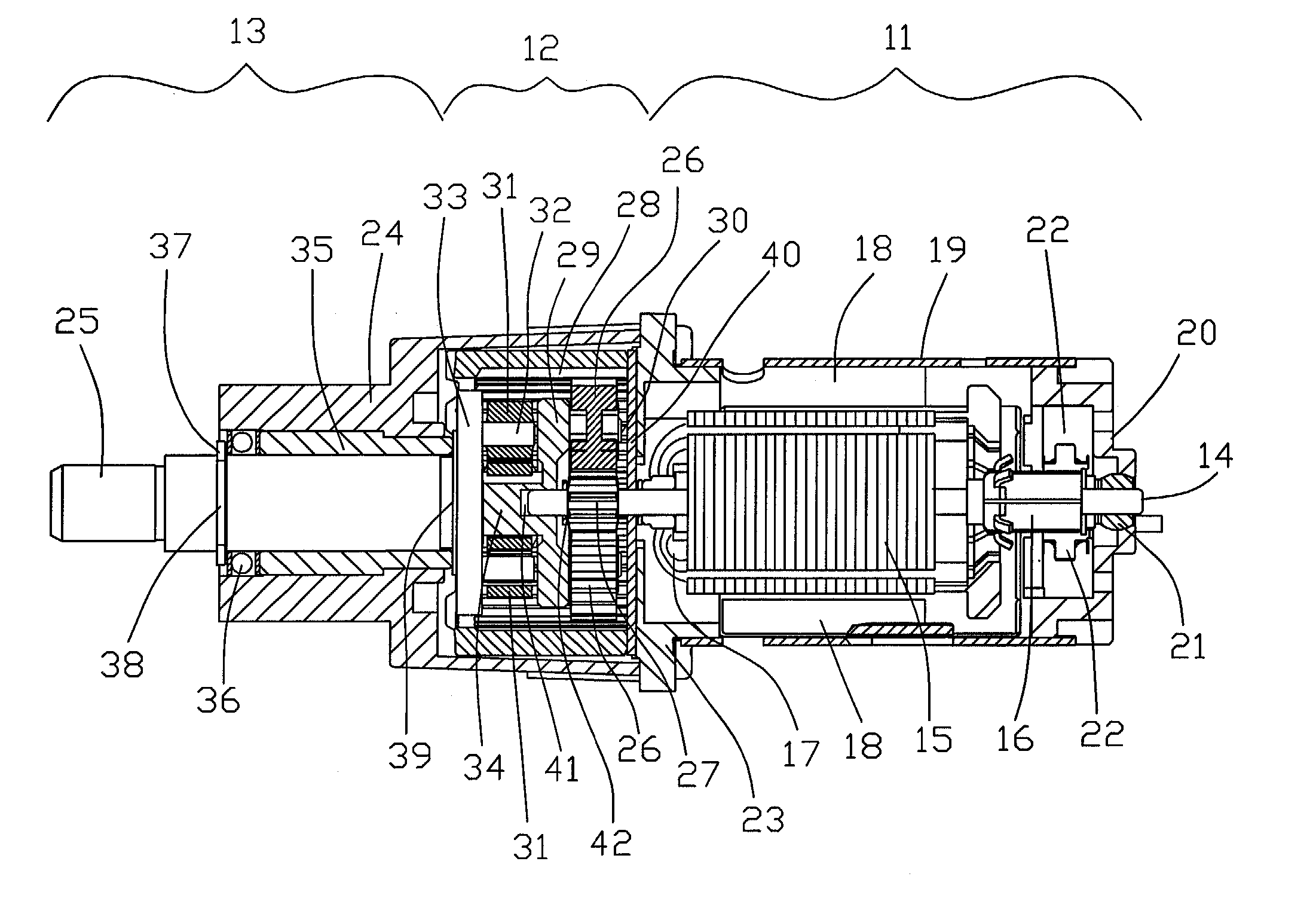

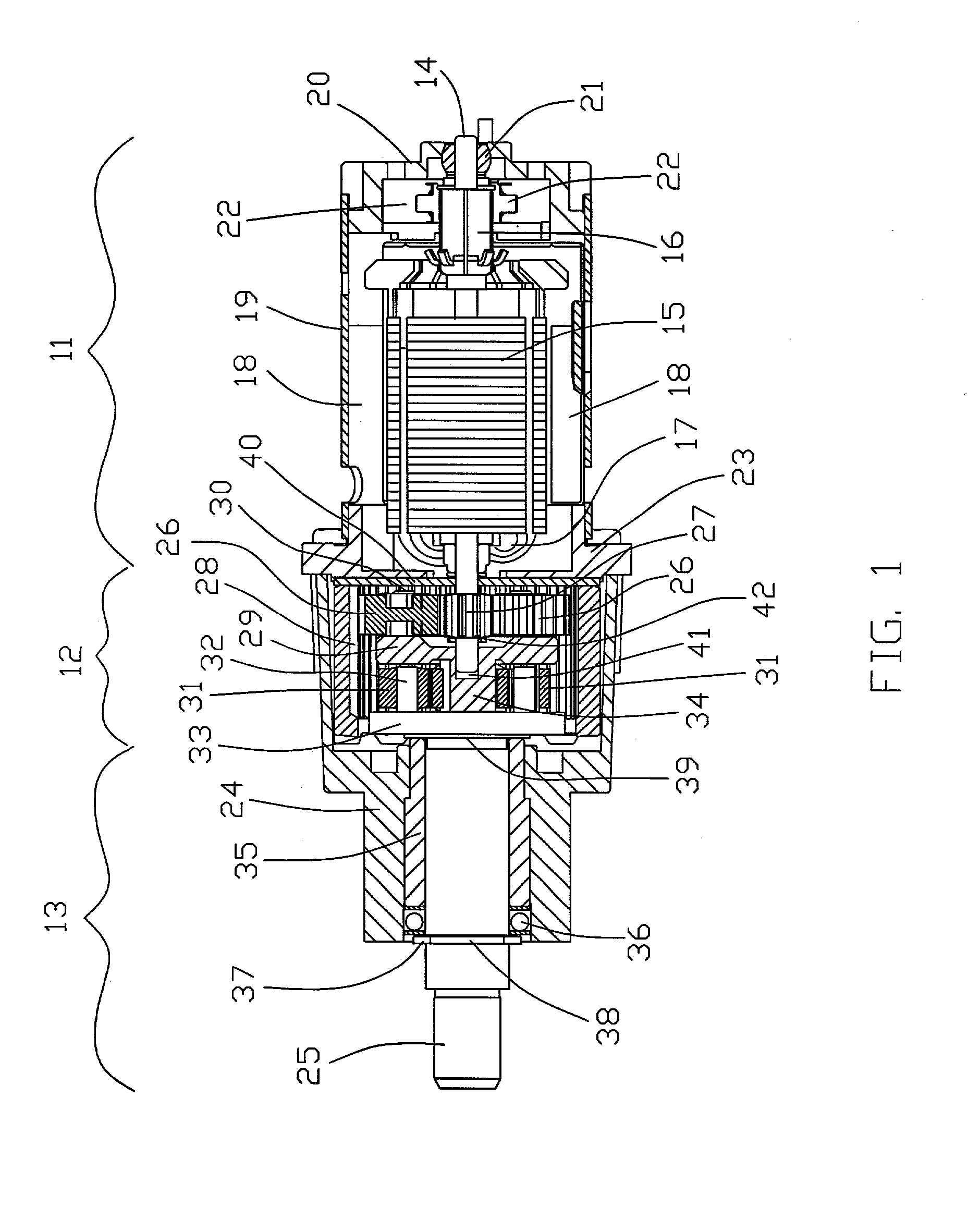

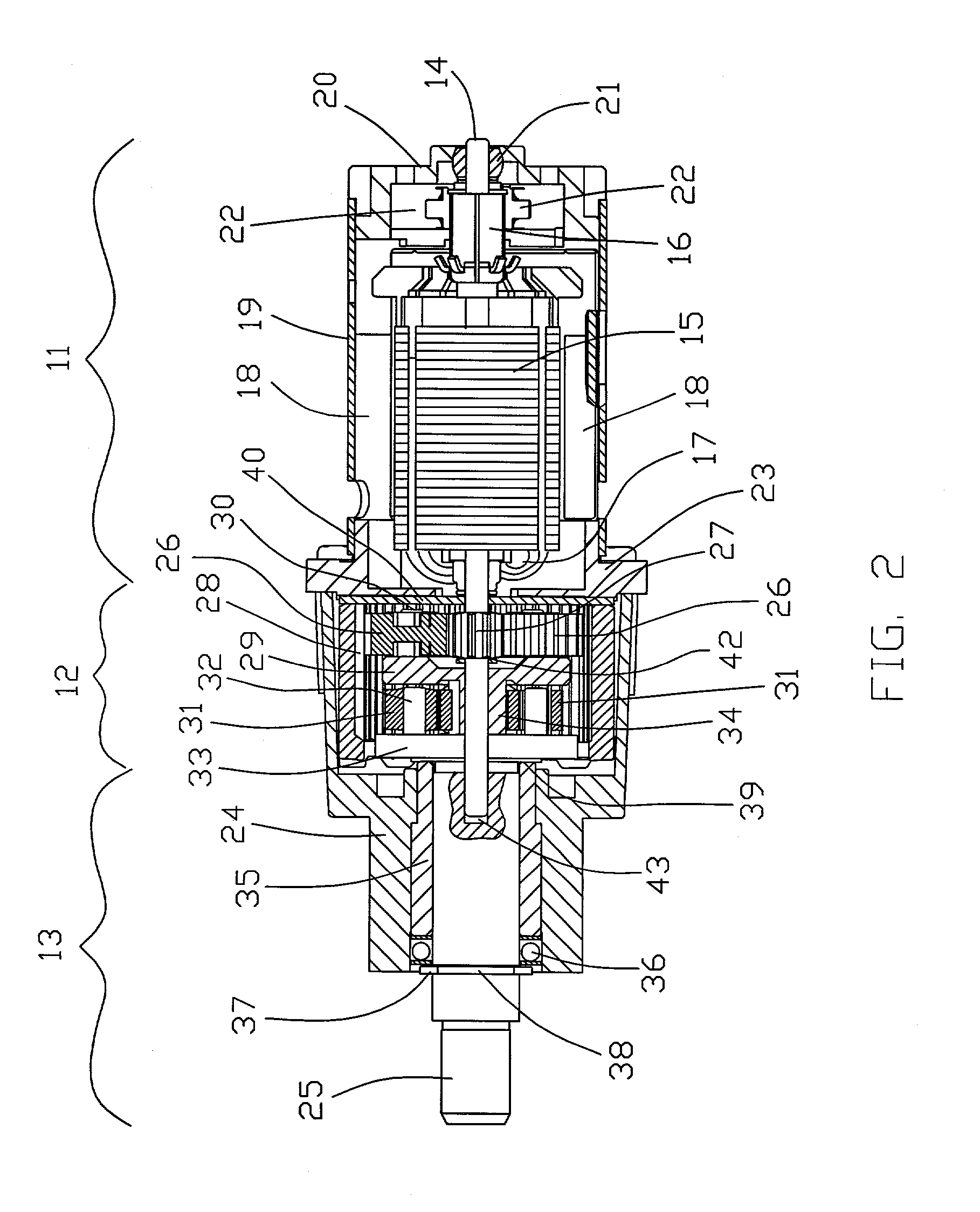

Gear motor for power tool

A compact gearbox / motor combination for a portable power tool has a single partition plate 23 closing an end of the gearbox housing 24 and the motor housing 19. A shaft 14 of the motor is journalled at one end in a self-aligning bearing 21 supported by an end cap 20 of the motor. The other end of the motor shaft 14 is journalled in a hole 41 in a gear carrier 29 of the gearbox.

Owner:JOHNSON ELECTRIC SA

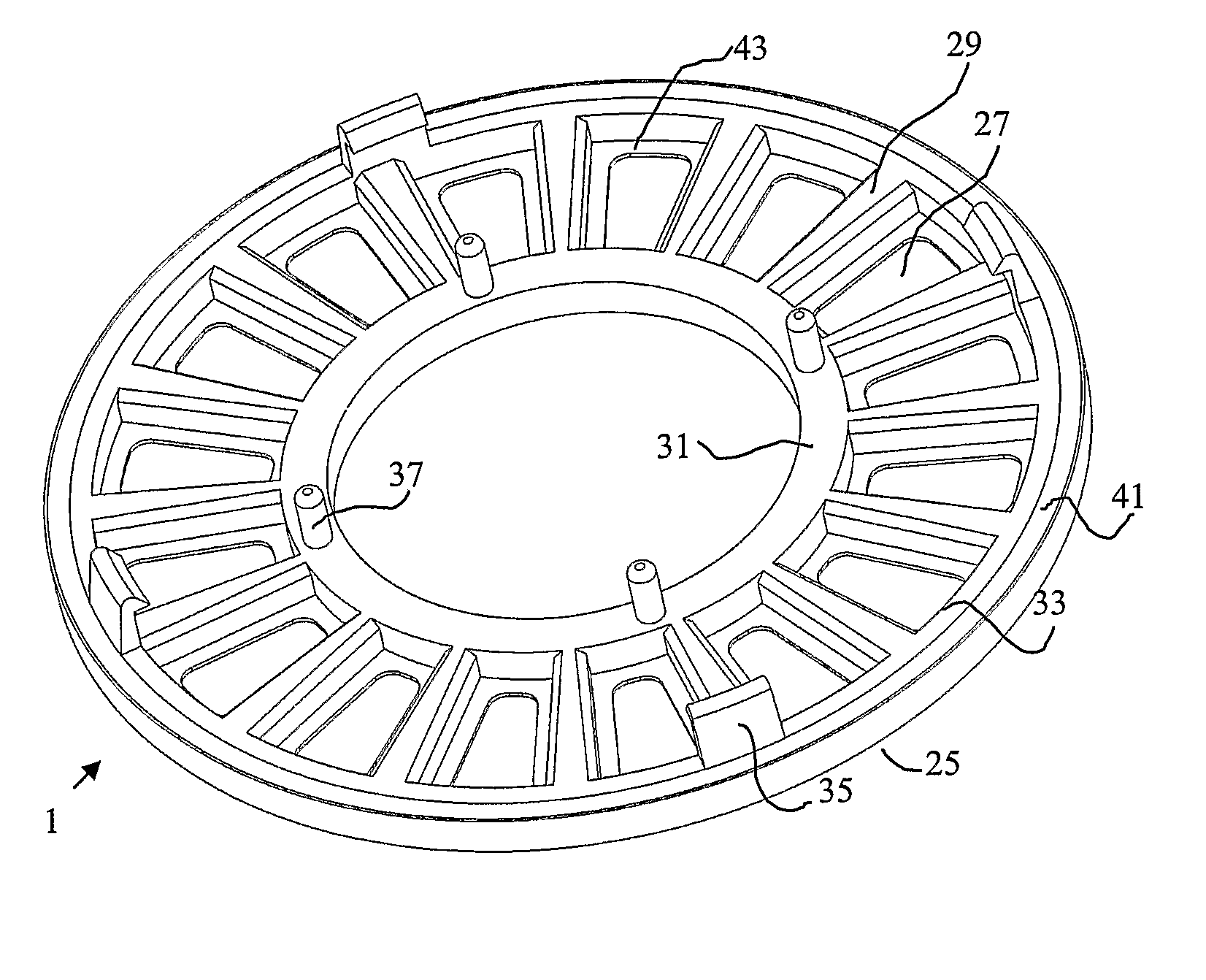

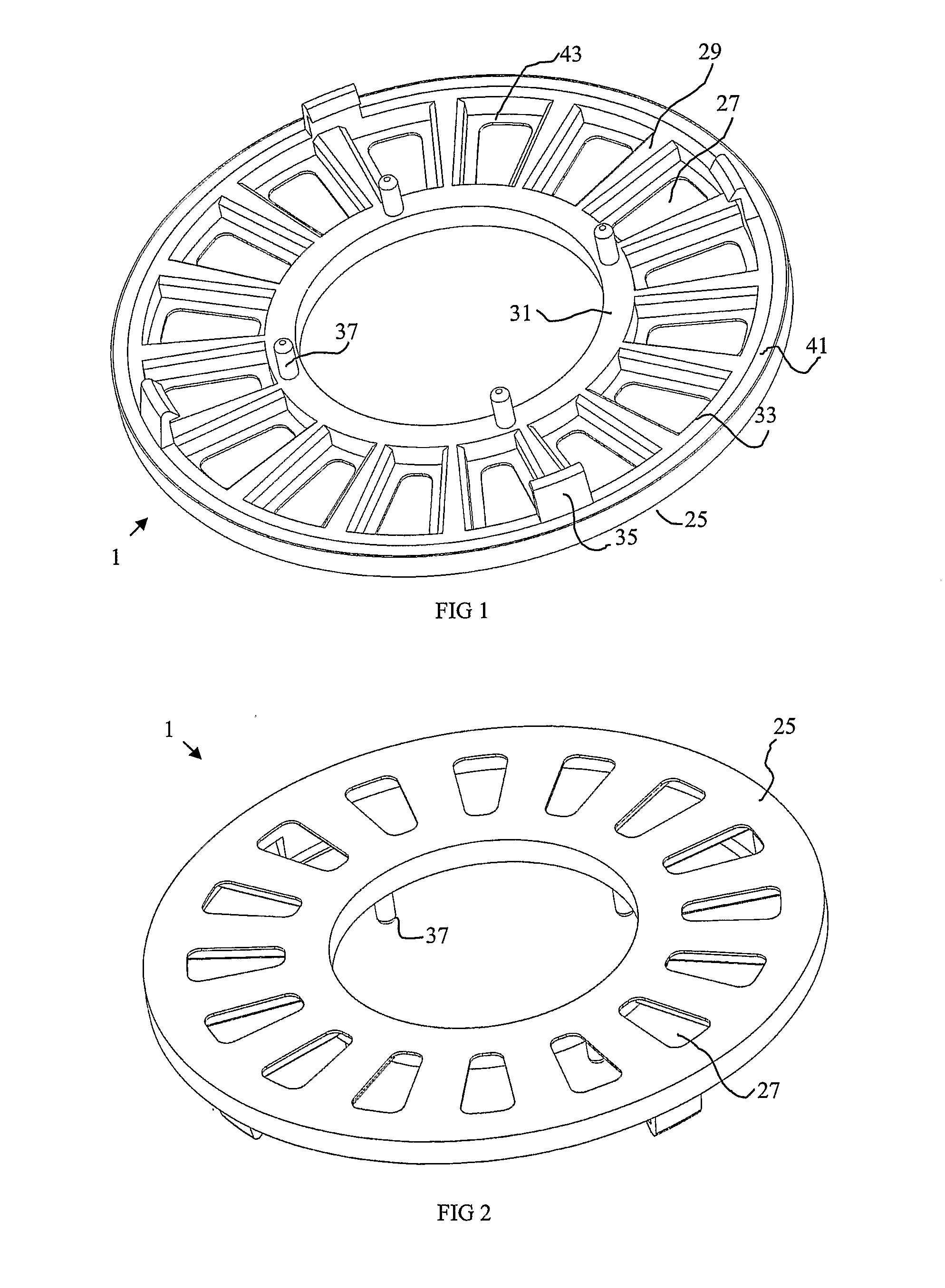

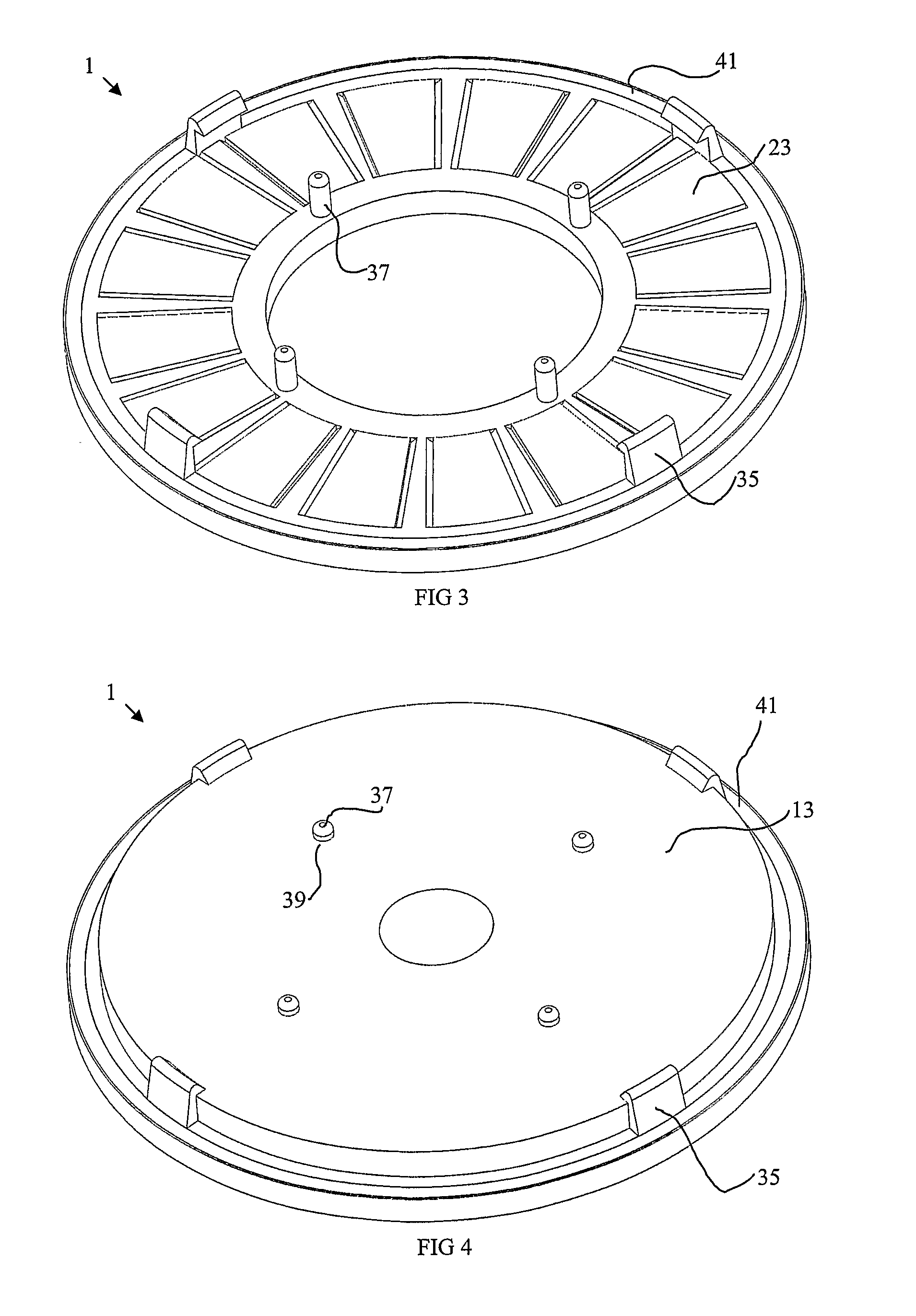

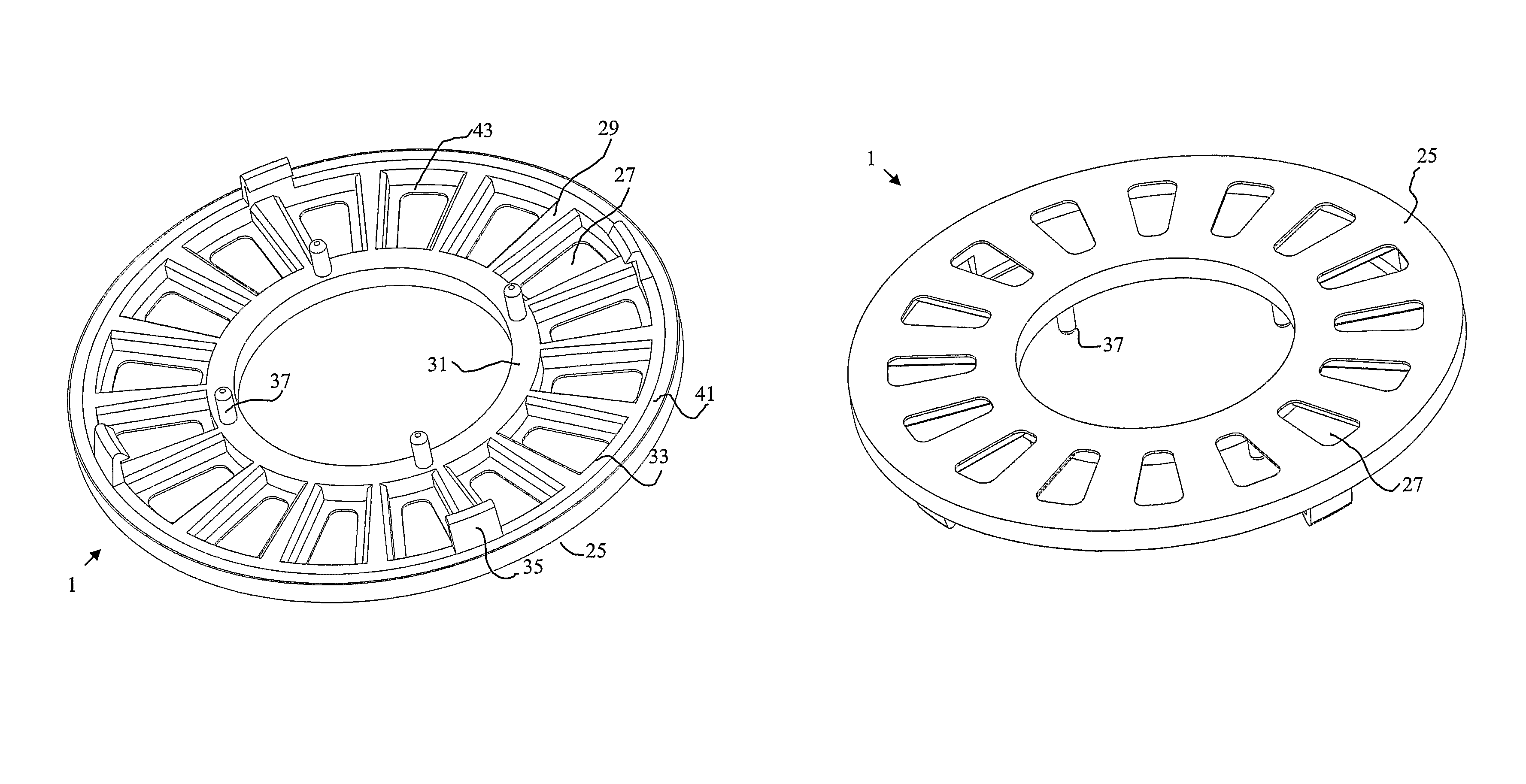

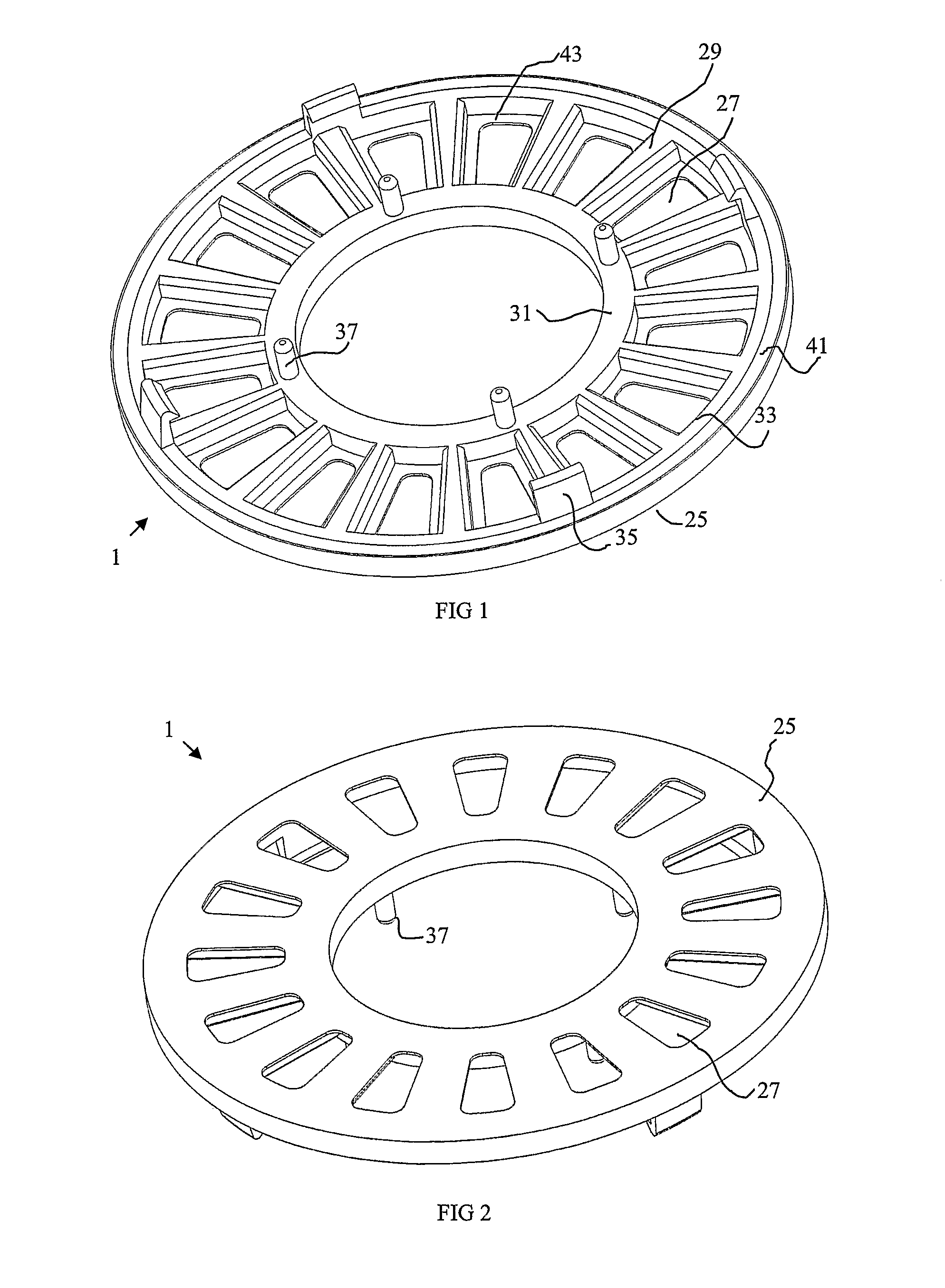

Rotor magnet positioning device

ActiveUS20100164316A1Prevent movementConsistent spacingMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsEngineering

A device for positioning a planar array of magnets within a permanent magnet electrical machine of the type having a rotor and stator with an air gap there between. The device includes a body made of non-ferrous material and having a first side which is attachable to the rotor and a second side which, in an assembled machine, faces the air gap. The first side of the body has a plurality of recesses therein for receiving a corresponding plurality of magnets. The recesses are shaped and arranged to separate the magnets from each other and maintain a consistent spacing between them. When the device is attached to the rotor the magnets are held in a fixed position against the rotor. The electrical machine may be a motor or a generator.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

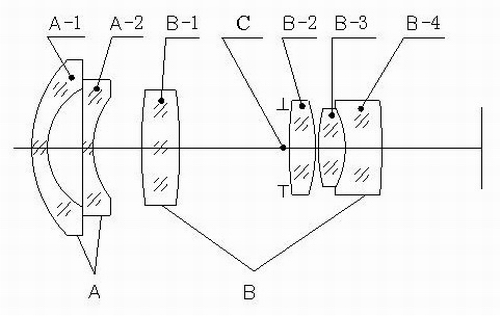

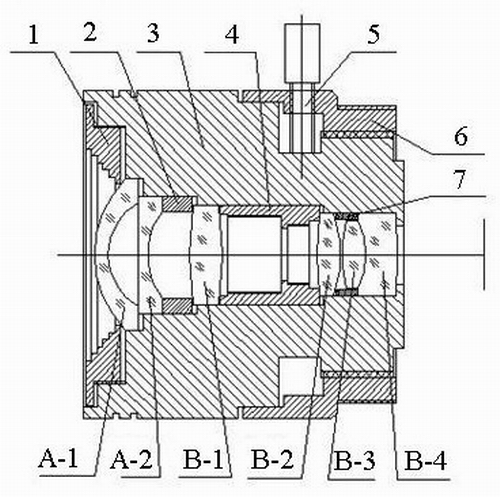

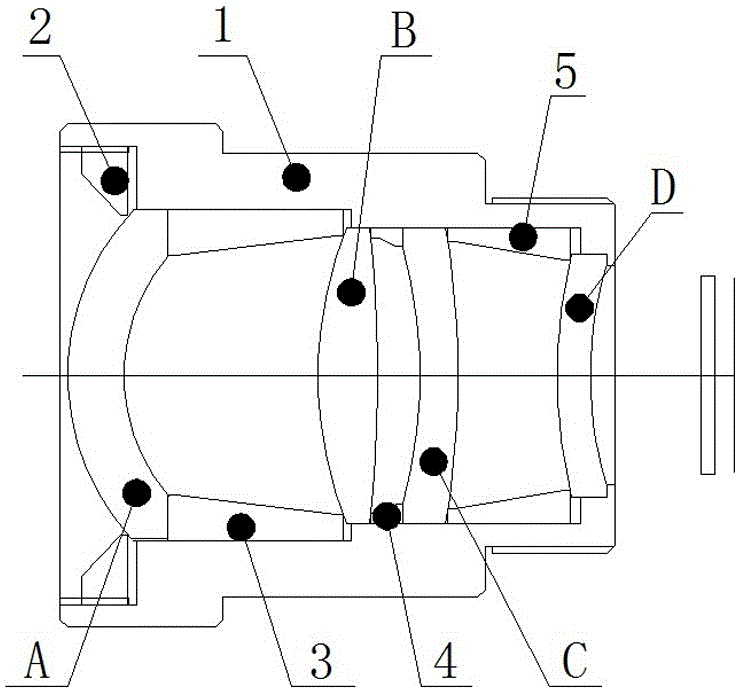

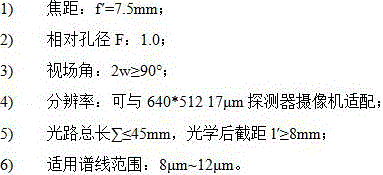

Ultra-wide-angle high resolution day and night dual-purpose camera lens

The invention relates to an ultra-wide-angle high resolution day and night dual-purpose camera lens which is characterized in that a front group (A) with negative focal power and a rear group (B) with positive focal power are respectively arranged along the incident direction from left to right of an optical path, the front group (A) comprises a negative meniscus lens (A-1) and a negative meniscus lens (A-2), the rear group (B) comprises a biconvex lens (B-1), a biconvex lens (B-2) and a cemented group with close connection of a biconvex lens (B-3) and a negative meniscus lens (A-4), and an optical stop (C) is positioned between the biconvex lens (B-1) and the biconvex lens (B-2). The ultra-wide-angle high resolution day and night dual-purpose camera lens has ultra-wide-angle, strong light power, high resolution and wide spectral confocal performance, and can provide a full-interface clear image better than 2 million pixels for a high-resolution network camera system and realize 24-hour continuous monitoring and no shift of an image focus during day-night switching.

Owner:FUJIAN FORECAM OPTICS CO LTD

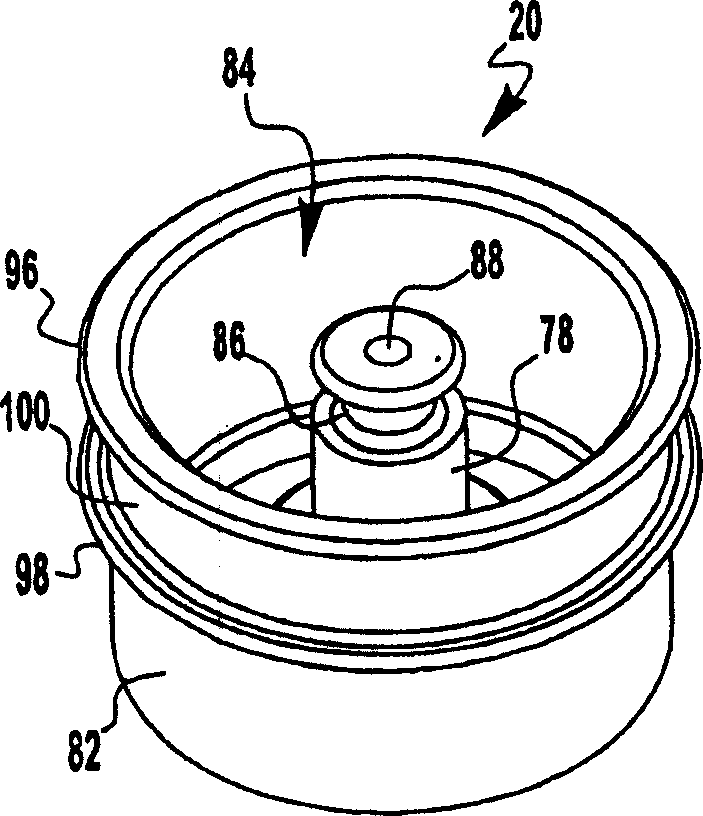

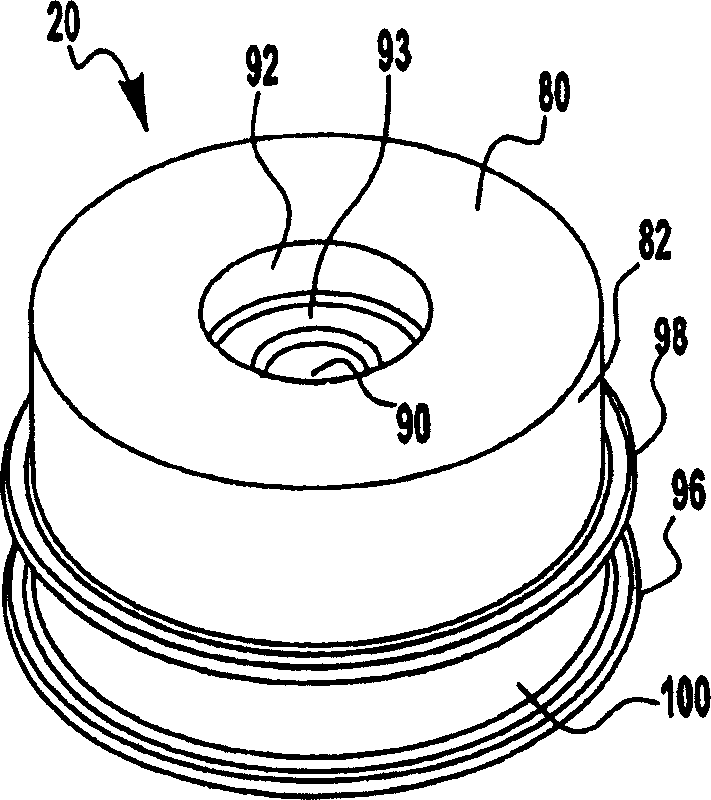

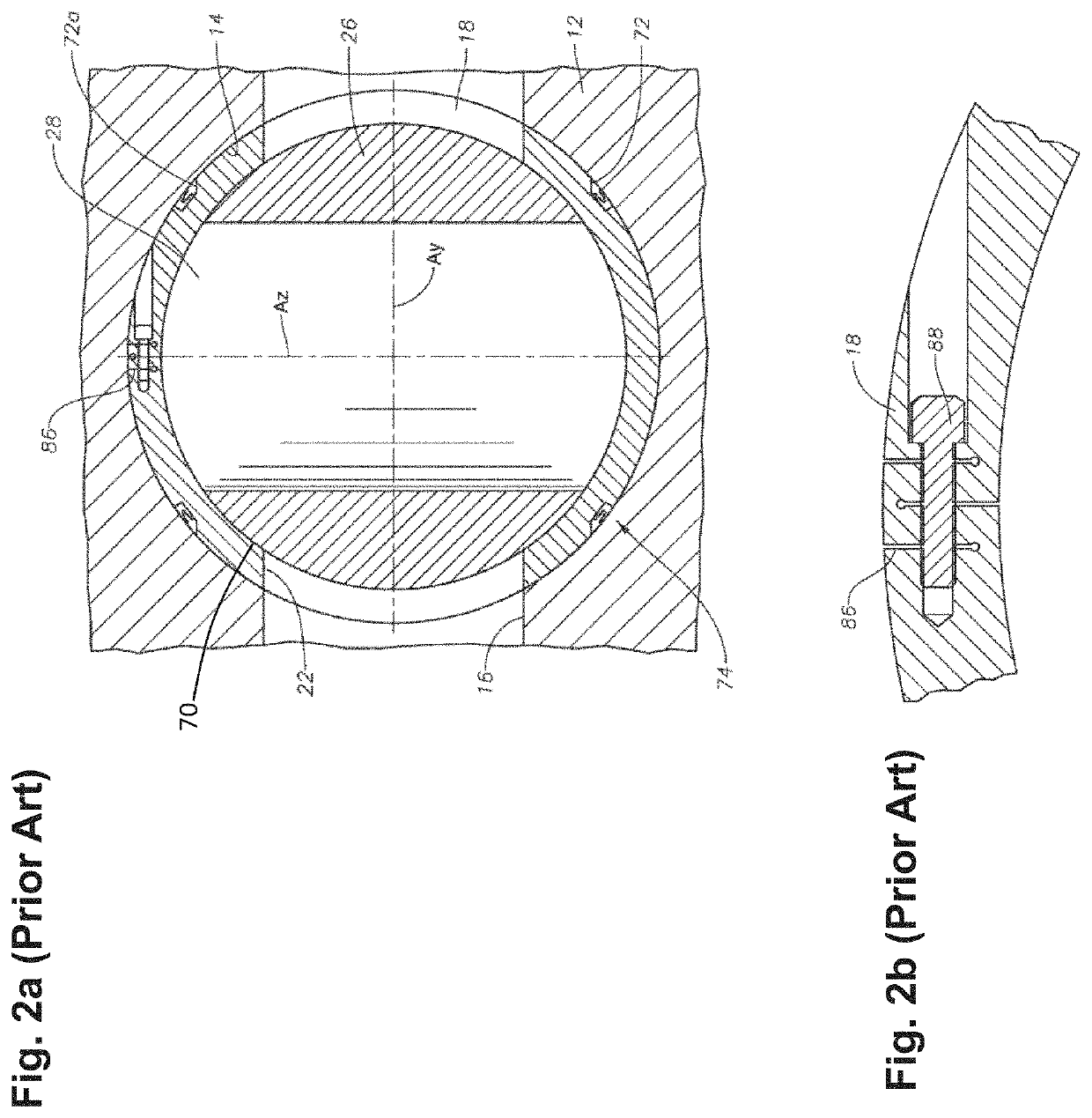

Rotor magnet positioning device

ActiveUS8598761B2Prevent movementConsistent spacingMagnetic circuit rotating partsManufacturing dynamo-electric machinesRotor magnetsEngineering

A device for positioning a planar array of magnets within a permanent magnet electrical machine of the type having a rotor and stator with an air gap there between. The device includes a body made of non-ferrous material and having a first side which is attachable to the rotor and a second side which, in an assembled machine, faces the air gap. The first side of the body has a plurality of recesses therein for receiving a corresponding plurality of magnets. The recesses are shaped and arranged to separate the magnets from each other and maintain a consistent spacing between them. When the device is attached to the rotor the magnets are held in a fixed position against the rotor. The electrical machine may be a motor or a generator.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

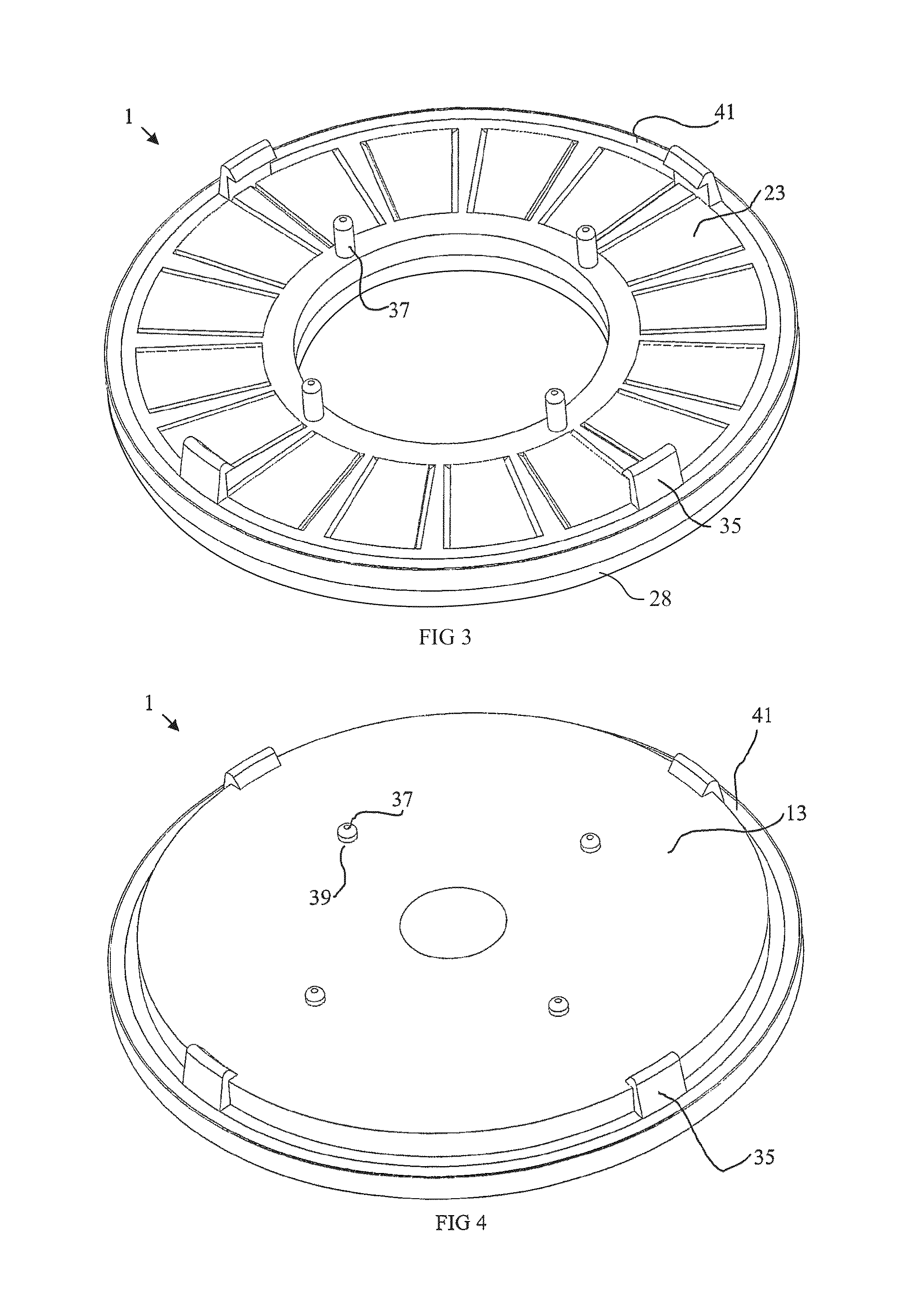

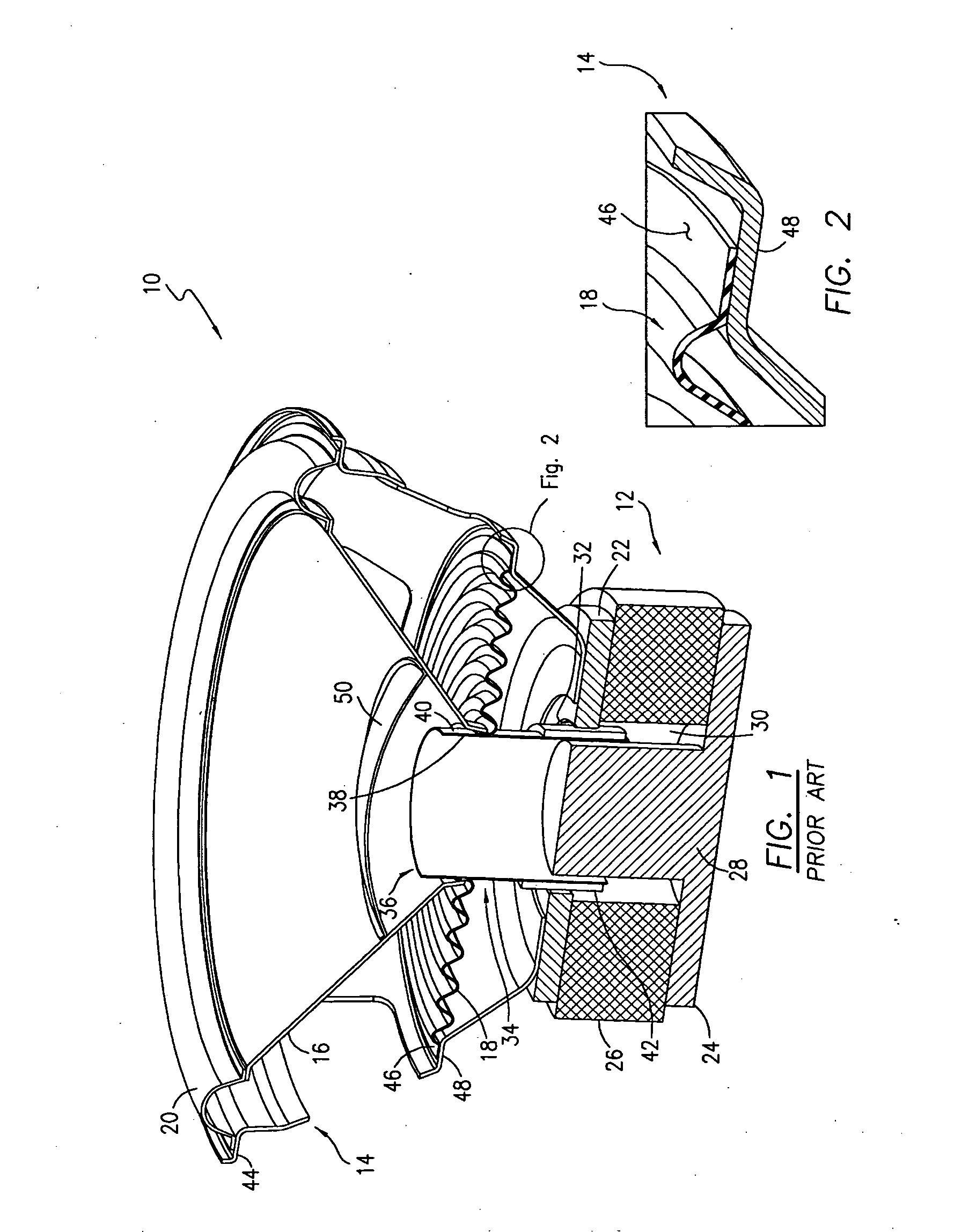

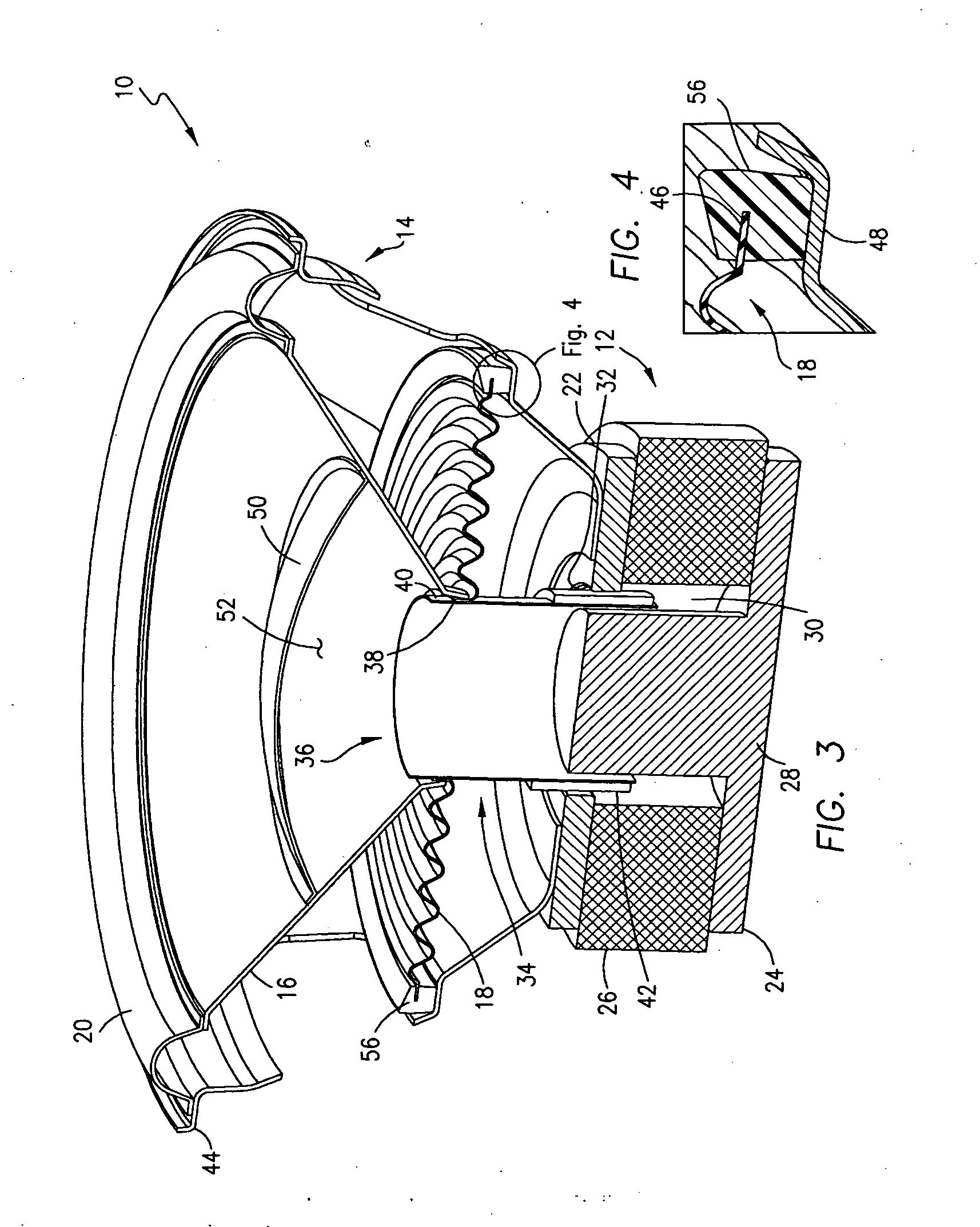

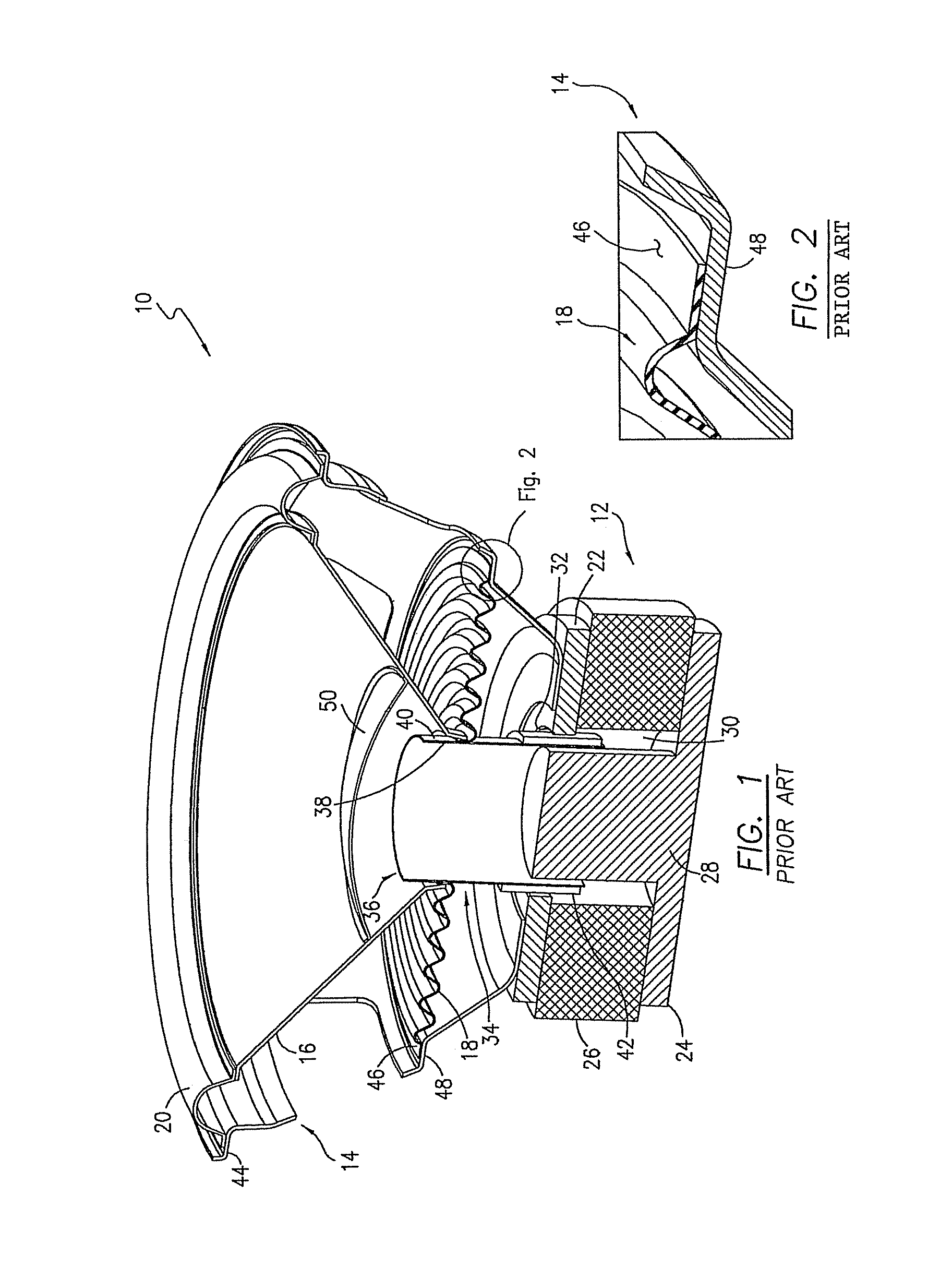

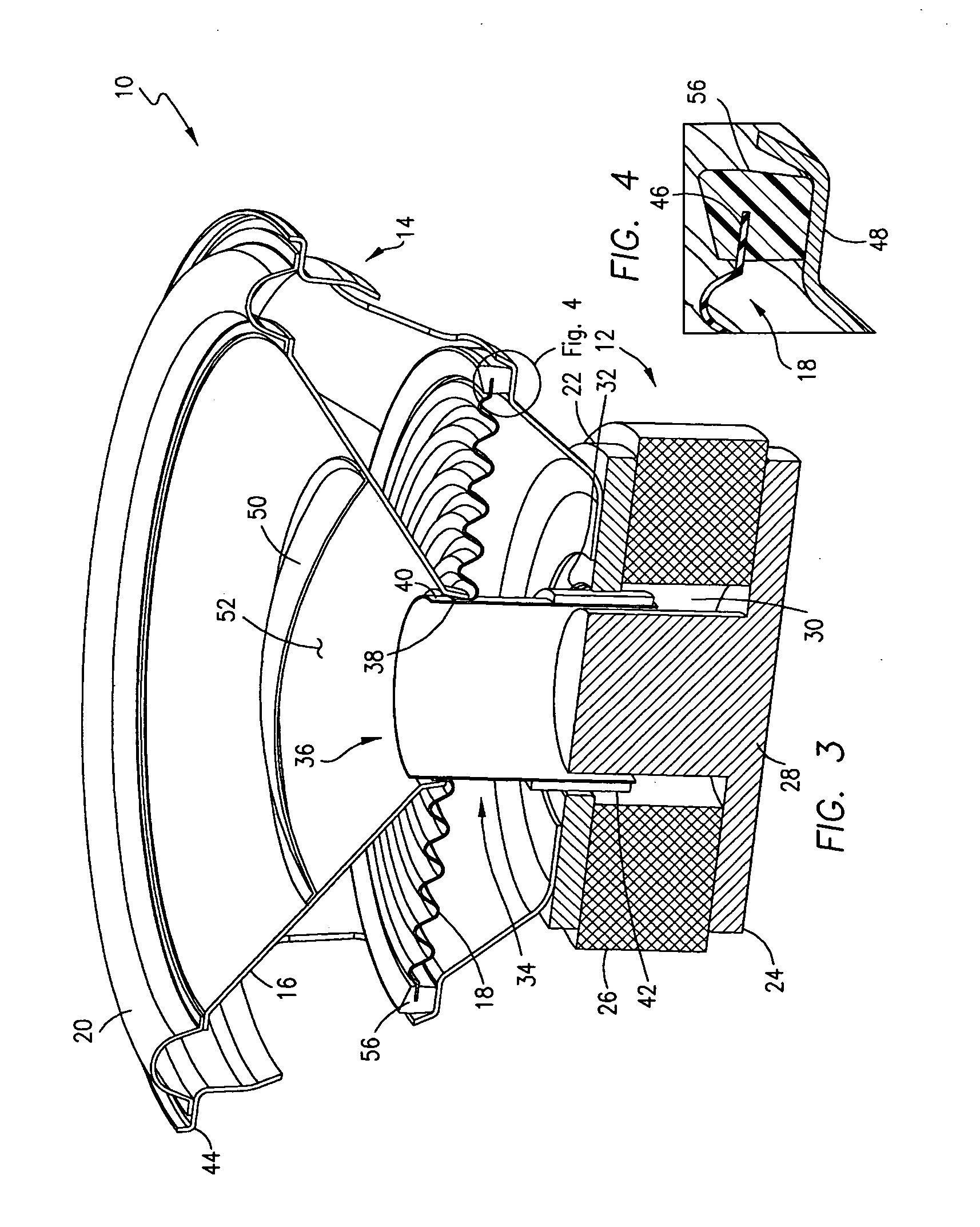

Loudspeaker with integrated spider standoff ring

ActiveUS20060133637A1Accurate centerAccurate locationTransducer casings/cabinets/supportsDiaphragm mounting/tensioningPlastic materialsEngineering

A loudspeaker is provided in which the outer diameter or foot of the spider is over molded with a standoff formed of a plastic material in an injection molding tool so that the spider and standoff form an integral unit. The standoff, in turn, is glued or otherwise affixed to the frame of the speaker to provide accurate centering of the voice coil relative to the magnetic gap of the motor structure.

Owner:JL AUDIO

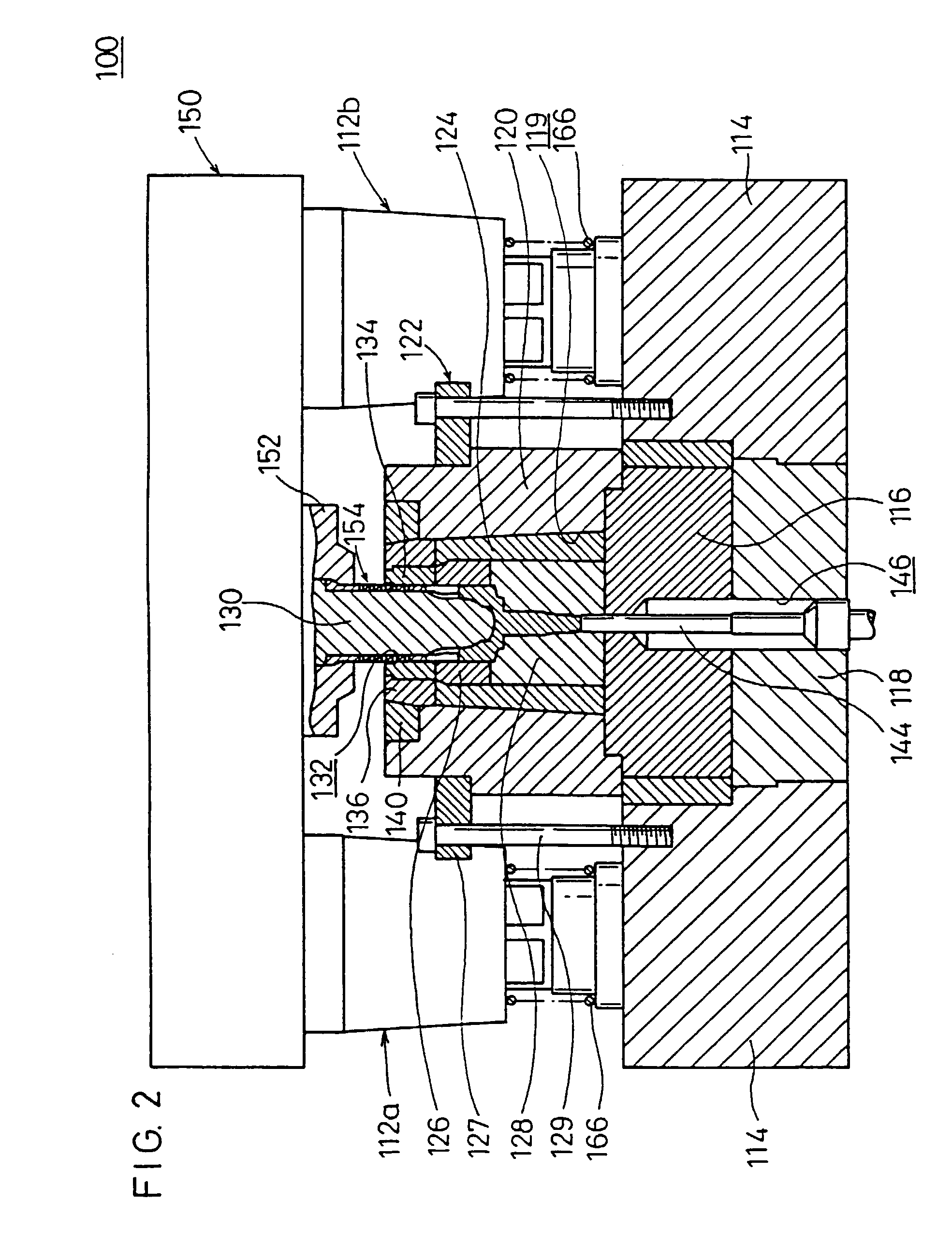

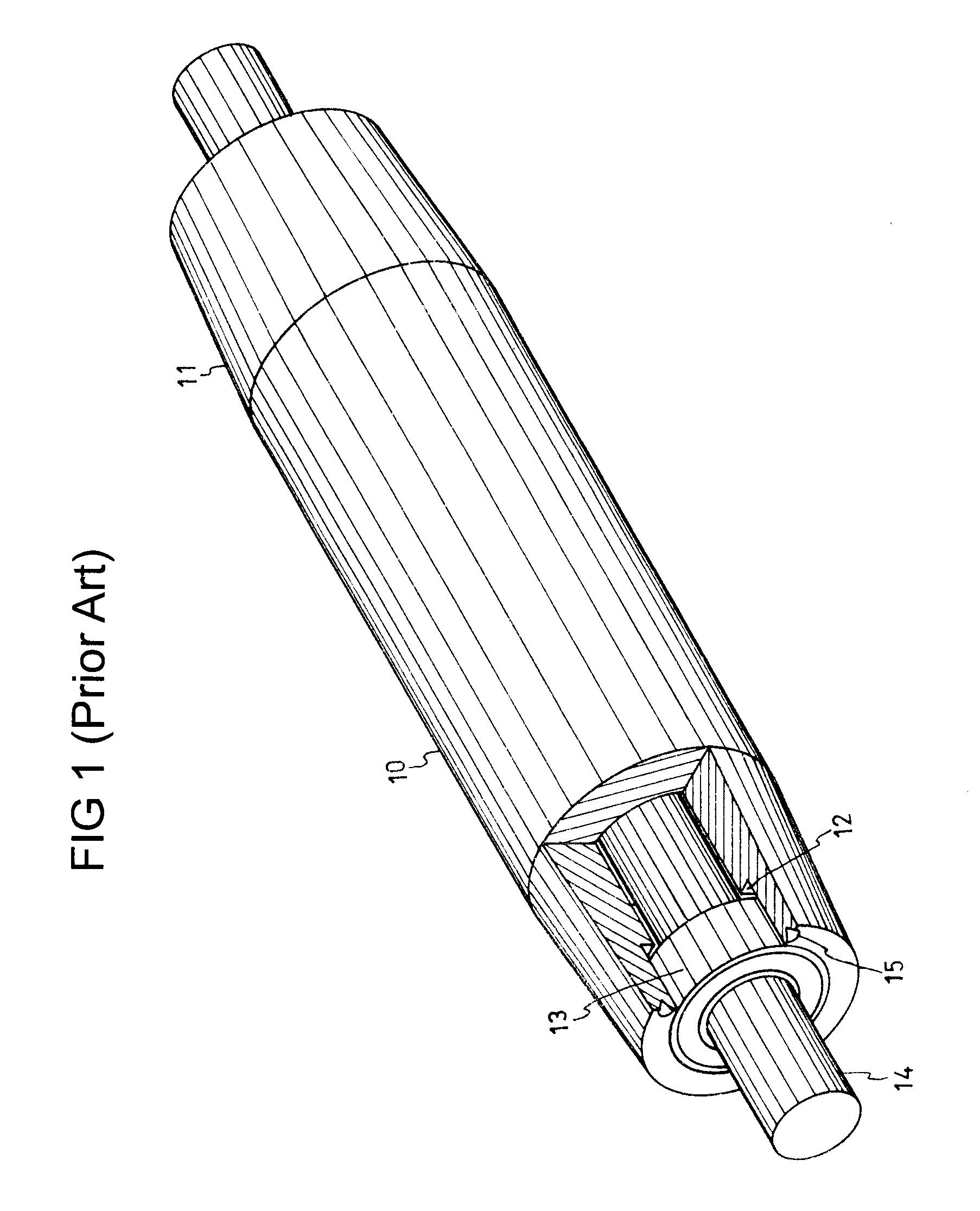

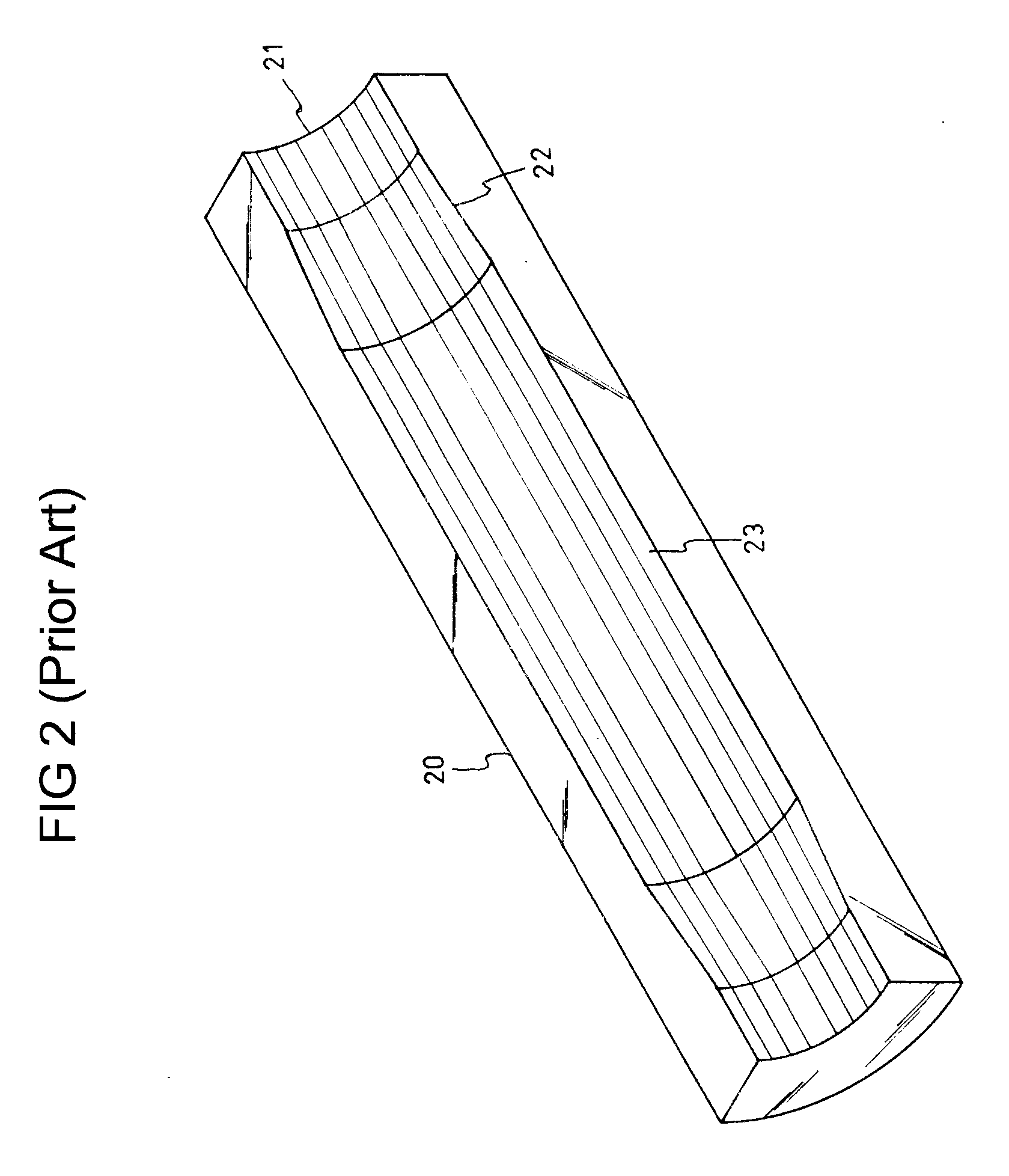

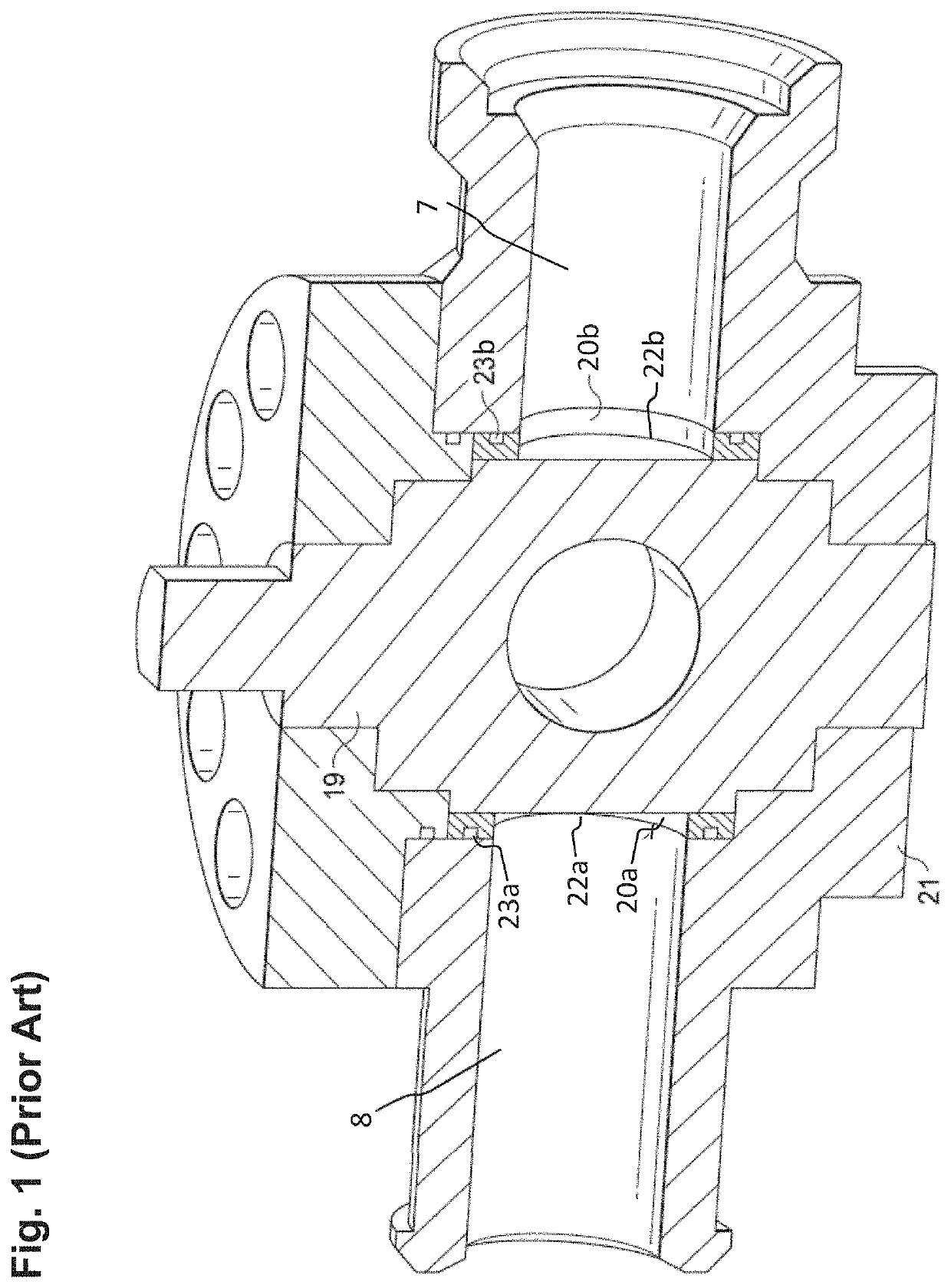

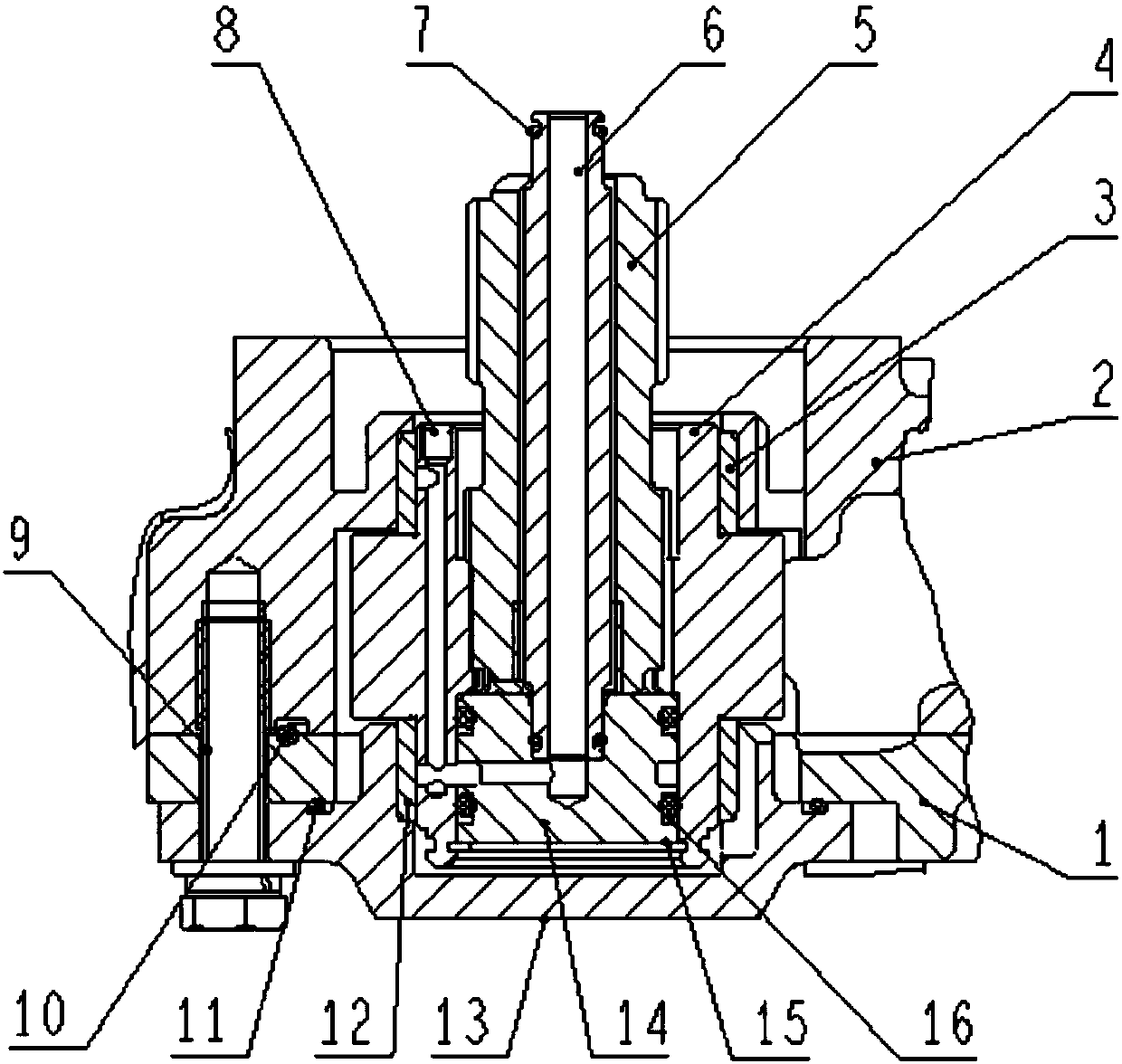

Forging die apparatus

InactiveUS7043955B2Accurate concentricityInhibitionForging hammersForging/hammering/pressing machinesEngineeringMechanical engineering

A forging die apparatus comprises a punch for applying a pressurizing force to a forging material arranged in a cavity, a cylindrical member installed to surround a part of outer circumference of the punch, for making displacement integrally with the punch, and a first ring member formed with a hole for forcibly inserting the cylindrical member therein when the punch applied the pressurizing force to the forging material.

Owner:HONDA MOTOR CO LTD

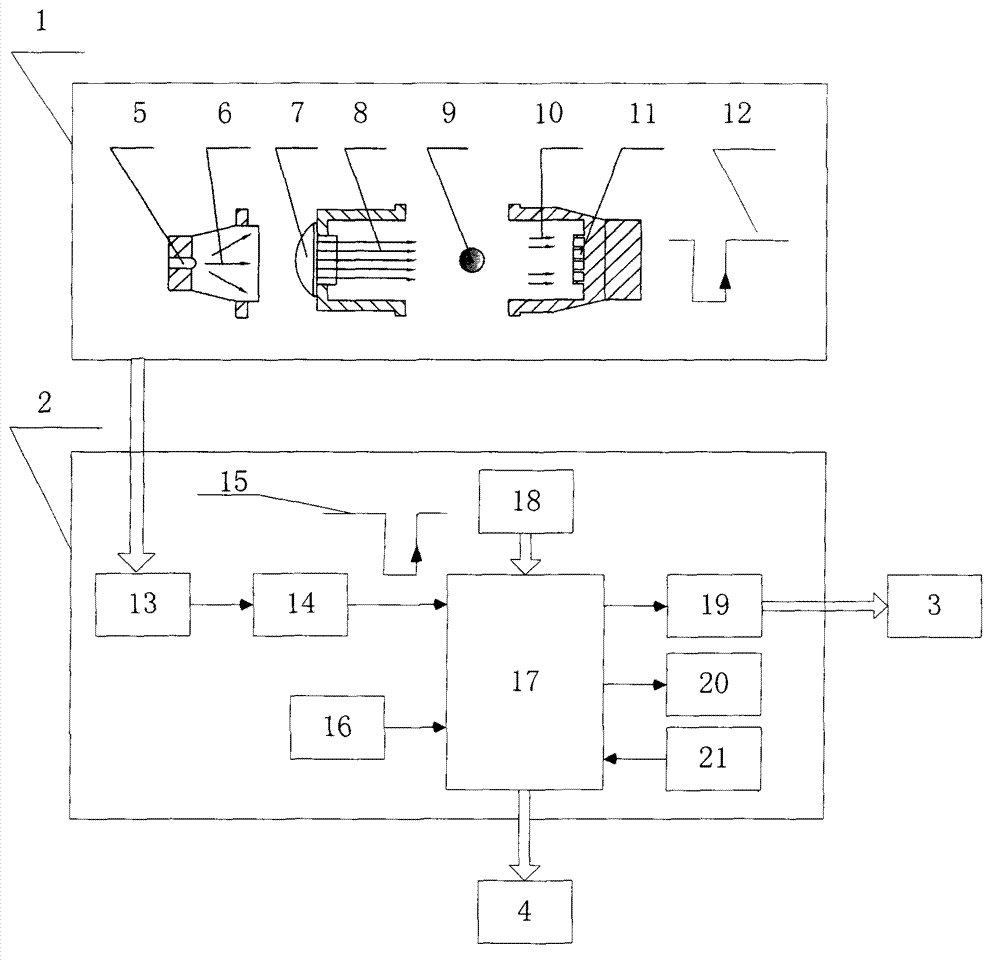

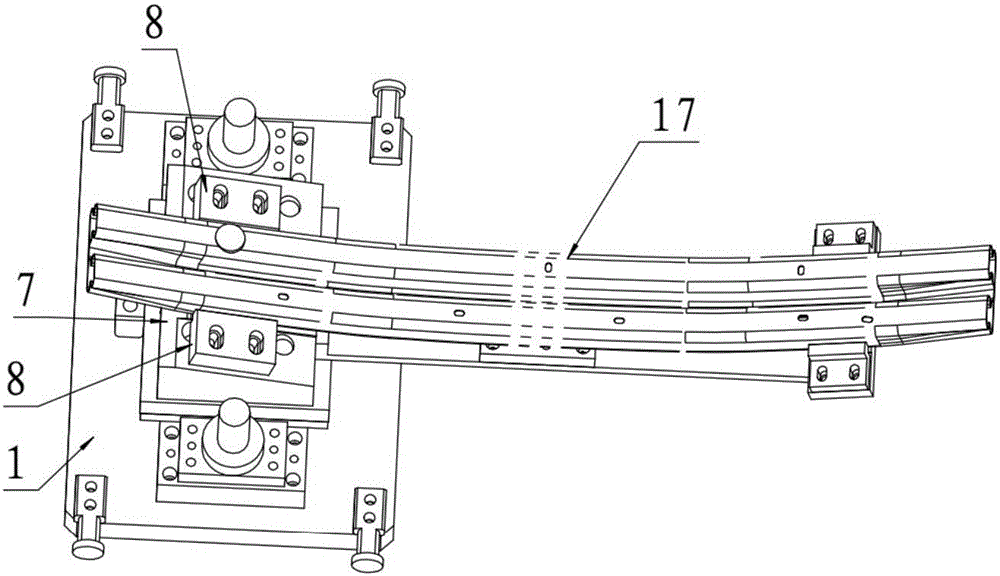

Seeding monitoring system of corn precision seeder

InactiveCN102968079APerfect measurement and control functionStrong interference abilityProgramme controlComputer controlMonitoring systemAgricultural engineering

The invention relates to a seeding monitoring system of a corn precision seeder and belongs to the technical field of agricultural machinery control. By means of the singlechip intelligent control and photoelectricity detection technology, the seeding monitoring system has the functions of counting seeding grains, automatically calculating seeding areas, alarming leaked seeding and the like. The seeding monitoring system aims at severe environments of agricultural machinery working sites, solves the problems of inaccurate counting, large errors, poor antijamming capability and the like and comprehensively improves quality of seeding operations.

Owner:CHANGCHUN UNIV OF SCI & TECH

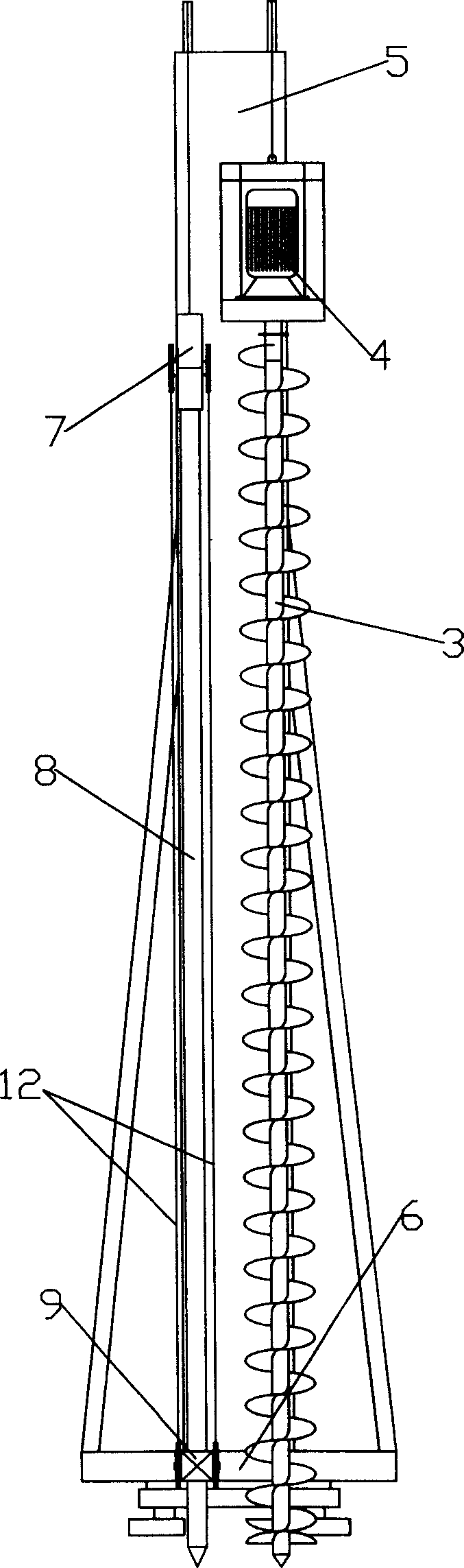

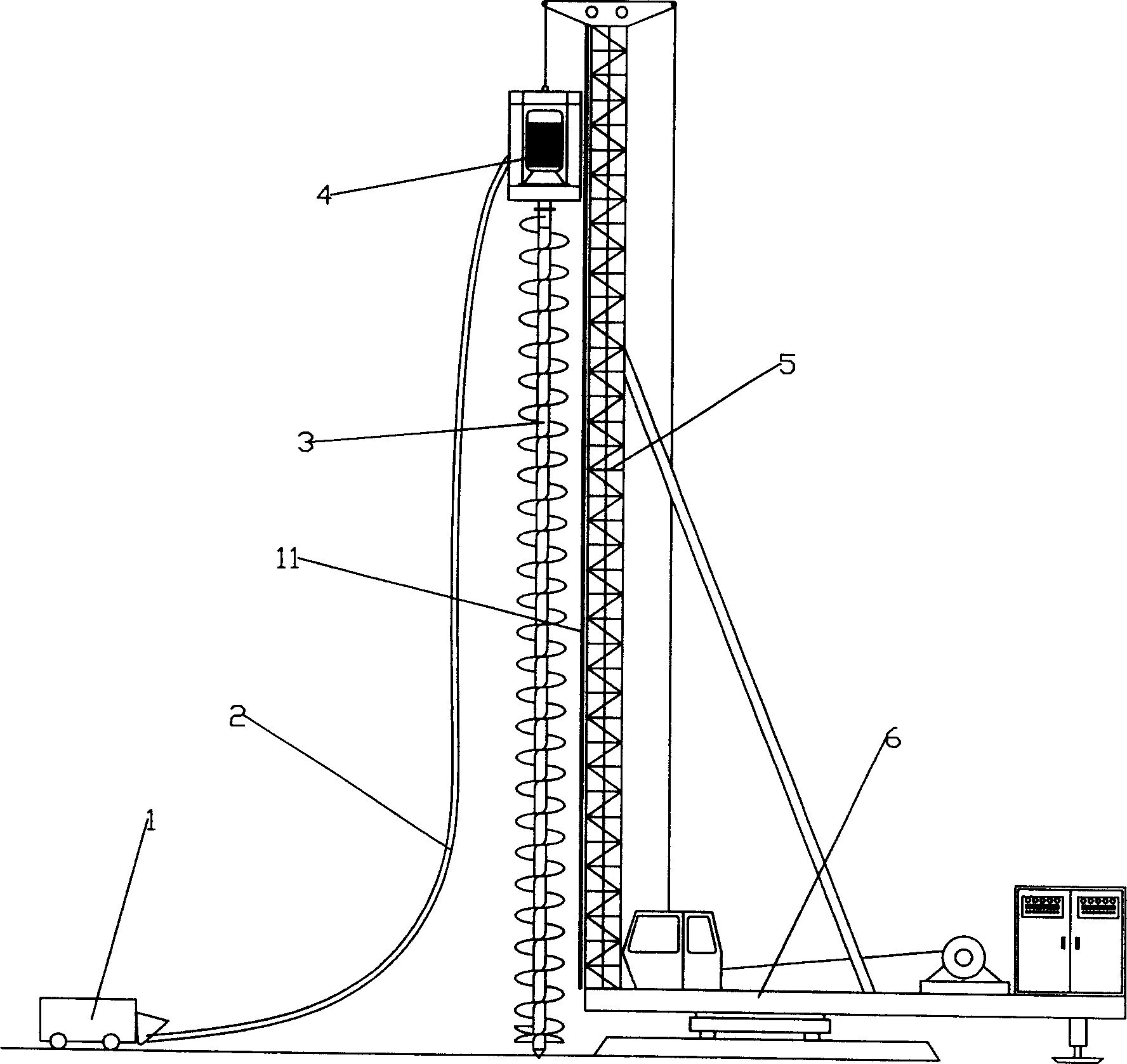

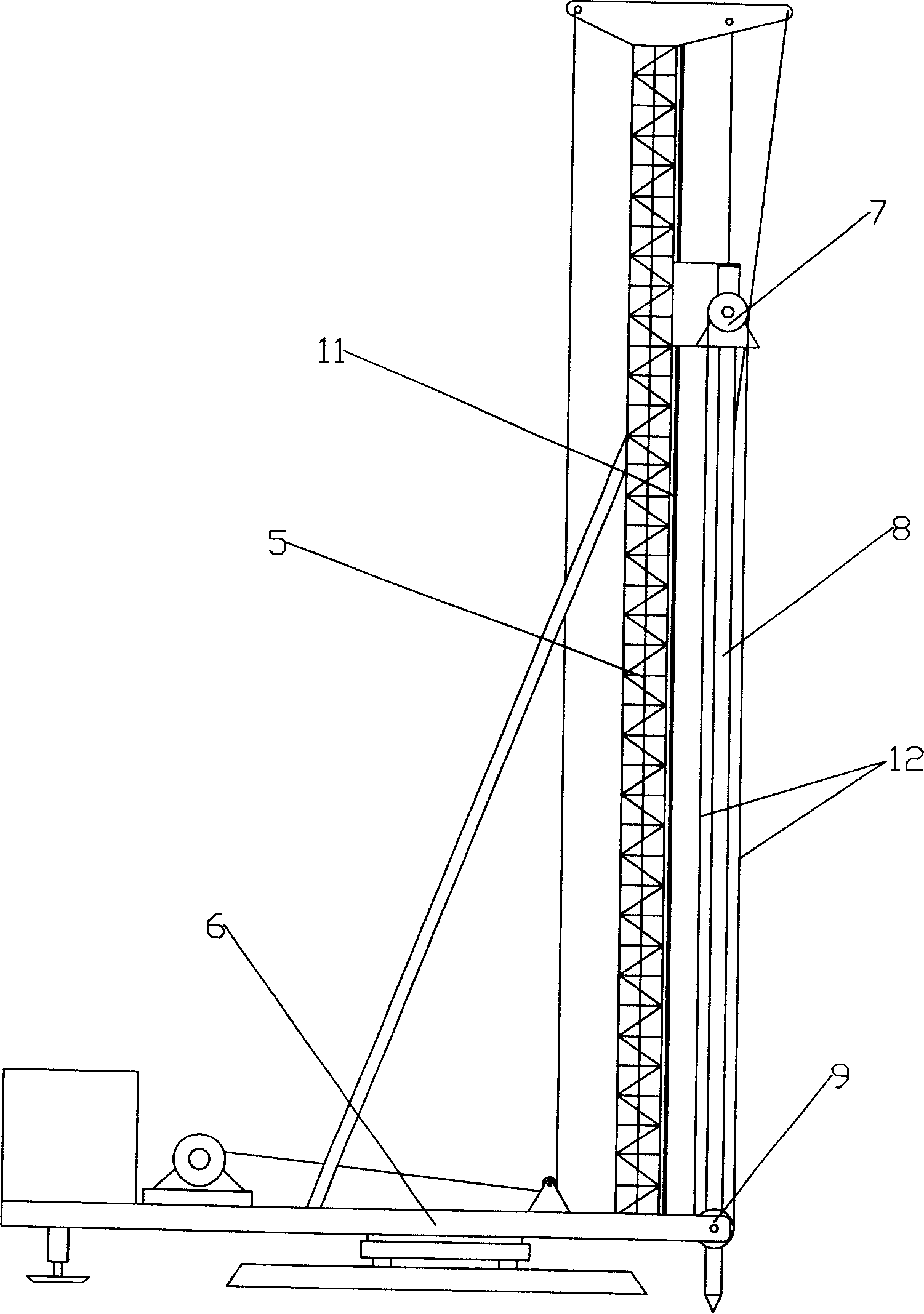

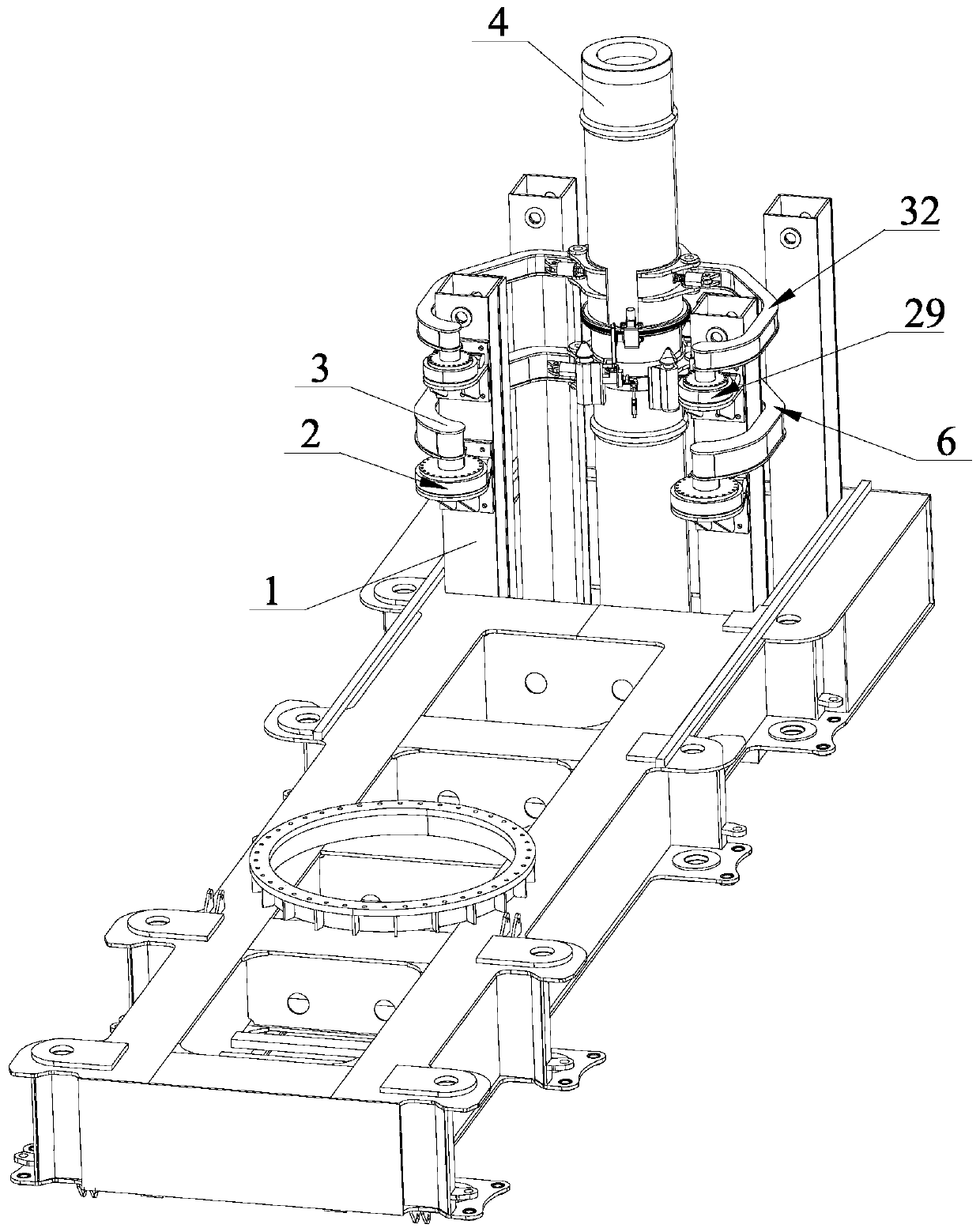

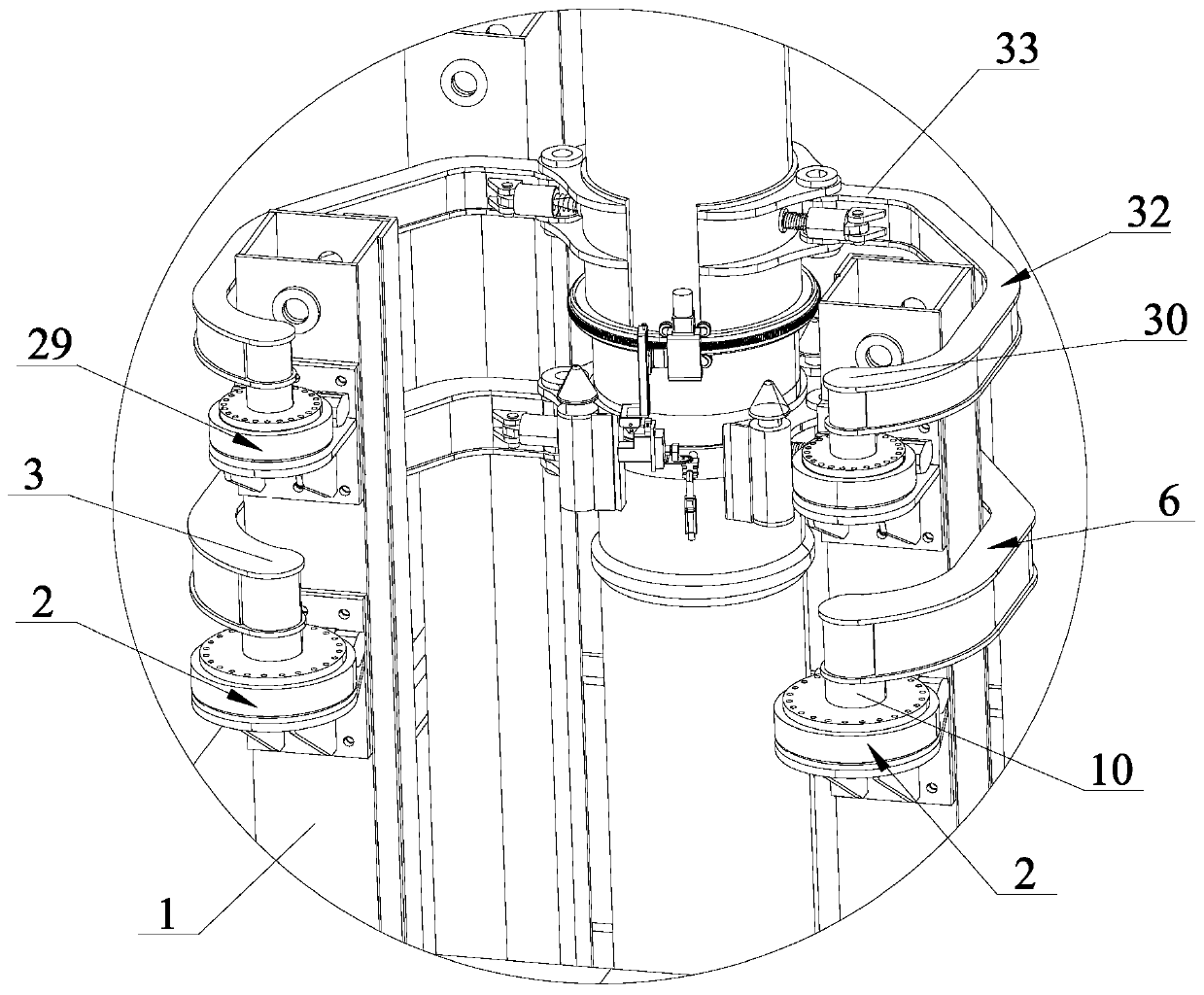

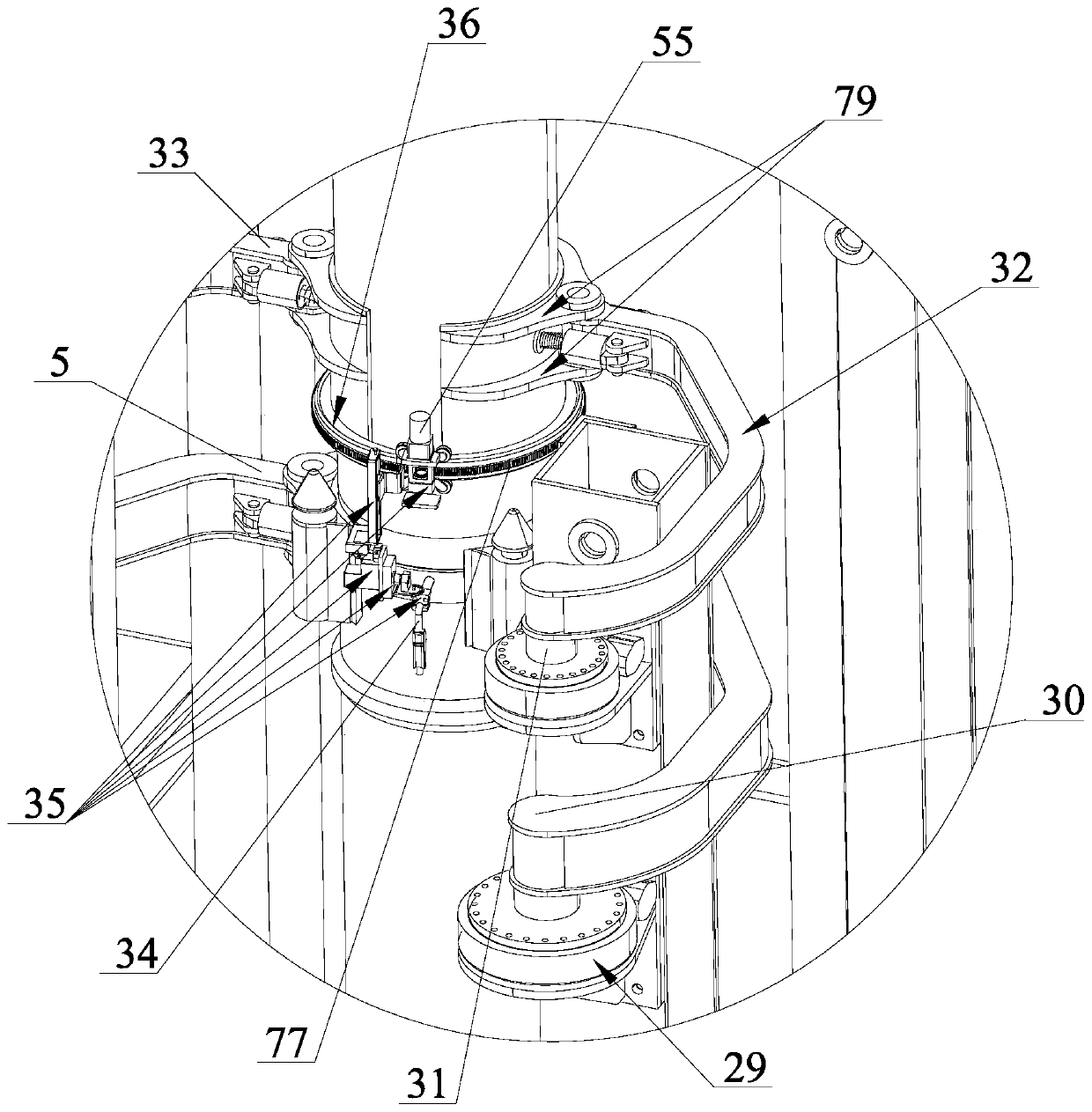

Construction machinery for long spiral press pouring concrete lock pin combination piles

The invention discloses a construction machine for long helical grouting concrete core-inserted composite piles. A long helical drilling and grouting pile mechanism and a static pressure pile mechanism are installed side by side on the walking chassis of a walking pile machine. The long helical auger The center points of the hole-pressing pile filling mechanism and the pile-pressing mechanism are all located on the same circle centered on the center point of the turntable of the traveling chassis of the pile machine. After the long spiral construction is completed, the static pile-pressing mechanism can be quickly aligned only by turning the turntable. The pile driver can independently complete the construction of the long spiral pressure grouting concrete core-inserted composite pile, and has the advantages of convenient construction, reliable quality and low construction cost.

Owner:雷玉华

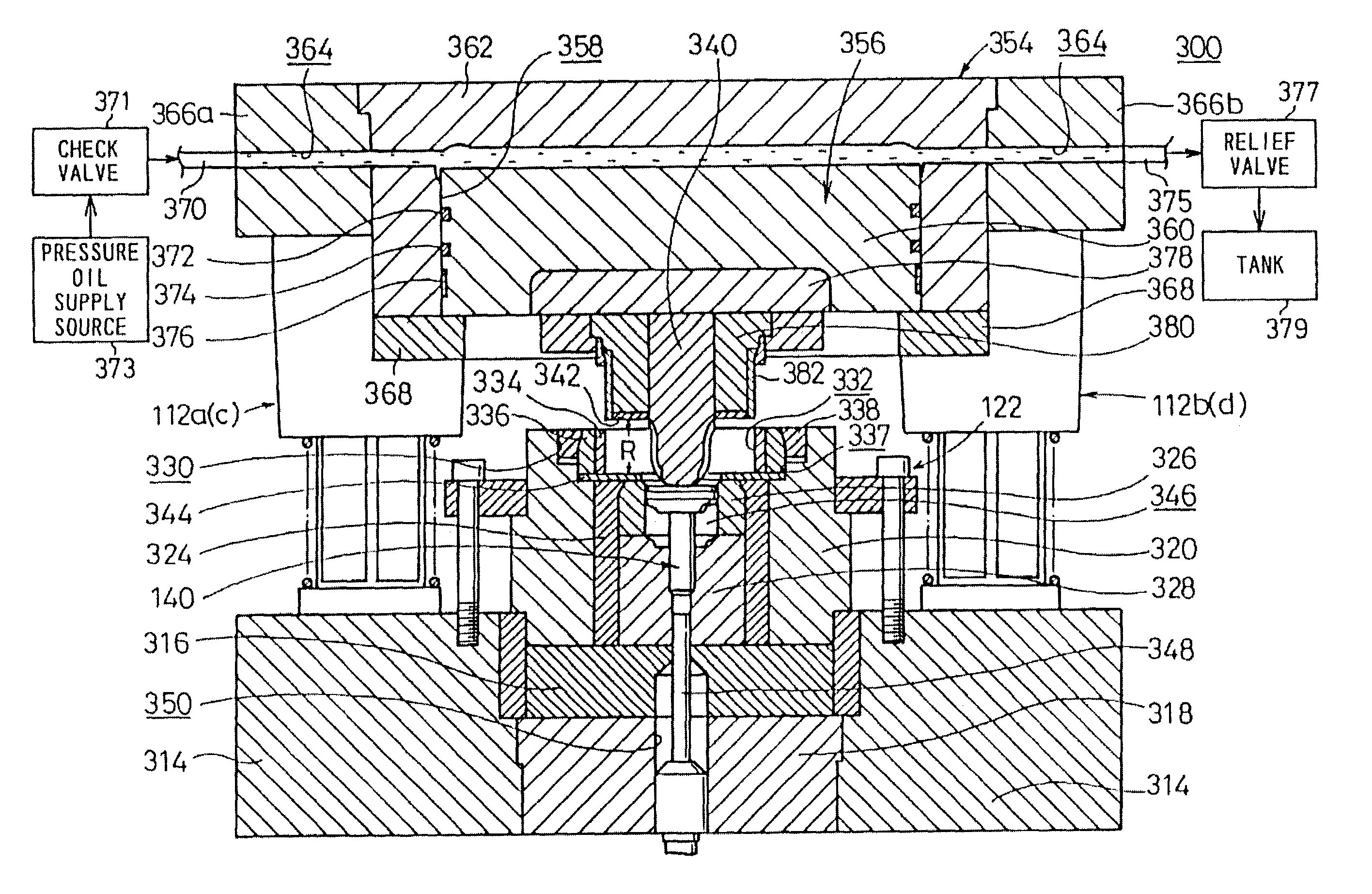

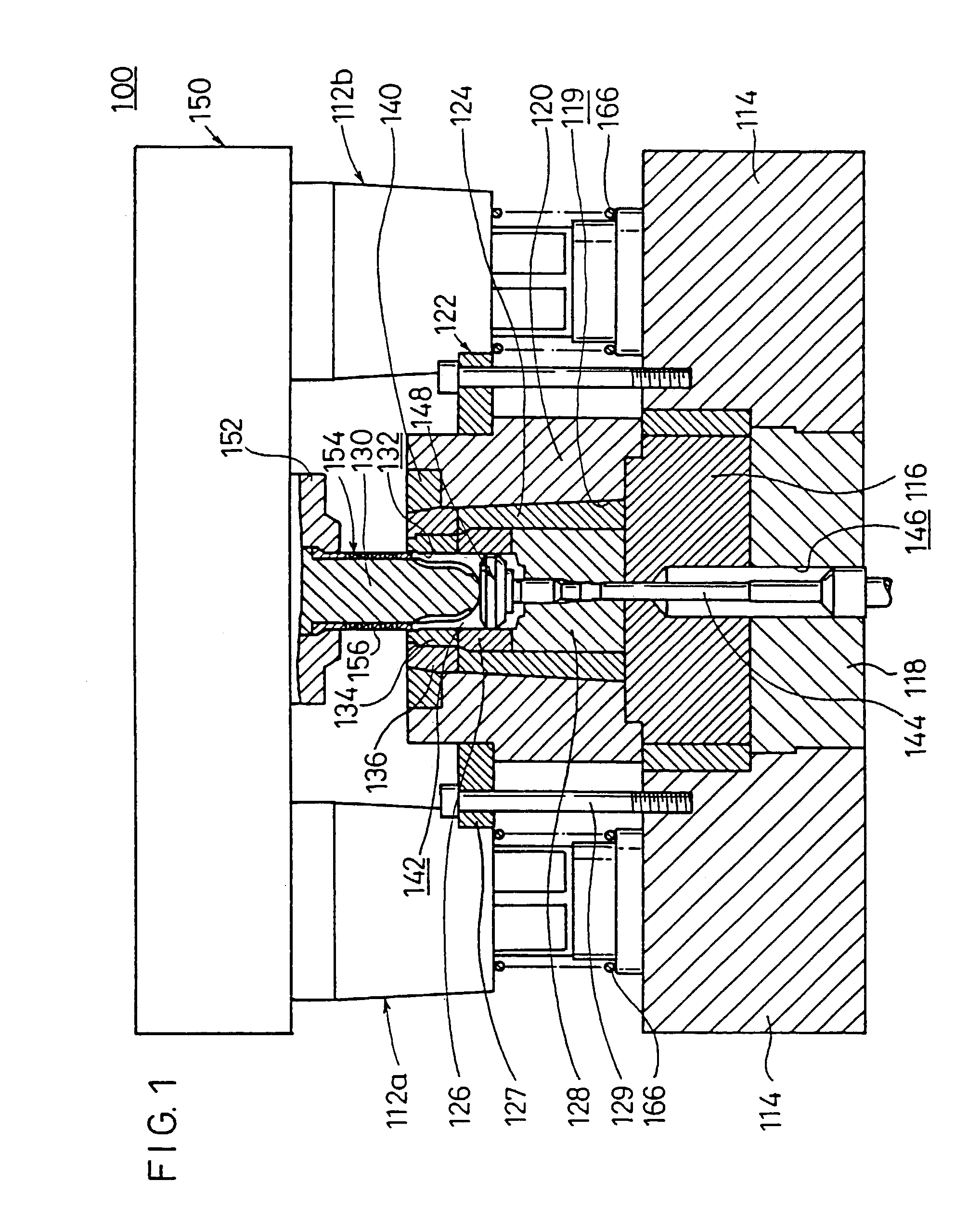

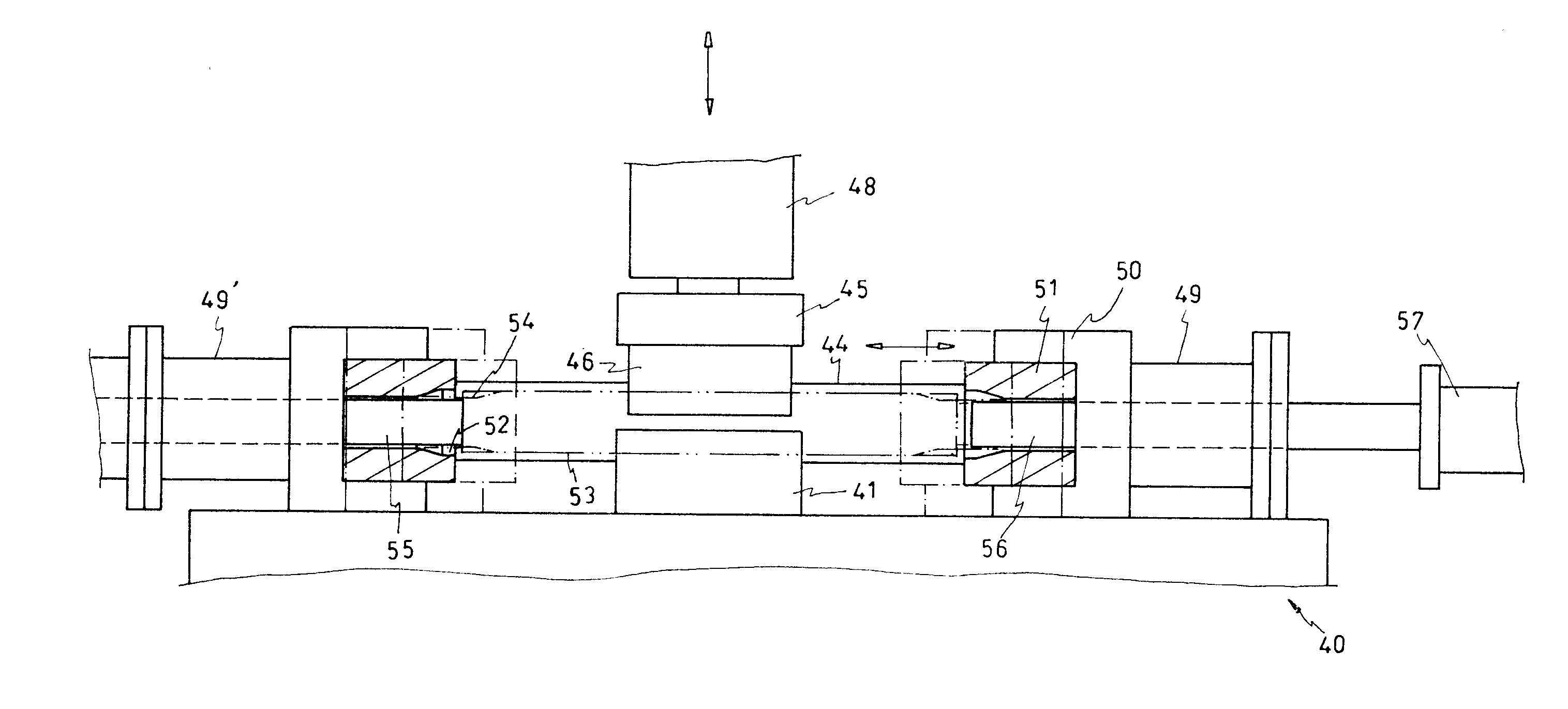

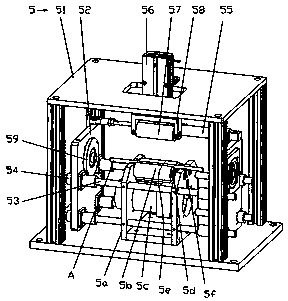

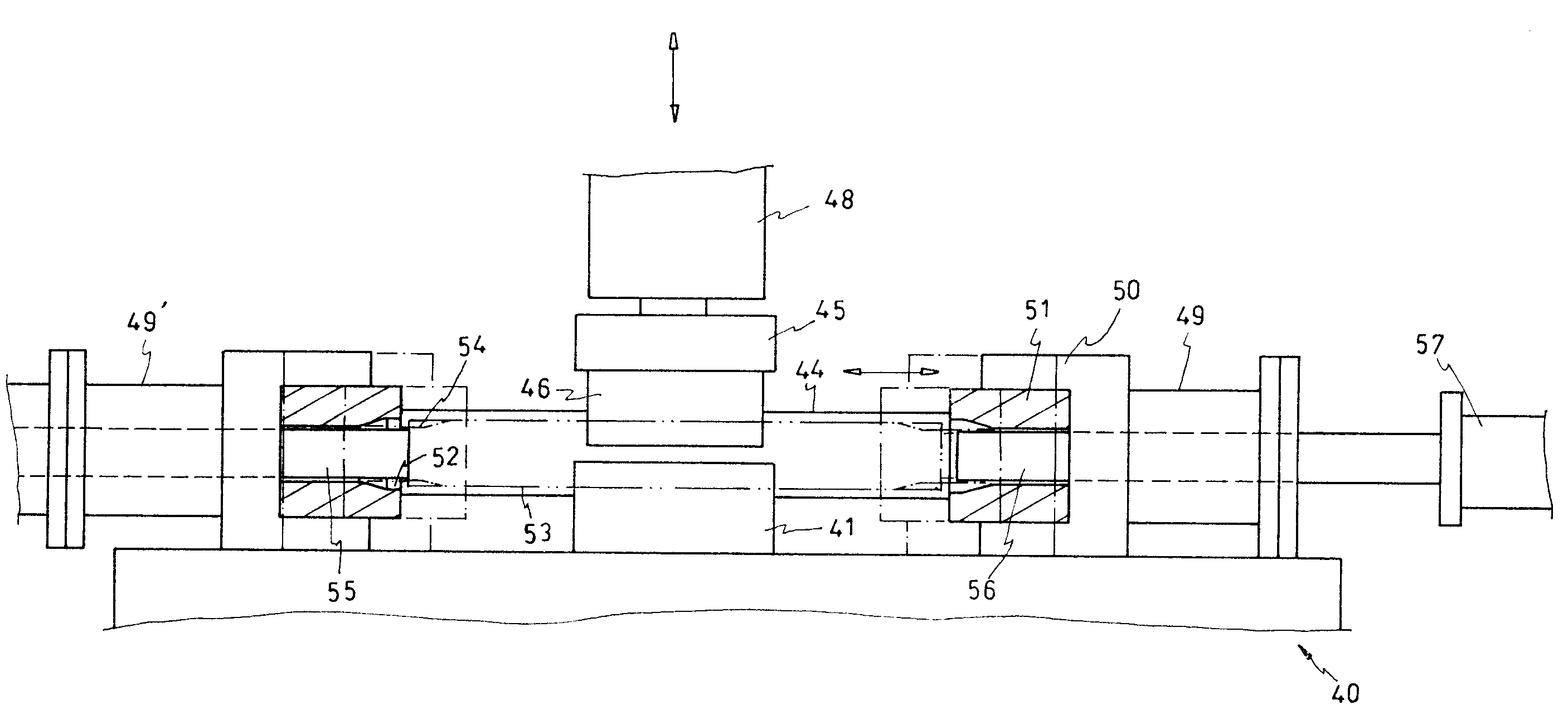

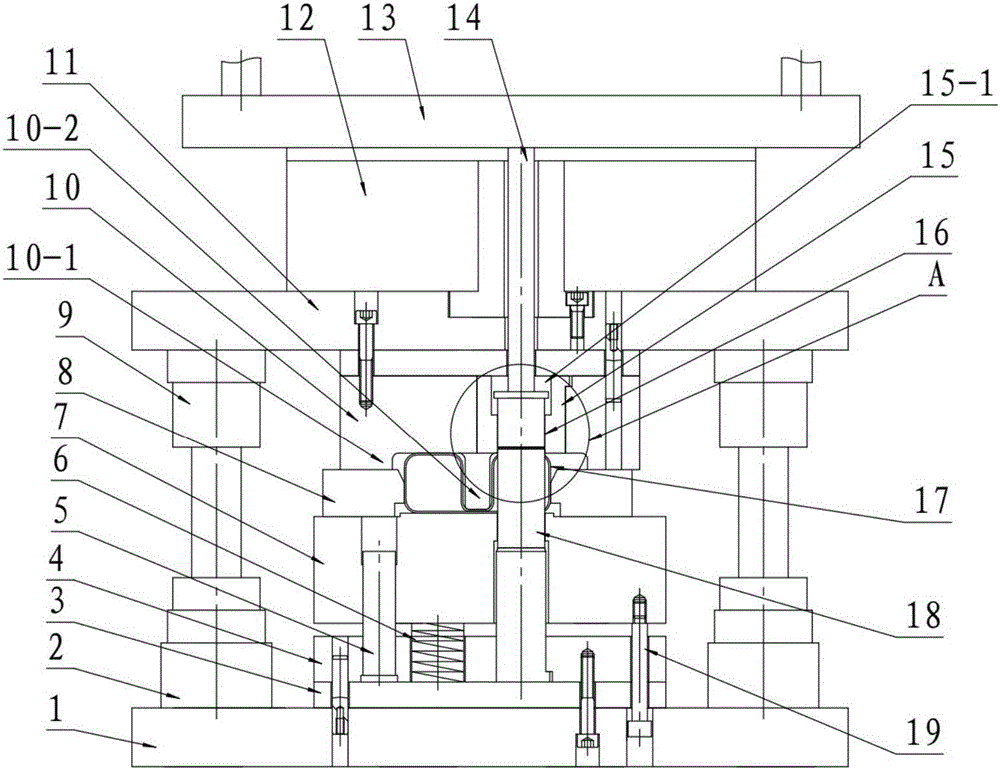

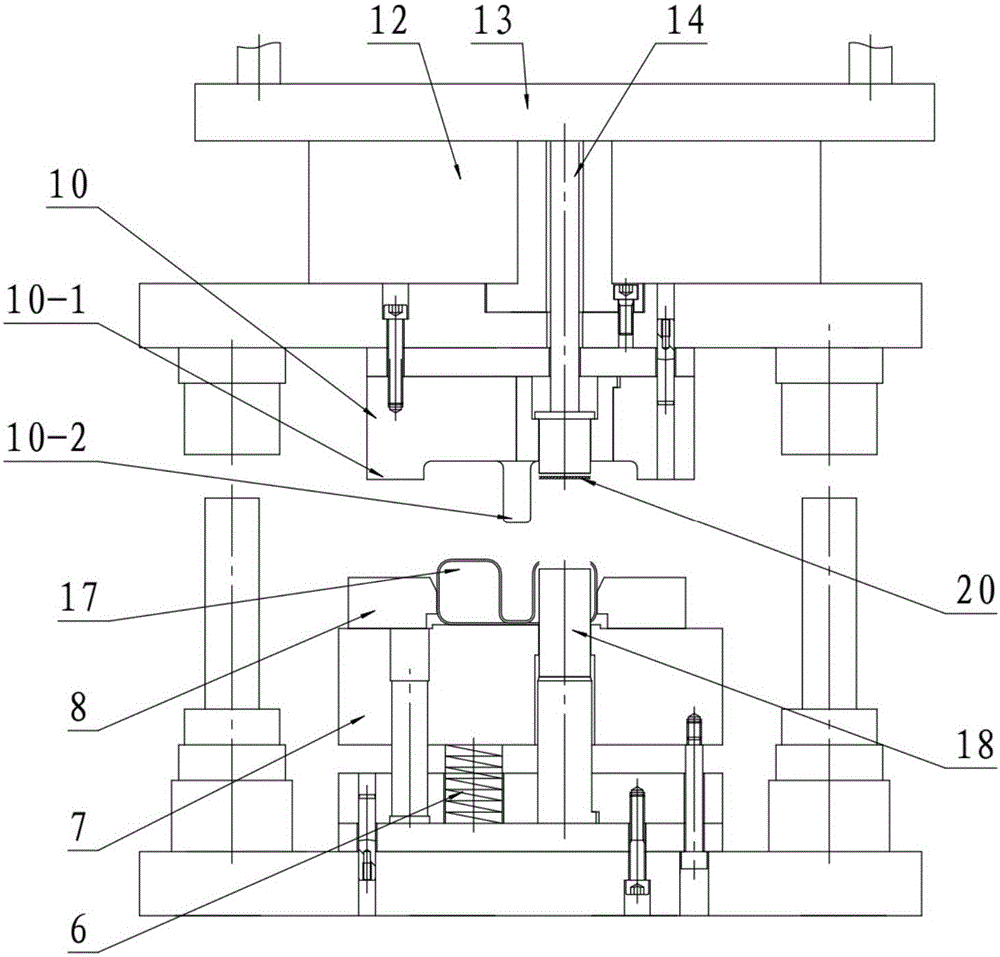

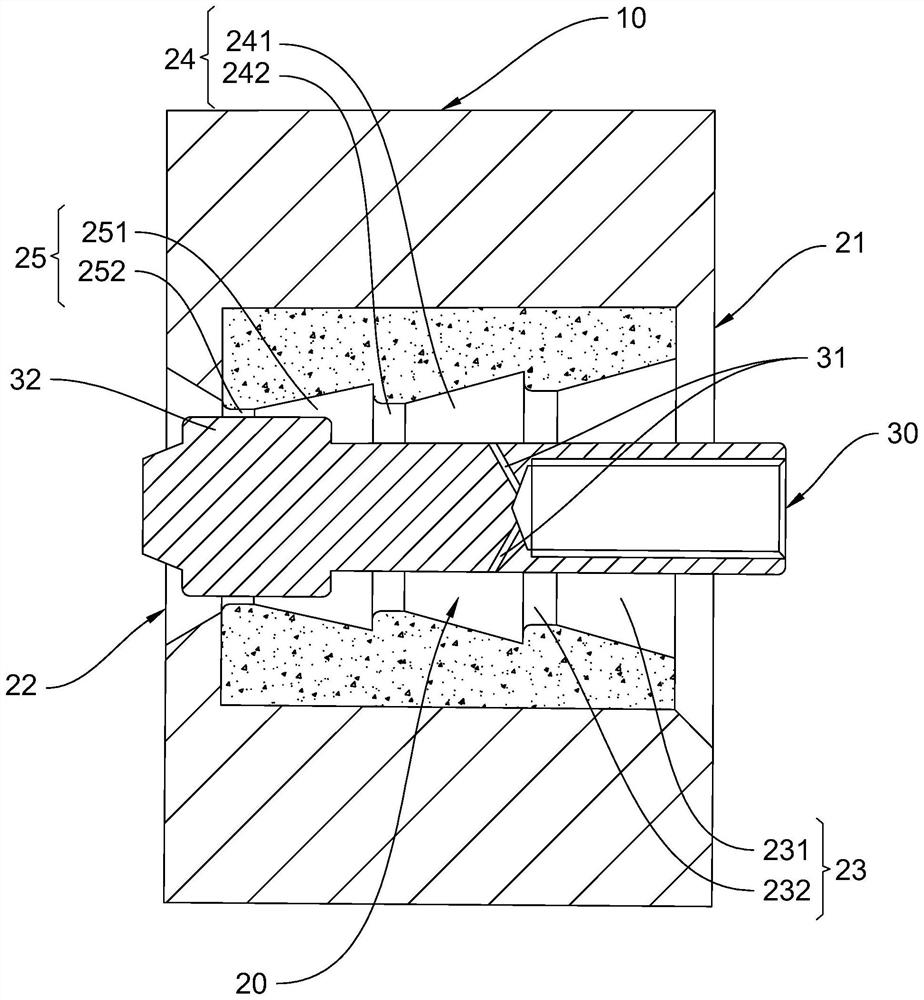

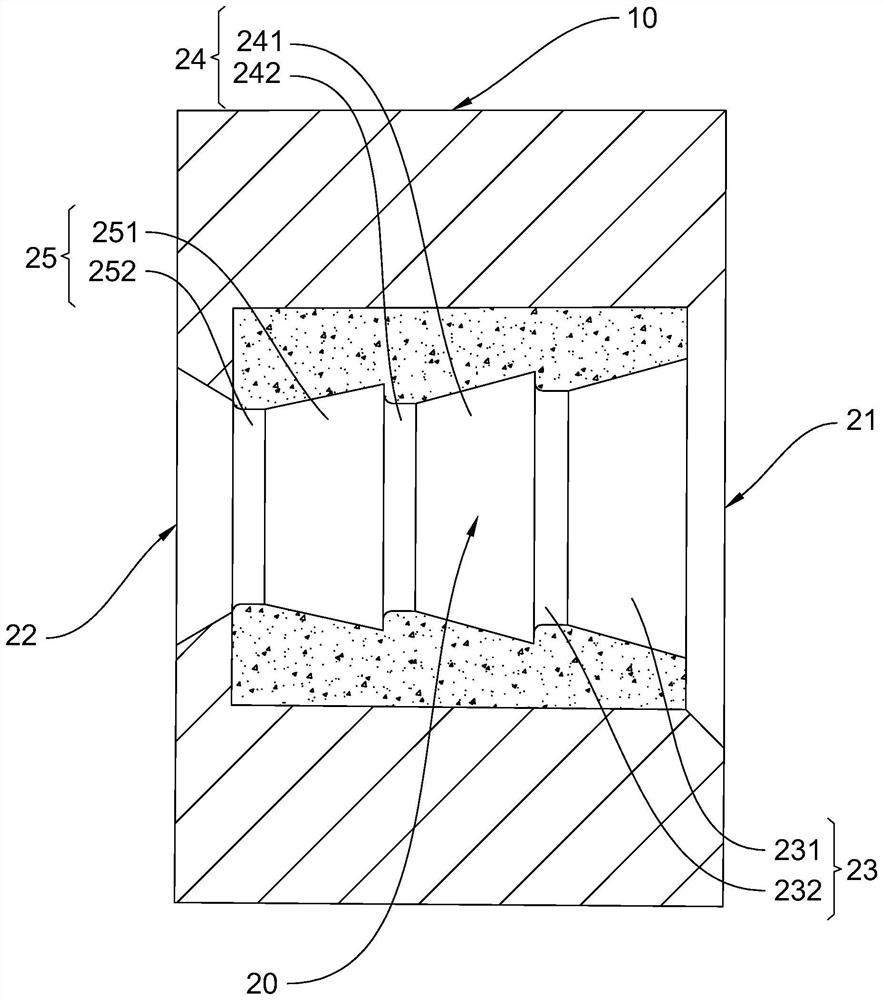

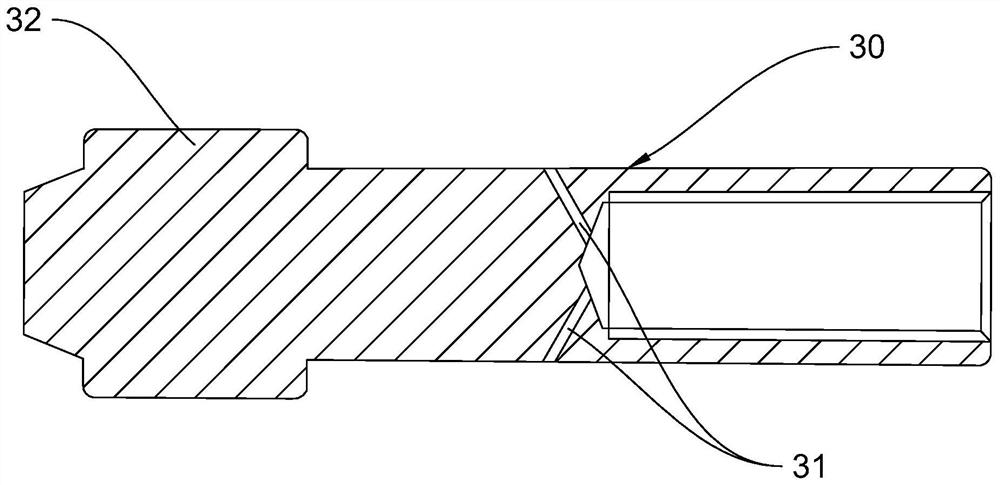

Concentric machining device for a roller

InactiveUS20070243280A1Production rate can be promotedAccurate concentricityShaping toolsCeramic shaping apparatusHydraulic cylinderMachining

A concentric machining device for a roller includes a movable upper base, a stationary lower base, two movable mold seats, two slide rods and four first hydraulic cylinders. Each of the mold seats has a forming mold inside, the forming mold has a fitting hole with an enlarged conical opening at the front side thereof, a locating shaft is received in the forming mold of the first mold seat and penetrates the fitting hole thereof and the first cylinder member, a clamping shaft is received in the forming mold of the second mold seat and penetrates the fitting hole thereof and the second hydraulic cylinder to connect with the fourth hydraulic cylinder. The roller is held by the bases and the shafts via two of the hydraulic cylinders and both ends of the roller are machined by the forming molds in the mold seats to provide squeezed and shrunk shapes once the mold seats are actuated by the other two hydraulic cylinders.

Owner:HUANG TE LI

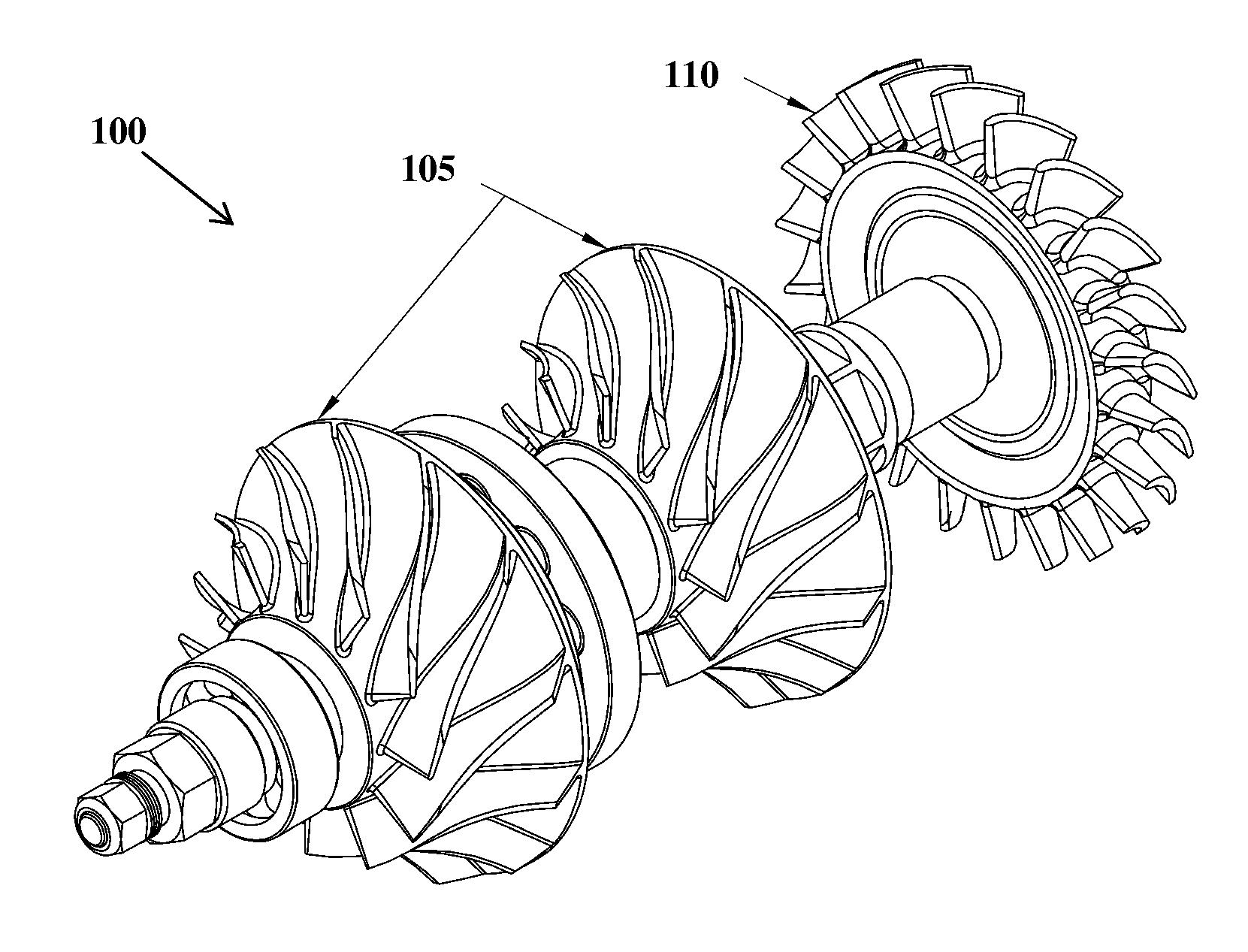

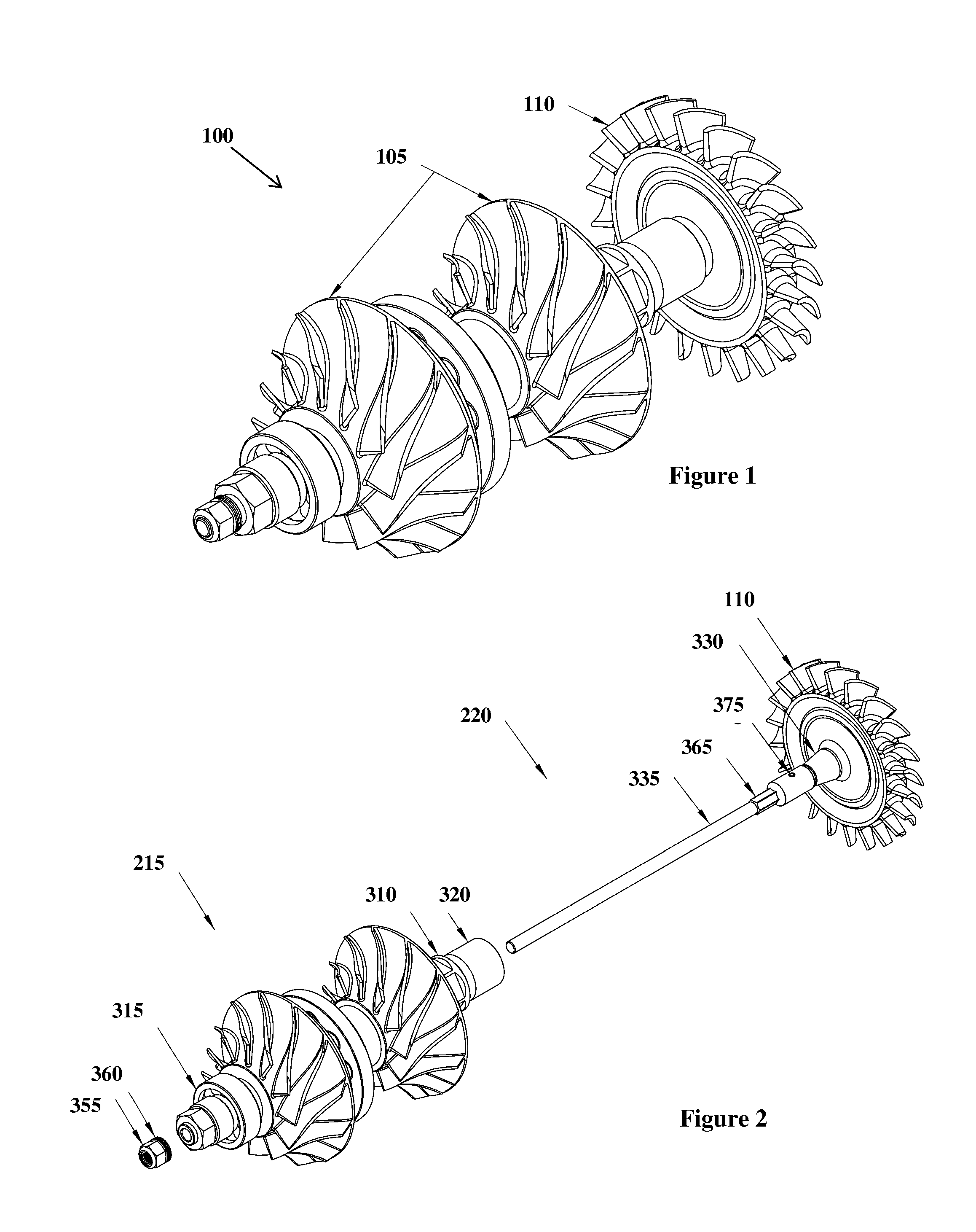

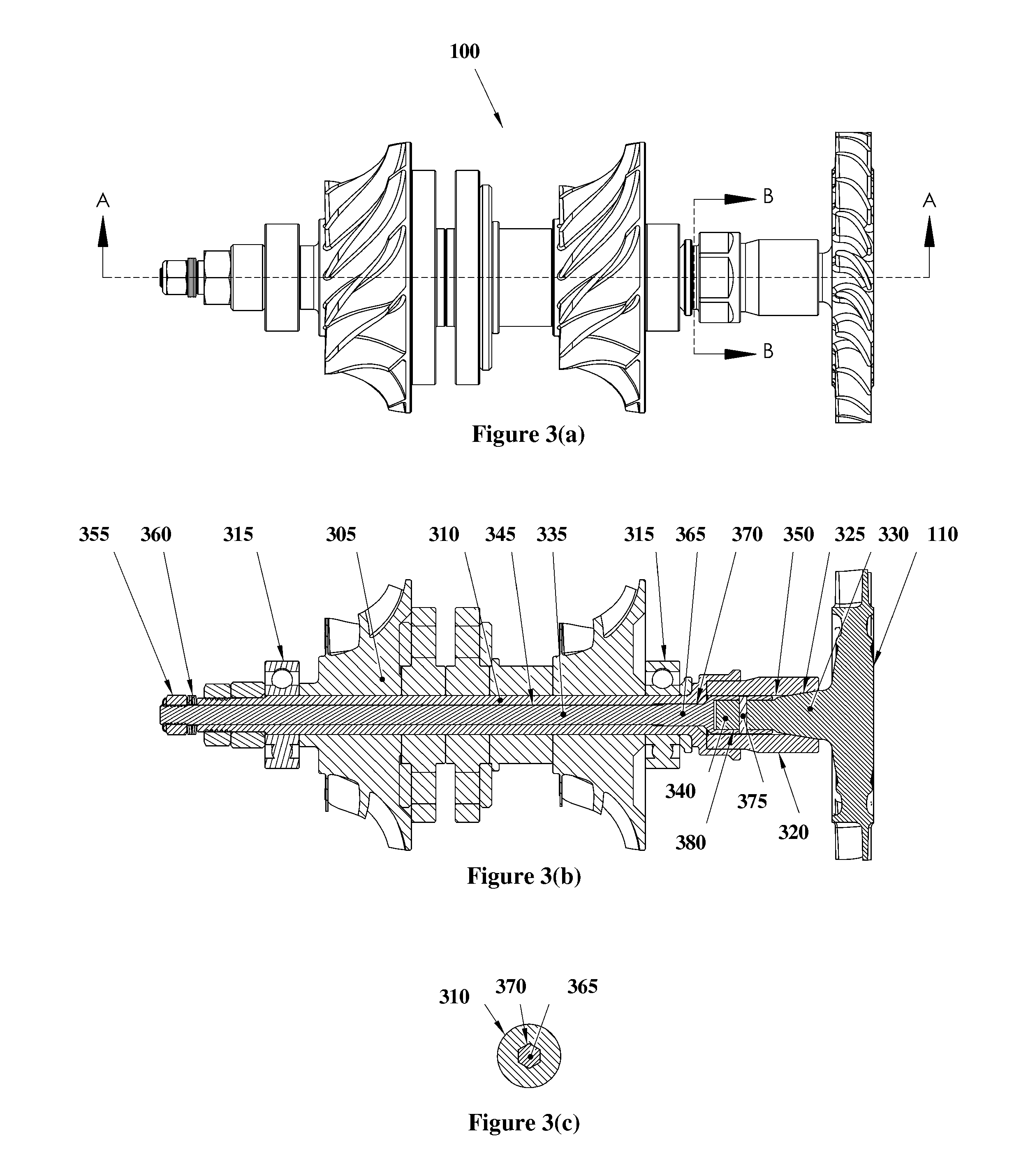

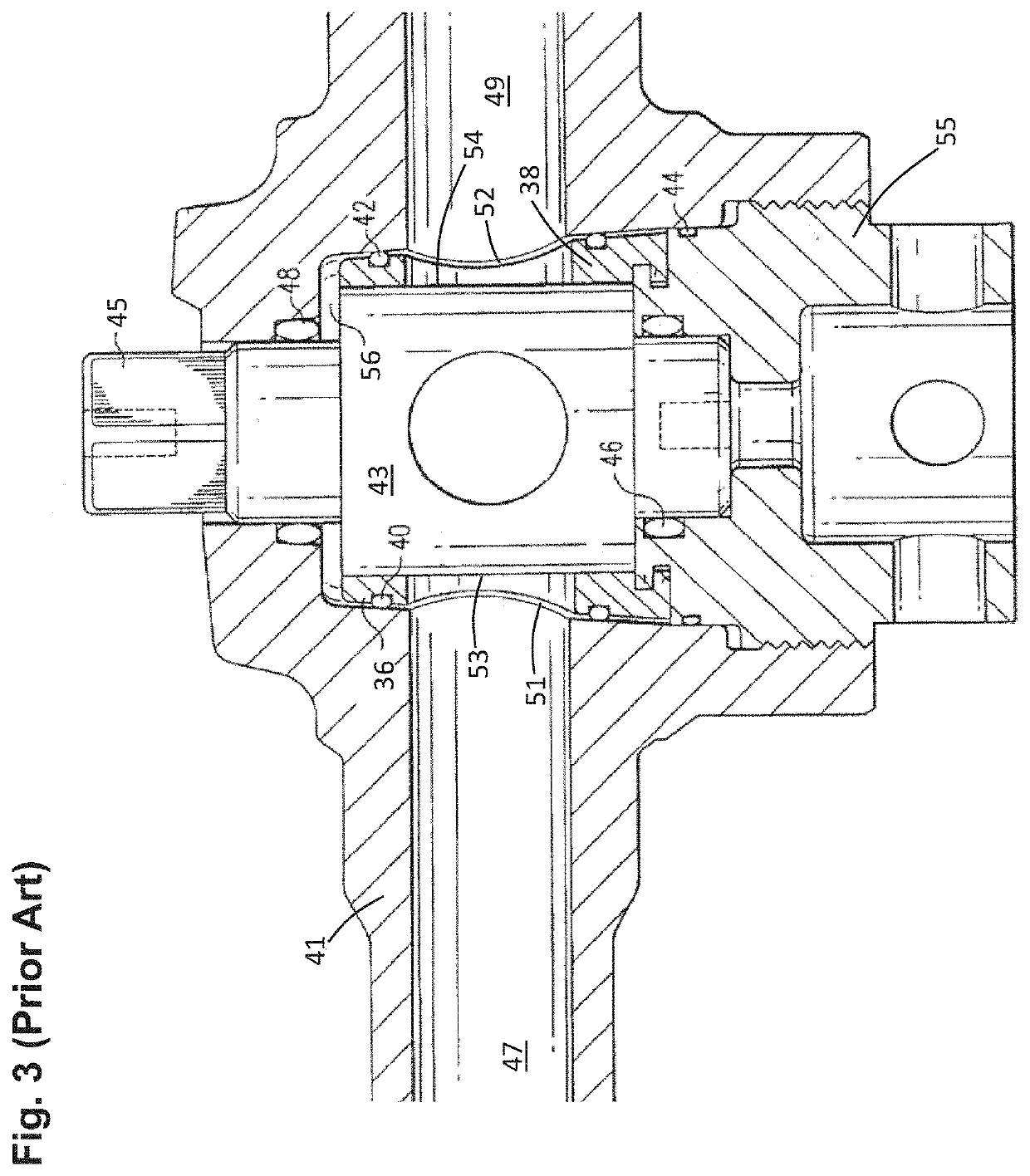

Thermally insulating turbine coupling

ActiveUS20120093661A1Control stressQuick and easy disassembly/reassemblyPump componentsEngine fuctionsCouplingTorque transmission

A rotor assembly, including at least one driven member, e.g., a compressor rotor, and at least one driving member, e.g., a turbine. At least one rotating thermal insulator rigidly attached to either the driven member or the driving member. A coupling feature that includes mating geometric surfaces on the driven member and the driving member, wherein the geometric surfaces are configured to allow radial sliding, relative centering, torque transmission, and axial constraint between the driven member and the driving member.

Owner:IMPERIAL INNOVATIONS LTD +1

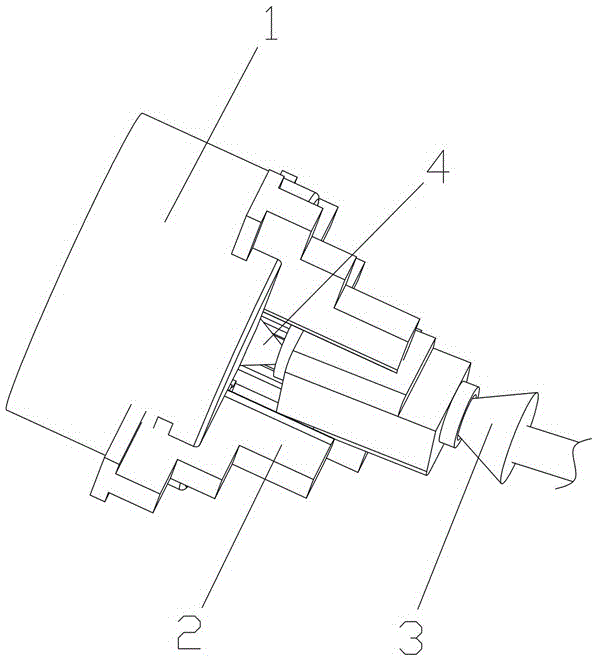

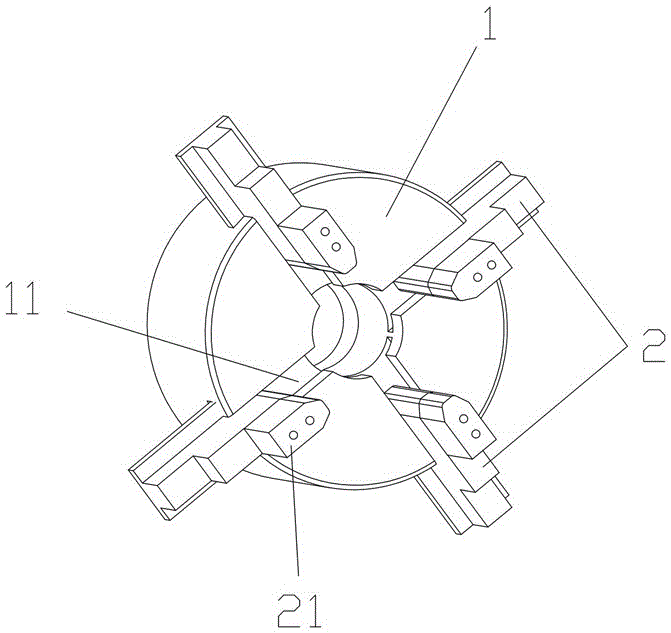

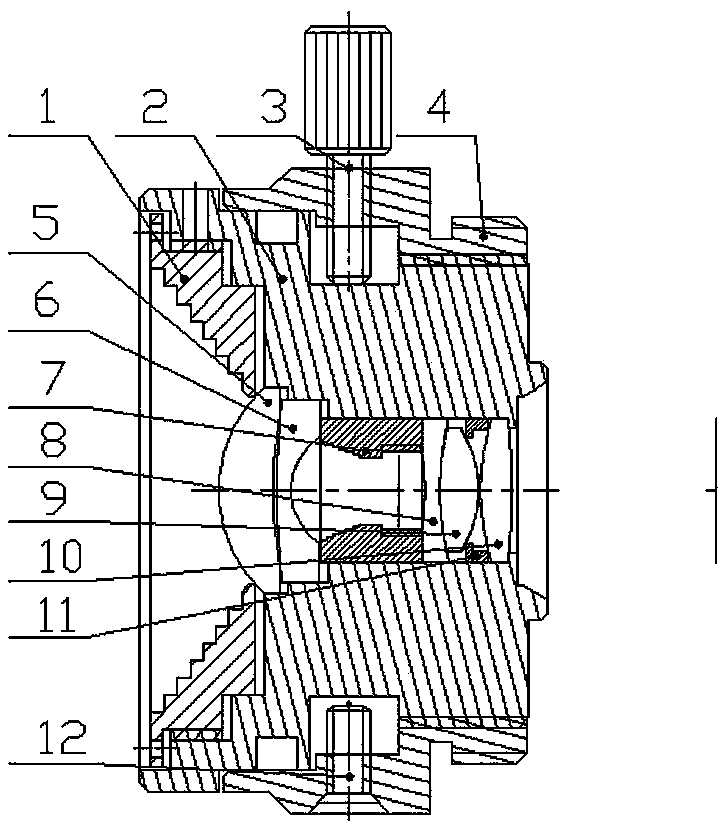

Self-centering multi-claw chuck device

The invention discloses a self-centering multi-claw chuck device which is used for being matched with a machine tool after clamping a workpiece so as to enable the machine tool to machine the clamped workpiece. The self-centering multi-claw chuck device comprises a chuck base, the chuck base is sequentially provided with multiple clamping claws in the circumferential direction, a fixing cavity where the workpiece is placed is defined by the multiple clamping claws, the multiple clamping claws can independently move forwards and backwards in the radial direction of the chuck base so as to clamp the workpiece in the fixing cavity, the bottom of the fixing cavity is provided with a centering center assembly used for being matched with a tailstock center on the machine tool, and the central axis of the centering center assembly coincides with the central axis of the tailstock center. In the working process, the tailstock center and the centering center assembly abut against the center points at the two ends of the workpiece correspondingly, then, the multiple clamping claws are sequentially adjusted to clamp and fix the workpiece, and therefore the workpiece is machined after being centered. The self-centering multi-claw chuck device has the advantages of being simple and compact in structure, low in production cost, convenient and fast to operate, and capable of effectively ensuring the coaxiality of two-end inner hole and outer circle machining of the workpiece, particularly an irregular workpiece.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

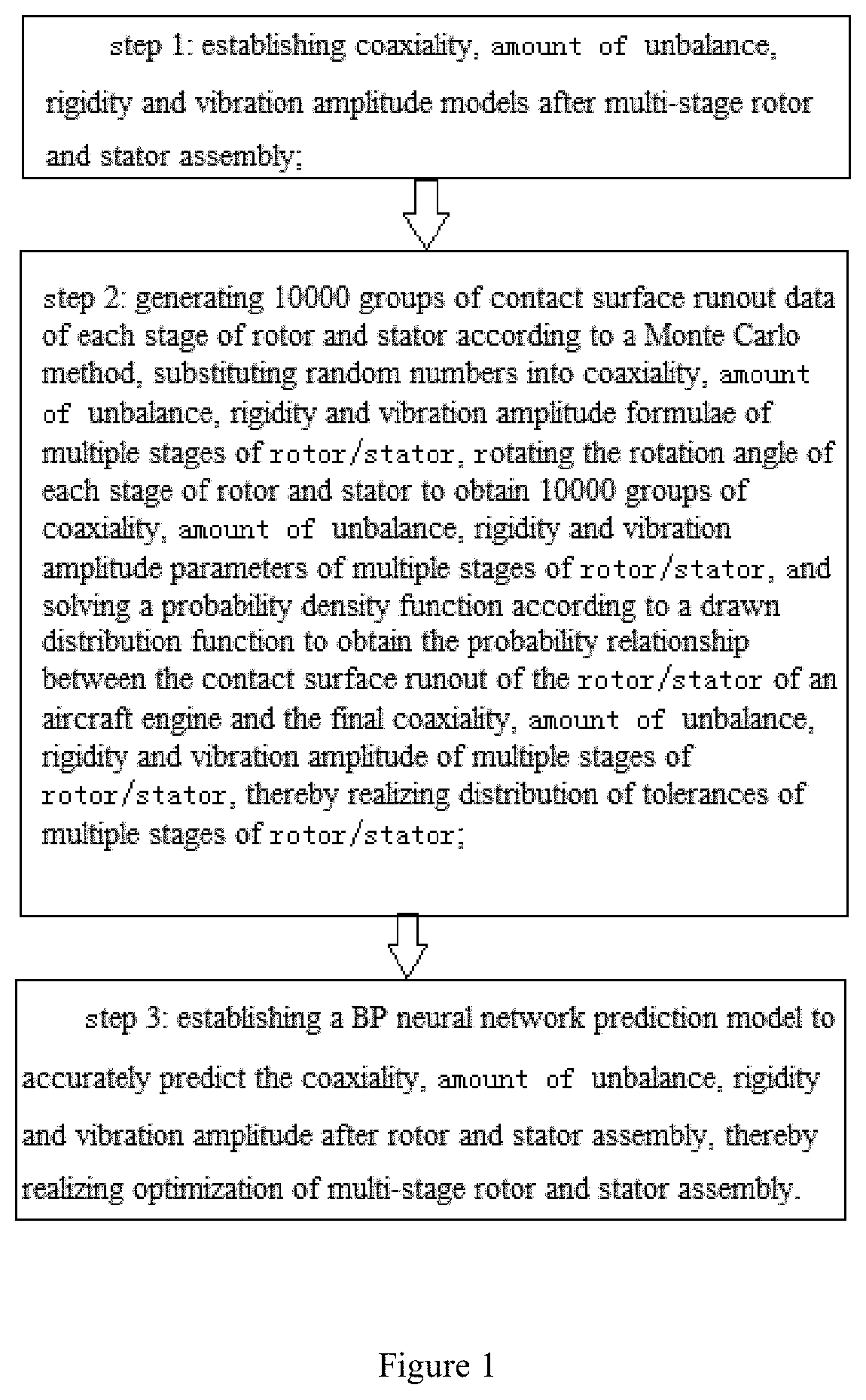

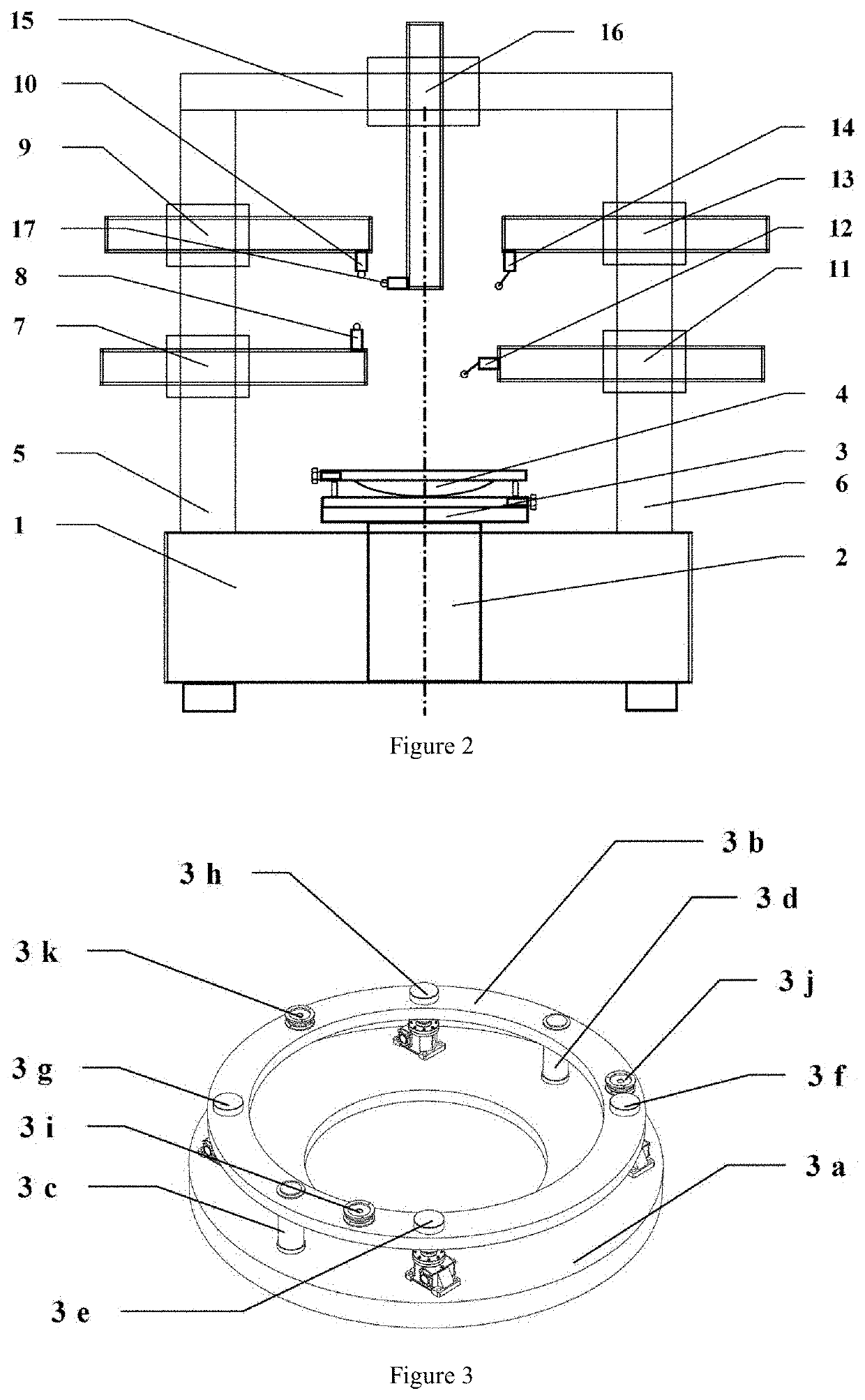

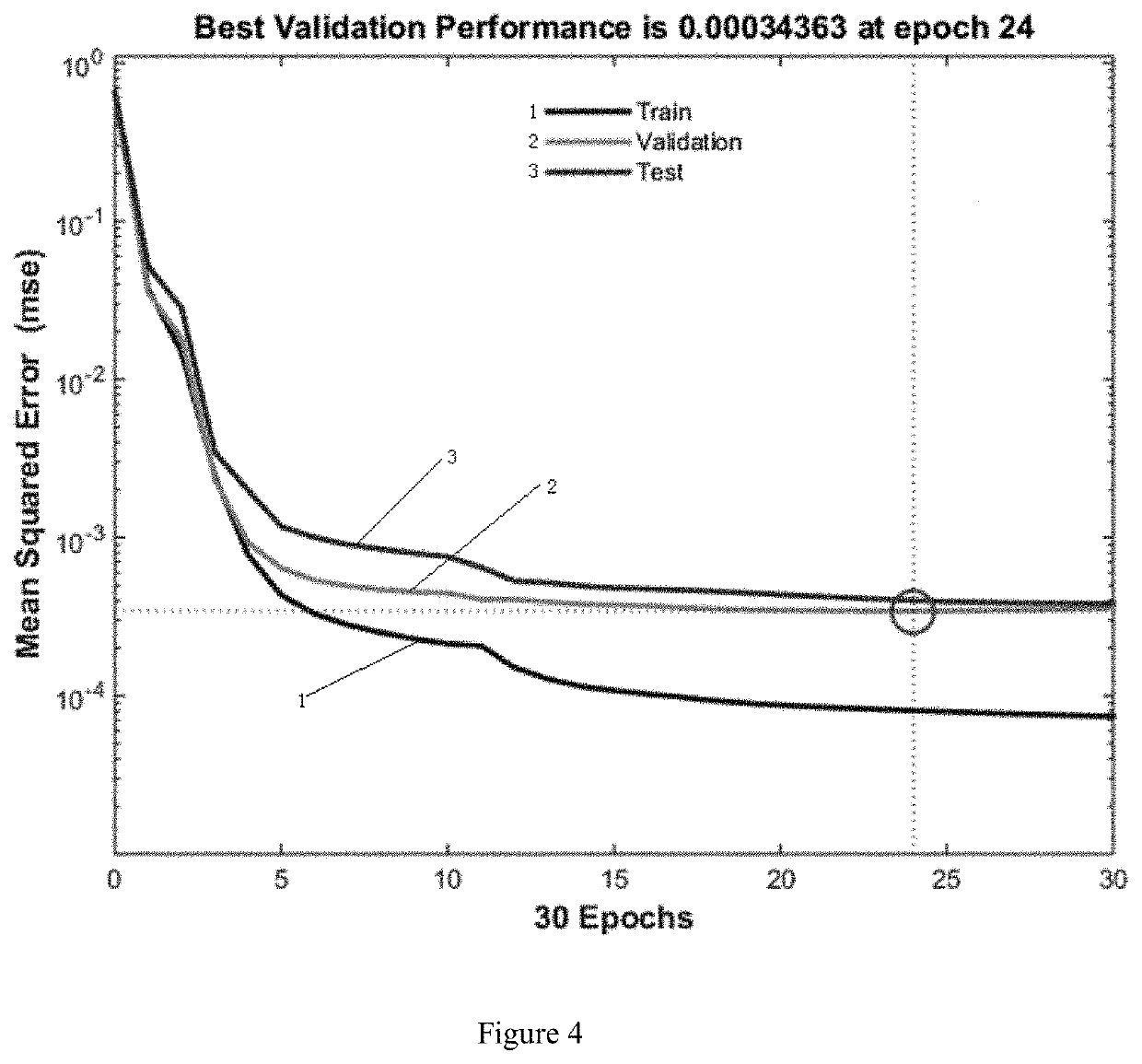

Deep learning regulation and control and assembly method and device for large-scale high-speed rotary equipment based on dynamic vibration response properties

ActiveUS20200217218A1Accurate concentricityMathematical modelsStatic/dynamic balance measurementAviationVibration amplitude

The present invention provides a deep learning regulation and control and assembly method and device for large-scale high-speed rotary equipment based on dynamic vibration response properties. The present invention starts from geometrical deviation of multiple stages of rotor / stator of an aircraft engine, amount of unbalance of rotor / stator, rigidity of rotor / stator and vibration amplitude of rotor / stator, considers the influence of the area of the assembly contact surface between two stages of rotors / stators, and sets the rotation speed of rotor / stator to be the climbing rotation speed to obtain vibration amplitude parameters. According to the calculation method of the coaxiality, amount of unbalance, rigidity and vibration amplitude of multiple stages of rotor / stator, an objective function taking assembly phases as variables is established, a Monte Carlo method is used to solve the objective function, and a probability density function is solved according to a drawn distribution function to obtain the probability relationship between the contact surface runout of the rotor / stator of the aircraft engine and the final coaxiality, amount of unbalance, rigidity and vibration amplitude of multiple stages of rotor / stator, thereby realizing assembly optimization and distribution of tolerances of multiple stages of rotor / stator.

Owner:HARBIN INST OF TECH

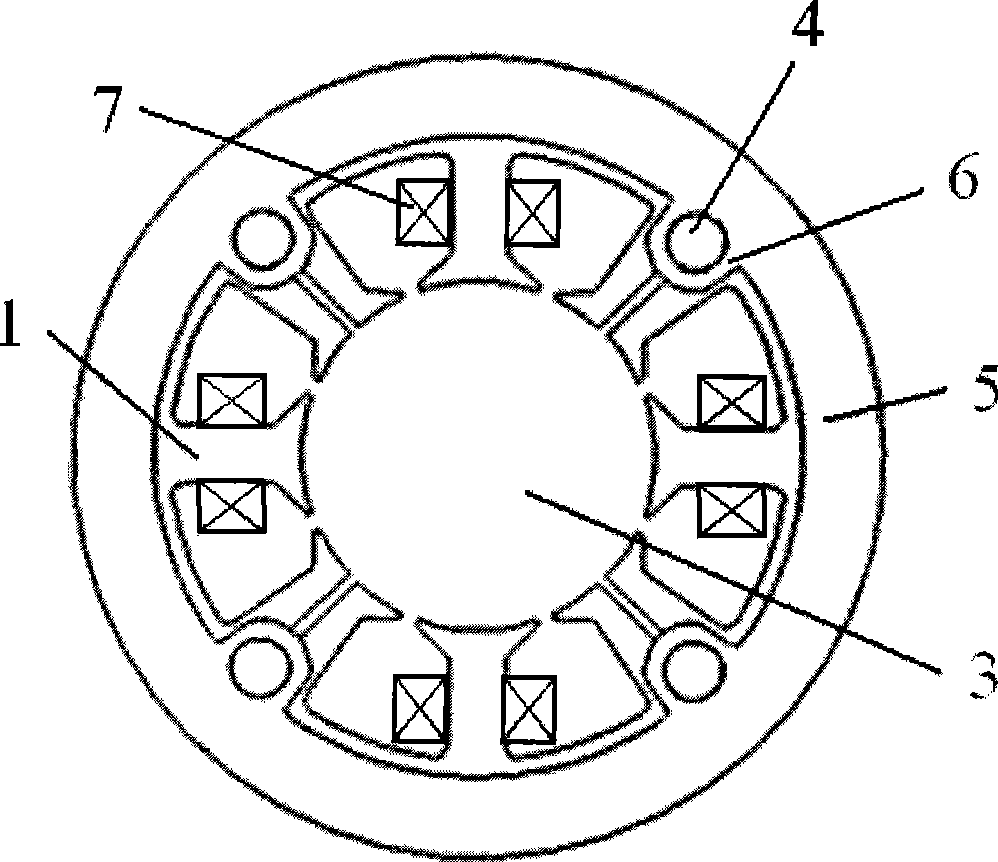

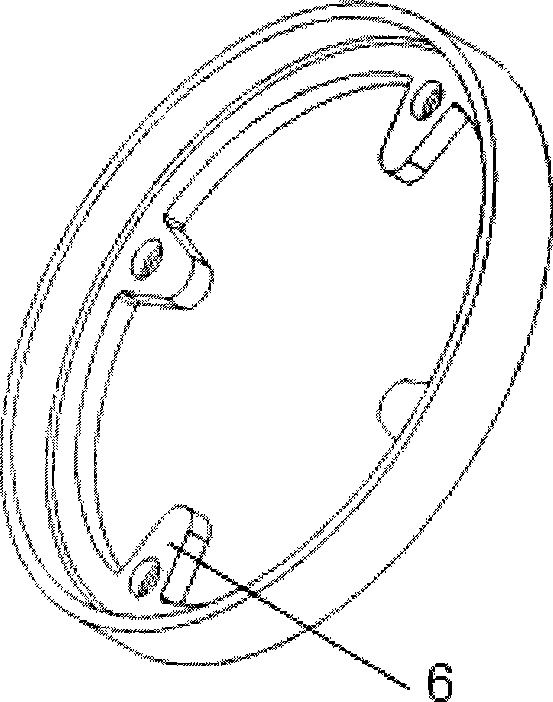

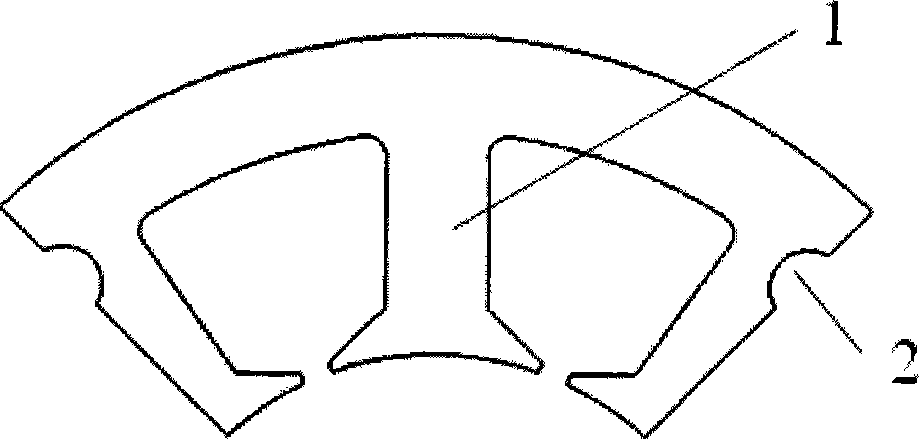

Magnetic field coupling-eliminating magnetic bearing and manufacturing method thereof

InactiveCN101482144ASimple preparation processEasy to operateBearing componentsMagnetic bearingsMagnetic tension forceMagnetic bearing

The invention relates to a magnetic bearing used for eliminating magnetic field coupling. The magnetic bearing consists of four magnet cores (1), four coils (7), two magnet isolating rings (5) and four rivets (4). The two magnet isolating rings are matched with the outer circles of the magnet cores by spigots of the magnet isolating rings and are respectively arranged at two sides of the magnet cores to clamp the magnet cores. The magnet isolating rings and the magnet cores are riveted as a whole by the rivets (4). The four magnet cores are respectively winded with a coil (7) to form the whole magnetic bearing. The four magnet cores of the magnetic bearing consist of a plurality of silicon steel sheets which are coincided and are all structured as character E, both two ends of each silicon steel sheet are provided with semicircular slots (2), and the rivets (4) restrain the circumferential position between each silicon steel sheet by the semicircular slots. The magnetic bearing adopts four magnet cores and four coils which are riveted as a whole by the magnet isolating rings made of non magnetic conduction material and the rivets, and each magnet core does not contact with each other, thereby eliminating the magnetic field coupling of the magnetic bearing.

Owner:WUHAN UNIV OF TECH

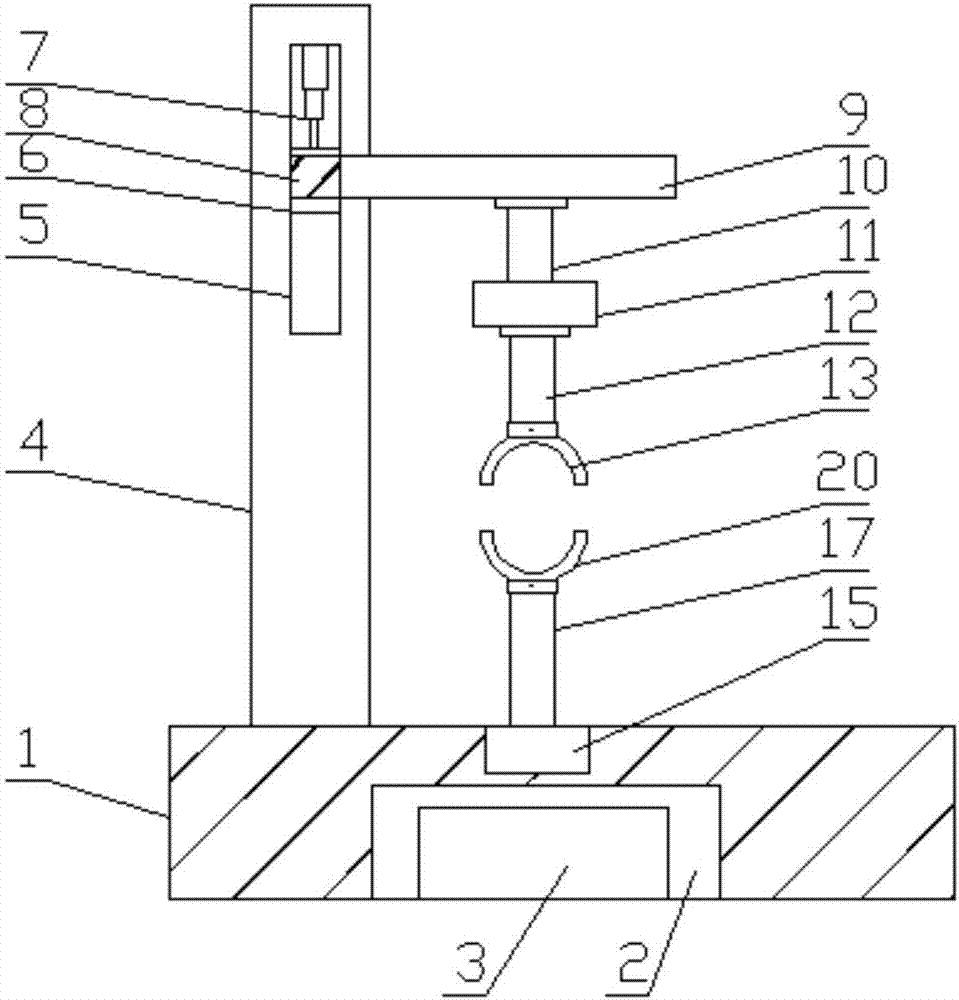

Device for aligning concentricity and carrying out automatic welding during planted pile butt joint

ActiveCN110695584APlay a buffer roleImprove construction efficiencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointIndustrial engineering

The invention discloses a device for aligning the concentricity and carrying out automatic welding during planted pile butt joint. The device comprises a round guide rail, a welding gun frame arrangedon the round guide rail in a running fit manner, and a welding gun mounted on the welding gun frame and further comprises a pair of first pile holding arms, a pair of second pile holding arms and tworotary motors mounted on a rack. The first pile holding arms and the second pile holding arms are symmetrically arranged and synchronously act. An output shaft of each rotary motor is fixed to the swing end of a respective swing arm, and respective supporting frames are hinged to the pile holding ends of the swing arms. Structures for allowing upper piles and lower piles to automatically align the concentricity when the upper piles fall off are arranged on the supporting frames. The pile holding ends of the swing arms are further connected with arc-shaped plates abutting against the butt joint positions of the upper pile and the lower piles through elastic devices. Semi-circular guide rails are fixed to the two arc-shaped plates, and after the two arc-shaped plates hold the piles, the twosemi-circular guide rails form a round guide rail. According to the device for aligning the concentricity and carrying out automatic welding during planted pile butt joint, the upper piles and the lower piles connected end to end can be automatically aligned, and the device can be automatically mounted at the butt joint positions of the piles.

Owner:厦兴科技(浙江)有限公司

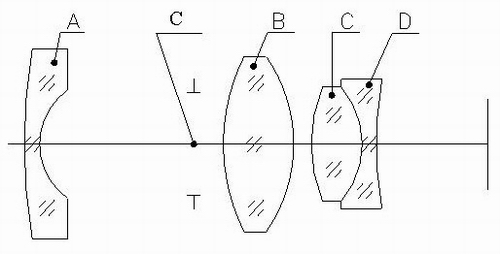

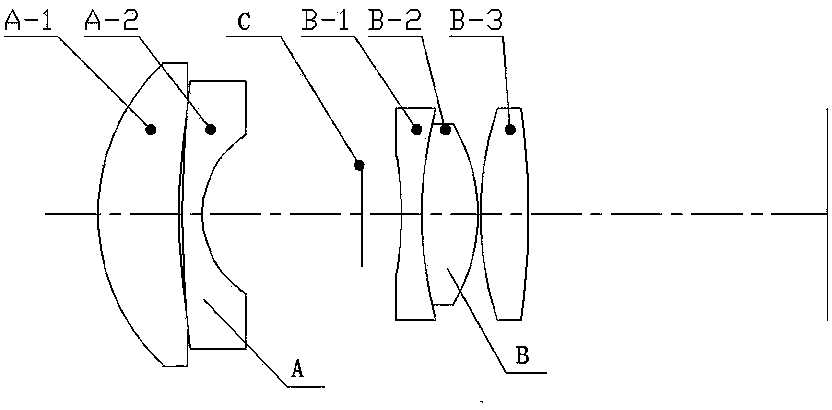

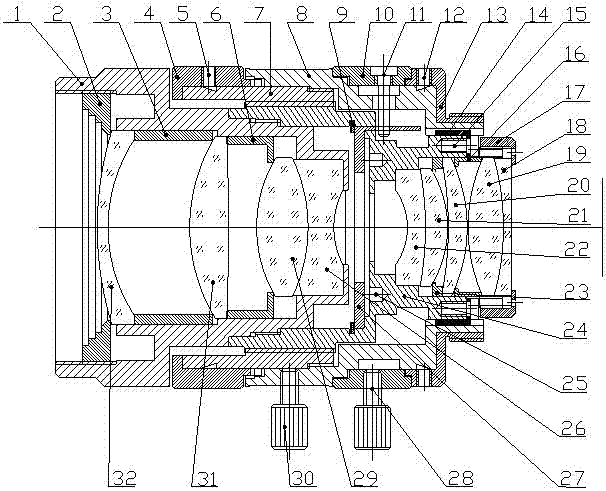

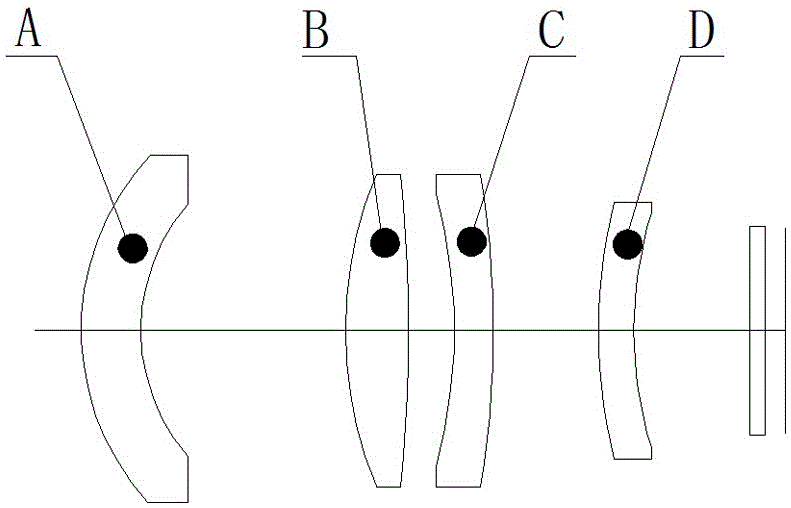

High-resolution fine adjustment day and night prime lens

ActiveCN104181674AImprove image qualityAchieving Broad Spectrum ConfocalMountingsPrime lensOptoelectronics

The invention relates to a high-resolution fine adjustment day and night prime lens. A front lens set A with negative focal power and a rear lens set B with positive focal power are arranged in the optical system of the lens sequentially in the left-to-right light incidence direction. An iris diaphragm C is arranged between the front lens set A and the rear lens set B. The front lens set A comprises a positive meniscus lens A-1 and a negative meniscus lens A-2 sequentially from left to right. The rear lens set B comprises a double-concave lens B-1 and double-convex lens B-2 tightly-connected gluing assembly and a double-convex lens B-3 sequentially from left to right. The high-resolution fine adjustment day and night prime lens has the advantages of small distortion, large relative aperture and high resolution, can meet the requirement of three-million-pixel high-resolution video shooting, and achieves the wide spectrum confocal aim.

Owner:FUJIAN FORECAM OPTICS CO LTD

Fluid actuator

InactiveCN1704615AImprove cycle lifeThe total bias force does not changePositive displacement pump componentsFluid-pressure actuatorsActuatorControl theory

A fluid actuator configured for achieving extended cycle life and reduced overall actuator height. The actuator may include a nesting arrangement between portions of the actuator to reduce overall height and provide stability. The actuator may also join movable members and include a guidance mechanism to avoid undesired contact between actuator portions.

Owner:SWAGELOK CO

Flexing slot for plug valve insert

ActiveUS20200025296A1Improve sealing propertiesSame sealing effectPlug valvesEngineeringMechanical engineering

An insert adapted for use in a plug valve includes a single-piece body having an inner sidewall adapted to interface with a sidewall of a valve plug. First and second opposing apertures are each defined through the single-piece body for selective alignment with a flow bore of the valve plug. First and second opposing slots are each defined through the single-piece body at an angle to the first and second opposing apertures for allowing the body to flex in the direction of the first and second opposing apertures.

Owner:BLUECORE COMPLETIONS LLC

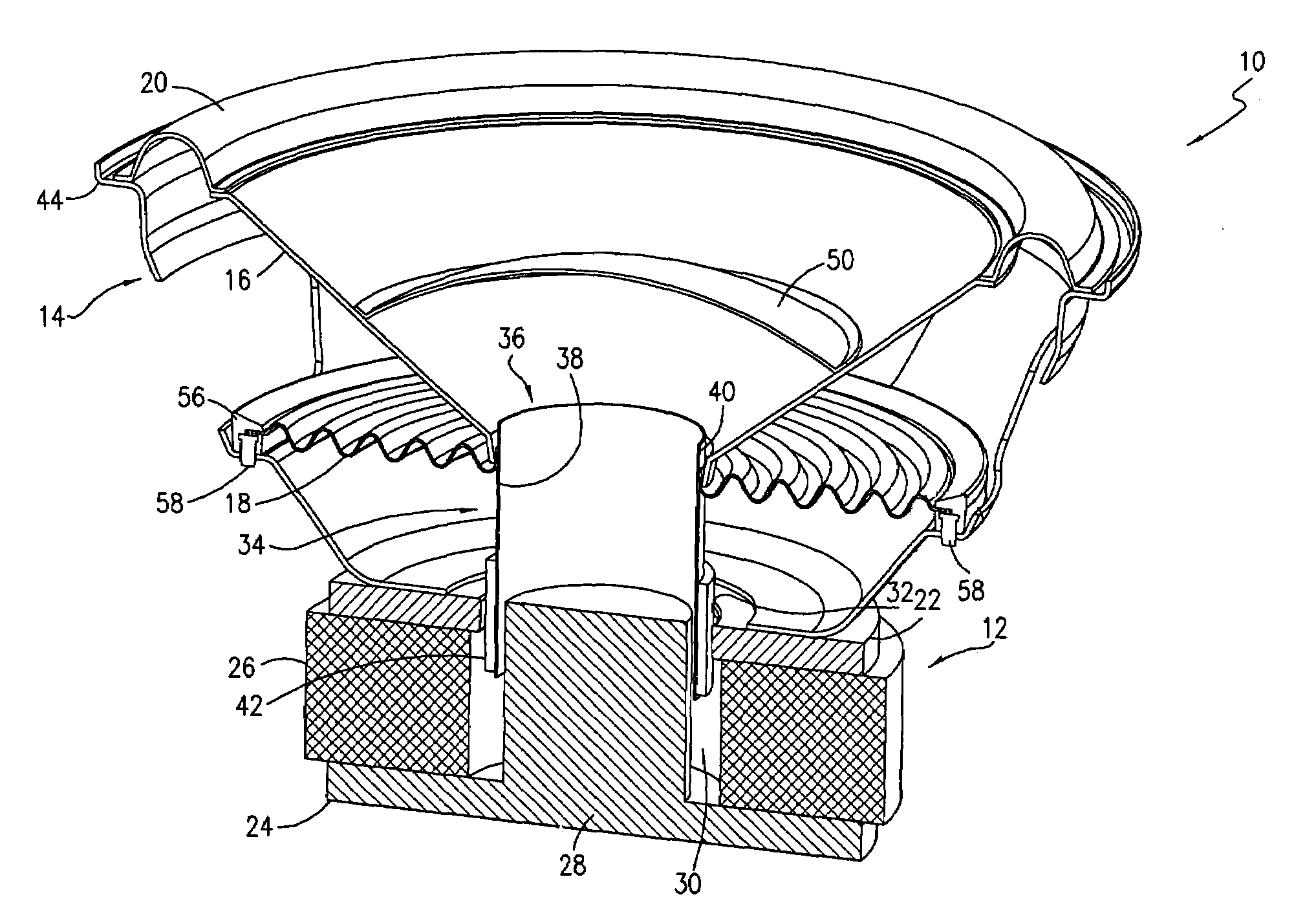

Loudspeaker with integrated spider standoff ring

ActiveUS7379558B2Accurate centerAccurate locationTransducer casings/cabinets/supportsDiaphragm mounting/tensioningPlastic materialsEngineering

A loudspeaker is provided in which the outer diameter or foot of the spider is over molded with a standoff formed of a plastic material in an injection molding tool so that the spider and standoff form an integral unit. The standoff, in turn, is glued or otherwise affixed to the frame of the speaker to provide accurate centering of the voice coil relative to the magnetic gap of the motor structure.

Owner:JL AUDIO

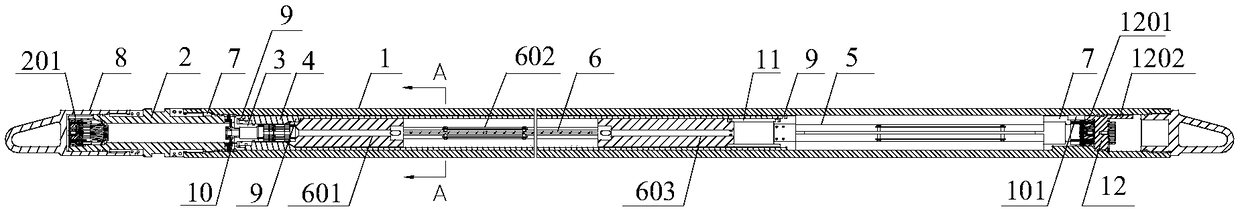

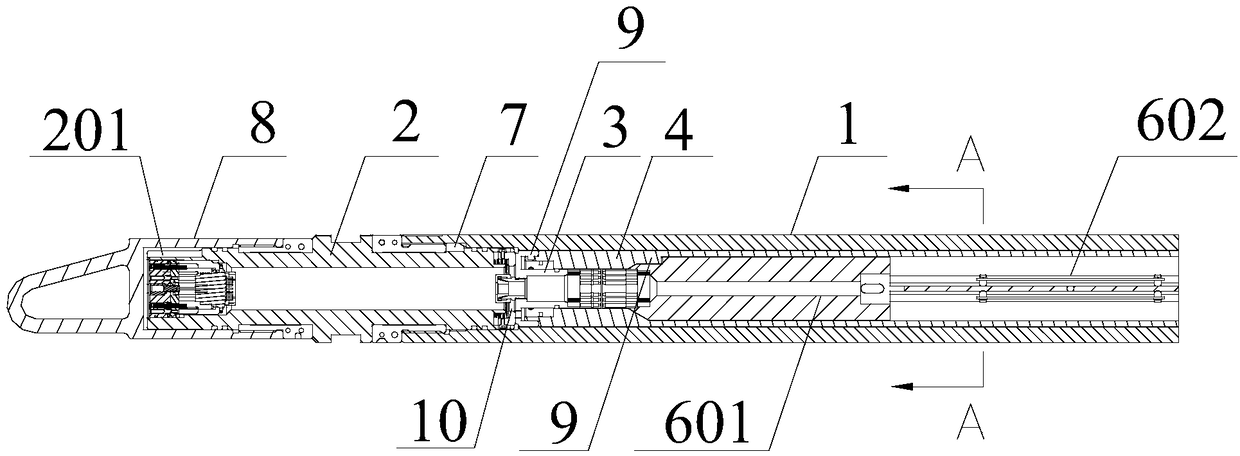

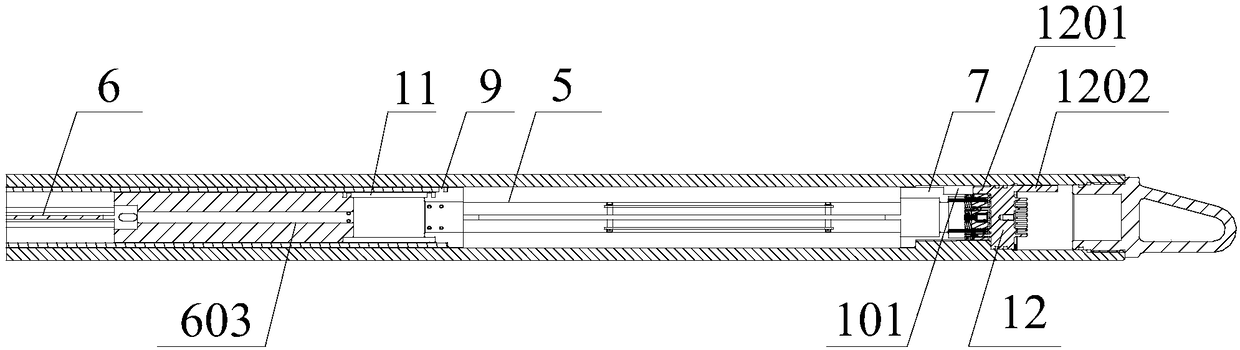

Logging instrument

PendingCN109236270ASave yourself the hassle of orientationSimple structureSurveyDrilling rodsBottlePetroleum engineering

The invention discloses a logging instrument. The logging instrument comprises a housing and a connector disposed at one end of the housing, the housing is internally provided with an electronic circuit assembly connected to the connector, and the electronic circuit assembly comprises a connecting block, a vacuum bottle and an outer framework which are connected in sequence; the vacuum bottle is internally provided with an inner framework assembly, the two ends of the inner framework assembly are connected with the connecting block and the outer framework respectively, the housing is separately connected with the connector and the electronic circuit assembly through first keys for circumferential positioning, and the vacuum bottle is separately connected with the connecting block, the inner framework assembly and the outer framework through second keys for circumferential positioning. The coaxiality of the components of the logging instrument is precise, it can be ensured that the highedges of multiple logging instruments are located on the same straight line after the are logging instruments are connected in series, and the step of adjusting the direction is omitted.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Gear shaft back-up bearing cover rotary alignment structure and alignment method

ActiveCN107649849ASimple processing technologyGuaranteed versatility and interchangeabilityMetal working apparatusEngineeringMachining process

The invention provides a gear shaft back-up bearing cover rotary alignment structure and an alignment method. The alignment structure is characterized in that a bush I and a bush II are pressed into bottom holes of a gear case and a bearing cover in an interference manner, shafts at the two ends of a gear are installed in inner holes of the bush I and the bush II, a spline housing matched with thegear is arranged in the gear, and the other end of the spline housing is matched with a cam shaft; and the bearing cover is assembled to a gear case cover, and the gear case cover is assembled on thegear case. By means of the structure and the method, the structure design of concentricity of the rotating inner holes of the two bushes is guaranteed through assembling; the machining process is greatly simplified, and the part universality and interchangeability are guaranteed.

Owner:CHINA NORTH ENGINE INST TIANJIN

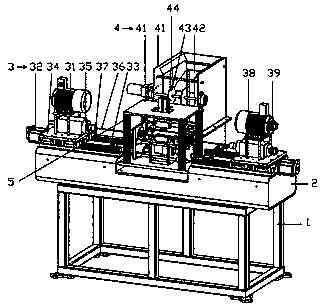

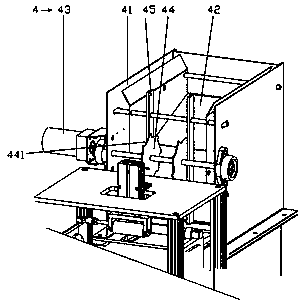

Straw perforating machine

PendingCN111483018AAccurate concentricityPrecise positioningStationary drilling machinesCane mechanical workingElectric machineryEngineering

Disclosed is a straw perforating machine. A workbench is fixedly arranged on a machine frame. A perforating mechanism is arranged on the workbench. The perforating mechanism is structurally characterized in that a liner sliding rail is fixed to the workbench, the linear sliding rail is sleeved with a sliding seat in an inserted mode, a perforating motor support is fixedly arranged on the sliding seat, a perforating motor is fixed to the perforating motor support, a spindle box is fixed to the sliding seat, the perforating motor drives a spindle of the spindle box through a synchronous belt wheel and a synchronous belt to rotate, and a perforating drill bit is installed on the spindle of the spindle box. A translation motor is fixed to the workbench. A lead screw is fixedly arranged on a rotating shaft of the translation motor, the lead screw and a nut are in screw connection together, and the nut is fixed to the lower portion of the sliding seat. Automatic perforating machining can beperformed on a wood material and a bamboo material, so that the materials are machined into wood and bamboo straws. The straw perforating machine is simple in structure and convenient to maintain, andfeeding and positioning are precise and rapid.

Owner:安吉庚康科技有限公司 +1

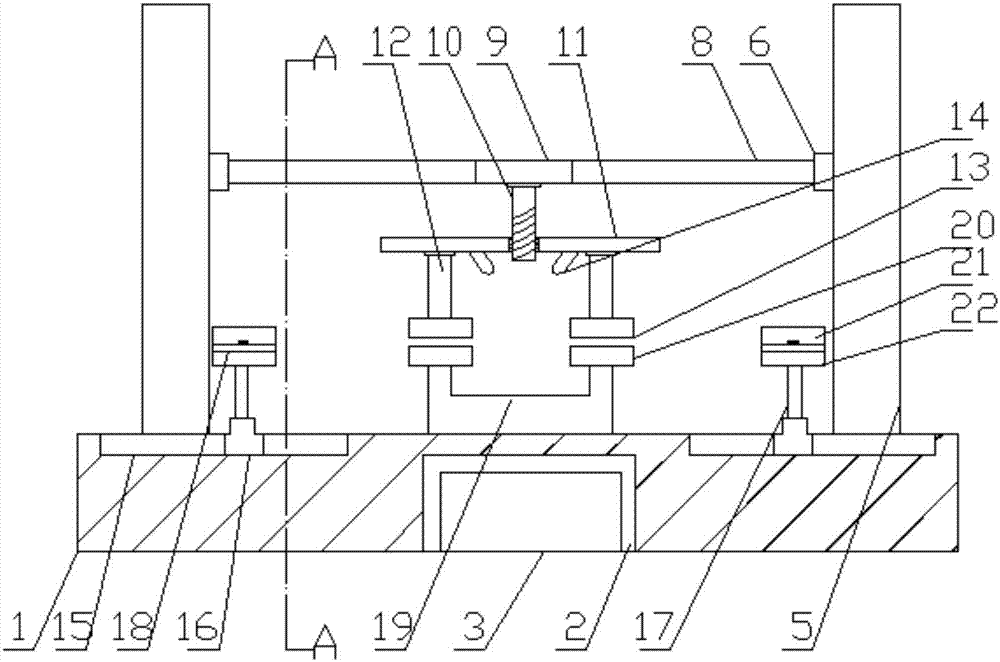

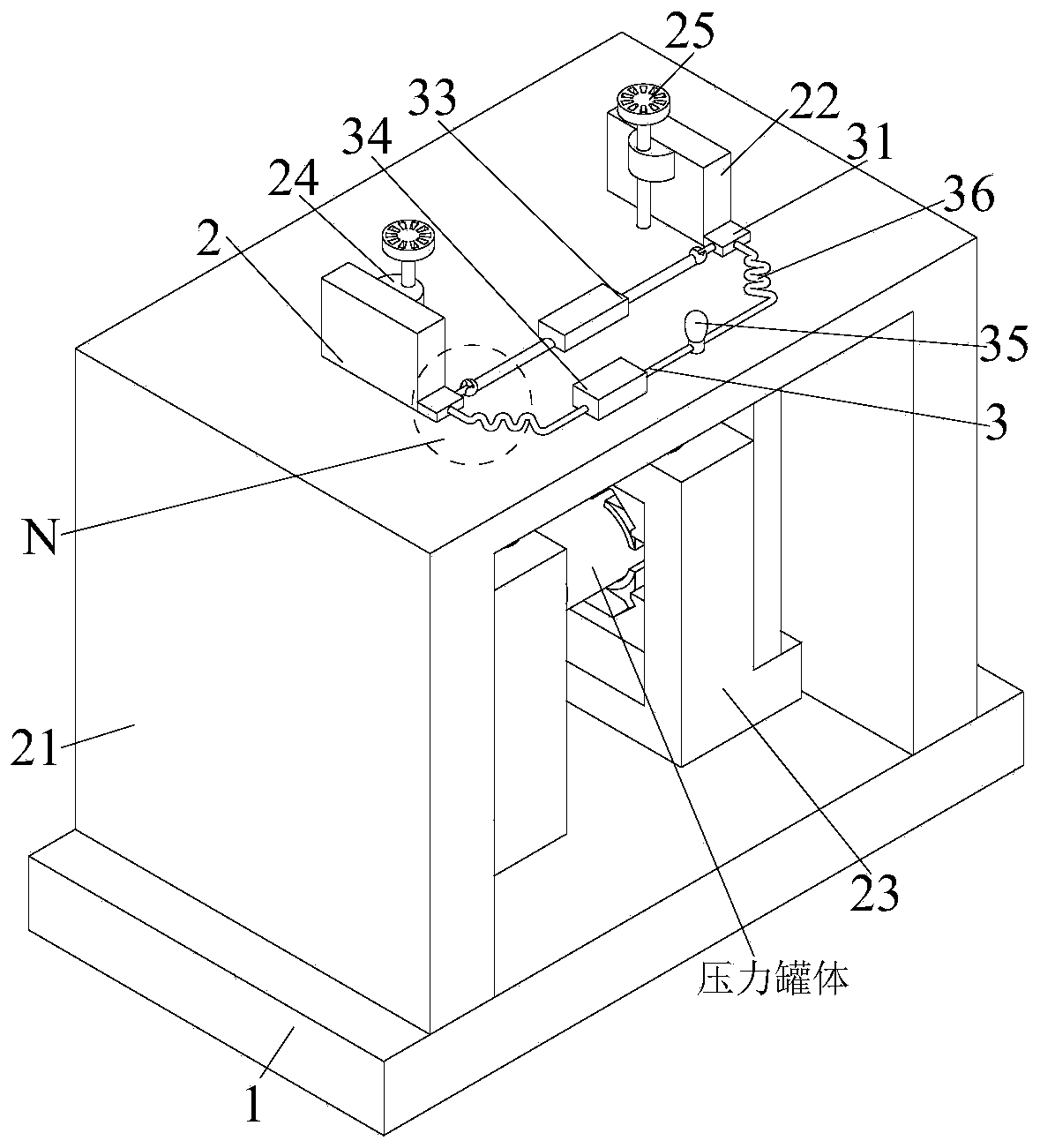

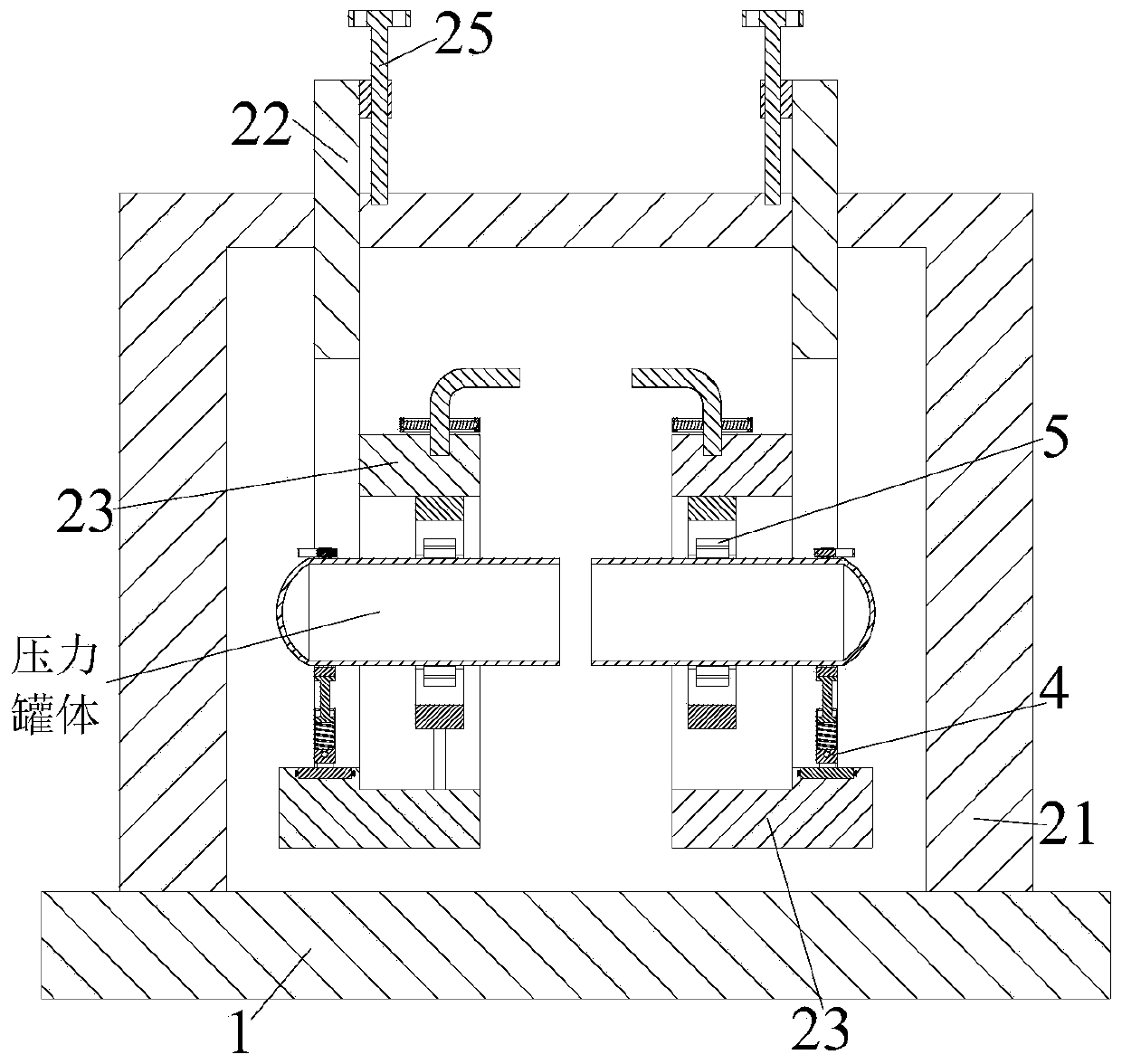

Home appliance refrigeration pipe connector positioning and welding clamp

InactiveCN107486678AImprove craftsmanshipAccurate concentricityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention discloses a home appliance refrigeration pipe connector positioning and welding clamp which comprises a base. A chamber is arranged in the base. A water tank is arranged in the chamber. Two vertical plates are arranged at the upper end of the base in parallel. First sliding grooves are formed in the opposite side walls of the two vertical plates. First convex sliding blocks are arranged in the first sliding grooves, and the top faces of the two first sliding grooves are both connected with hydraulic cylinders. Piston rods of the hydraulic cylinders are arranged downwards vertically. The lower ends of the piston rods of the hydraulic cylinders are connected with the upper ends of the first convex sliding blocks. A first transverse plate is arranged between the two vertical plates. The two ends of the first transverse plate are connected with the side walls of the two first convex sliding blocks correspondingly. The side wall of the first transverse plate is connected with a transverse rod which is close to the middle of the first transverse plate. The lower end of the transverse rod is fixedly connected with a threaded rod, and the threaded rod is arranged at the end, away from the first transverse plate, of the transverse rod. According to the home appliance refrigeration pipe connector positioning and welding clamp, the concentricity of two welded pipes can be controlled more accurately, and a welding point can be cooled rapidly.

Owner:谢兴艺

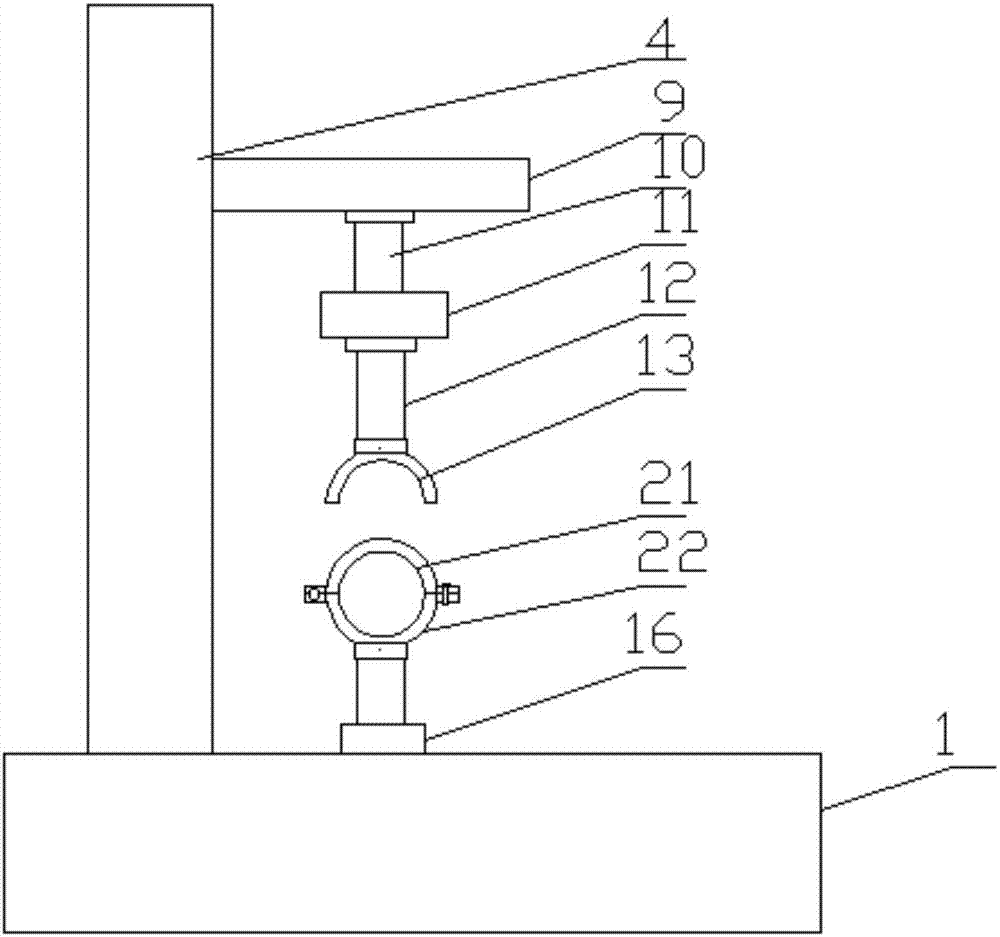

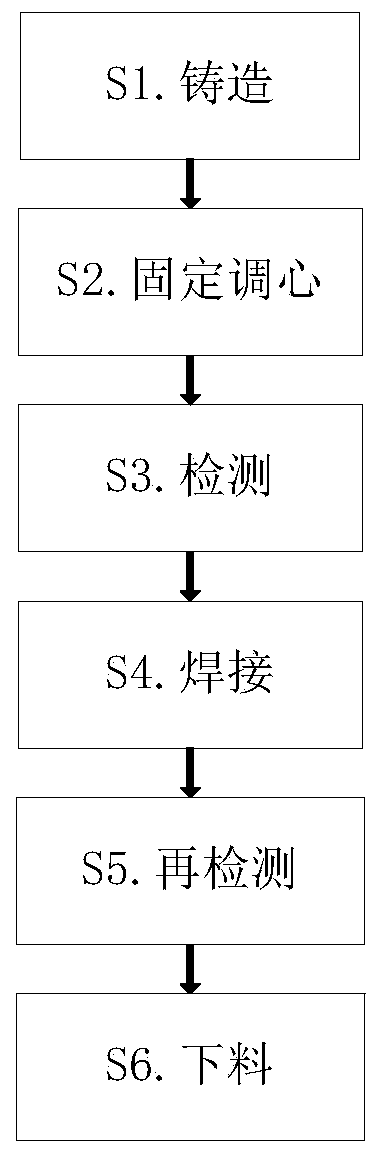

Chemical industry pressure vessel tank body fabrication method

ActiveCN111347213AConvenient spin weldingImprove manufacturing precisionWelding/cutting auxillary devicesFoundry mouldsChemical industryIndustrial engineering

The invention relates to a chemical industry pressure vessel tank body fabrication method. Equipment used in the chemical industry pressure vessel tank body fabrication method comprises an installation plate, position adjusting devices, a detection device, two locking devices and two center adjusting devices, wherein the upper end of the installation plate is provided with the position adjusting devices, the upper ends of the position adjusting devices are provided with monitoring devices, the lower ends of the position adjusting devices are provided with the locking devices in a bilateral symmetry manner, and the inner sides of the locking devices are provided with the center adjusting devices. By means of the chemical industry pressure vessel tank body fabrication method provided by theinvention, the problems that when a chemical industry pressure vessel is fabricated manually, the chemical industry pressure vessel is firstly fixed and spliced and then is welded, then concentricitydetection is performed after welding is finished, and the chemical industry pressure vessel single-time fabrication process is tedious; when existing chemical industry pressure vessel fabrication equipment performs fabrication, the chemical industry pressure vessel is firstly fixed and welded and then is detected after the welding is finished, the process of detecting after the welding is prone tocausing the concentricity of the fabricated chemical industry pressure vessel to be inaccurate, and repairing needs to be performed on the fabricated chemical industry pressure vessel again; and thelike can be solved.

Owner:江苏格安德环保工程科技有限公司

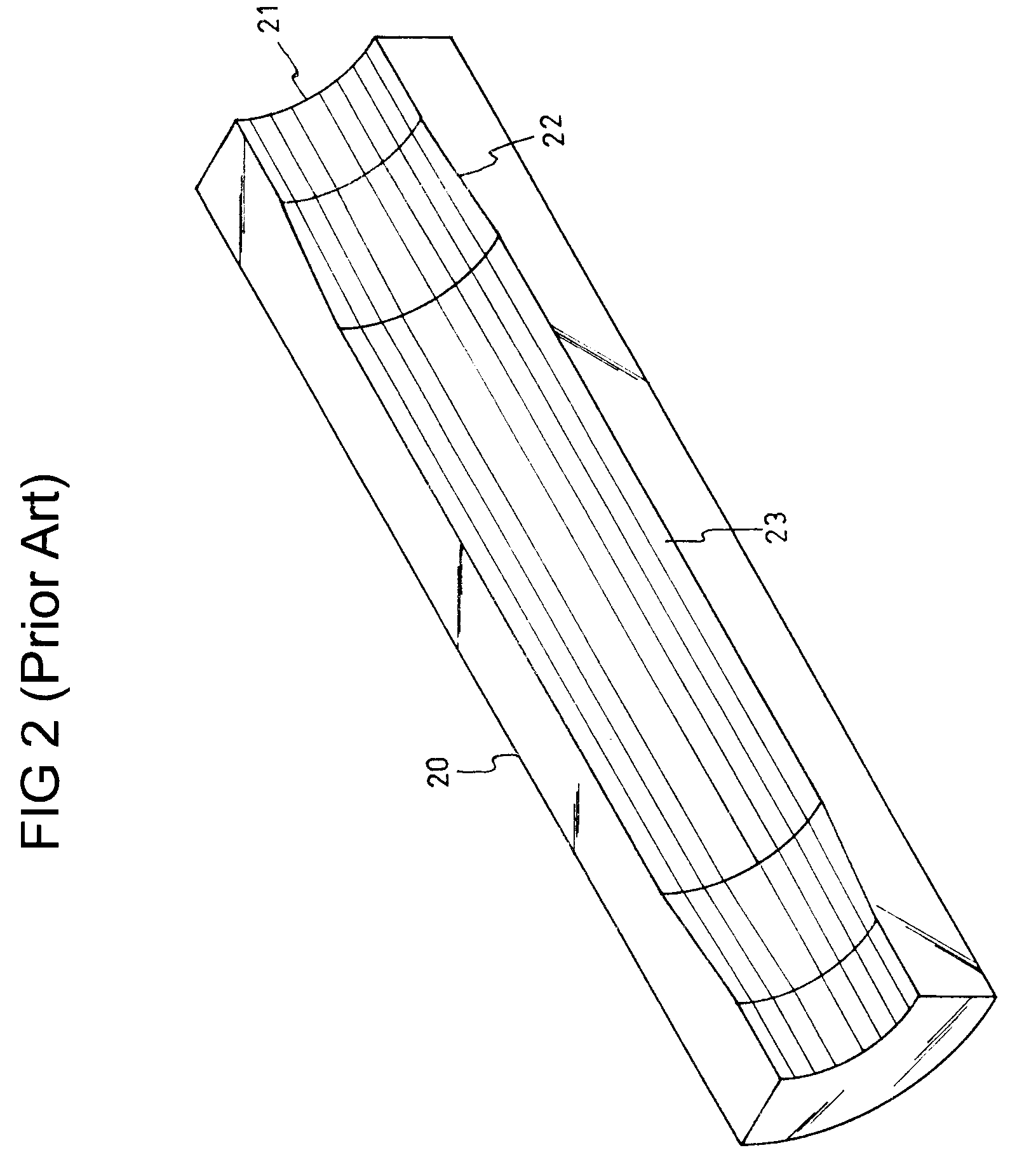

Concentric machining device for a roller

InactiveUS7549312B2Ensure concentricityPromote productionShaping toolsCeramic shaping apparatusHydraulic cylinderEngineering

A concentric machining device for a roller includes a movable upper base, a stationary lower base, two movable mold seats, two slide rods and four first hydraulic cylinders. Each of the mold seats has a forming mold inside, the forming mold has a fitting hole with an enlarged conical opening at the front side thereof, a locating shaft is received in the forming mold of the first mold seat and penetrates the fitting hole thereof and the first cylinder member, a clamping shaft is received in the forming mold of the second mold seat and penetrates the fitting hole thereof and the second hydraulic cylinder to connect with the fourth hydraulic cylinder. The roller is held by the bases and the shafts via two of the hydraulic cylinders and both ends of the roller are machined by the forming molds in the mold seats to provide squeezed and shrunk shapes once the mold seats are actuated by the other two hydraulic cylinders.

Owner:HUANG TE LI

Punching mould for inner cambered-surface towing hook mounting hole of closed bumper

ActiveCN105964772ASimple structureImprove product production efficiencyPerforating toolsStripping-off devicesEngineeringTowing

The invention discloses a punching mould for an inner cambered-surface towing hook mounting hole of a closed bumper. The punching mould comprises an upper molding board, a lower molding board, a concave mould and a convex mould, wherein the upper molding board is fixedly connected to a concave mould fixing plate; the concave mould is fixedly connected to a concave mould fixing plate; the lower molding board is fixedly connected to a convex mould base plate; the convex mould base plate is fixedly connected to a convex mould fixing plate; the convex mould fixing plate is fixedly connected to the convex mould; a discharging plate is arranged on the low molding board; the discharging plate is in floating connection to the lower molding board; a convex mould hole is formed in the discharging plate; the convex mould passes through the convex mould hole and is in sliding fit to the convex mould hole; a processed closed bumper product is arranged on the discharging plate; and the upper part of the convex mould is positioned in an outer cambered-surface towing hook mounting hole of the closed bumper product. According to the punching mould, by adopting an inversion structure for the convex mould and the concave mould, the convex mould can be used a positioning part accurate positioning-punching hole of a processed product, and is pressed to move downwards along with the discharging plate in a mould closing process to realize a convex mould punching process. While precise coaxiality of the inner cambered-surface towing hook hole and the outer cambered-surface towing hook hole and high mass-production stability are guaranteed, the production efficiency is improved.

Owner:广州凌云汽车零部件有限公司

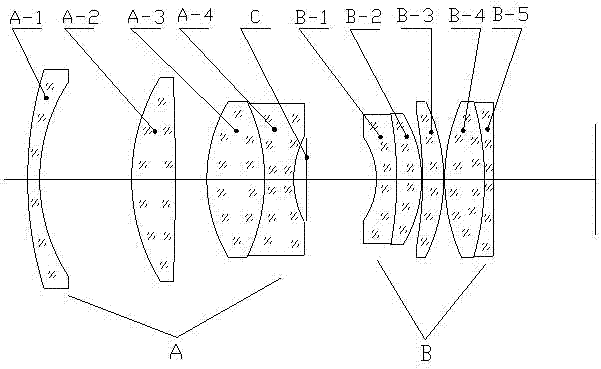

High-resolution camera shooting lens for full-group mobile industry

The invention relates to a high-resolution camera shooting lens for a full-group mobile industry. According to the lens, a front group A, an iris C and a rear group B are sequentially arranged along an incident direction of light rays from left to right in an optical system, wherein the front group A is sequentially provided with a negative meniscus lens A-1, a biconvex lens A-2, and a first gluing group formed by tightly connecting a biconvex lens A-3 and a biconcave lens A-4; and the rear group B is sequentially provided with a second gluing group formed by tightly connecting a positive meniscus lens B-1 and a negative meniscus lens B-2, a negative meniscus lens B-3, and a third gluing group formed by tightly connecting a biconvex lens B-4 and a plano-concave lens B-5. The high-resolution camera shooting lens has the characteristics of high resolution, large target surface, low distortion, small close-up distance and the like and can be matched with a high-definition charge coupled device (CCD) or a complementary metal oxide semiconductor (CMOS) camera, the high-definition video shooting is realized, the clear imaging with the close-up distance of 0.3m can be realized, and the distortion rate is less than 1 percent.

Owner:FUJIAN FORECAM OPTICS CO LTD

Tubular product drawing die and drawing process

InactiveCN111922105ASmall outer diameterIncrease wall thicknessDrawing mandrelsDrawing diesMechanical engineeringIndustrial engineering

The invention discloses a tubular product drawing die and a drawing process. The drawing process adopts the tubular product drawing die. The tubular product drawing die comprises a die main body and adie core. A drawing channel which penetrates the die main body is arranged on the die main body, the drawing channel is provided with a feed inlet and a discharge hole, and the drawing channel is successively provided with a correction tape, a thickening tape and a sizing tape capable of reducing the outer diameter of a tubular product progressively from the feed inlet to the discharge hole; andthe die core is inserted into the drawing channel, a gap where the side wall of the tubular product penetrates is formed between the outer side wall of the die core and the side wall of the drawing channel, and the radial dimension of the part, corresponding to the sizing tape, of the die core is greater than the radial dimensions of the parts, corresponding to the correction tape and the thickening tape, of the die core. The tubular product is in an empty-drawing state when passing through the correction tape and the thickening tape, so that the outer diameter of the tubular product is reduced and the wall thickness of the tubular product is increased. As the tubular product is relatively small in wall thickness when entering the correction tape, the tubular product can be corrected to rectify the coaxiality of the tubular product, and relatively large fluctuation of dimension of the tubular product in the process that the tubular product passes through the sizing tape can be avoided,so that the CPK value is increased.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

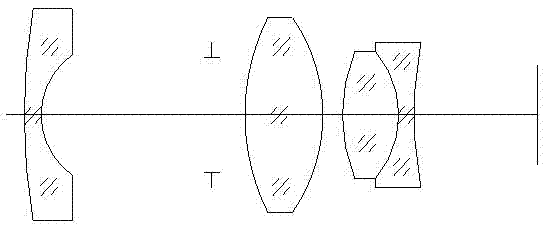

Large target surface high-precision optics heat-free temperature measurement lens and adjustment method

InactiveCN106405782AThe imaging is clear and stableEasy to useRadiation pyrometryMountingsLow distortionOptical axis

The invention relates to a large target surface high-precision optics heat-free temperature measurement lens which comprises a crescent lens A, a lenticular lens B, a crescent lens C and a crescent lens D, wherein the crescent lens A, the lenticular lens B, the crescent lens C and the crescent lens D are arranged in order along the left-right incident direction of light. The invention further relates to a large target surface high-precision optics heat-free temperature measurement lens adjustment method. According to the invention, the temperature measurement lens has the advantages of large relative aperture, large field angle, low distortion, large target surface, self-adaptive optics heat-free compensation, light structure and the like; different refractive index changes of an optical material at different temperatures are used to compensate the influence of temperature change on a focal plane; a heat-free design structure is simpler; the structure of the whole product is smaller; the weight is lighter; stable optical axis imaging is more clear; the reliability is higher; the requirement of the product imaging performance of a user is met; and the structure is more convenient for a customer to use.

Owner:FUJIAN FUGUANG TIANTONG OPTICS

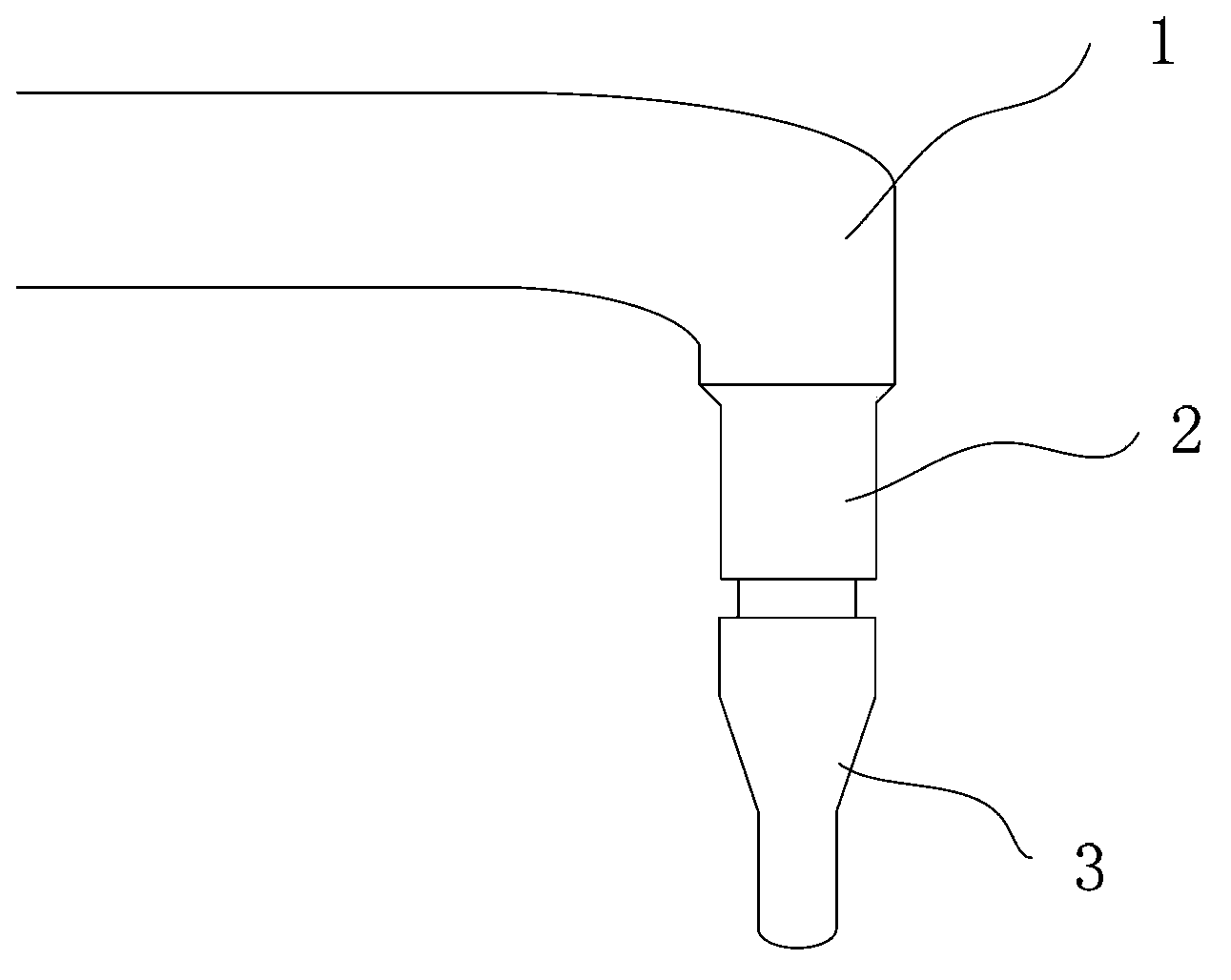

Automatic station welding gun electrode stem for robot

The invention relates to an automatic station welding gun electrode stem for a robot. The automatic station welding gun electrode stem for the robot comprises a stem body of the electrode stem and a base which is arranged at the front end of the stem body, wherein an electrode cap sleeves the base. The length of the stem body is larger than that of an existing stem body, the length of the base is larger than that of an existing base, and the electrode cap is shortened by the length the same as the length by which the stem body and the base are lengthened, so that the length of the whole electrode stem is in accordance with the existing length. Compared with the prior art, the automatic station welding gun electrode stem for the robot has the advantage that the machining quality and the machining efficiency can be improved.

Owner:SHANGHAI ANDELAI AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com