Patents

Literature

32results about How to "Same sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

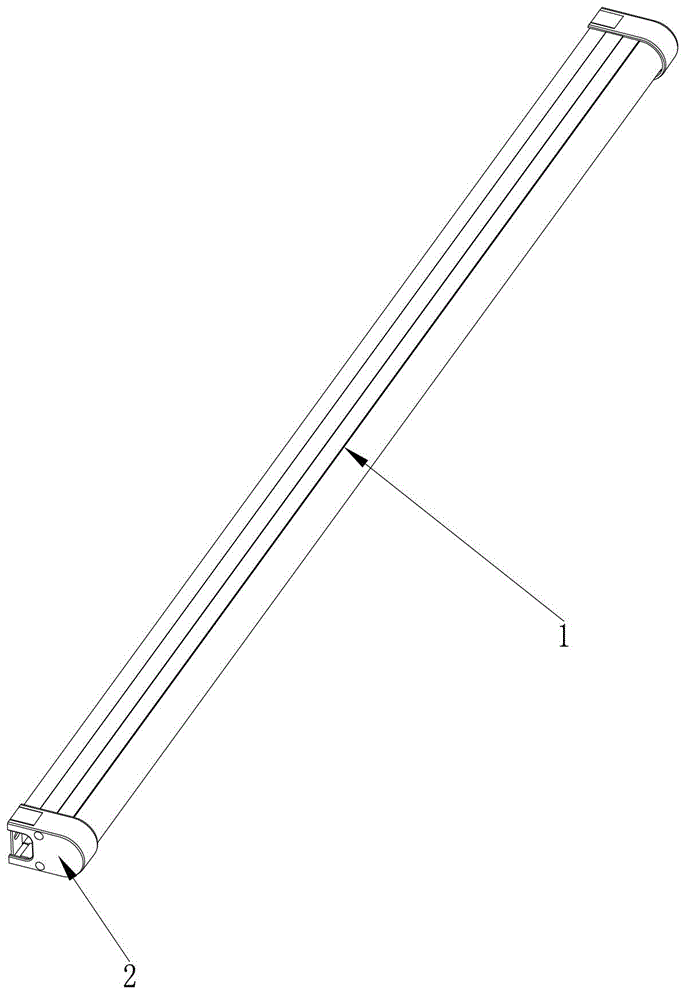

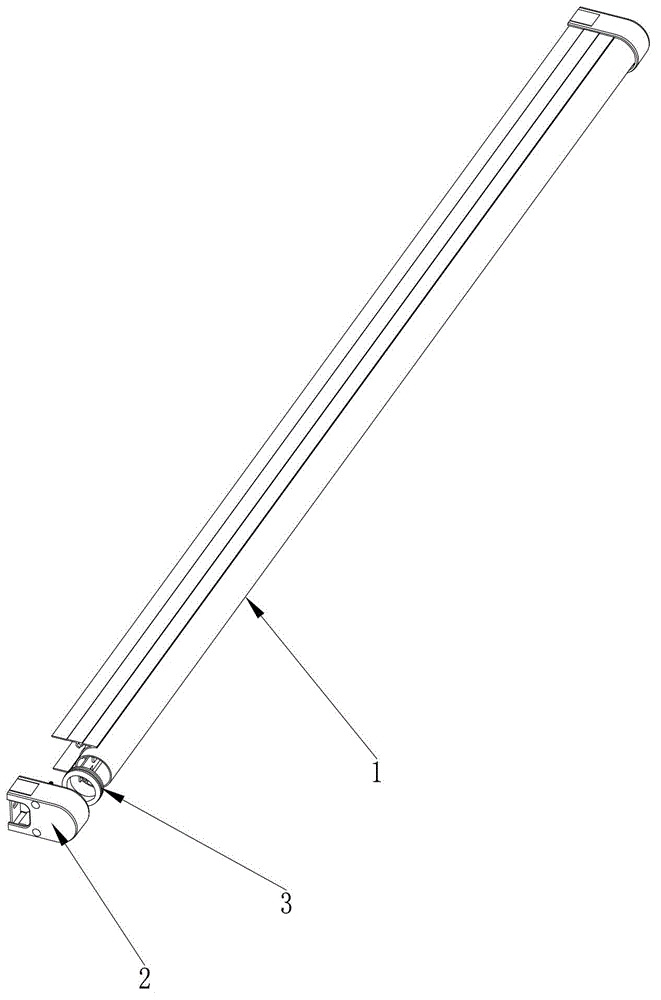

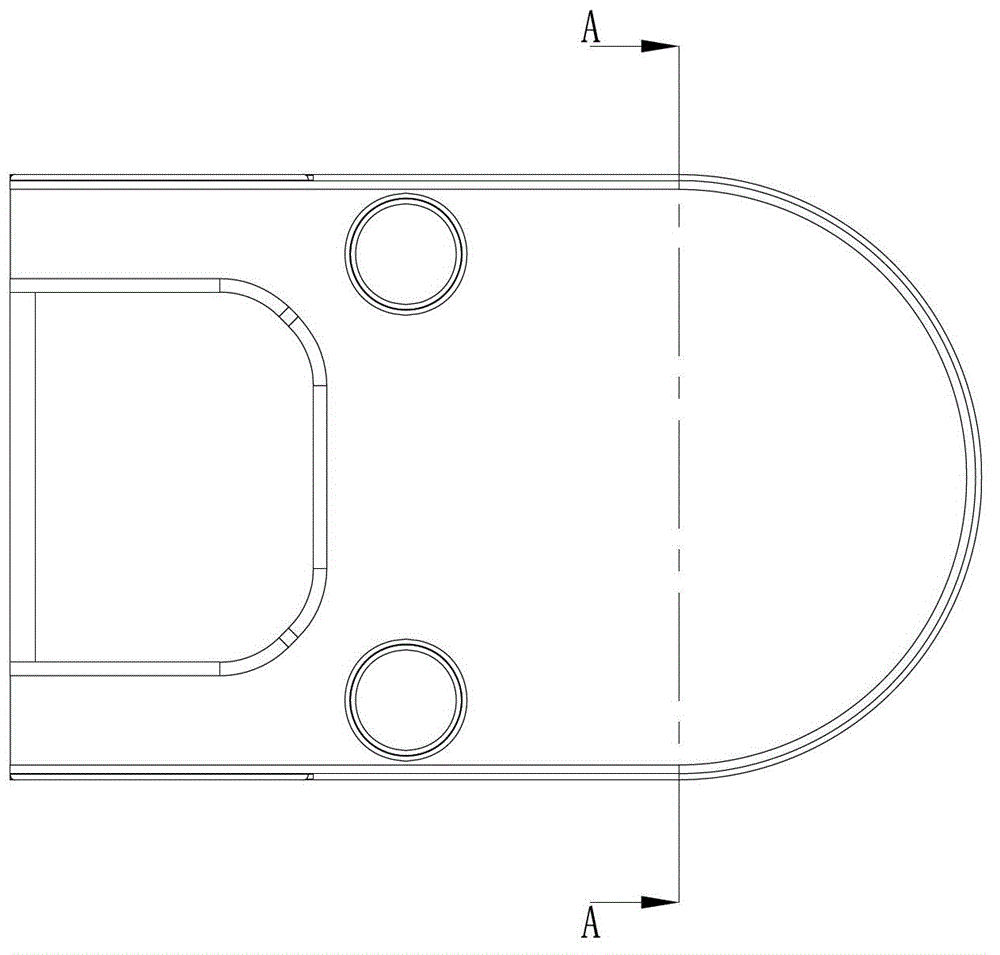

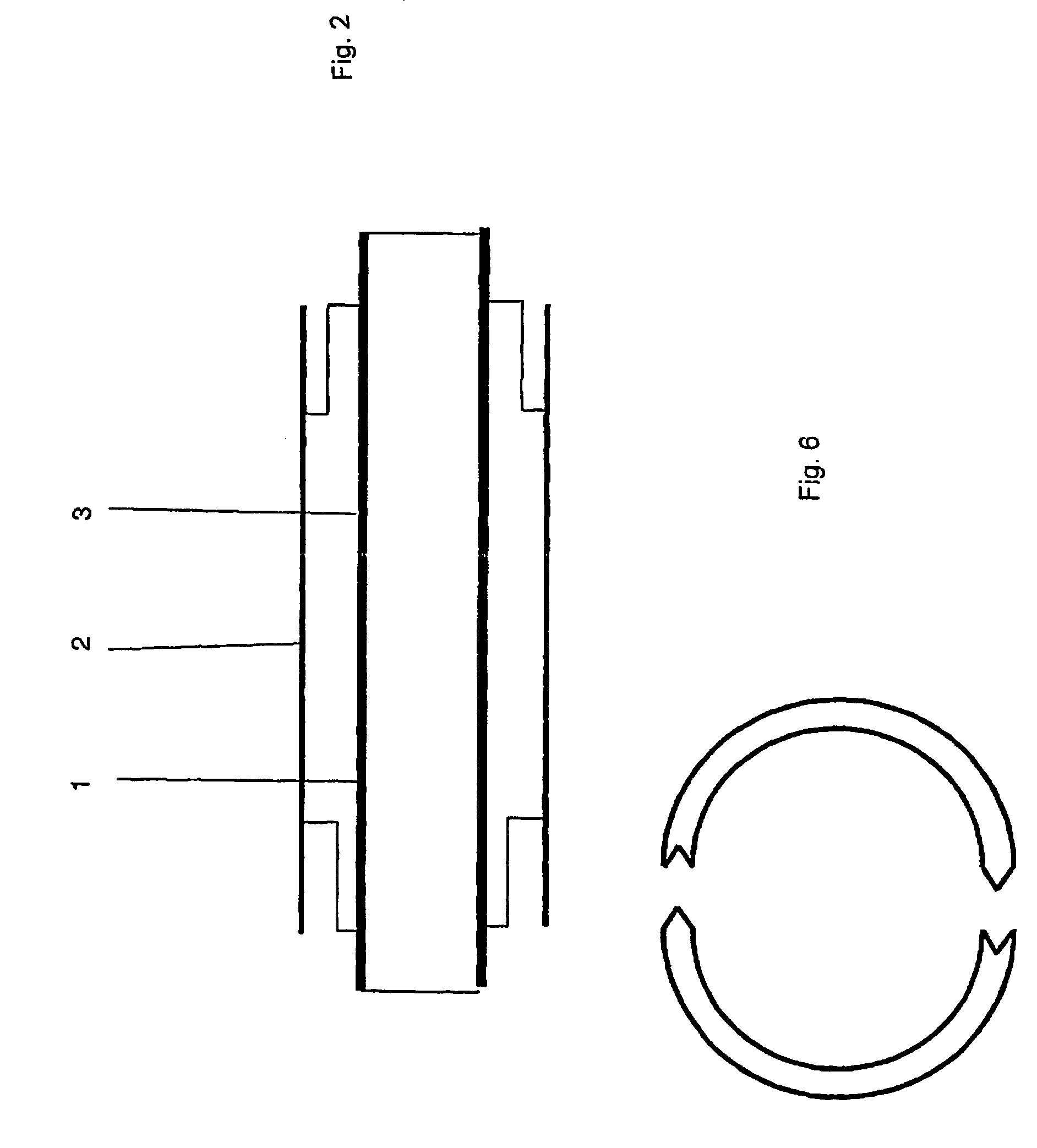

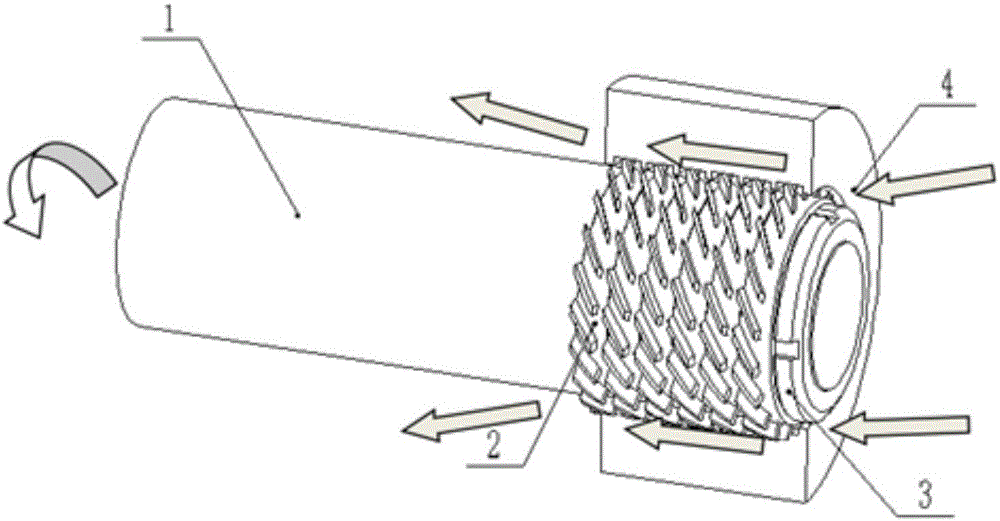

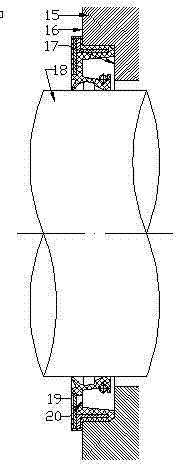

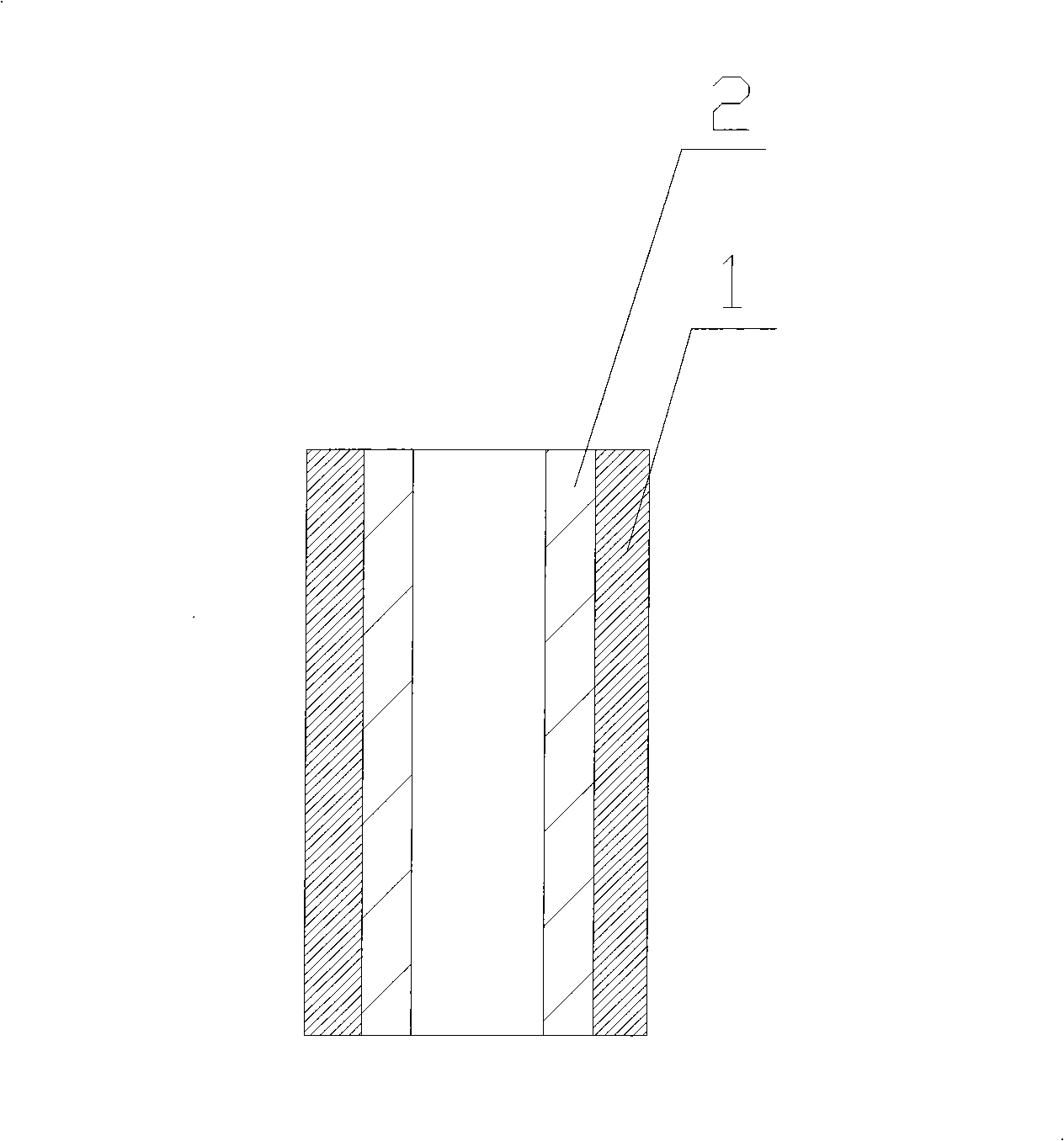

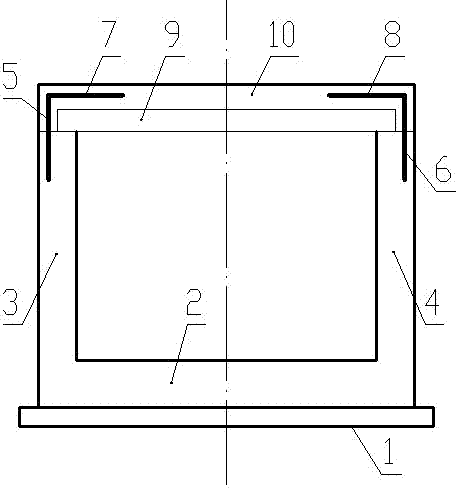

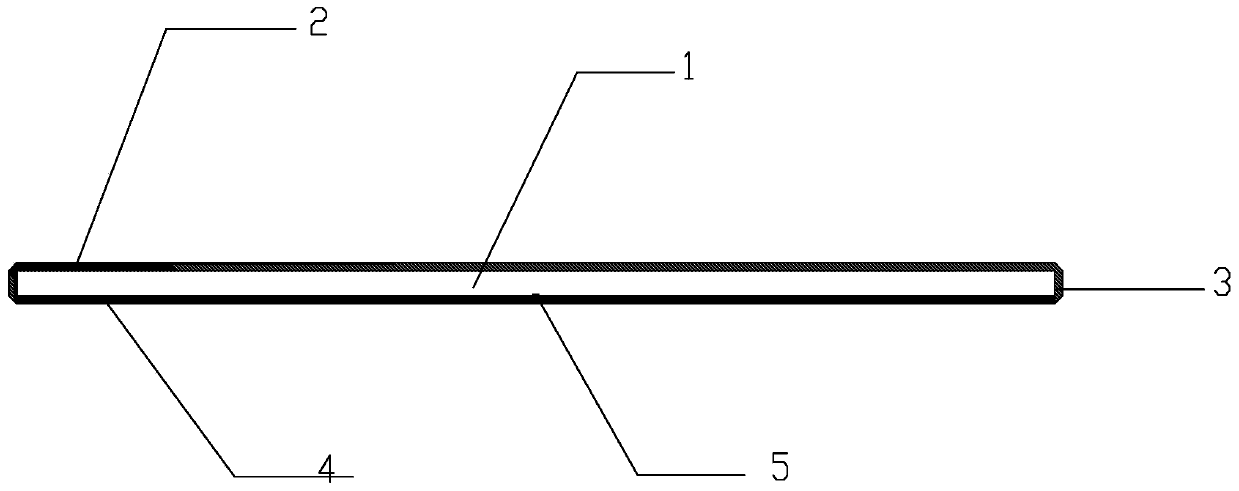

Waterproof and dustproof sealing structure for illuminating lamp

InactiveCN102913885AWon't slipImprove sealingPoint-like light sourceElongate light sourcesEngineeringSilica gel

The invention discloses a waterproof and dustproof sealing structure for an illuminating lamp. The waterproof and dustproof sealing structure comprises a lamp tube (1), wherein end covers (2) are mounted at two ends of the lamp tube (1); seal rings (3) are arranged between the end covers (2) and the lamp tube (1); U-shaped grooves are formed on the seal rings (3) and sleeved at the end parts of the lamp tube (1) and wrap the inner wall and the outer wall of the lamp tube (1); anti-slip and sealing ring-shaped bulges (31) are formed on the inner surface and the outer surface of the sides of the seal rings (3) positioned on the outer wall of the lamp tube (1); grooves are formed in the end covers (2); the grooves on the end covers (2) wrap the seal rings (3); the ring-shaped bulges (31) on the seal rings (3) are clung to the inner wall of the end covers (2); and the seal rings (3) are made of silica gel.

Owner:广东恒辰光电科技有限公司

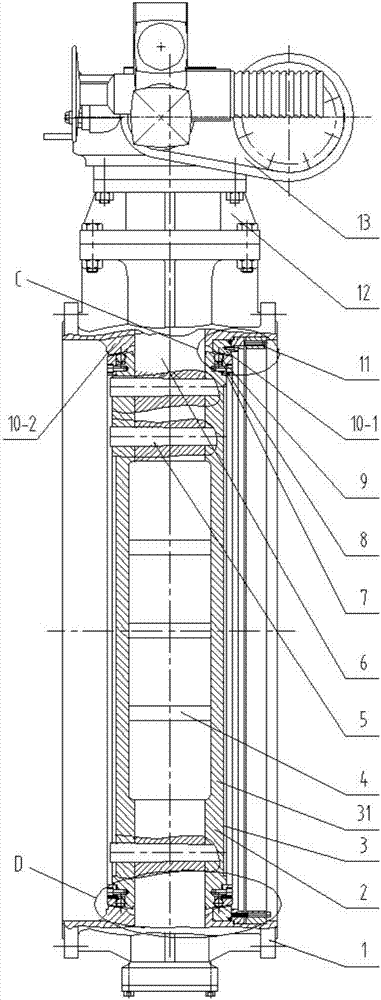

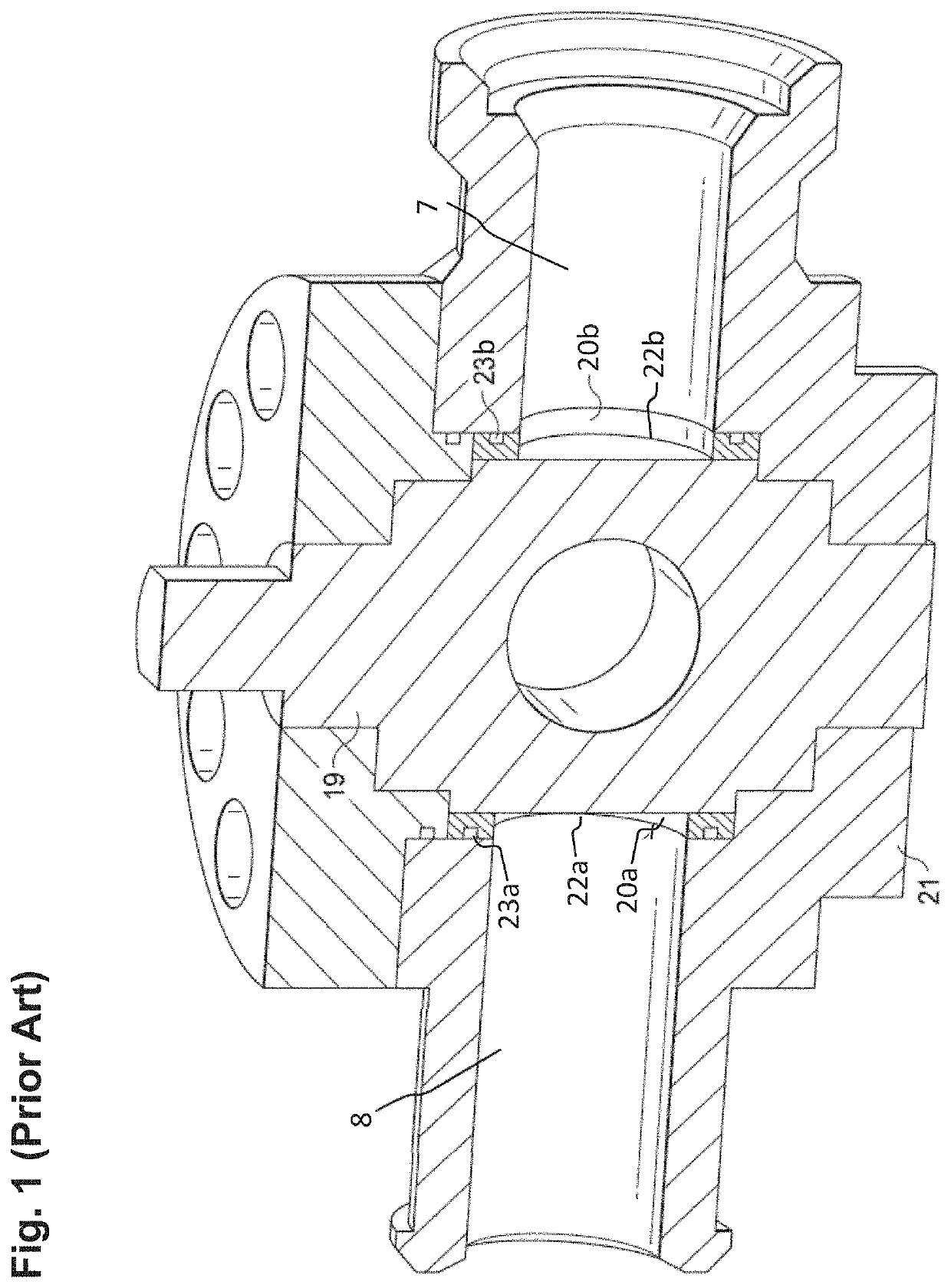

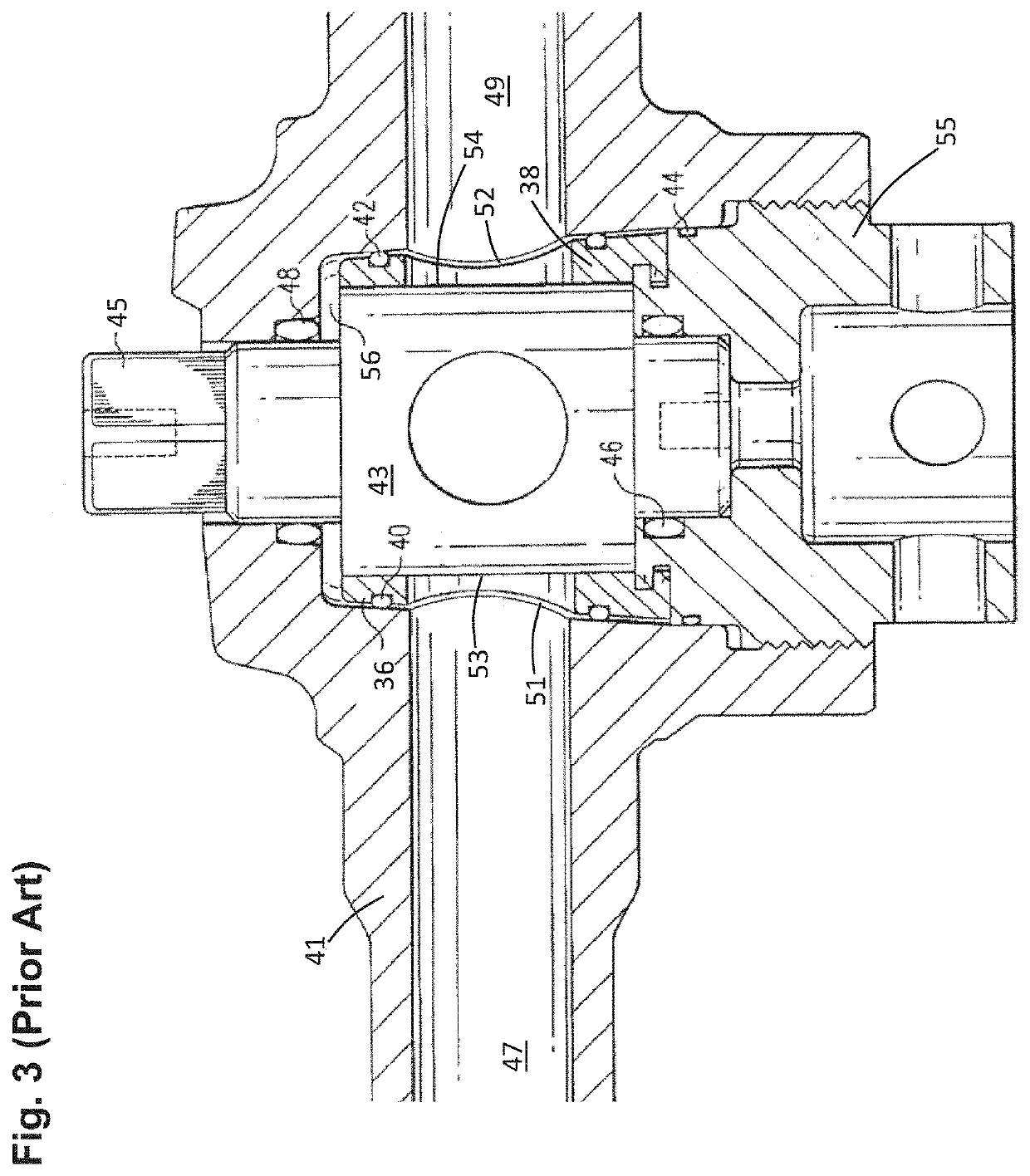

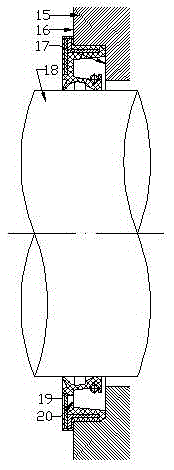

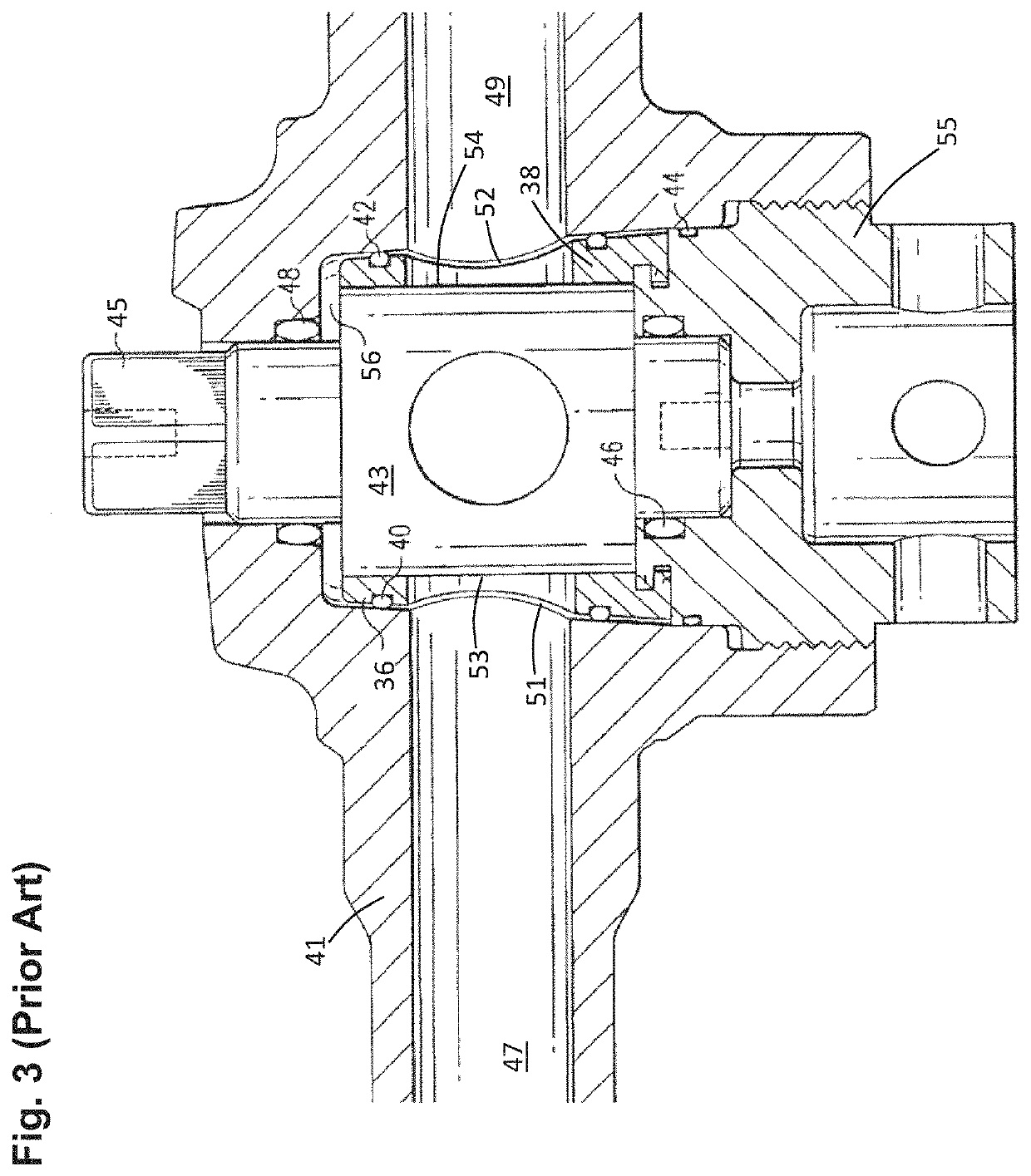

Electric power transport system comprising a cold dielectric superconducting cable

InactiveUS7358435B2Prevent penetrationAvoid damageSuperconductors/hyperconductorsCable fittings for cryogenic cablesElectric power transmissionTransport system

Electric power transport system having a cold dielectric superconducting cable, a cryostat and a cryogenic fluid. The cryostat has modules including an inner tube, an outer tube, a couple of gaskets, and a duct connected to the coupling surface between the gaskets of at least one flange with the environment external to the cryostat.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

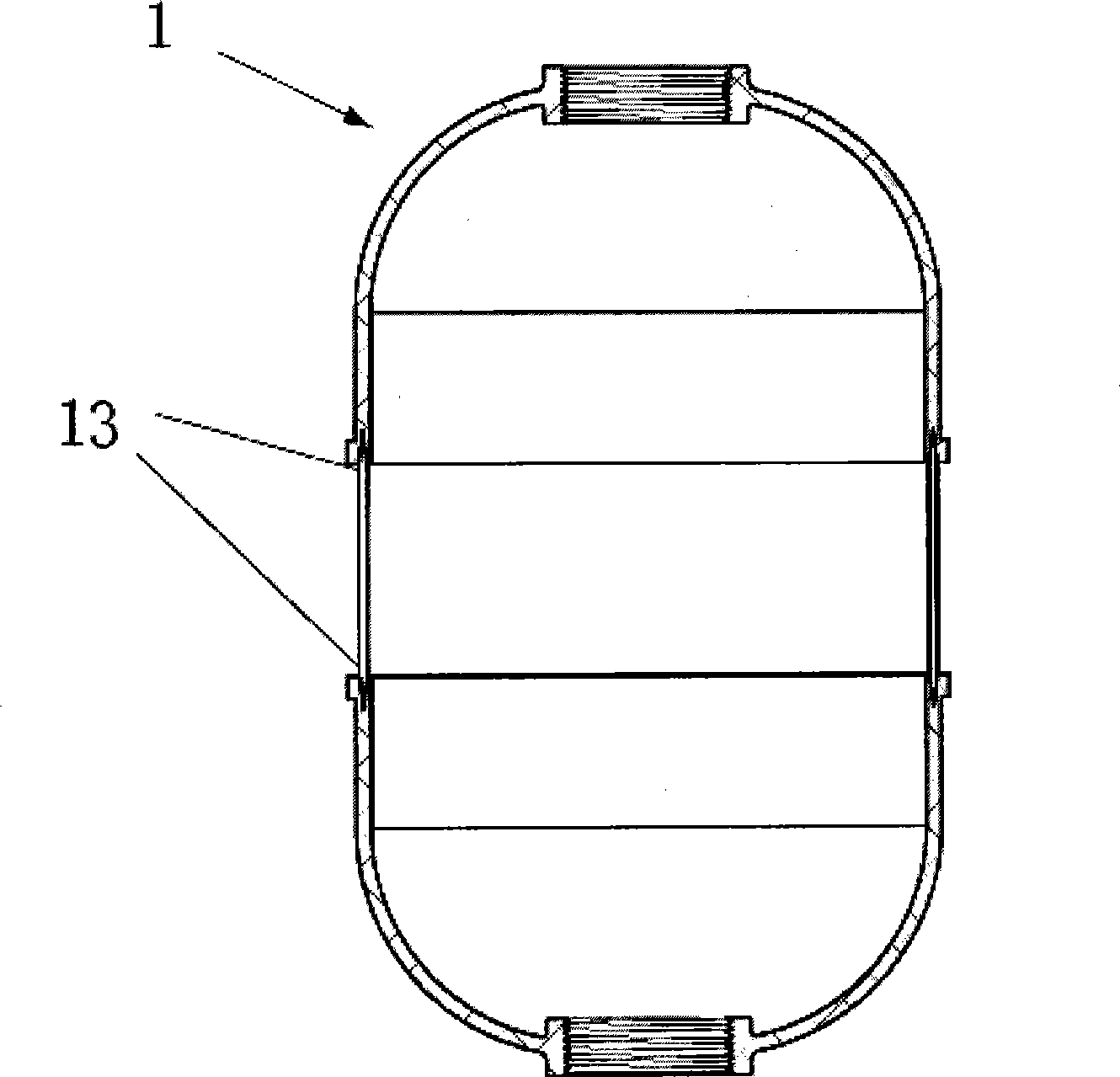

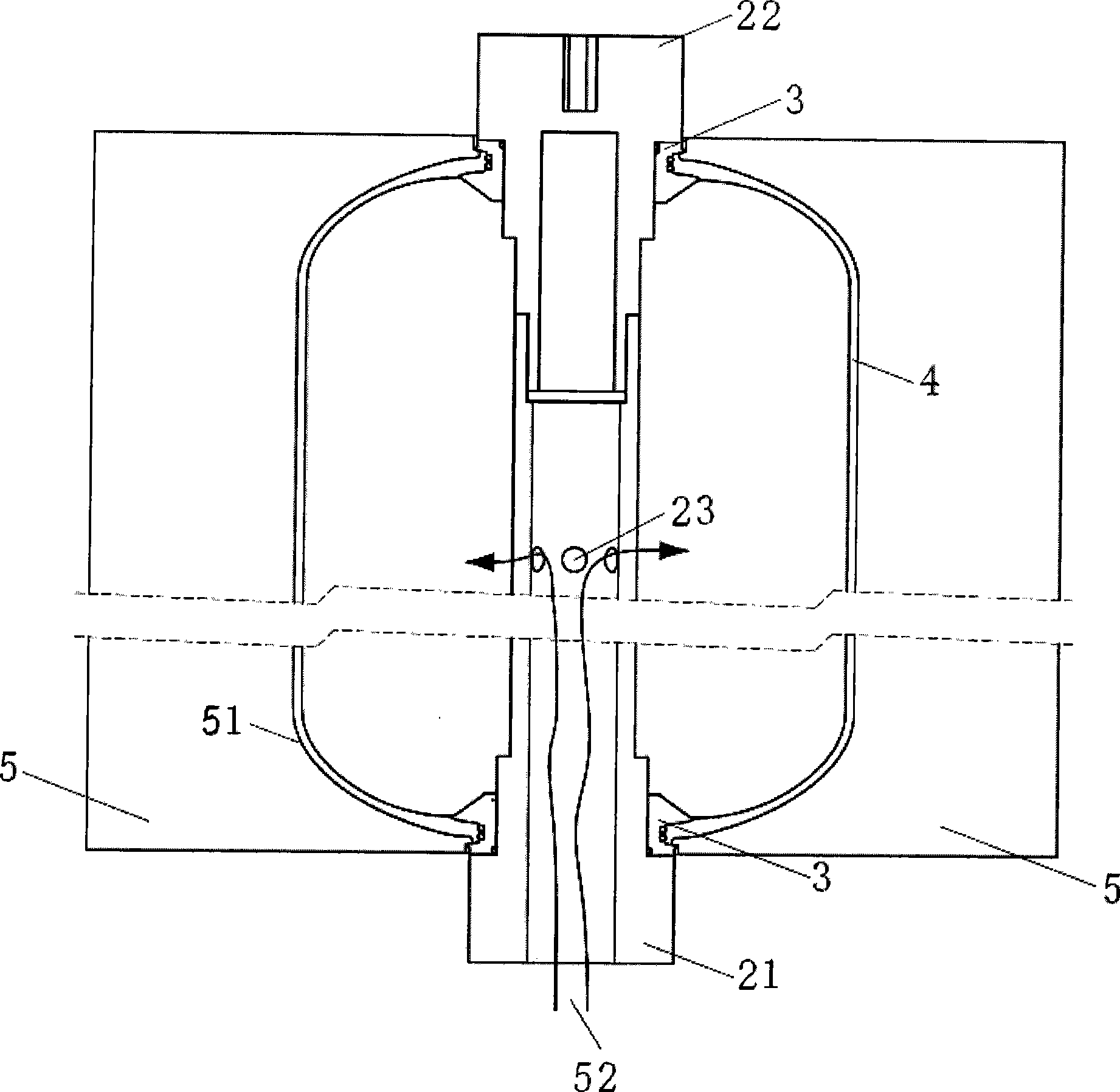

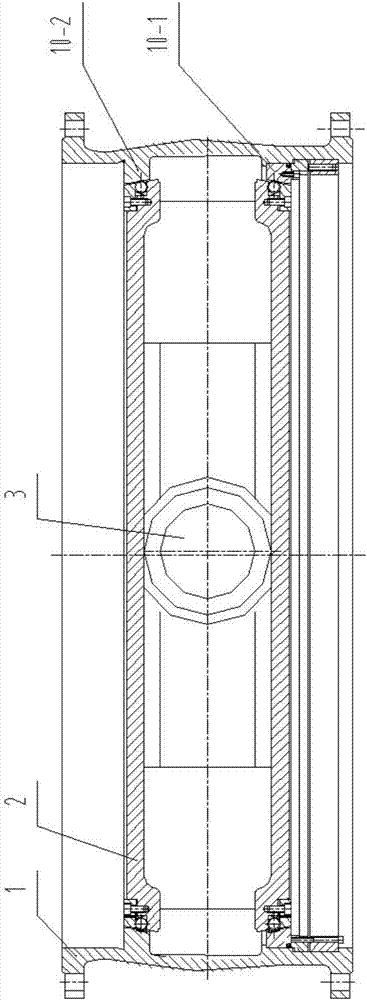

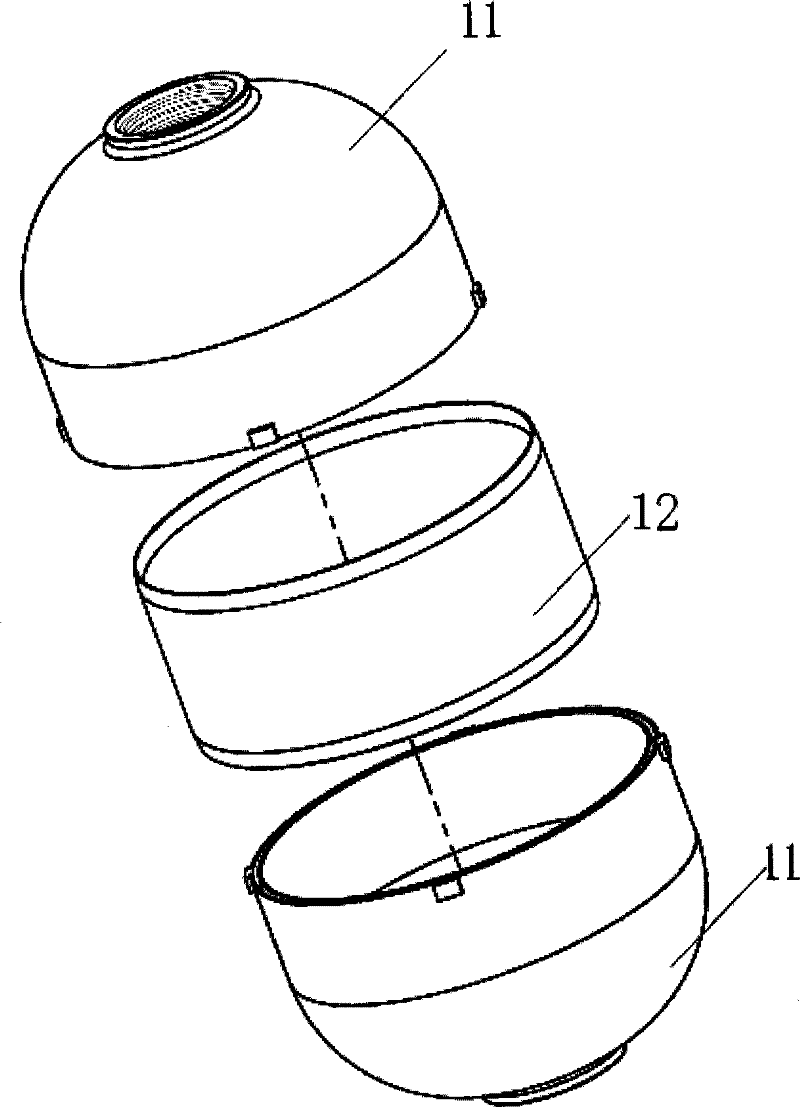

Method for producing fiber reinforced plastic pressure container

The invention provides a method for producing a fiber reinforced plastic pressure container, which comprises the following steps that: S1, a blowing needle is divided into a plurality of segments, and source nipples are respectively fixed on the uppermost blowing needle and the lowermost blowing needle; S2, the segmented blowing needles are connected into a whole and fixed under a liner molding material extruding outlet, and a blow molding machine extrudes a liner material to a position where the liner material completely covers the blowing needle; S3, a mold is matched, high-pressure air is input from the lower part of the blowing needle for pressure maintaining after the mold is matched so as to make a liner completed formed; and S4, the mold is opened and the blowing needle is screwed out. The pressure container produced by the method has the integral liner, has the same pressure-bearing and sealing properties as a pressure container with a single-head source nipple, and high process productivity and product percent of pass, needs no subsequent processing, and can meet the requirement of mass production.

Owner:CANATURE HEALTH TECH GRP CO LTD

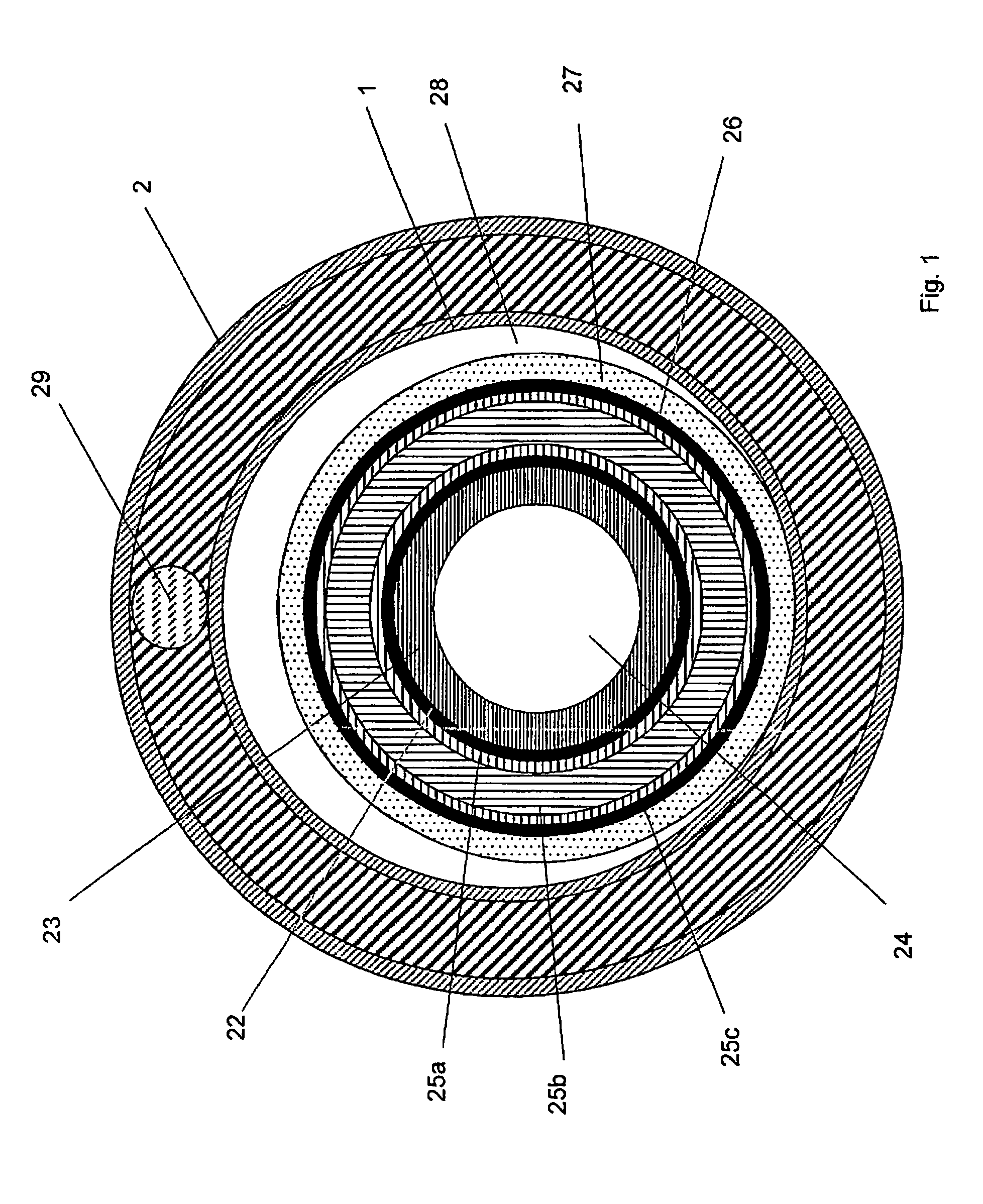

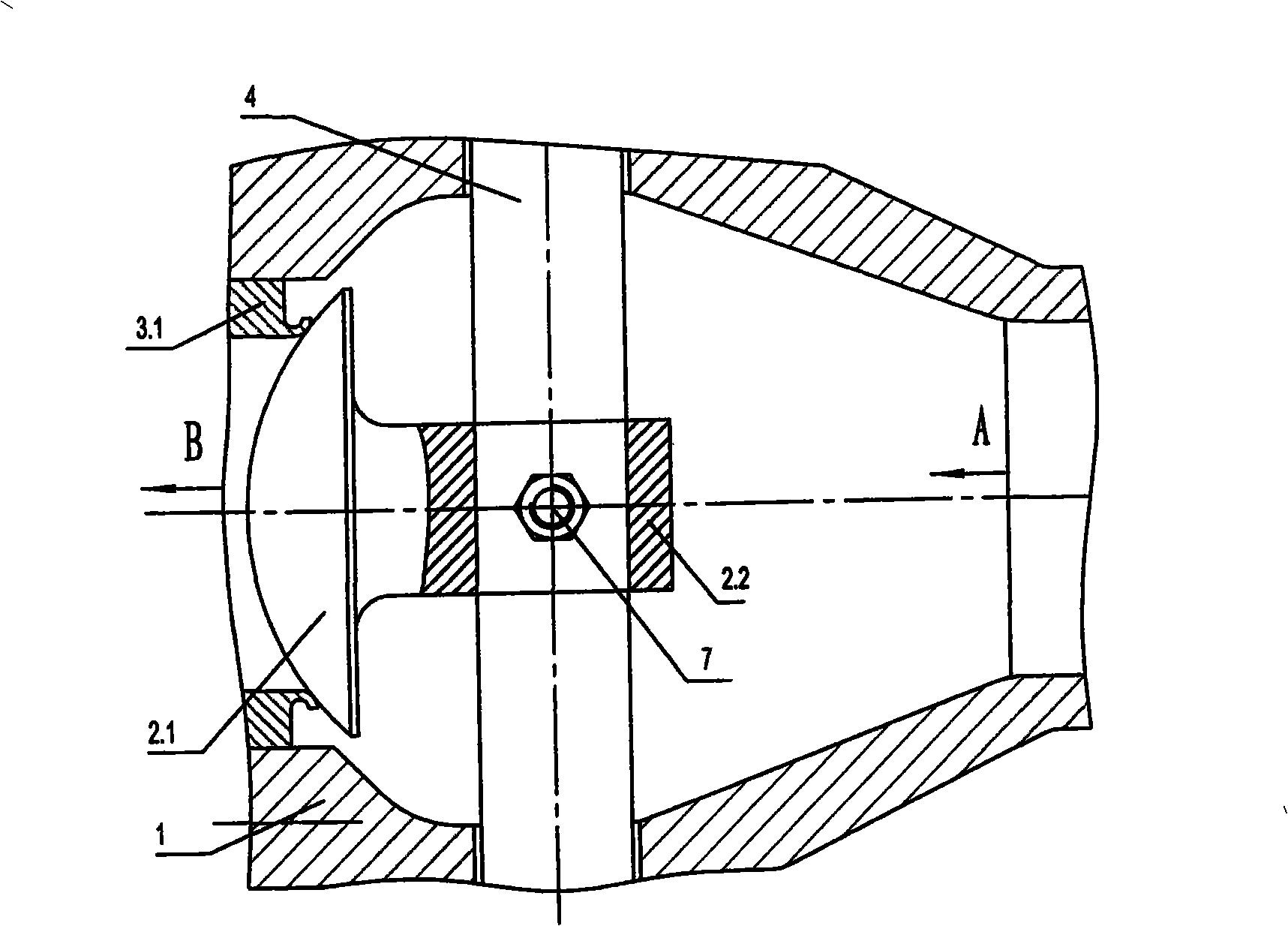

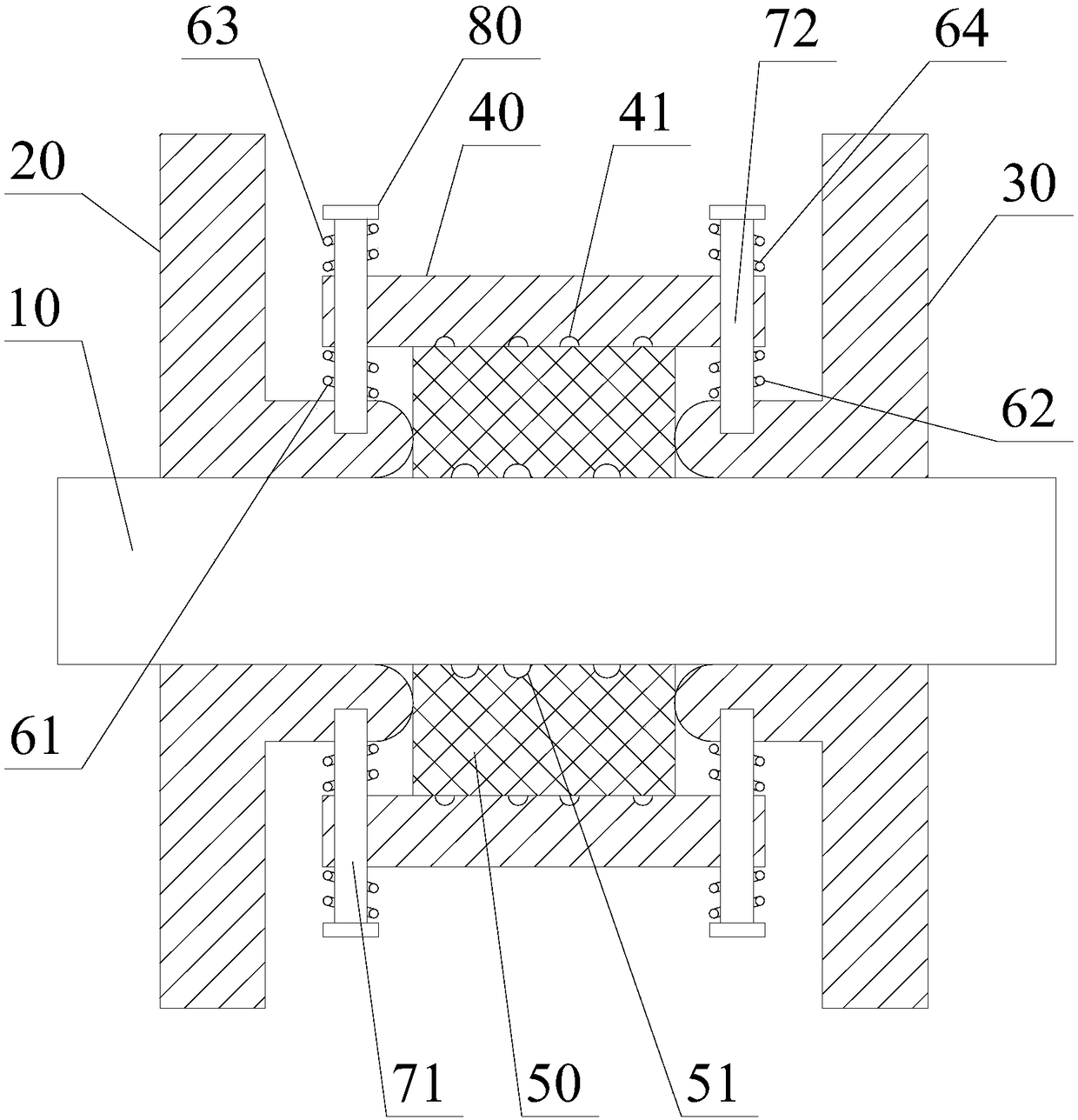

Static and dynamic composite sealing structure and method for rotary machine rotor

The invention relates to a static and dynamic composite sealing structure and method for a rotary machine rotor. High-pressure lubricating liquid is added to a sliding bearing, so that in the floating stage and the low-speed rotating stage of the rotor, leakage of the lubricating liquid is stopped through the static sealing function of lip sealing rings with lip points attached to the rotor. Along with increase of the rotating speed of the rotor, an air inlet channel of an external high-pressure air source is opened, air pressure is slowly increased, the lip points of the lip sealing rings are separated from the surface of the rotor, and an annular air wall is formed on the surface of the rotor; and a large part of lubricating liquid is thrown into a left annular oil return groove and a right annular oil return groove to flow out due to the centrifugal function, and a small part of lubricating liquid flowing in the axial direction of the rotor is limited from flowing through sealing of the floating lip points and dynamic sealing of the air wall. Thus, good sealing is guaranteed within the start, stop and rotating full-speed range of the rotor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

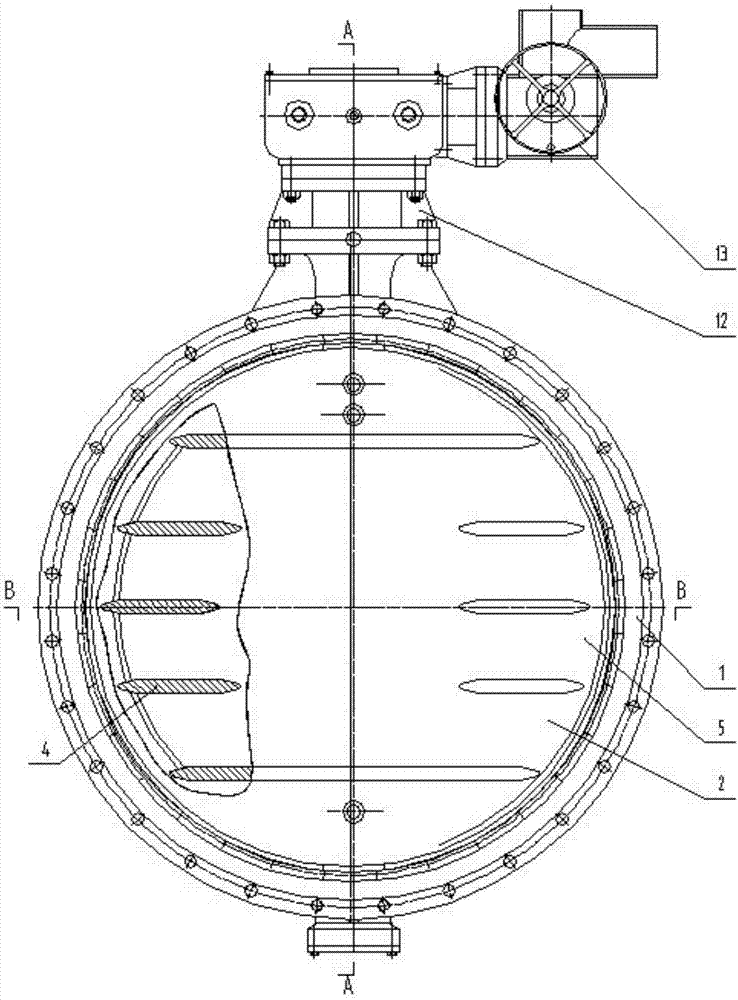

Double-plate double-valve-seat bi-directional metal-sealed butterfly valve

InactiveCN107355548AScientific and reasonable structure designSimple structureLift valveCircular discEngineering

The invention relates to a double-plate double-valve-seat bi-directional metal-sealed butterfly valve, which comprises a drive device, a support, a filler, a filler gland, a bottom cover, a valve body, a butterfly plate, an upper valve shaft, a lower valve shaft, a valve shaft pin, valve seats, a butterfly plate metal seal ring, a pressing plate, a valve seat pressing plate, a check ring and an adjustable valve seat seal ring. The valve seats are oppositely arranged between a disk and the valve body at two sides of the upper valve shaft; the valve seats are oppositely arranged between the disk and the valve body at two sides of the lower valve shaft; and the valve seats are fixed valve seat and / or adjustable valve seats. The butterfly valve has a scientific and reasonable structure design, a simple structure, easiness in processing and manufacturing, large caliber, high flow capacity, high pressure resistance, high temperature resistance, corrosion resistance, diversion stability, small vibration, low noise, long service life, and capability of on-line overhauling and replacing a sealing element, and a double-sealed pair works cooperatively or independently when at a two-way alternative pressure-bearing state so as to further realize two-way sealing.

Owner:王中杰

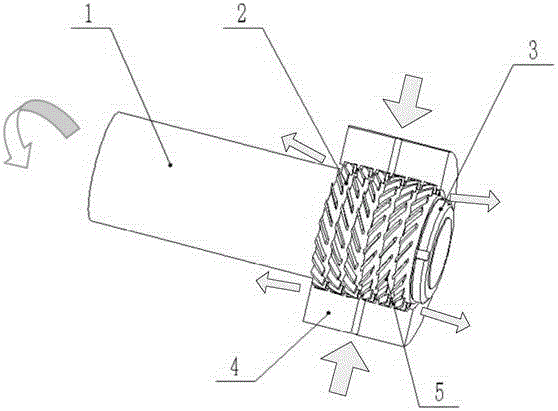

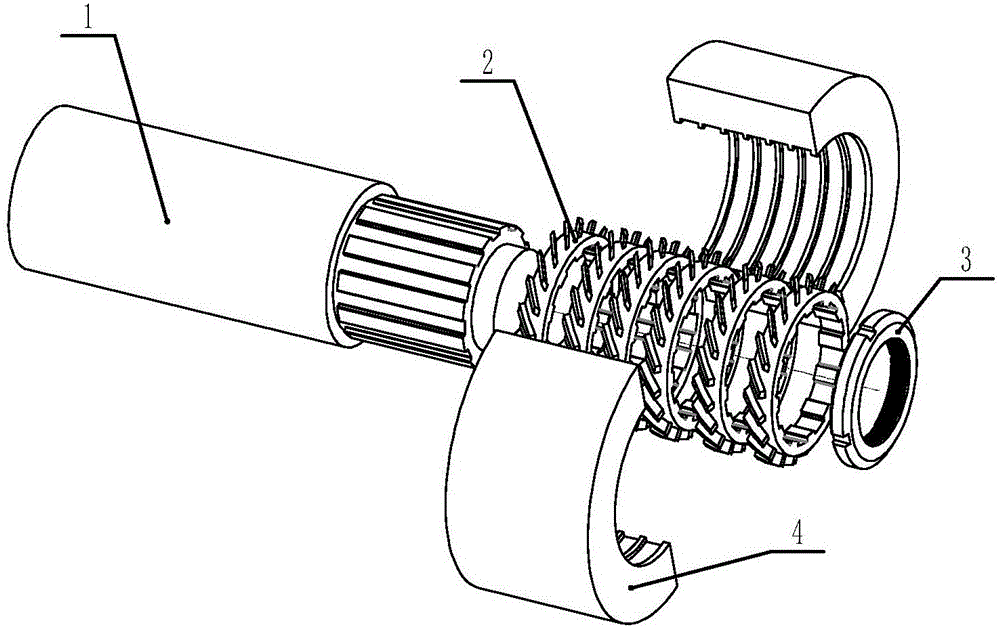

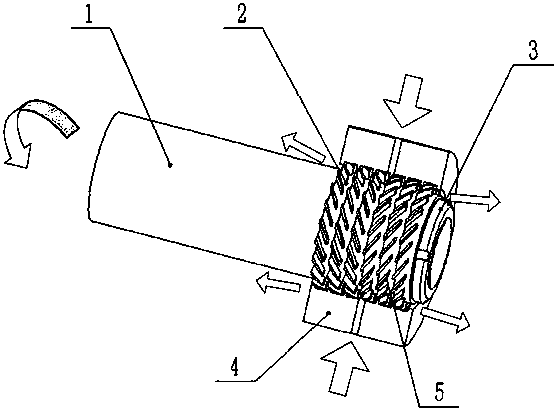

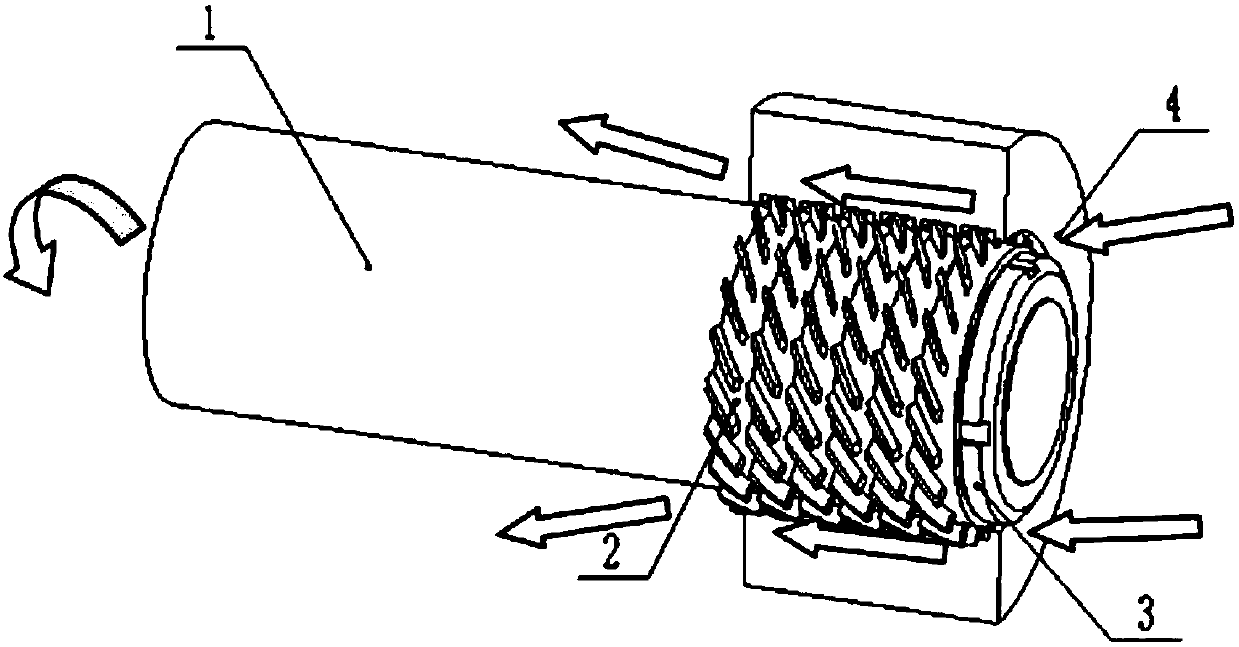

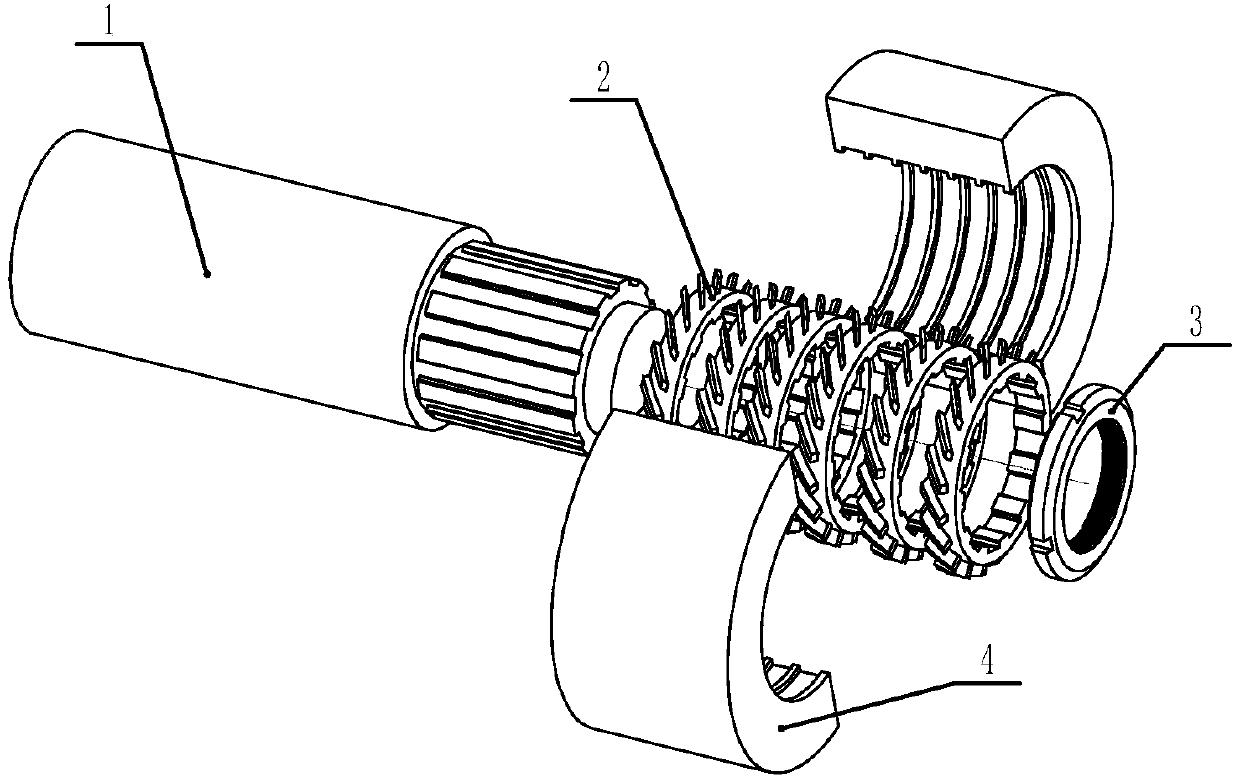

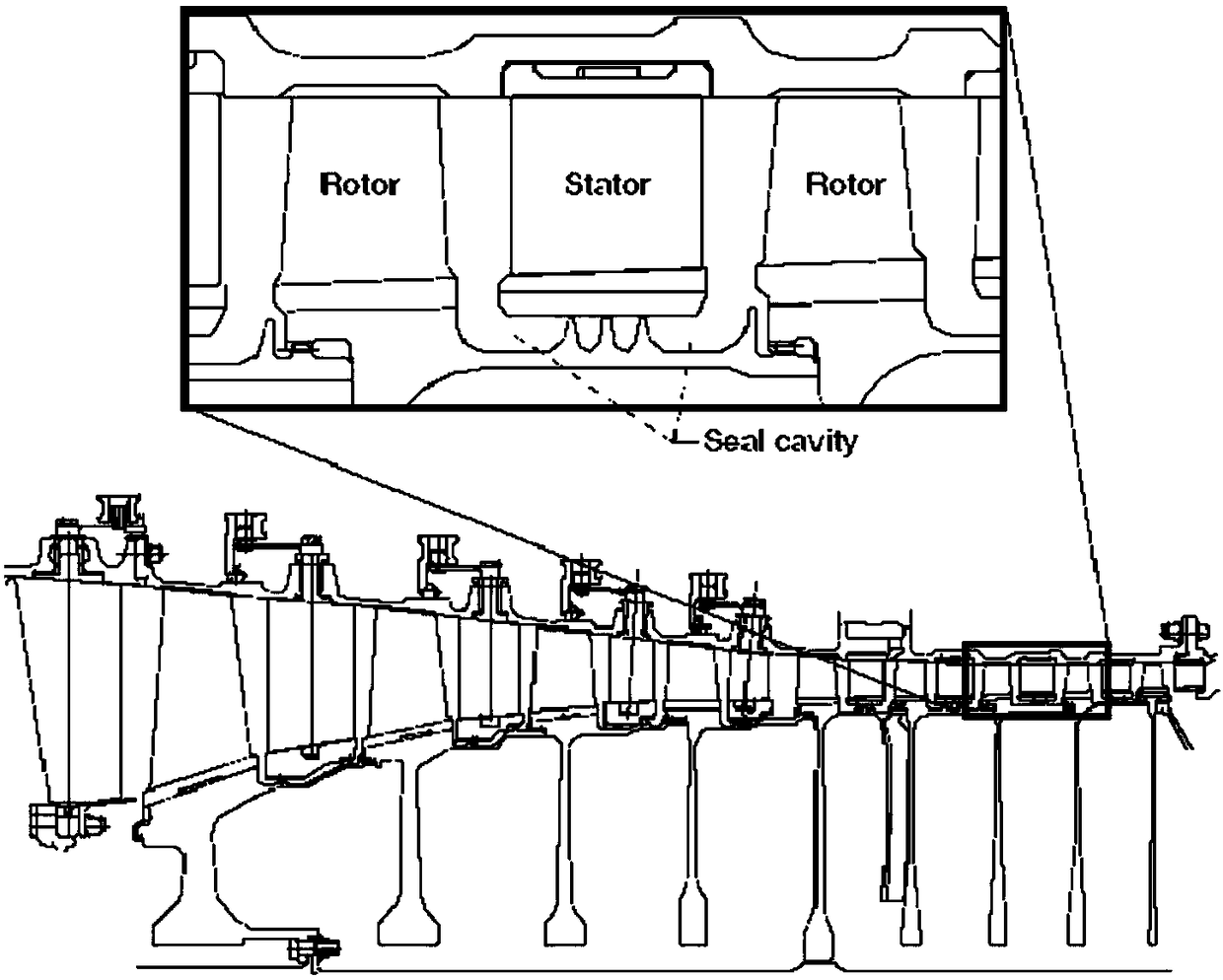

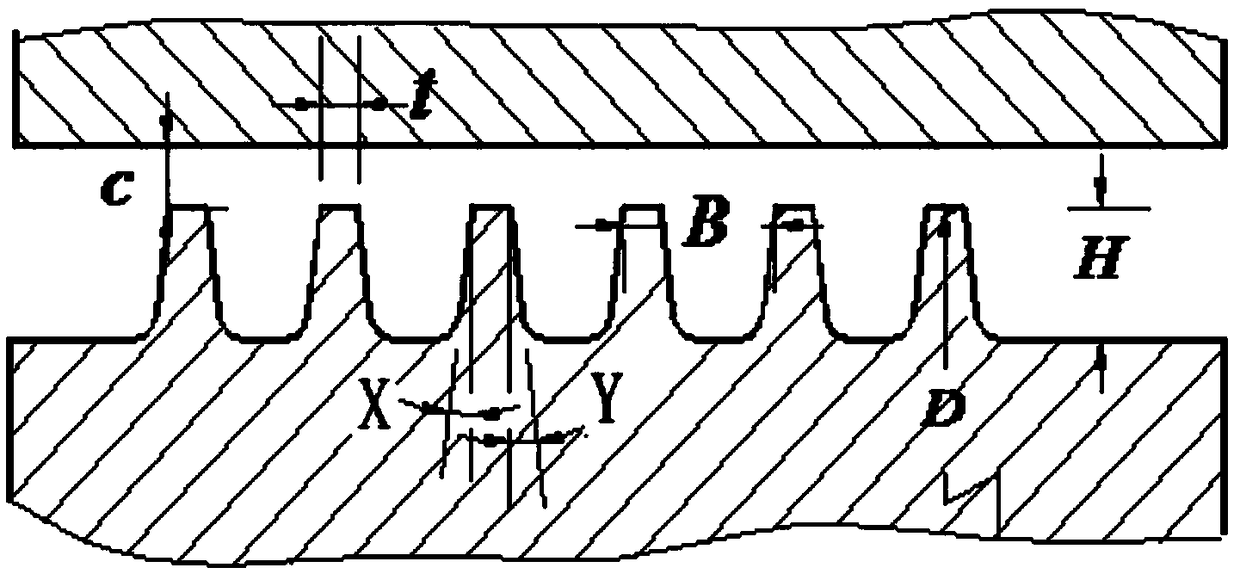

Active labyrinth seal structure

The invention provides an active labyrinth seal structure. The active labyrinth seal structure comprises a rotor, blade seal rings, seal jackets and a locking nut, wherein the blade seal rings are fastened with the rotor through spline joints; the number of blade seal rings can be increased as needed; a shaft end of the rotor is fastened by using the locking nut; the two semi-round seal jackets are fastened on the blade seal rings; rectangular teeth on the seal jackets are crossed with blades; and when rotating, the rotor drives the blade seal rings to rotate, and the blades on the seal rings can form active reverse air flow in a seal channel, so that the air leakage can be effectively inhibited. The active labyrinth seal structure is simple in structure and better in seal effect.

Owner:ESURGING TIANJIN TECH CO LTD

Flexing slot for plug valve insert

ActiveUS20200025296A1Improve sealing propertiesSame sealing effectPlug valvesEngineeringMechanical engineering

An insert adapted for use in a plug valve includes a single-piece body having an inner sidewall adapted to interface with a sidewall of a valve plug. First and second opposing apertures are each defined through the single-piece body for selective alignment with a flow bore of the valve plug. First and second opposing slots are each defined through the single-piece body at an angle to the first and second opposing apertures for allowing the body to flex in the direction of the first and second opposing apertures.

Owner:BLUECORE COMPLETIONS LLC

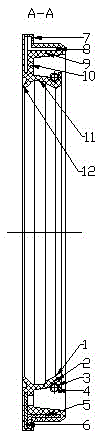

Outside mounted type two-lip framework oil seal

ActiveCN103574037ASolve the support strength problemHigh mechanical strengthEngine sealsWater vaporMechanical engineering

The invention relates to a bearing box or gear box lubricating oil (grease) sealing device for a rotating shaft of mechanical equipment, in particular to an outside mounted type two-lip framework oil seal. The outside mounted type two-lip framework oil seal comprises a sealing lip, a crown part, a spring groove, a limiting step, a shoulder part, a back part, a waist part, a secondary lip and a locating groove, wherein an integral structure of the outside mounted type two-lip framework oil seal is formed by the sealing lip, the crown part, the spring groove, the limiting step, the shoulder part, the back part, the waist part, the secondary lip and the locating groove; the sealing lip is arranged on the outer side of the crown part; the spring groove is formed in the inner side of the crown part; the secondary lip is arranged on the outer side of the waist part; the outside mounted type two-lip framework oil seal further comprises a circular pad type framework and an L-shaped framework; the limiting step is integrally connected with the shoulder part, the back part, the secondary lip, the waist part, the crown part, the sealing lip, the spring groove, the circular pad type framework and the L-shaped framework; a spring is arranged in the spring groove. The secondary lip is used for preventing external impurities such as water vapor and smoke from entering a sealing cavity; the sealing lip is used for preventing oil (grease) in the sealing cavity from leaking outside. The oil seal thoroughly solves the problem of inconvenient online dismounting, has the advantages of simple structure, low cost, high adaptability and convenience in online replacement, and can totally replace a standard framework oil seal.

Owner:HUBEI XINZHI TECH CO LTD

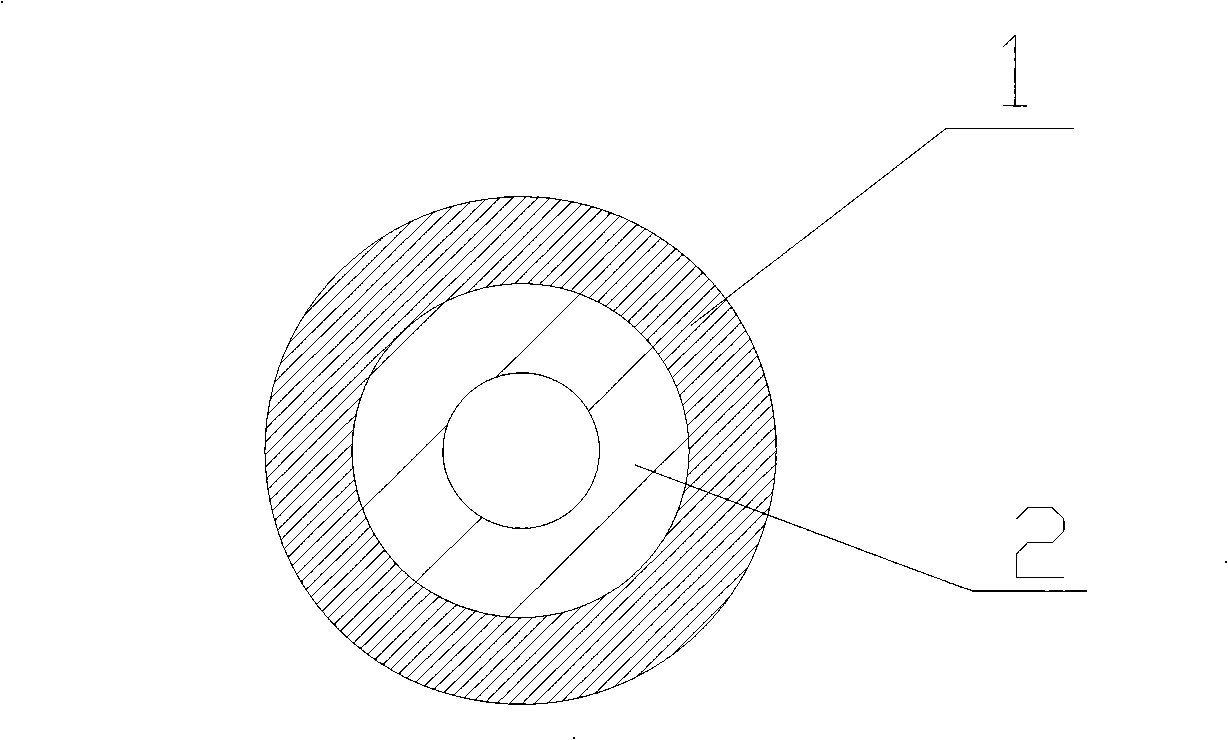

Novel seal components

The invention provides a novel sealing element, in particular to the novel sealing element made of a bimetallic material with high-temperature resistance and high-pressure resistance. The appearance of the sealing element is of a hollow cylinder body, wherein the cylinder body is generally of a round shape or a square shape, and the hollow part is used for fluid passing through. The novel sealing element consists of at least two layers of different metals, and also can be combined of different metals with three layers or more than three layers. The novel sealing element solves the problem of difficult sealing in a high-temperature high-pressure environment, and makes up the defects in the prior art.

Owner:JIANGSU HENGLI CHEM FIBER

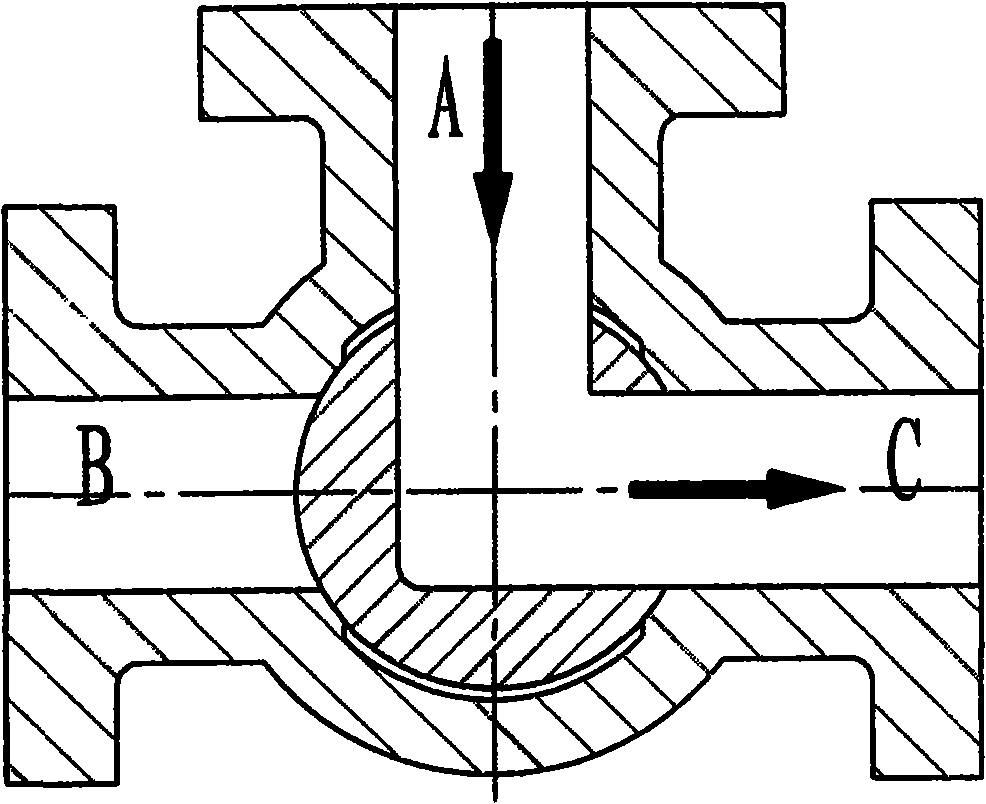

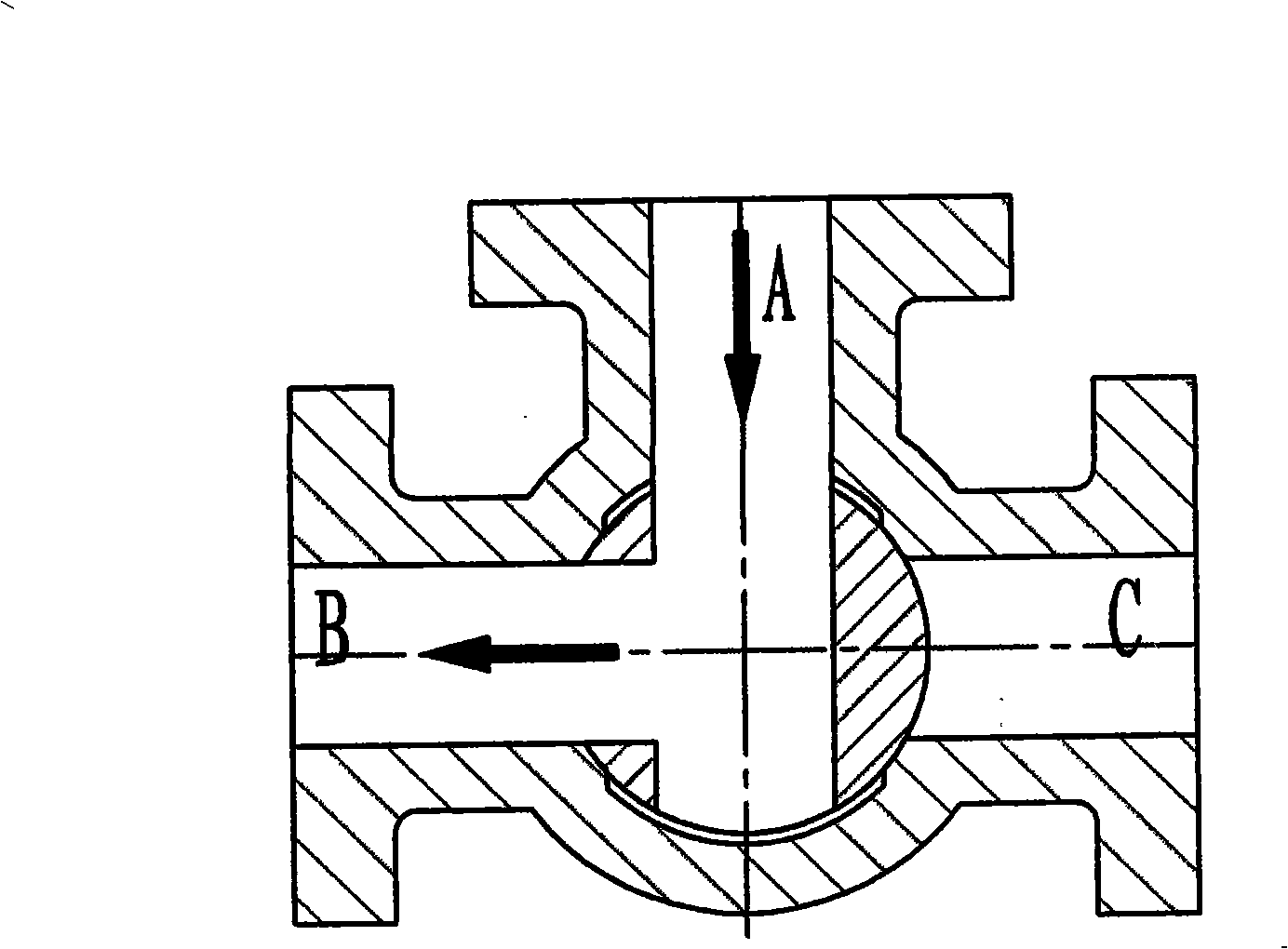

Three-way ball valve

InactiveCN101270828ANo longer affects pathReduce volumePlug valvesMultiple way valvesPilot holeImpurity

The invention discloses a three-way ball valve, including a valve body, a valve seat, a valve core and a valve rod. The valve body has a medium inflow channel and two medium outflow channels. The internal orifice of each medium outflow channel is provided with the valve seat. The valve core is fixedly connected with the valve rod. The sealed working face of the valve core is a spherical surface, which corresponds to the valve seat. The valve core is a hemispheric spherical cap which has the spherical surface and a plane. The spherical surface is the sealed working face corresponding to the valve seat. The plane of the spherical cap has a handle which is provided with a pilot hole for connecting the valve rod. The invention has the beneficial technological effects that the medium channel does not run through the valve core and does not influence the path of the valve any more. The bulk of the valve is reduced and the medium can flow smoothly. The crystals and the solid impurities are taken out of the valve, which neither gather inside the valve and form stoppage nor enter into the matching surface of the ball core and the valve seat to form hard friction and destroy the seal.

Owner:四川华林自控科技有限公司

Cast-in-place drainage channel structure of free-form construction top plate and construction method

The invention discloses a cast-in-place drainage channel structure of a free-form construction top plate. The cast-in-place drainage channel structure comprises a cushion layer, wherein a bottom plate is poured on the cushion layer; a left side wall and a right side wall are poured on the left side and the right side of the bottom plate separately; a left connecting rebar and a right connecting rebar are buried into the tops of the left side wall and the right side wall; a top plate member is arranged between the tops of the left side wall and the right side wall; and a top plate wrapping body is poured on the tops of the left side wall and the right side wall and on the top plate member. The invention further discloses a construction method of the cast-in-place drainage channel structure of the free-form construction top plate. The method comprises the steps of prefabricating the top plate member in batches; casting the cushion layer, the bottom plate, the left side wall and the right side wall on site; installing the top plate member; and casting the top plate wrapping body. The sealing property of a drainage channel can be ensured, the problem that a bottom form and a support used for casting the top plate in a traditional construction method are difficult to remove is solved, the construction efficiency is relatively high, and the proficiency requirement on filling operation of a worker is lower than that in a traditional ''cover plate method prefabricating method''.

Owner:ZHENGZHOU MUNICIPAL ENG CORP

An active labyrinth seal structure

ActiveCN105757257BContainment leakImprove sealingEngine sealsLeakage preventionEngineeringMechanical engineering

The invention provides an active labyrinth seal structure. The active labyrinth seal structure comprises a rotor, blade seal rings, seal jackets and a locking nut, wherein the blade seal rings are fastened with the rotor through spline joints; the number of blade seal rings can be increased as needed; a shaft end of the rotor is fastened by using the locking nut; the two semi-round seal jackets are fastened on the blade seal rings; rectangular teeth on the seal jackets are crossed with blades; and when rotating, the rotor drives the blade seal rings to rotate, and the blades on the seal rings can form active reverse air flow in a seal channel, so that the air leakage can be effectively inhibited. The active labyrinth seal structure is simple in structure and better in seal effect.

Owner:ESURGING TIANJIN TECH CO LTD

A kind of Ni-MH battery sealing oil preparation method

The invention belongs to the technical field of nickel-hydrogen battery manufacturing and provides a method for preparing sealing oil of nickel-hydrogen batteries. This Ni-MH battery sealing oil preparation method includes the following steps: select battery-grade asphalt, heat and stir in a container to melt the asphalt completely; cool to 40°C-50°C, and set the mass ratio of asphalt to gasoline at 1:0.2-0.8 Slowly add gasoline in a proportion of 100%, stirring while adding; cool to room temperature, and seal the package for later use. According to the method for preparing the sealing oil of the nickel-metal hydride battery of the present invention, gasoline is relatively less harmful to the human body, and gasoline is used as a solvent to prepare the sealing oil, which can achieve the same sealing effect.

Owner:HUNAN GREPOOW NEW ENERGY CO LTD

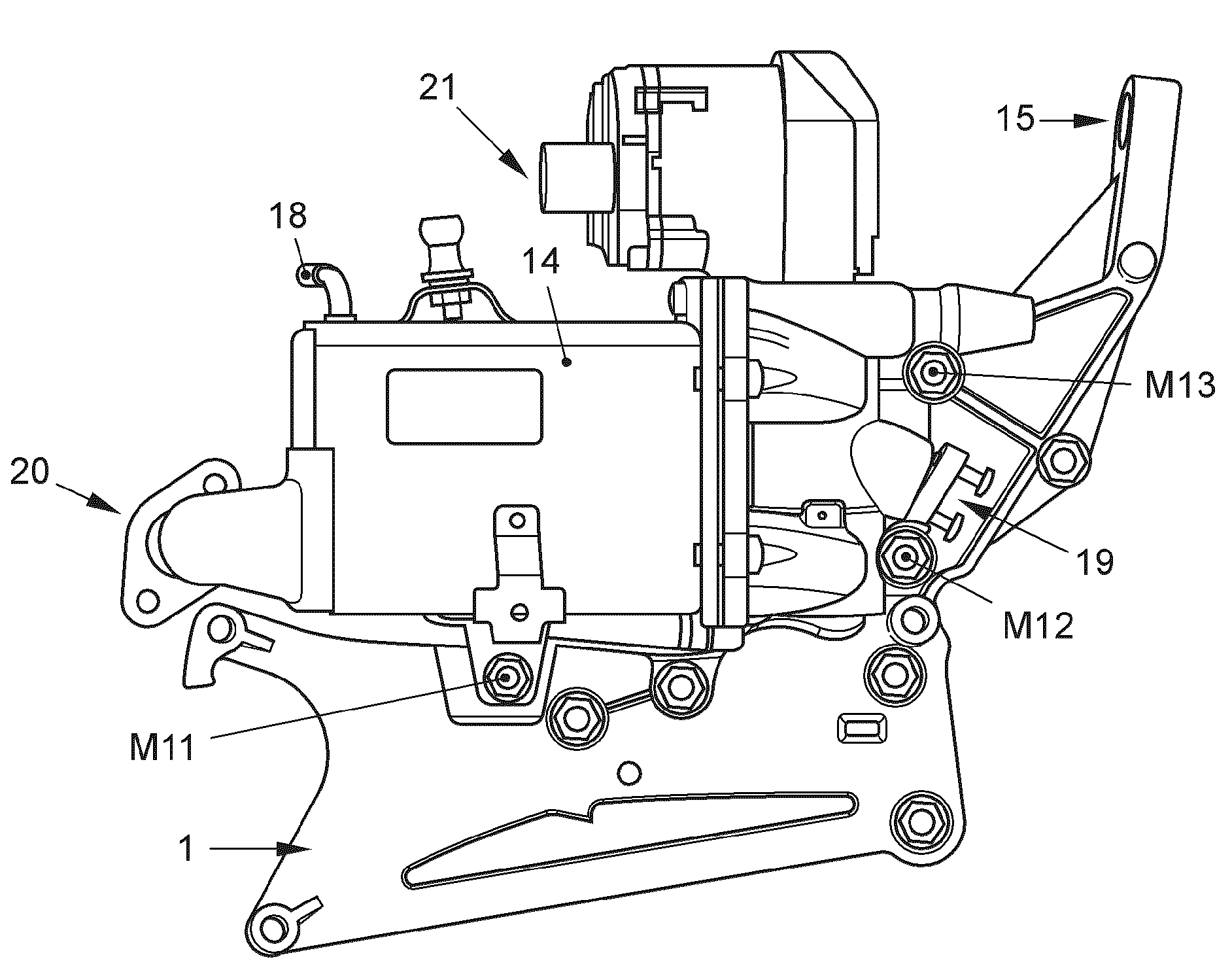

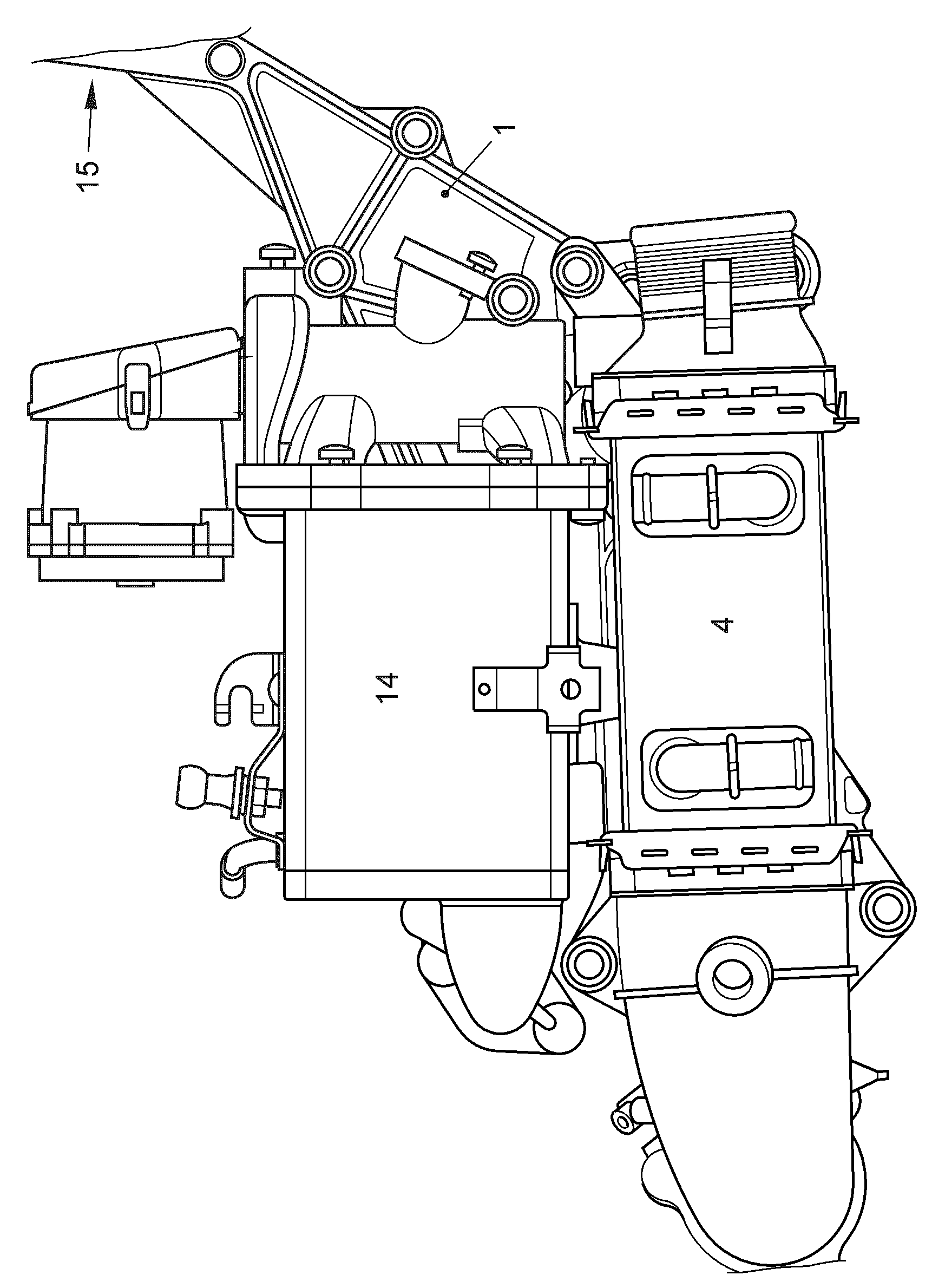

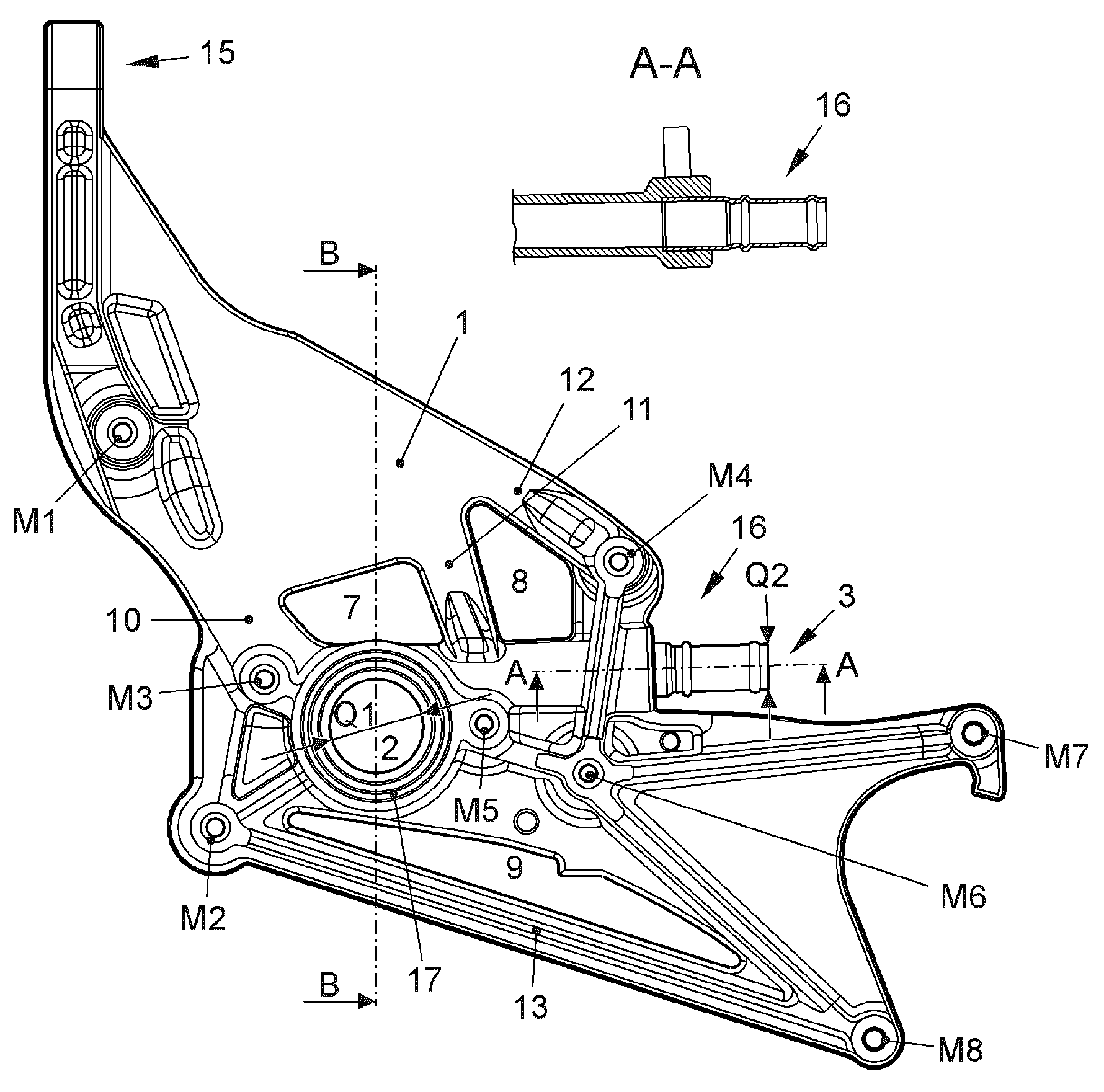

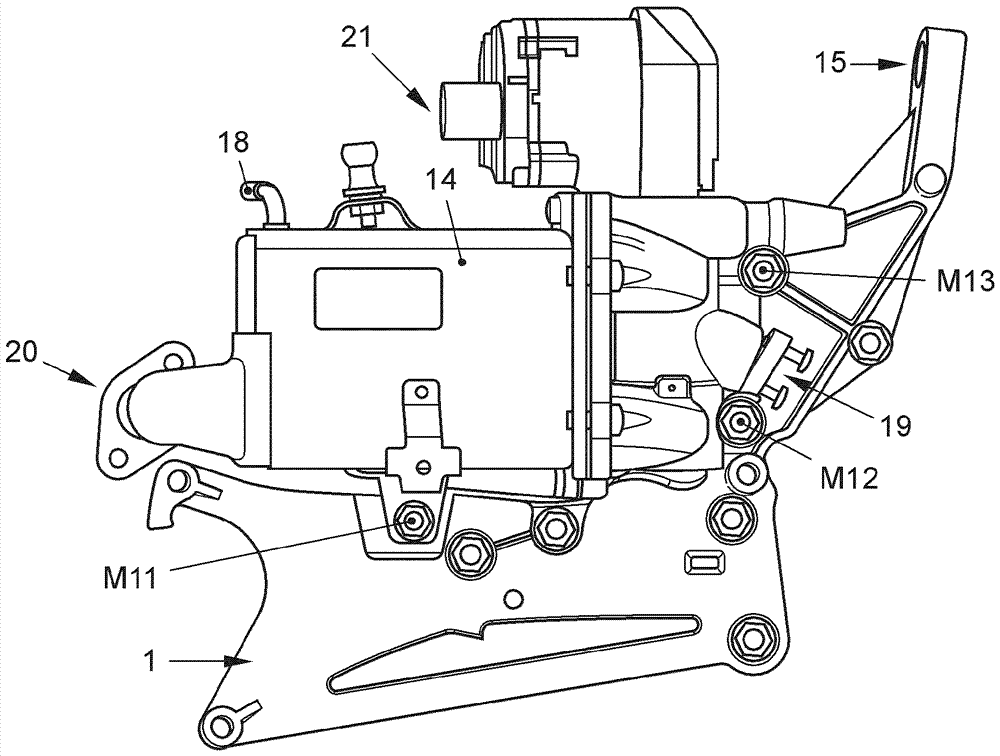

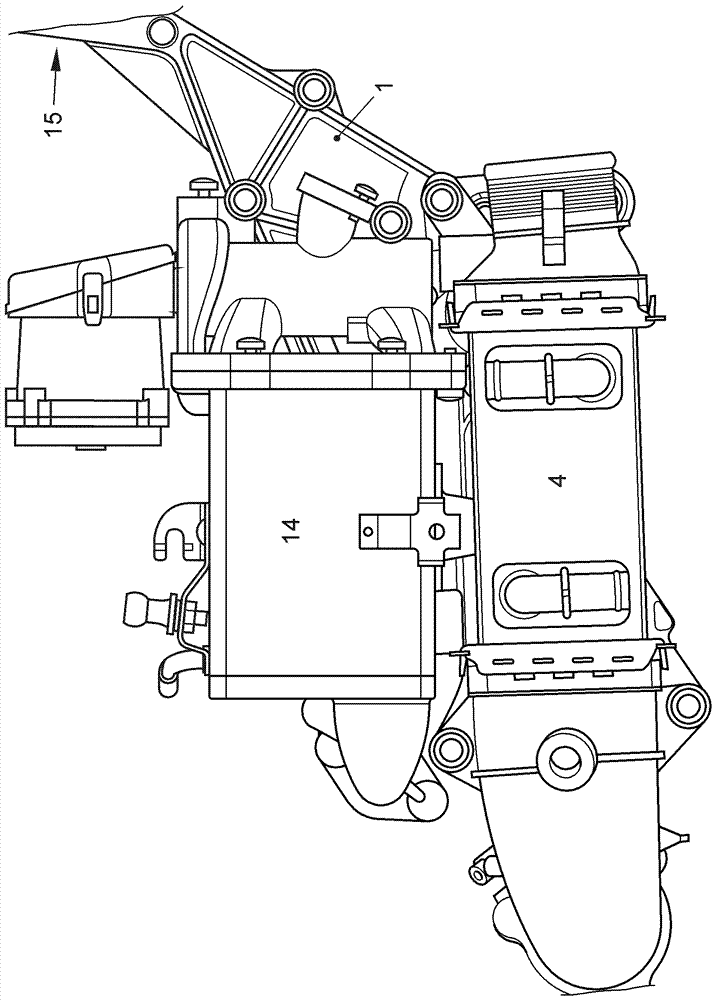

Functional module for engine

ActiveCN104343582ASimple and compact constructionEffective guidanceLiquid coolingCasingsComputer moduleEngineering

The invention relates to a functional module for an engine, wherein the functional module has a coolant inlet and a coolant outlet. It is known that multi-functional modules are very complex and configured as a link between the engine and a structure unit. The object of the invention is to realize a space-saving connection between the motor and a structural element. The functional module for the engine comprises the coolant inlet and the coolant outlet, and characterized by the fact that on one hand, the functional module can be connected with an engine housing, on the other hand, the functional module can be connected with the structural element, wherein the functional module forms a support function for the structural element and a channel function for the coolant inlet and the coolant outlet, wherein the coolant inlet and the coolant outlet are not directly in operative connection with the structural element. The functional module is advantageous in that the module is simple and compact, and the structural element can be arranged at the functional module and is not directly in operative connection with the functional module.

Owner:VOLKSWAGEN AG

External double lip skeleton oil seal

ActiveCN103574037BSolve the support strength problemHigh mechanical strengthEngine sealsEngineeringMoisture

A lubricating oil (grease) sealing device for a bearing box or a gear box for a rotating shaft in mechanical equipment, in particular an external double-lip skeleton oil seal. Including the sealing lip, crown, spring groove, limit step, shoulder, back, waist, auxiliary lip, and positioning groove that constitute the integrated structure of the external double-lip skeleton oil seal. The sealing lip is located outside the crown, and the spring groove is located inside the crown. , the auxiliary lip is located on the outside of the waist, and also includes a ring cushion-shaped skeleton and an L-shaped skeleton. As a whole, a spring is arranged in the spring groove. The auxiliary lip is used to prevent impurities such as water vapor and dust from entering the sealing cavity, and the sealing lip is used to prevent the oil (grease) in the sealing cavity from leaking out. This oil seal completely solves the problem of inconvenient disassembly on-line. It has simple structure, low cost, strong adaptability, easy on-line replacement, and can completely replace the standard skeleton oil seal.

Owner:HUBEI XINZHI TECH CO LTD

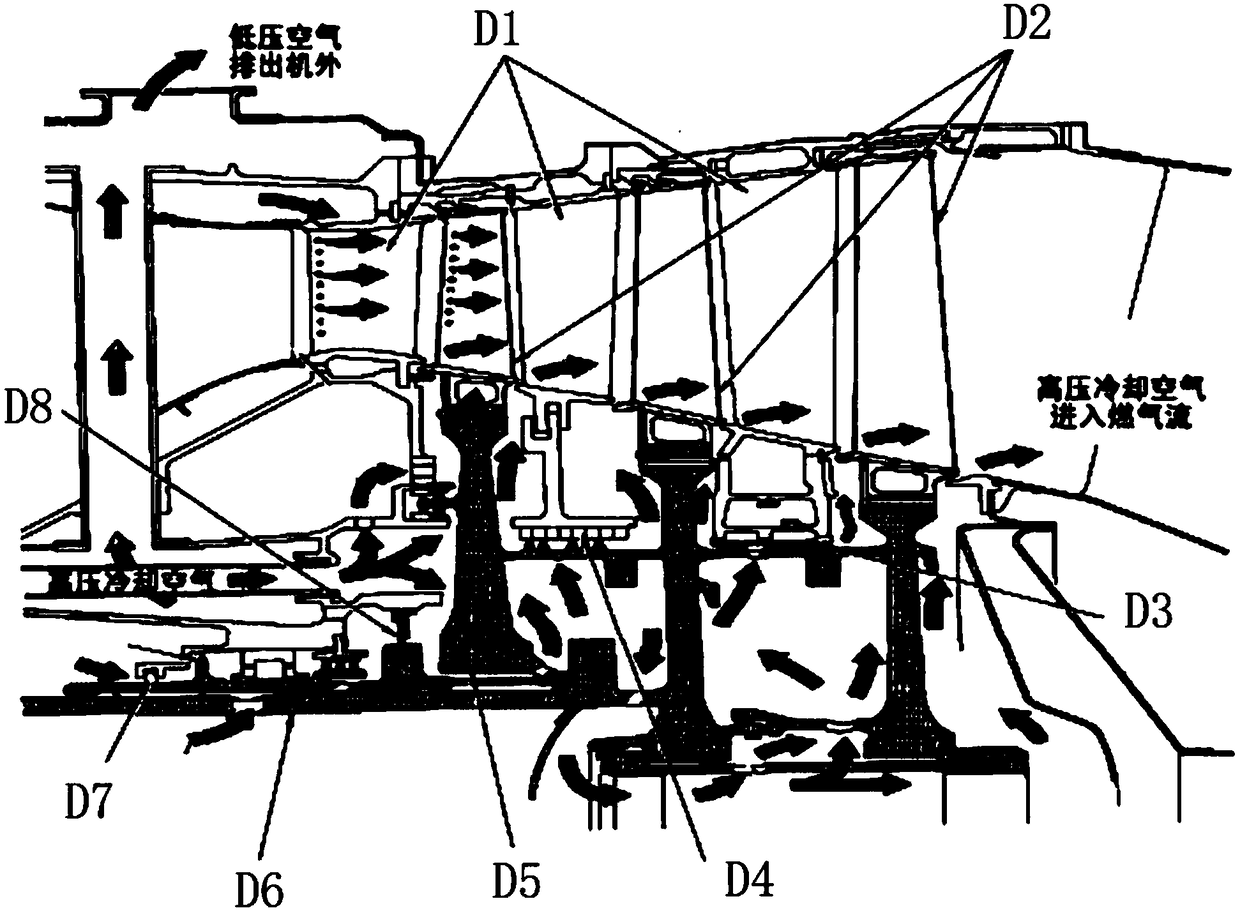

A sealing structure of aero-engine grate tooth with curved windward sharp-angle tooth

ActiveCN106089323BEnhanced blendingReduce leakageLeakage preventionGas turbine plantsAcute angleConvex side

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

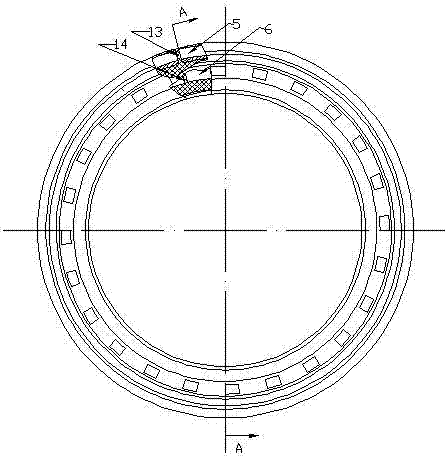

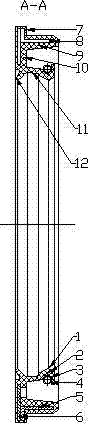

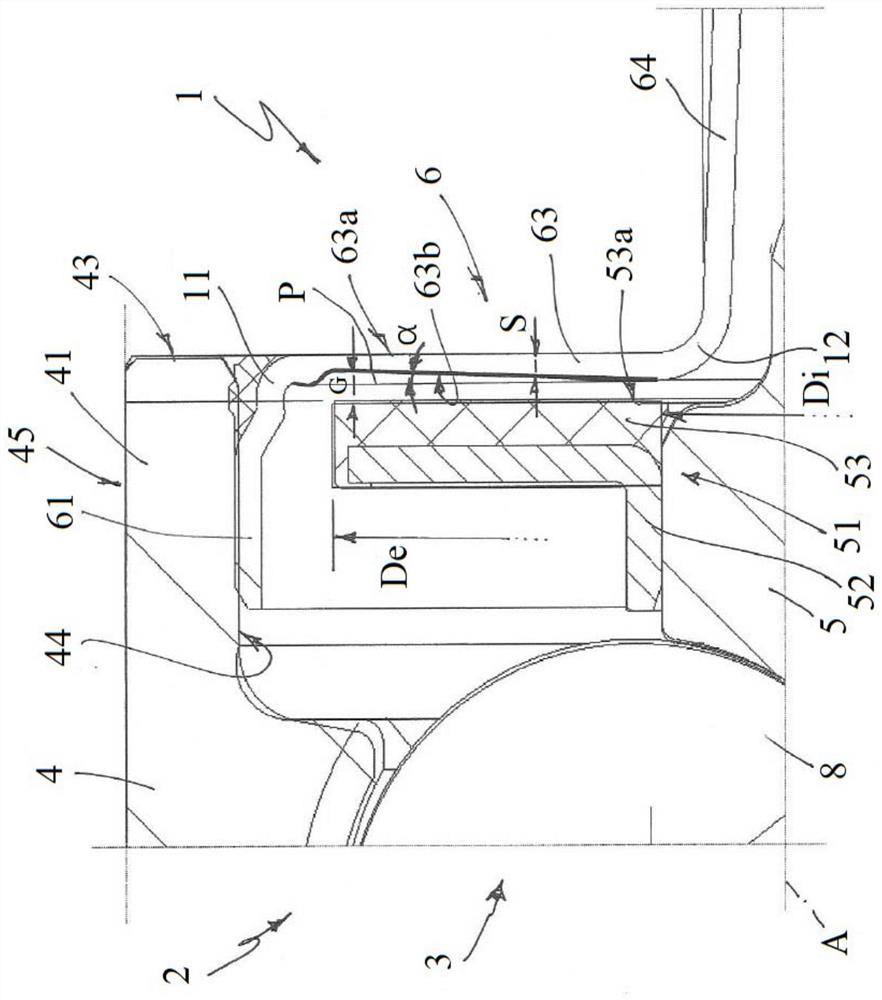

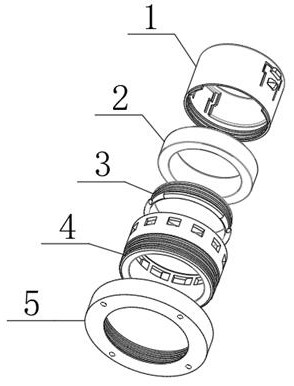

Sealing device for hub unit and hub unit equipped with the same

ActiveCN109931335BSame sealing effectRolling contact bearingsBearing assemblyRolling-element bearingMechanical engineering

Owner:AB SKF

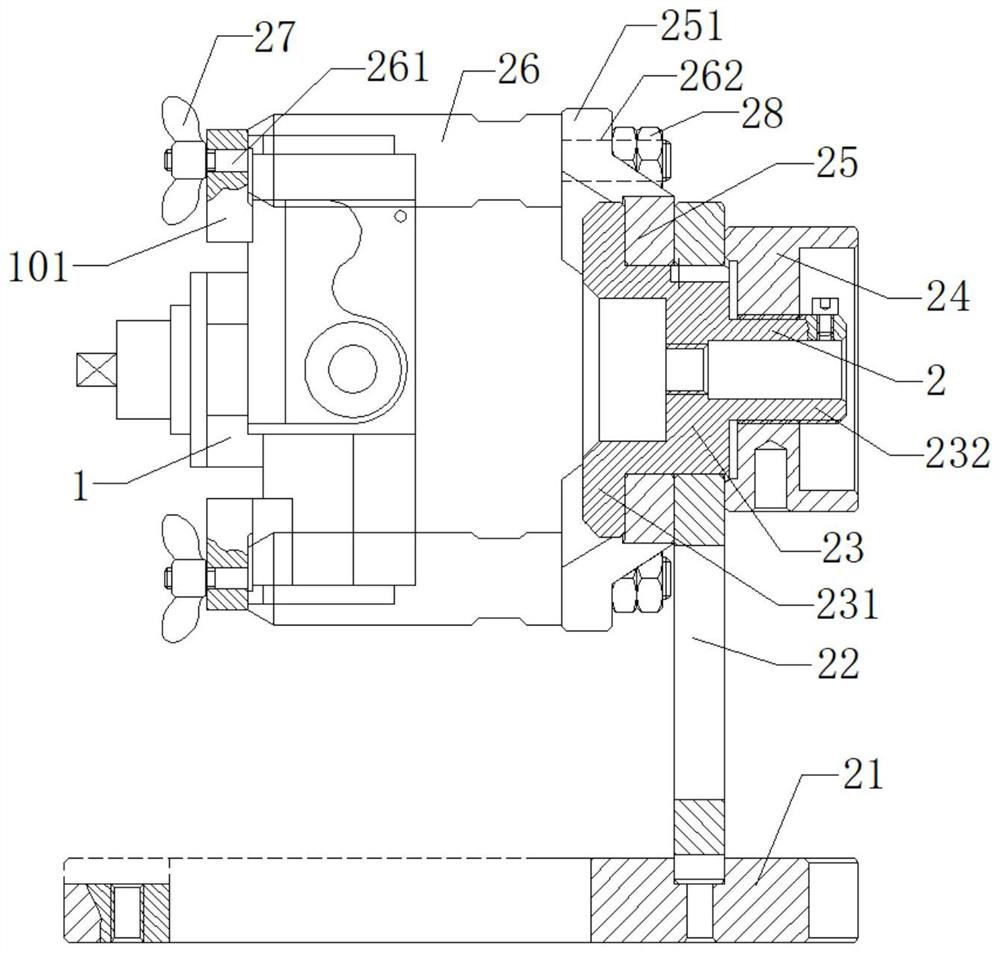

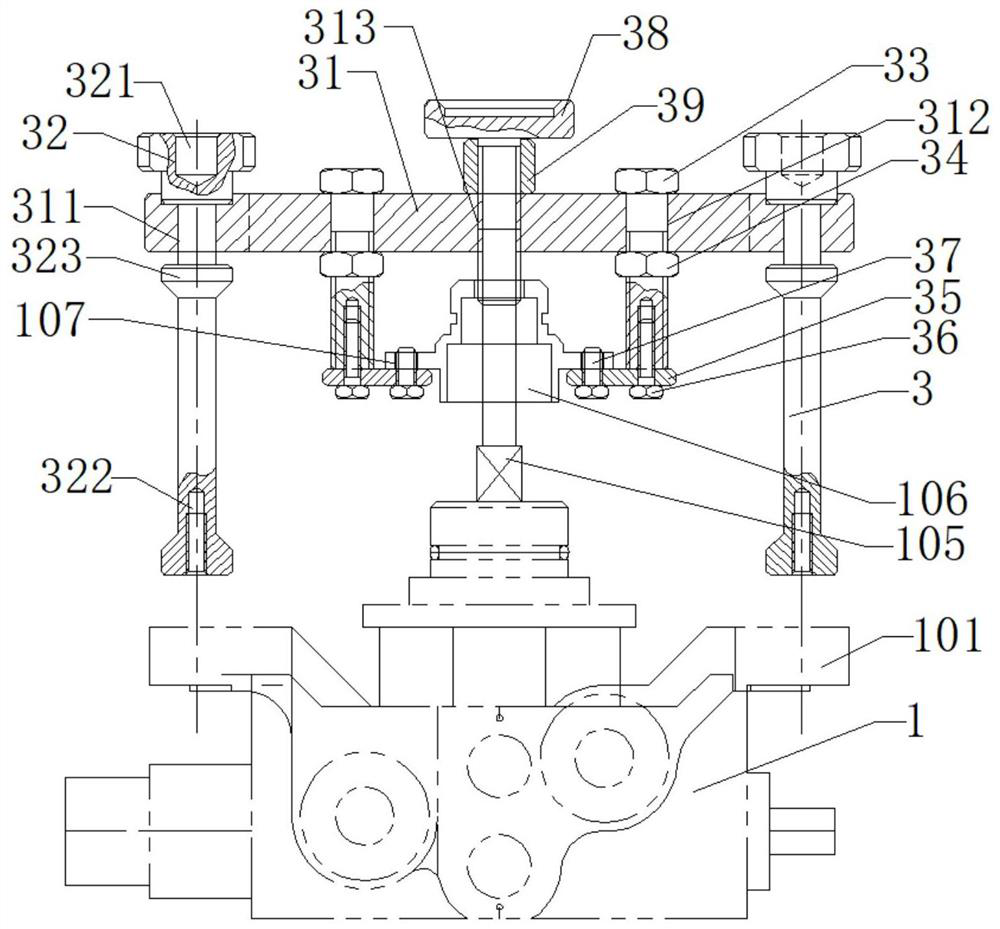

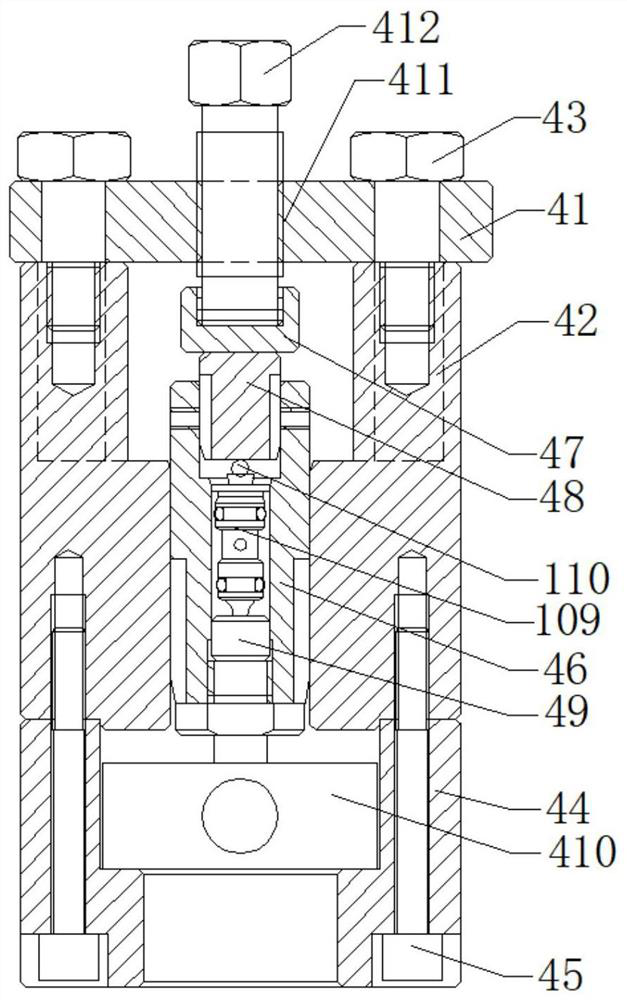

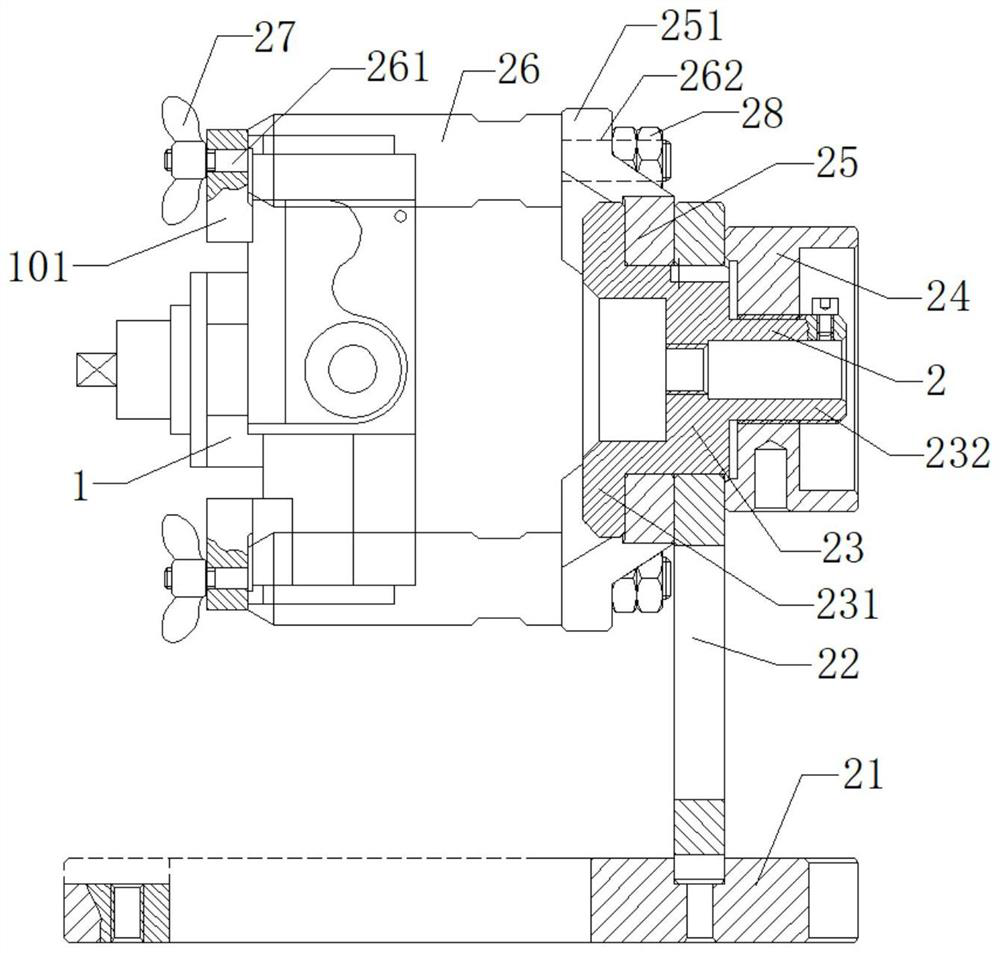

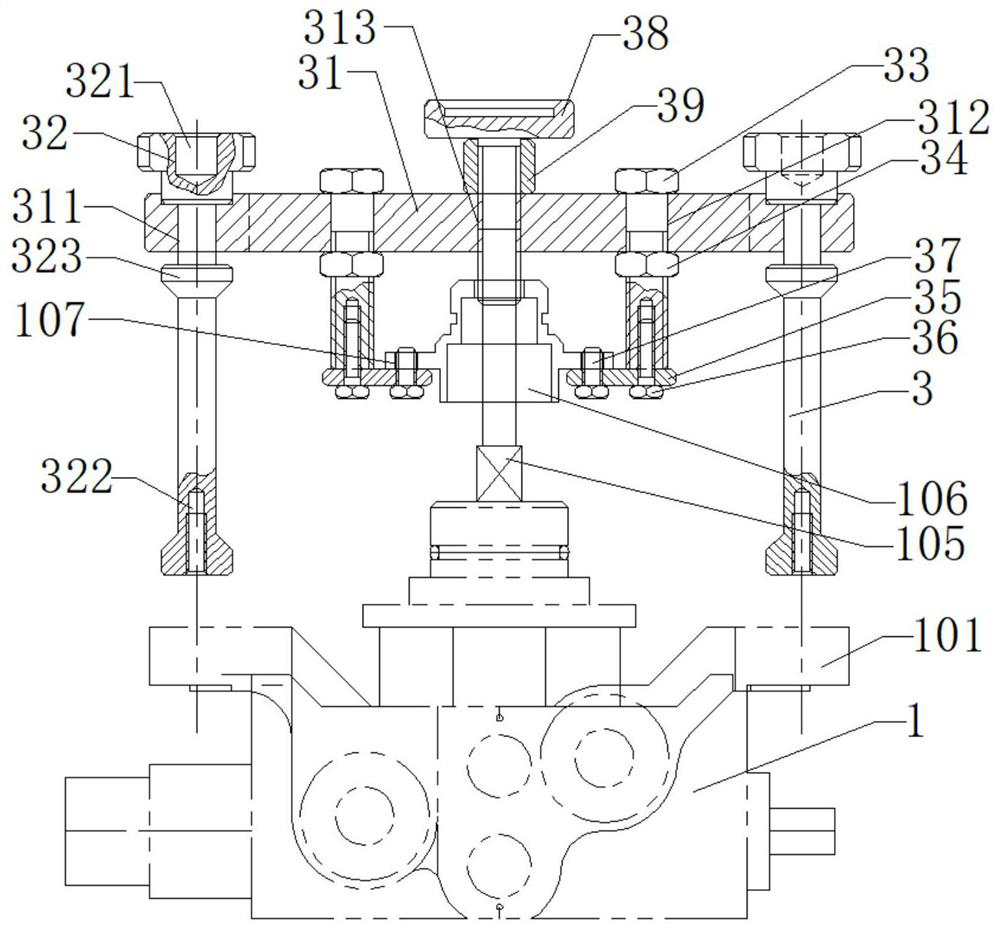

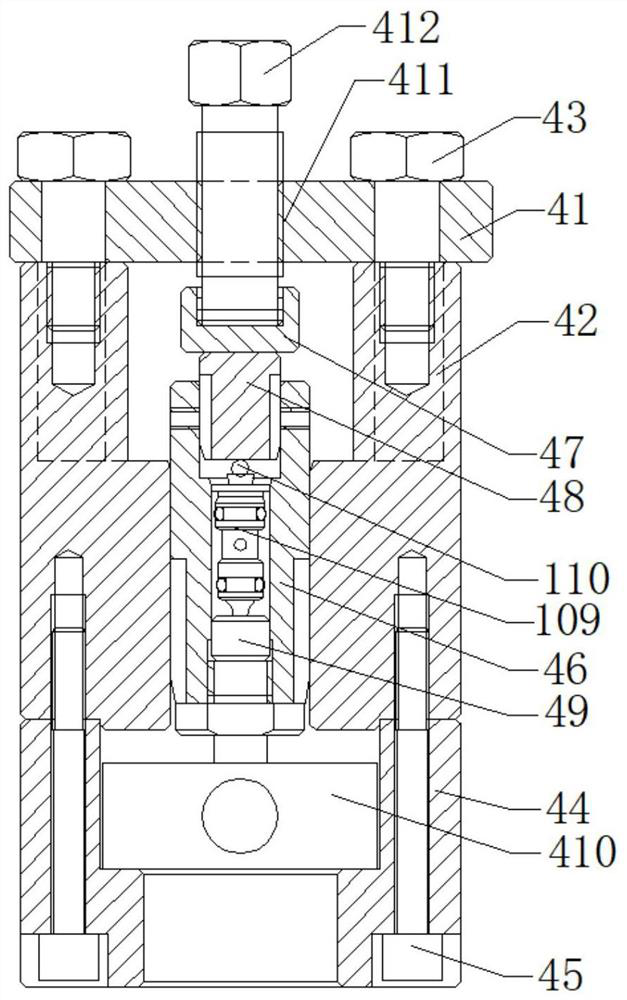

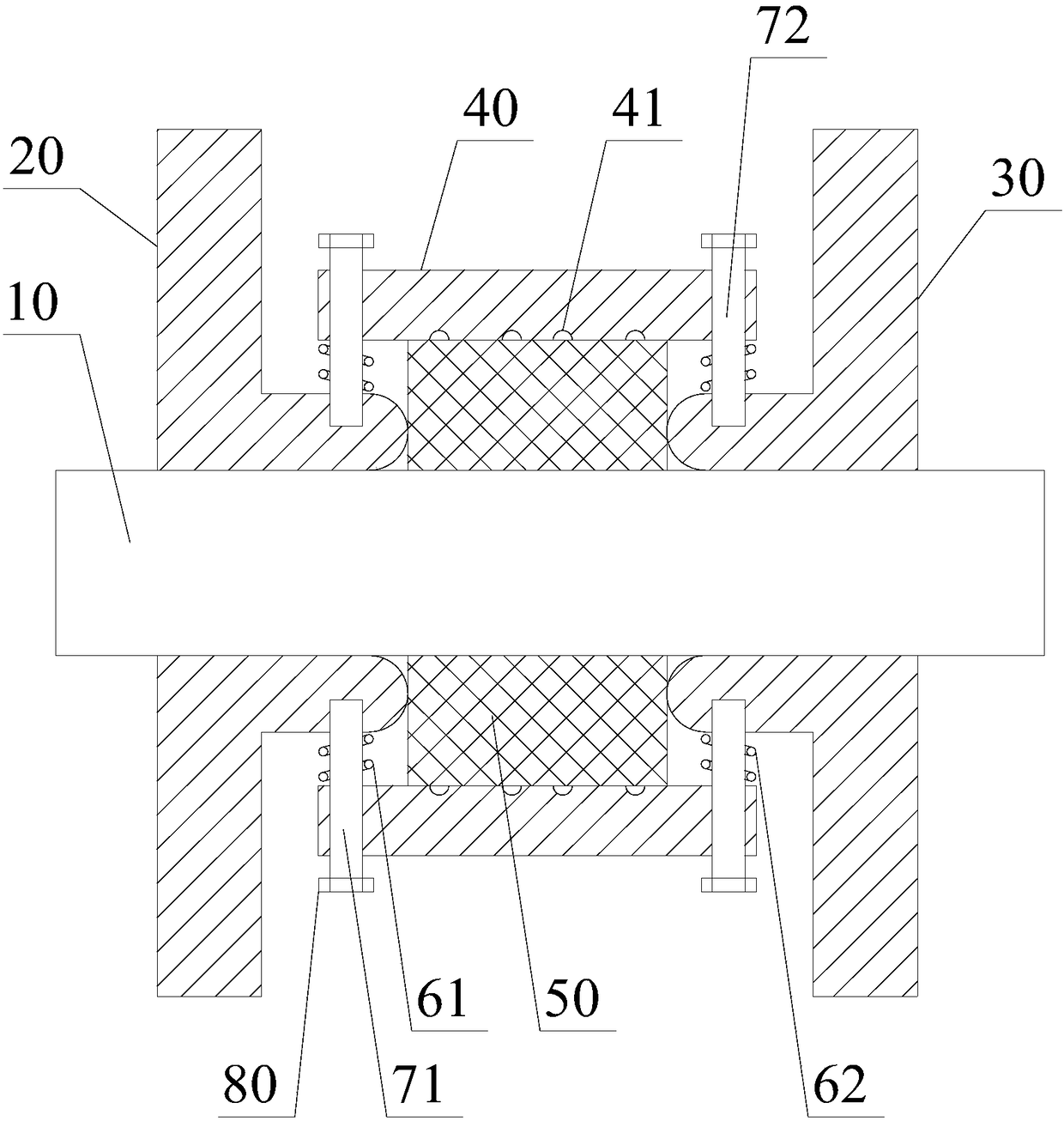

A tooling assembly for manual selection valve assembly

ActiveCN113478428BEasy to assembleQuick installationWork holdersMetal-working hand toolsConstant loadEngineering

The invention discloses a tooling assembly for manual selection of valve assembly, comprising a positioning tool, an end cover installation device and a constant load pressure sealing device. Fixing and positioning; the end cover installation device is installed and fixed by setting the bearing plate, end cover hanger, pressing long bolts, etc. to assist the installation and fixing of the central shaft and the end cover, and the fixed load pressure sealing device is installed by setting the connecting plate, base frame and loading Compared with the prior art, the beneficial effect of the present invention is: the installation of the positioning tool facilitates the assembly of the valve, and the end cover installation device realizes the The quick installation of the cover and the central shaft protects the components in place during the installation process and avoids damage to the components. The constant-load pressurized sealing device conveniently and quickly completes the pressurized sealing between the sealing steel ball and the valve body, improving the sealing effect. , to improve the stability of components in use.

Owner:沈阳北方飞机维修有限公司

Method for producing fiber reinforced plastic pressure container

The invention provides a method for producing a fiber reinforced plastic pressure container, which comprises the following steps that: S1, a blowing needle is divided into a plurality of segments, and source nipples are respectively fixed on the uppermost blowing needle and the lowermost blowing needle; S2, the segmented blowing needles are connected into a whole and fixed under a liner molding material extruding outlet, and a blow molding machine extrudes a liner material to a position where the liner material completely covers the blowing needle; S3, a mold is matched, high-pressure air is input from the lower part of the blowing needle for pressure maintaining after the mold is matched so as to make a liner completed formed; and S4, the mold is opened and the blowing needle is screwed out. The pressure container produced by the method has the integral liner, has the same pressure-bearing and sealing properties as a pressure container with a single-head source nipple, and high process productivity and product percent of pass, needs no subsequent processing, and can meet the requirement of mass production.

Owner:CANATURE HEALTH TECH GRP CO LTD

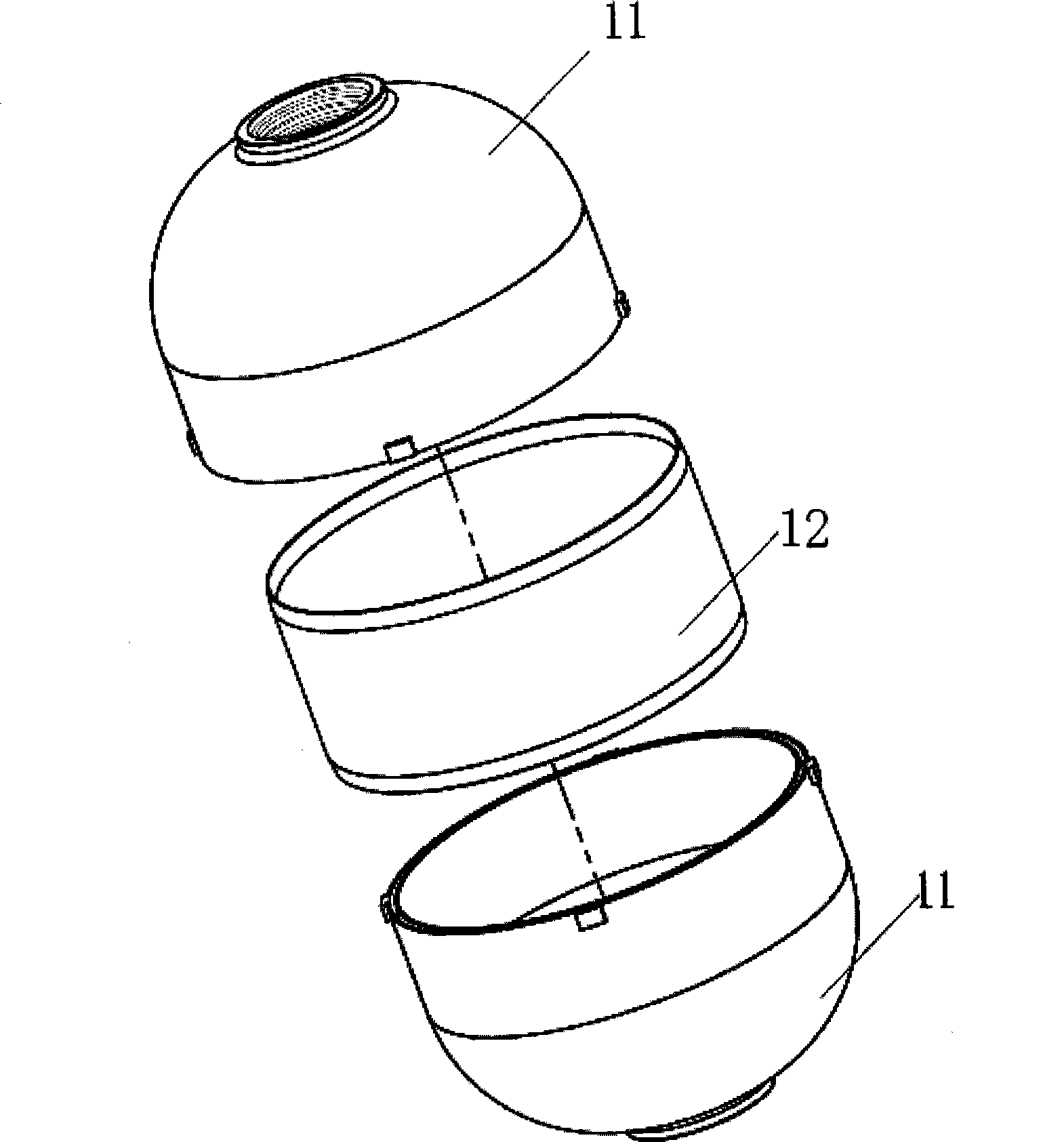

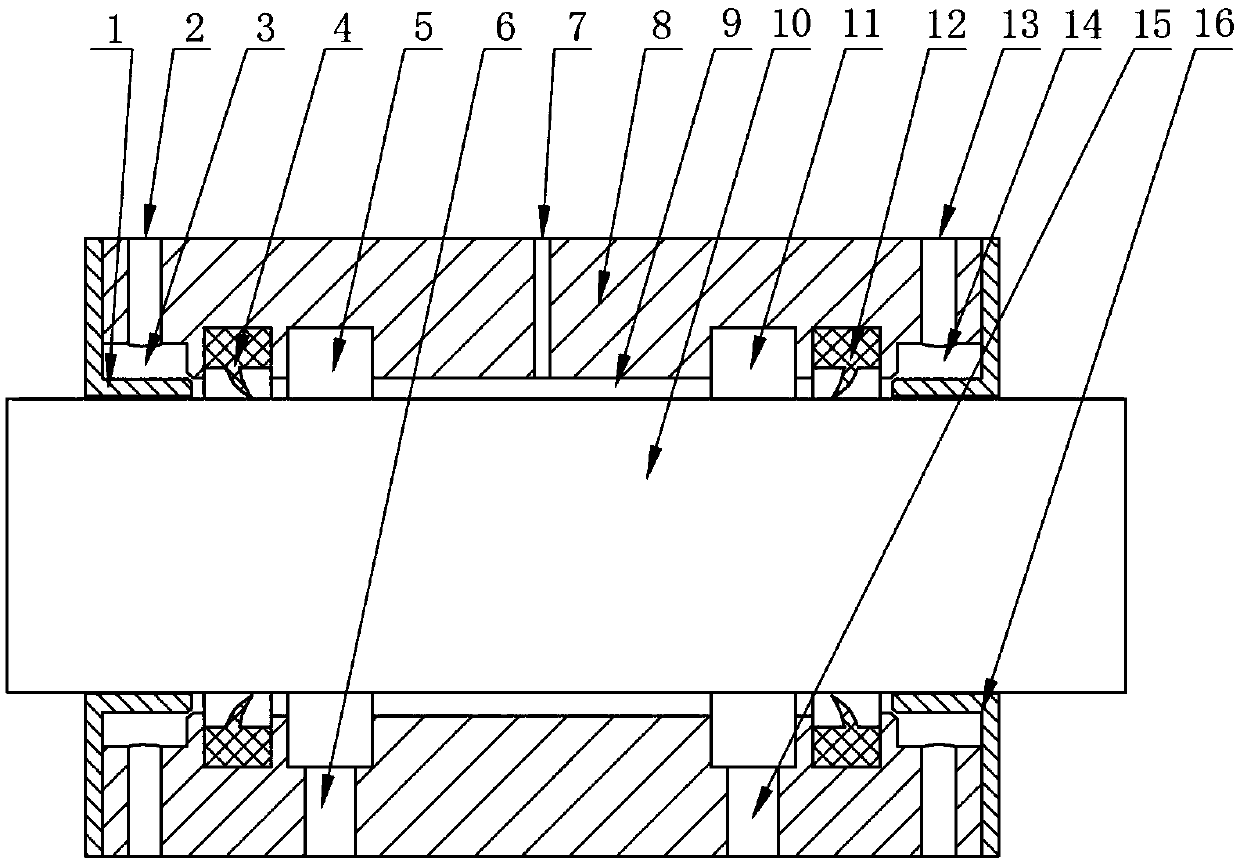

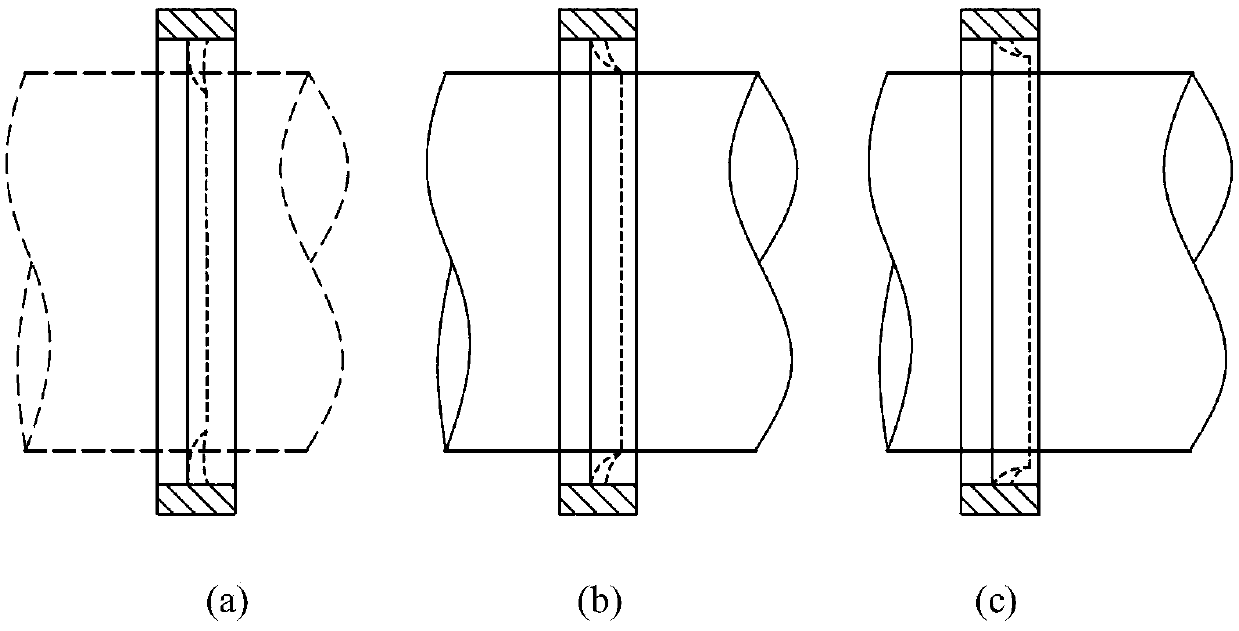

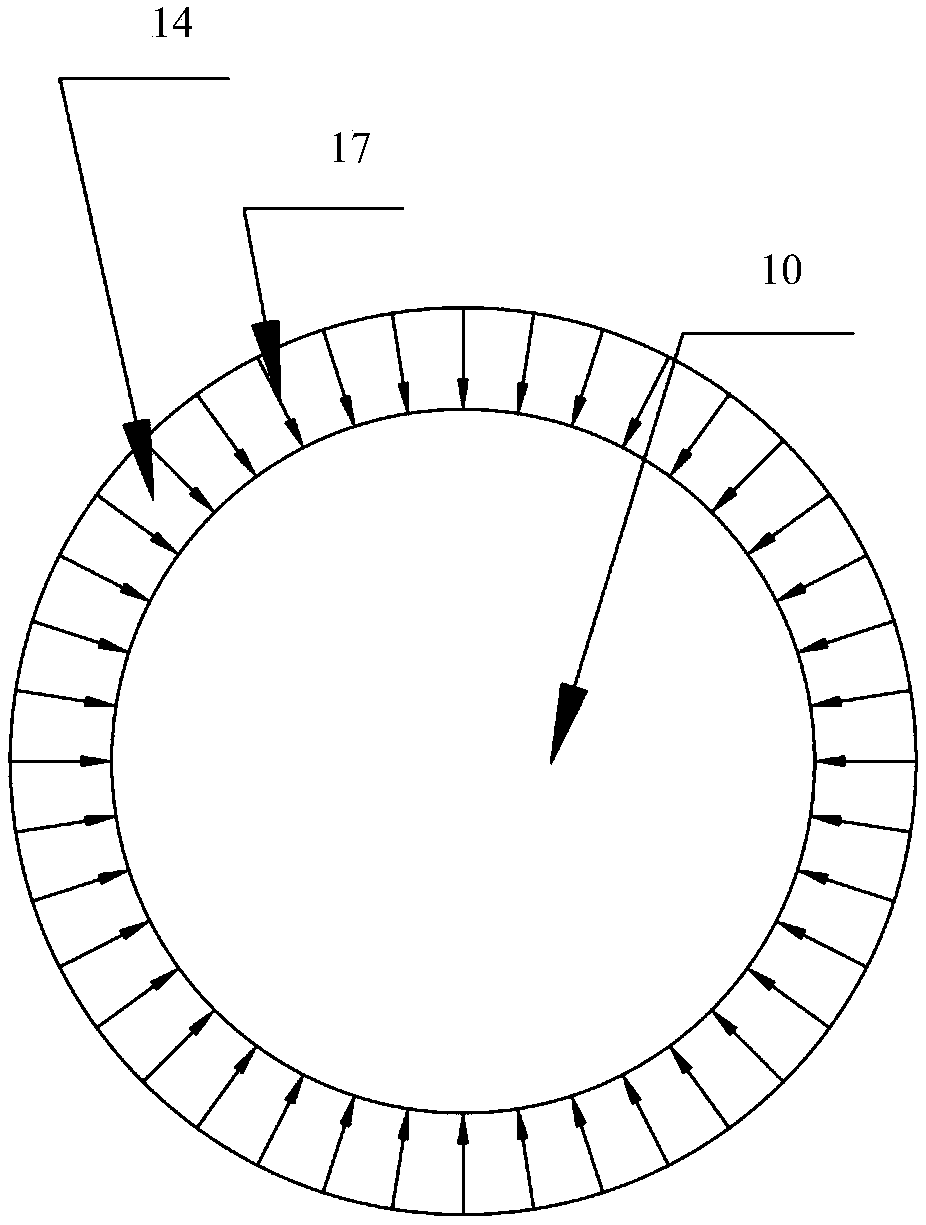

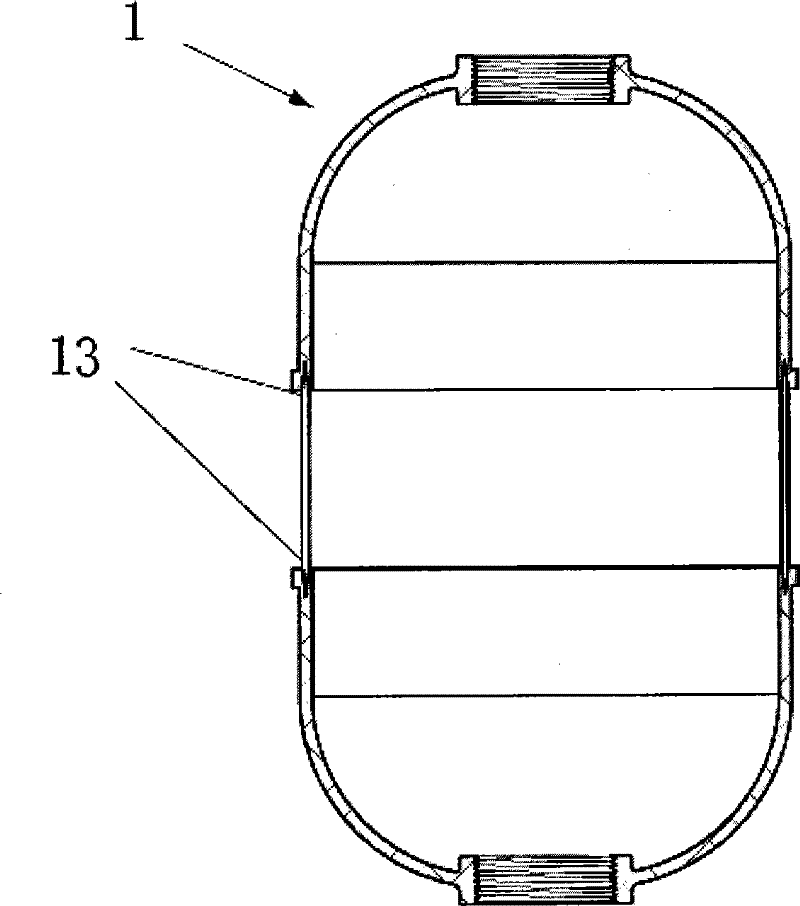

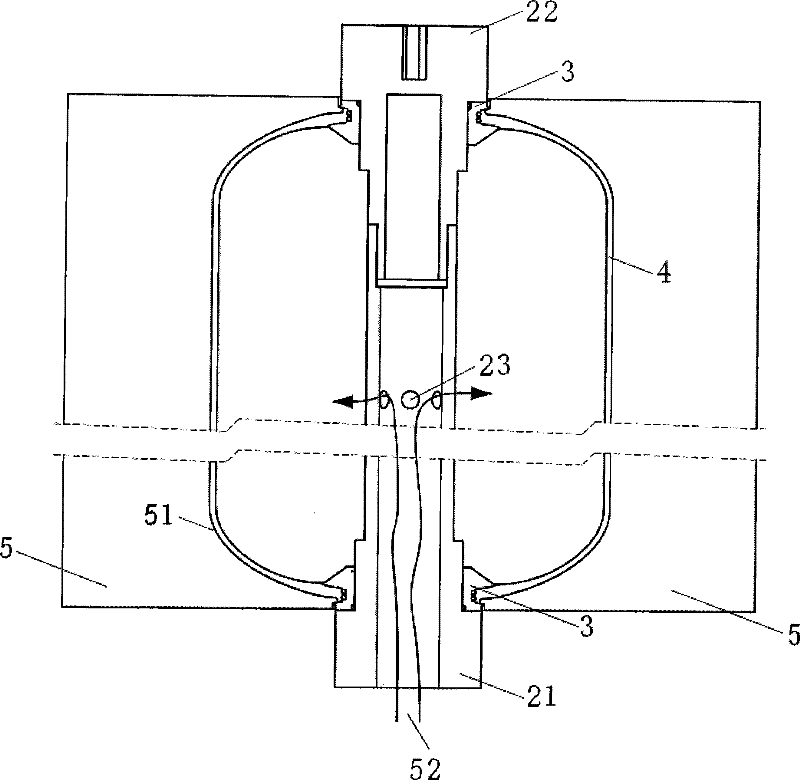

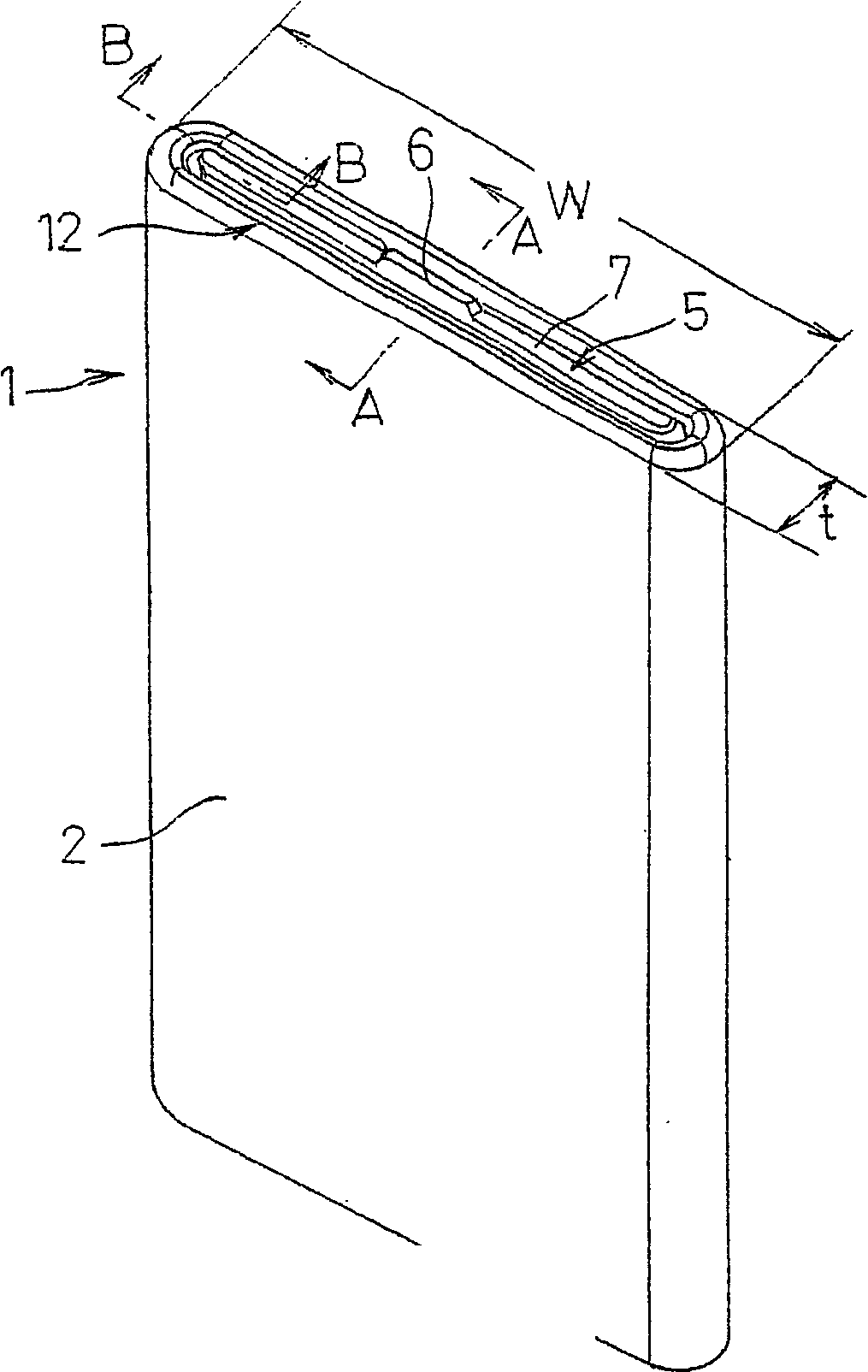

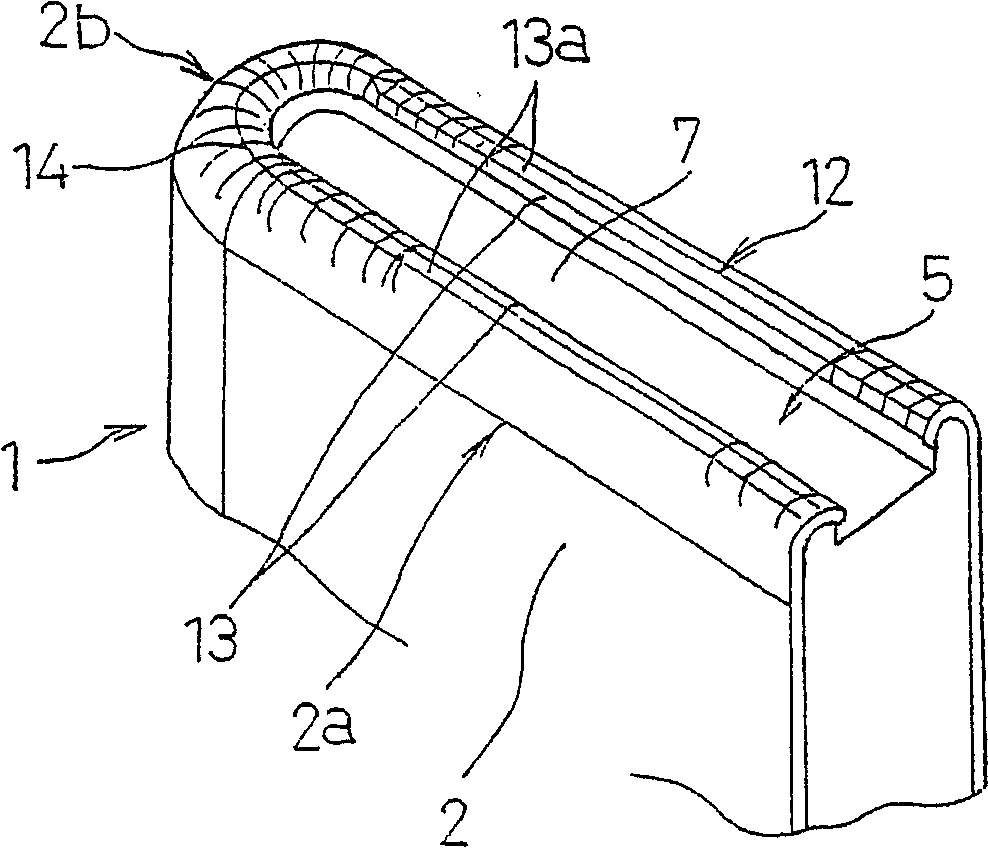

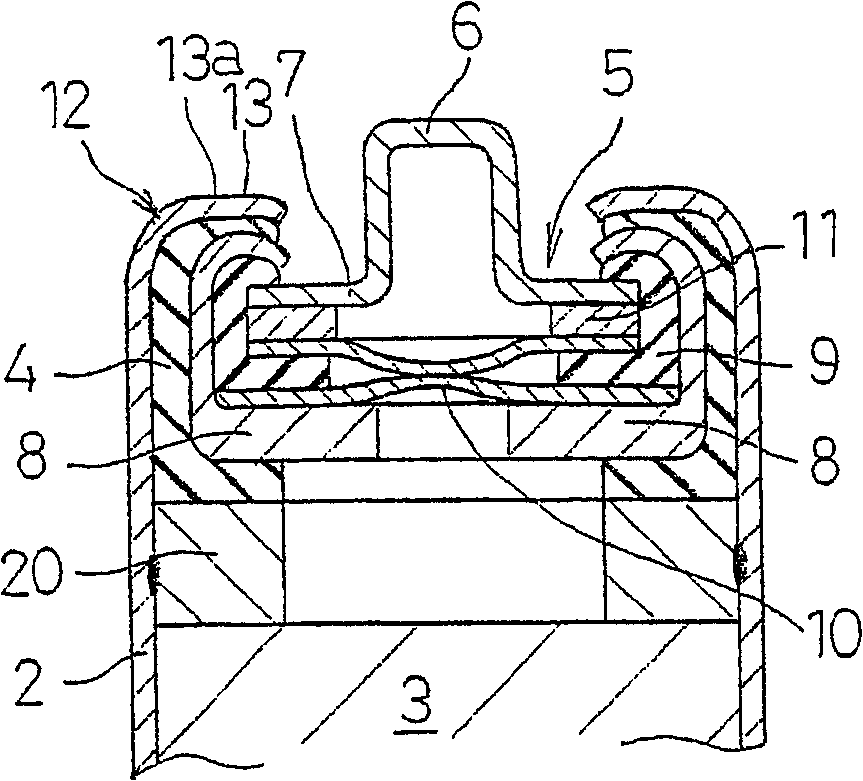

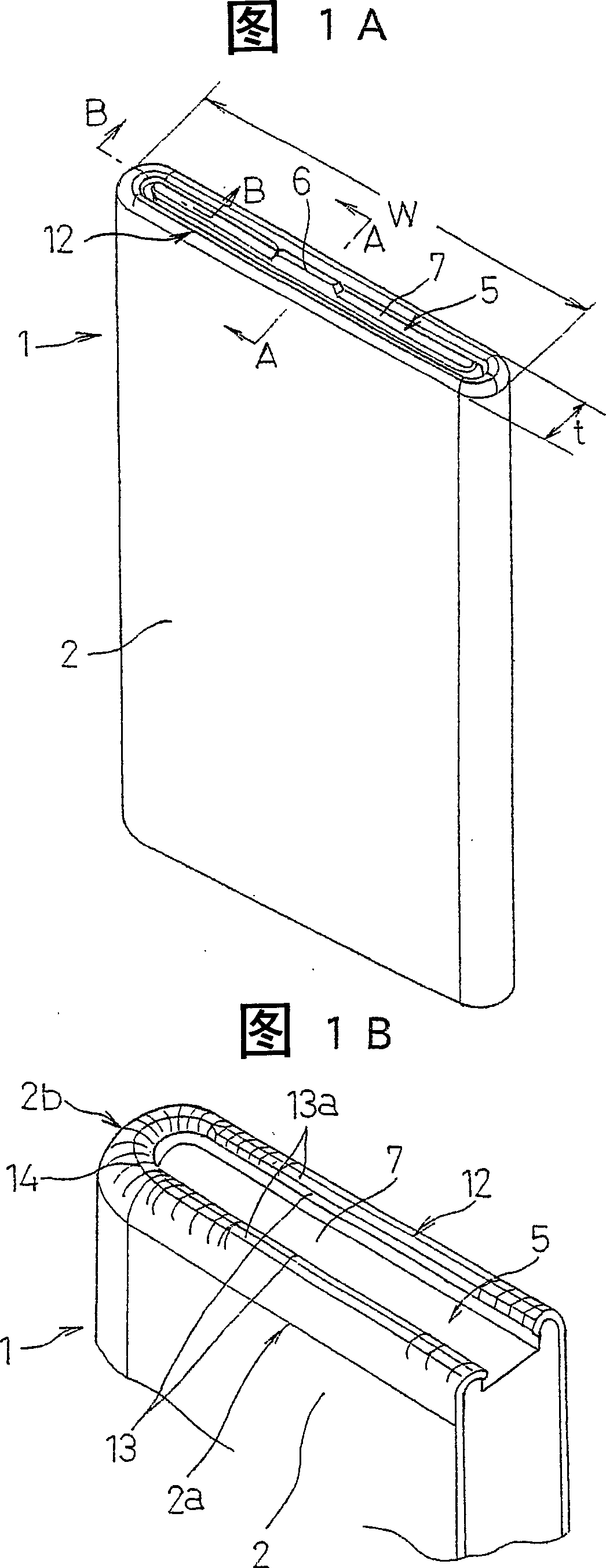

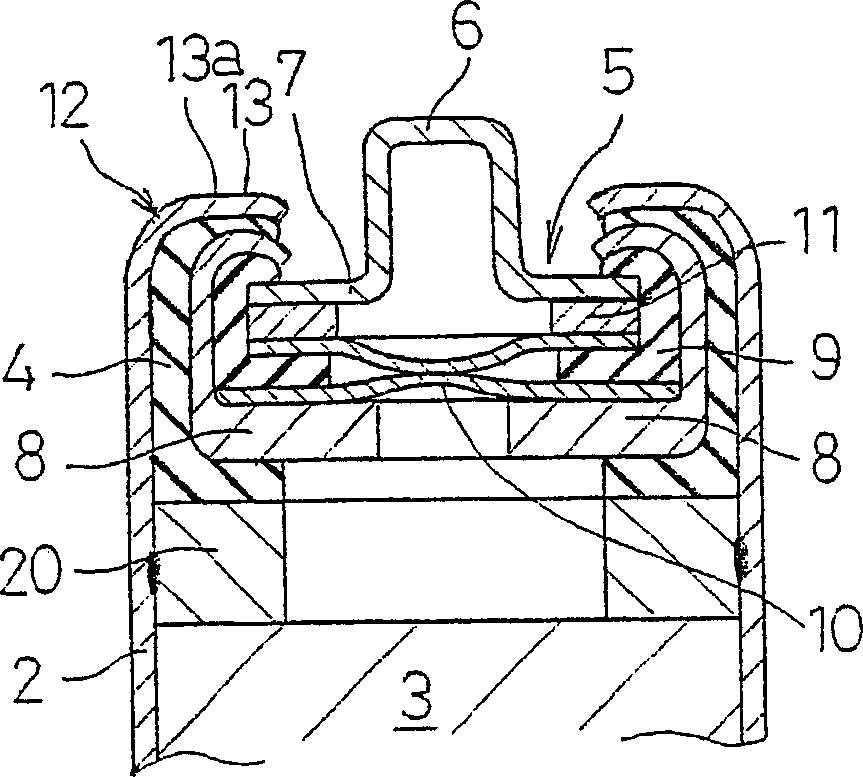

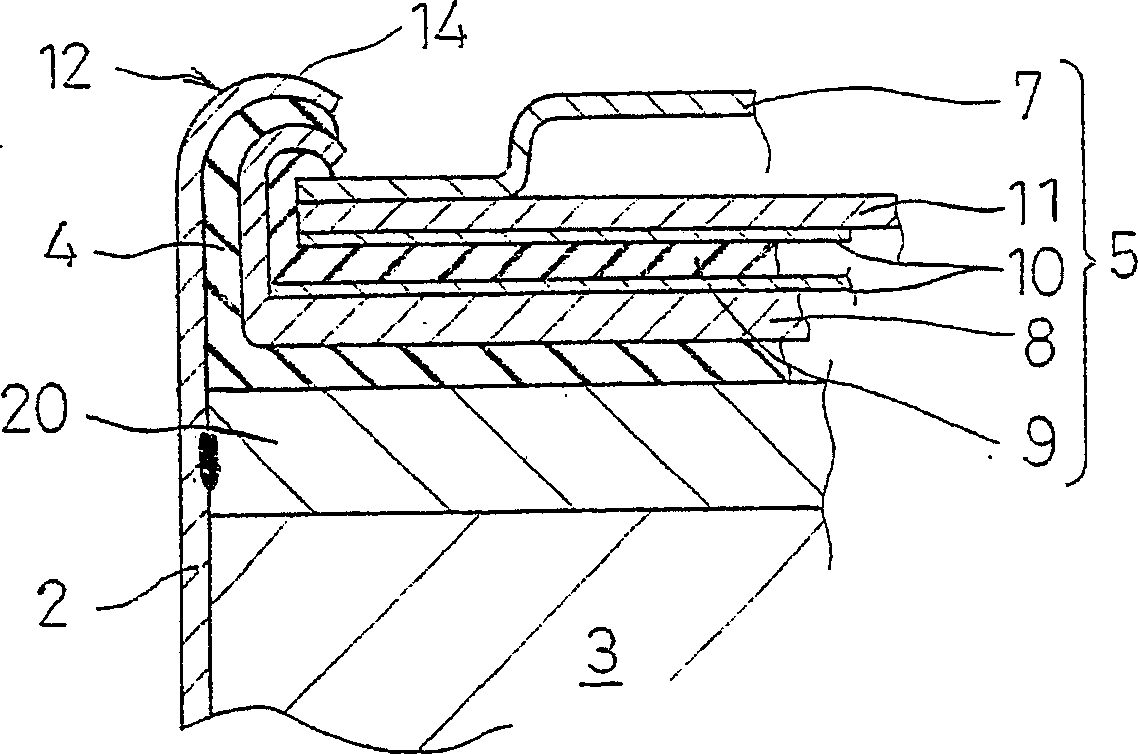

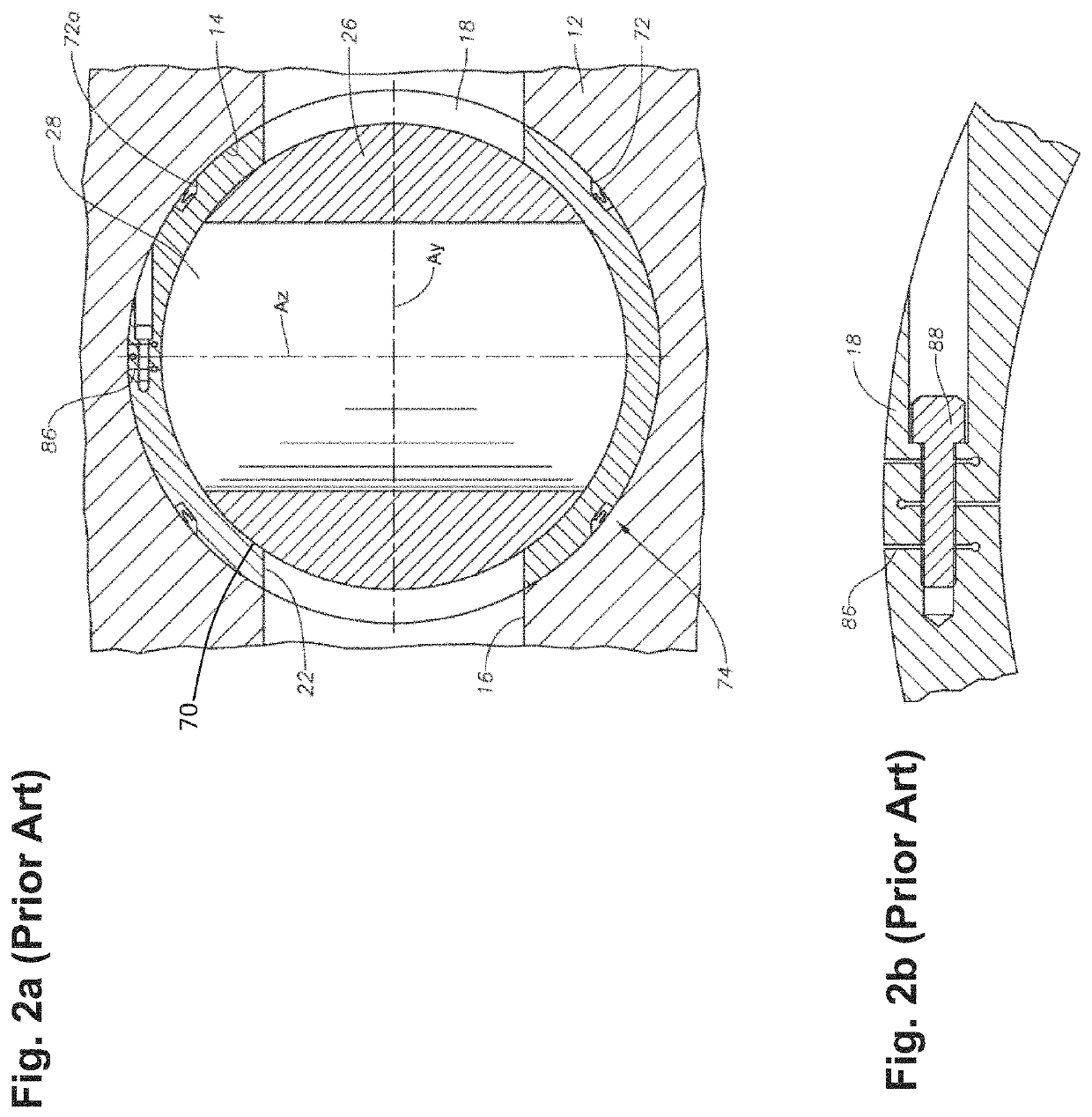

Battery and method of producing the same

InactiveCN100440581CUniform compressionImprove leak resistanceFinal product manufactureSmall-sized cells cases/jacketsElectromotive forceGasket

A battery manufacturing method including a step of accommodating elements for electromotive force (3) in a battery case (2) having an oval cross section, a step of placing a sealing member (5) on an open end of the battery case (2) with a gasket interposed therebetween, and a step of sealing the battery by inwardly crimping the open end of the battery case (2). In the sealing step, long side edges (2a) of the battery case (2) are crimped by a forming surface (17) having a rounded cross section, and arc-shaped edges (2b) connecting both long side edges are crimped by a flat forming surface (18). A battery having excellent safety properties with no risk of liquid leakage due to its uniform, airtight, and highly reliable seal around the entire circumference of the open end of the battery case (2) is thus provided.

Owner:PANASONIC CORP

Battery and method of producing the same

InactiveCN1757126AUniform compressionImprove leak resistanceFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectromotive force

A battery manufacturing method including a step of accommodating elements for electromotive force (3) in a battery case (2) having an oval cross section, a step of placing a sealing member (5) on an open end of the battery case (2) with a gasket interposed therebetween, and a step of sealing the battery by inwardly crimping the open end of the battery case (2). In the sealing step, long side edges (2a) of the battery case (2) are crimped by a forming surface (17) having a rounded cross section, and arc-shaped edges (2b) connecting both long side edges are crimped by a flat forming surface (18). A battery having excellent safety properties with no risk of liquid leakage due to its uniform, airtight, and highly reliable seal around the entire circumference of the open end of the battery case (2) is thus provided.

Owner:PANASONIC CORP

Shaft seal structure for automobile

The invention discloses a shaft seal structure for an automobile. The shaft seal device comprises a rotation shaft, a left sealing barrel, a right sealing barrel, a middle sealing barrel, a sealing barrel, a first spring, a second spring, a third spring, a fourth spring, a first fixing bolt, a second fixing bolt and nuts. According to the shaft seal structure, it can be guaranteed that the sealingforce between the sealing barrels on the two sides of the rotation shaft and the rotation shaft is the same, and sealing barrel abrasion due to rotation shaft jumping is avoided. The nuts are used for avoiding large-range sliding of the middle sealing barrel. The first spring, the second spring, the third spring and the fourth spring are used for absorbing part of radial force generated during rotation shaft jumping, and the service life of the sealing barrel is further prolonged. The third spring and the fourth spring can play an anti-loosening role on the nuts. Annular grooves are formed inthe inner surface of the sealing barrel and used for providing the compression allowance when the sealing barrel is compressed, and the sealing barrel is prevented from being pressed and broken.

Owner:重庆乐迪机车车辆配件有限公司

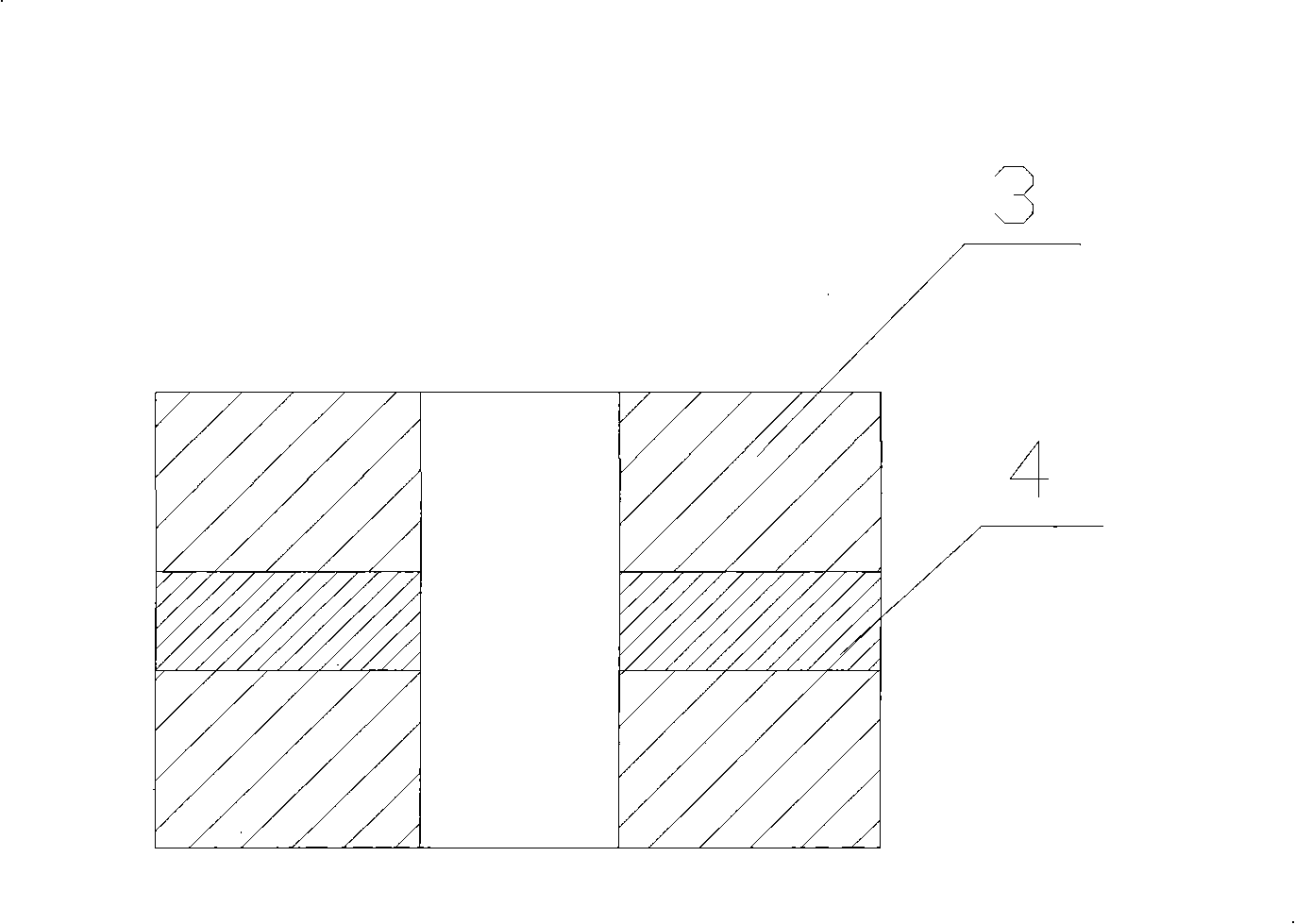

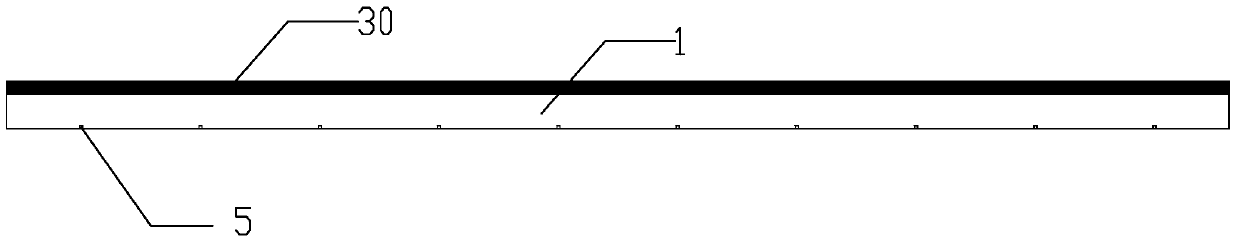

Parallel seam welding alloy cover plate for integrated circuit packaging and preparation method thereof

ActiveCN105529311BNo need to increase welding currentSame sealing effectSemiconductor/solid-state device detailsSolid-state devicesResistAlloy

The invention relates to a parallel seam welded alloy cover plate for integrated circuit packaging and a preparation method thereof, comprising an alloy cover plate body, characterized in that: the outer surfaces of the front and side surfaces of the alloy cover plate body are respectively formed with a first electroplated nickel layer and For the second electroplating nickel layer, an electroless nickel plating layer is formed on the reverse outer surface of the alloy cover body. The preparation method of the parallel seam welded alloy cover plate for integrated circuit packaging includes the following steps: coating the first resist coating on the front side of the alloy cover plate; electroless nickel plating on the reverse side of the alloy cover plate to form an electroless plating Nickel layer; remove the first resist coating; coat the second resist coating on the surface of the electroless nickel plating layer; cut the alloy cover plate into a single alloy cover plate; form the first plate on the front and side of the single alloy cover plate An electroplating nickel layer and a second electroplating nickel layer; removing the second resist coating on the surface of the electroless nickel plating layer. The invention satisfies the high reliability requirement of packaging devices by adopting parallel seam welding and sealing technology through different coating structures on the front and back sides.

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS

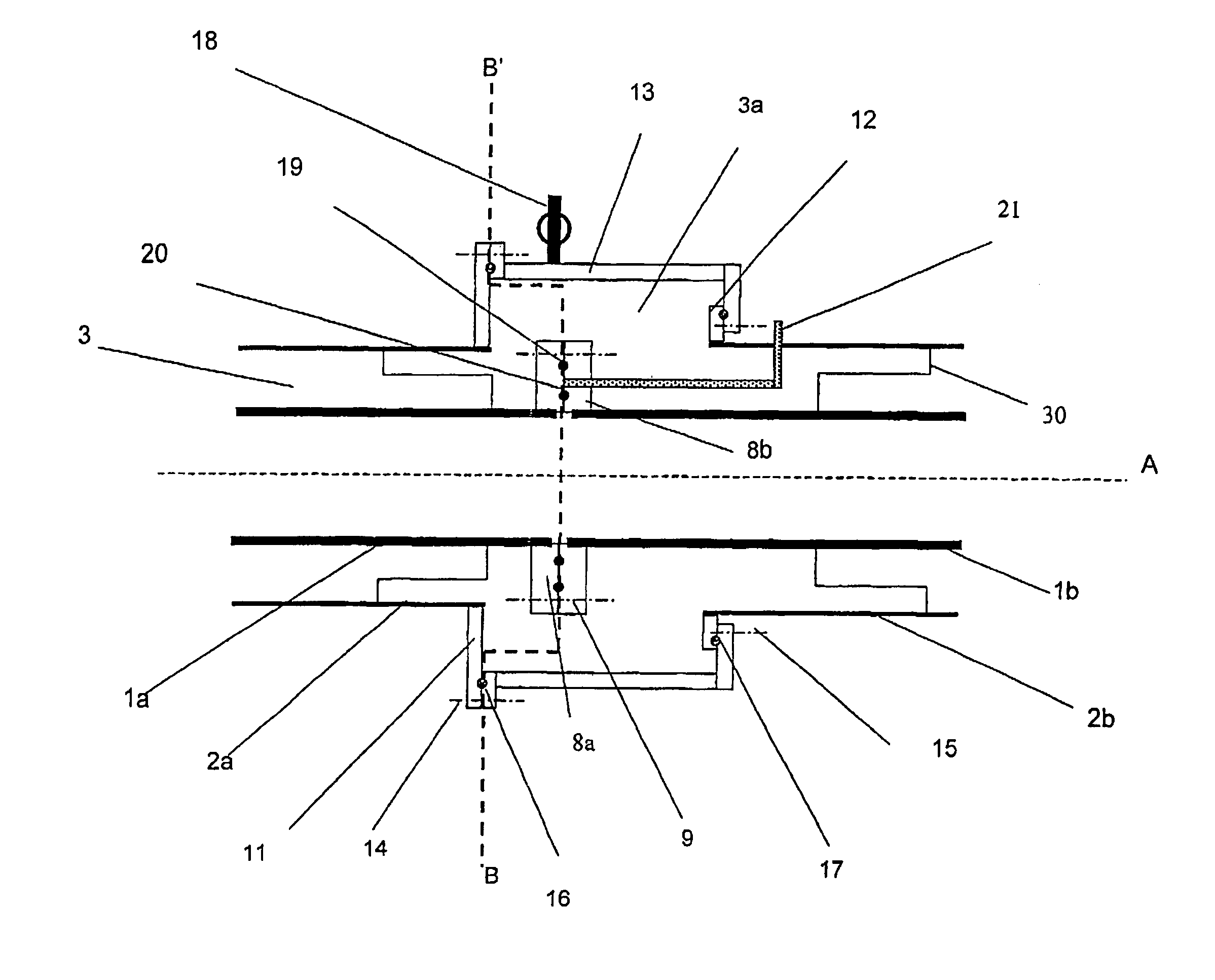

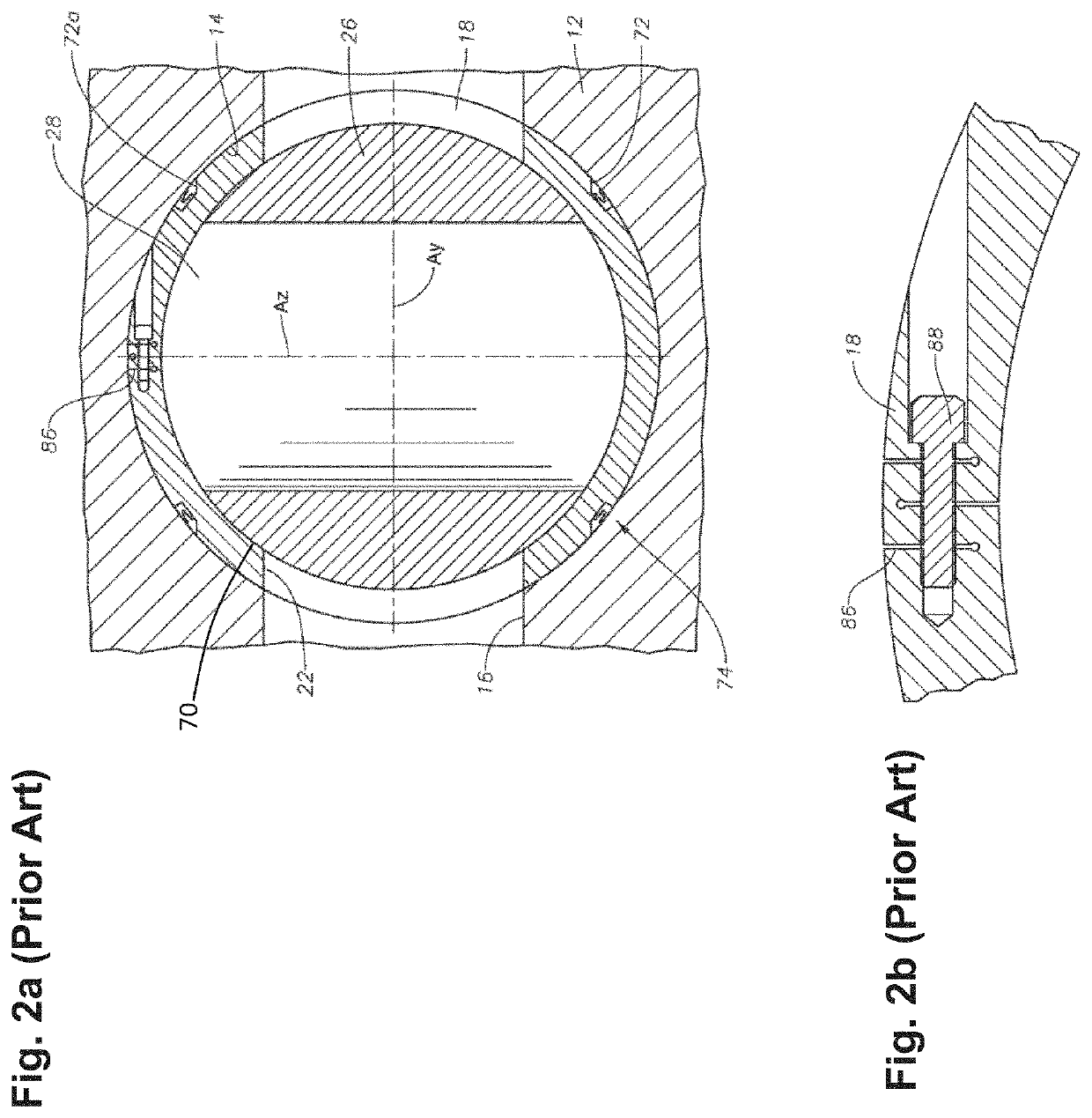

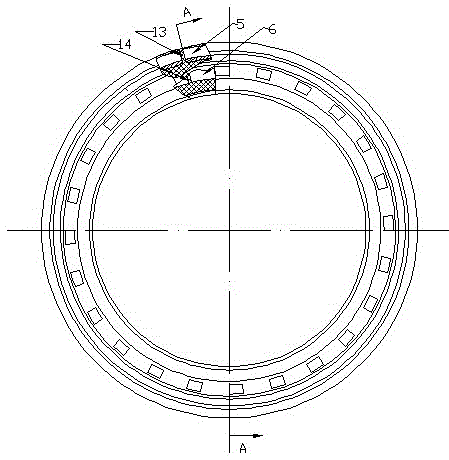

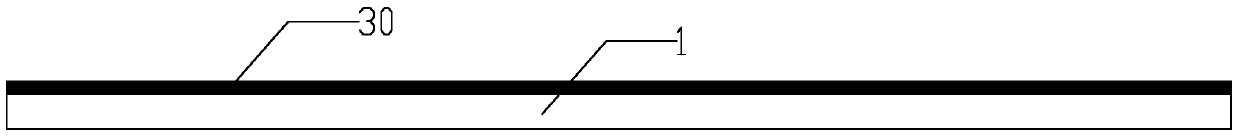

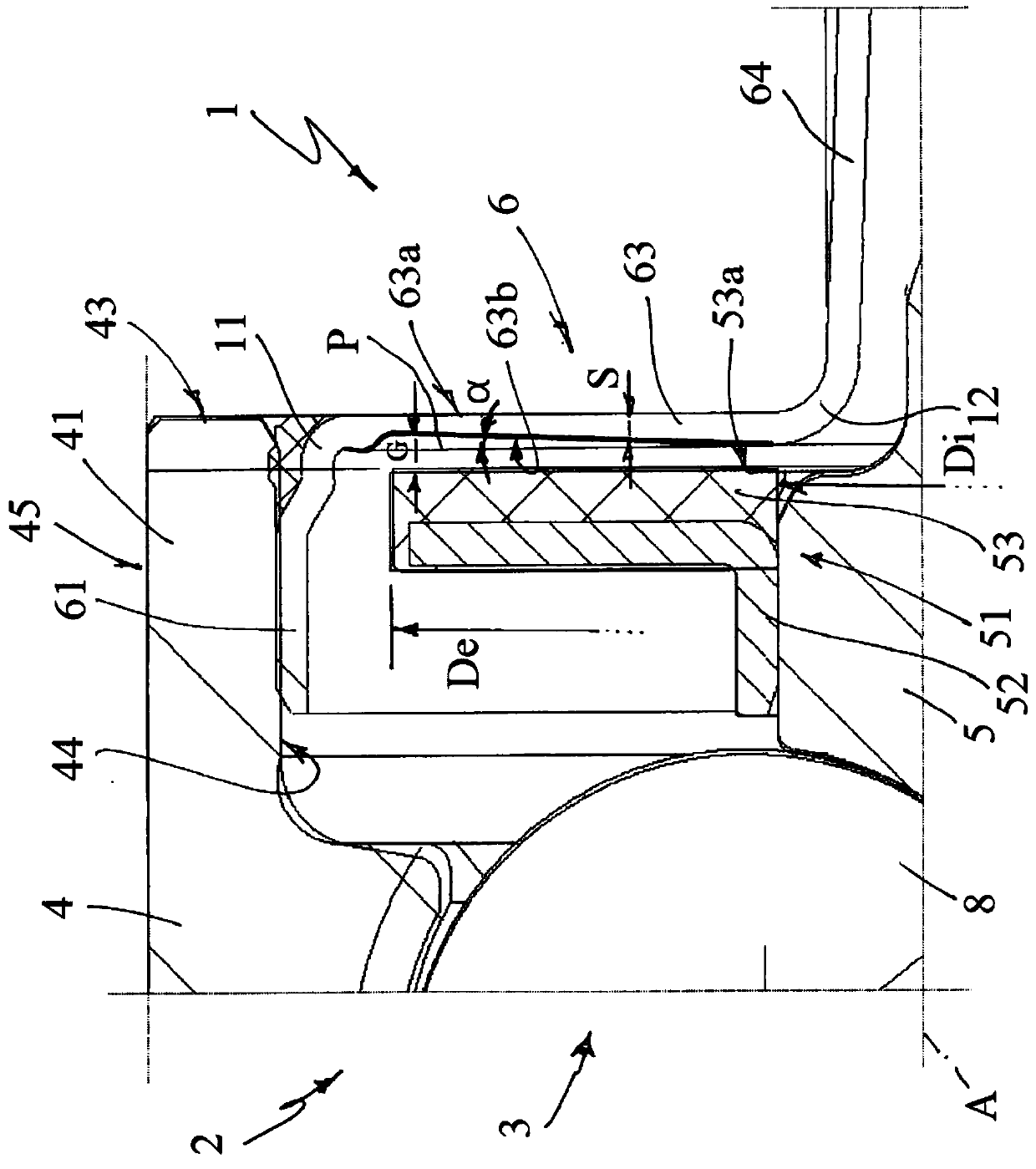

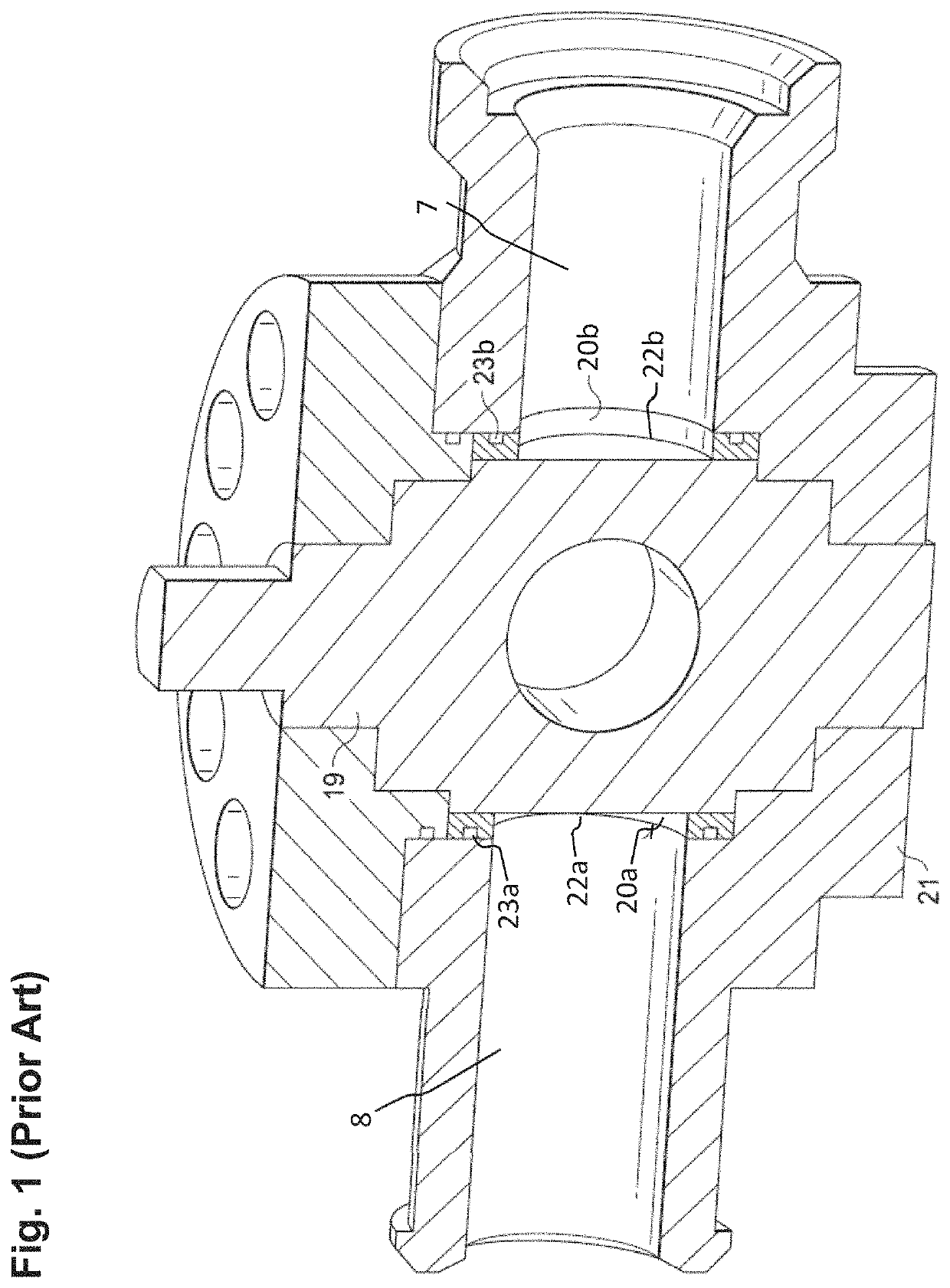

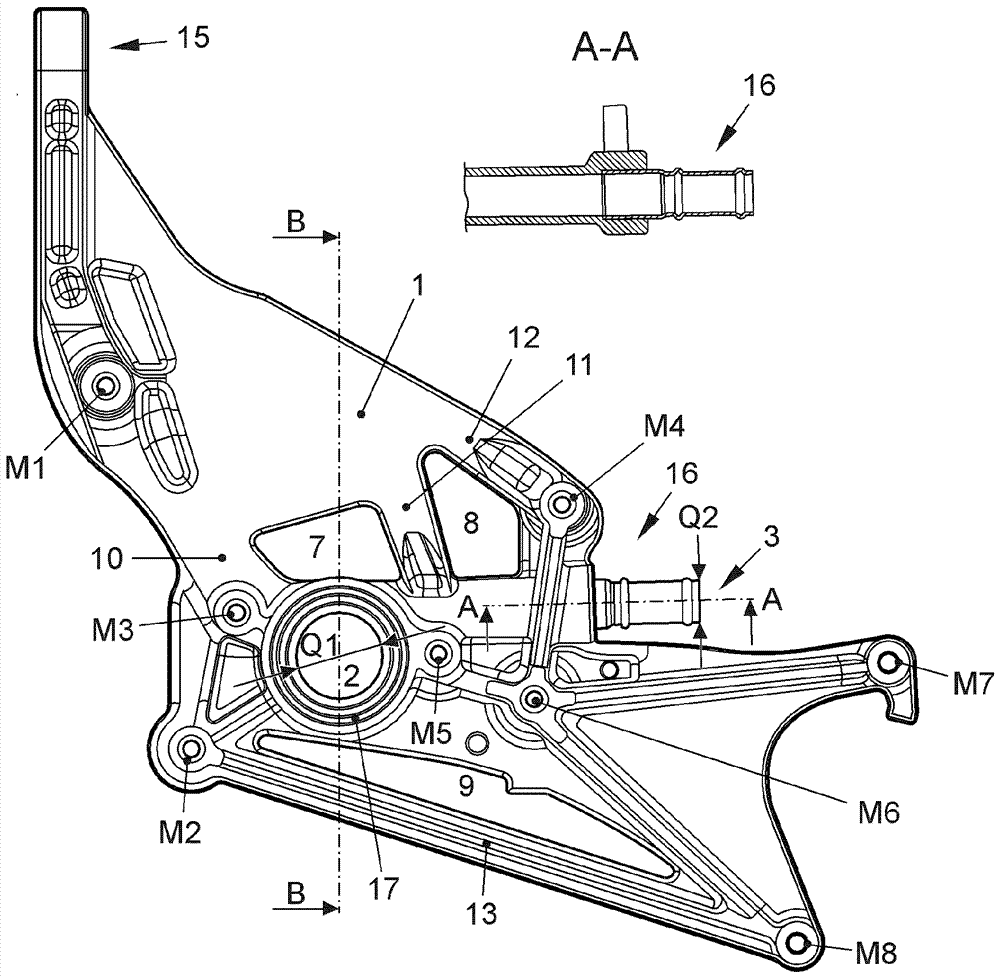

Sealing device for a wheel-hub unit and wheel-hub unit equipped with such a sealing device

A sealing device (1) for a wheel-hub unit (1) provided with a rolling bearing (3) and having a central axis (A) is provided with a shielding member (6) joined together with an outer ring (4) of the bearing so as to sealingly isolate the bearing, and then is equipped with a cylindrical mounting wall (61) coaxial with the central axis and engaged with a collar (41) of an outer ring of the bearing, and an annular reading wall (63), arranged transversely with respect to the axis (A), connected to the cylindrical wall (61) and facing a phonic wheel (51) mounted inside the bearing. The thickness (S)of the annular reading wall (63) can be variable radially depending on an angle (alpha) of oscillation of the phonic wheel between an undeformed position of the annular front surface (53a) of the phonic wheel equidistant from the plane P perpendicular to the axis (A) and a possible deflection position of the annular front surface (53a), which may be arranged to be equidistant from the annular reading wall but not in contact with the annular reading wall, of the phonic wheel.

Owner:AB SKF

Rotary sealing device

PendingCN113669450AImprove practicalityImprove installation efficiencyEngine sealsElectrical apparatusEngineeringMechanical engineering

The invention discloses a rotary sealing device which comprises a base. A rotating body is arranged at one end of the inner side of the base, a rotating piece and a fixing piece are arranged at the inner side of the rotating body, the rotating piece and the fixing piece are connected in a rotating manner, elastic rubber is arranged at one side of the rotating piece and one side of the fixing piece, and the elastic rubber is of an annular structure; and the elastic rubber is arranged in the inner side of the rotating body. According to the rotary sealing device, sealing is carried out in a screwing and extruding manner, sealing can be carried out within the deformation range of the elastic rubber and within the range that the internal diameter reaches zero, the sealing range is ultra-wide, and the sealing practicability is improved; when the device is used, the sealing structure can be pre-installed in advance, sealing can be carried out by screwing the rotating piece after a cable penetrates through the sealing structure, the installation time is saved, and the installing efficiency is improved; and meanwhile, the sealing structure is simple and convenient to install, later part replacement is facilitated, secondary construction is not needed, and the practicability of the device is improved.

Owner:南京赛弗尼电气有限公司

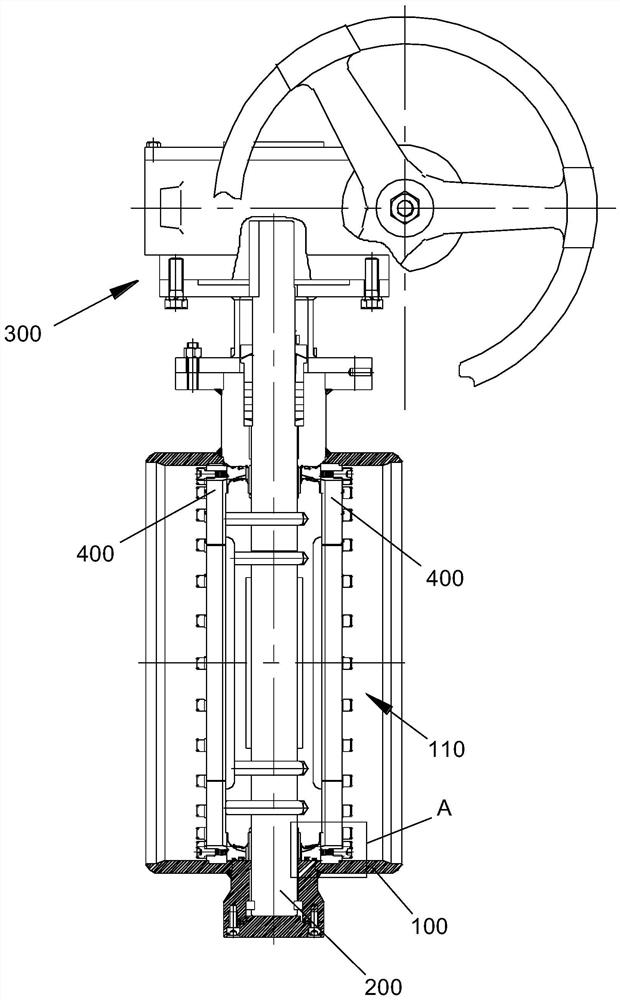

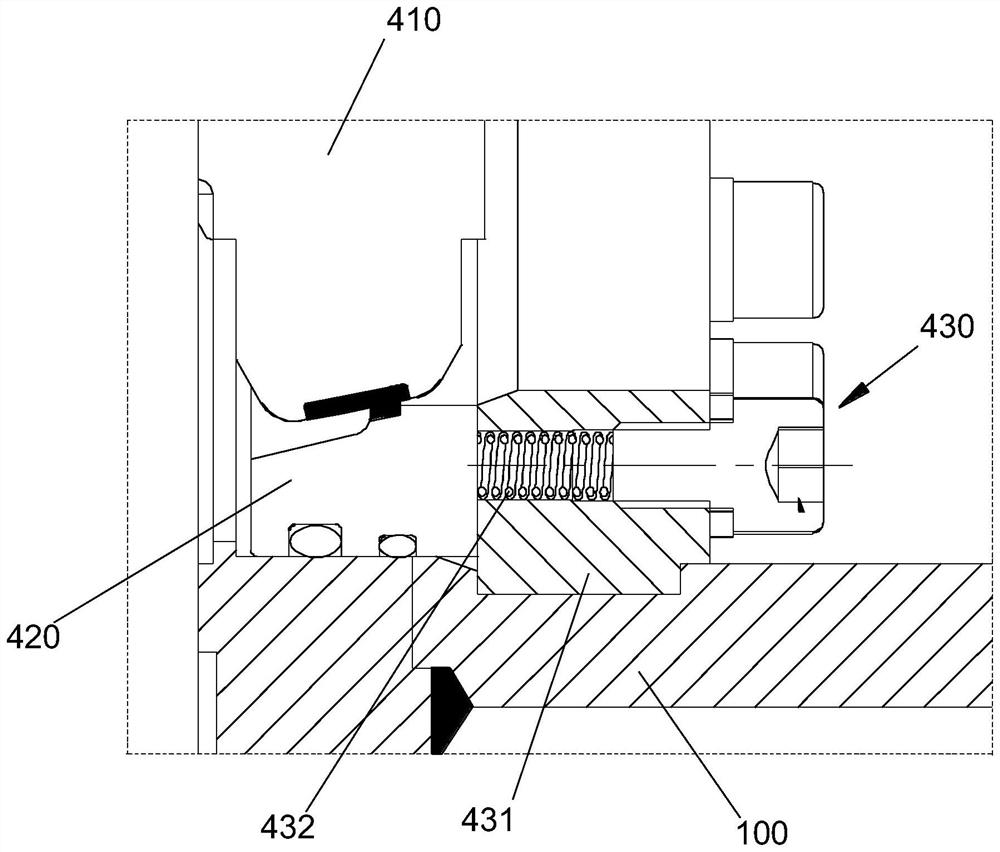

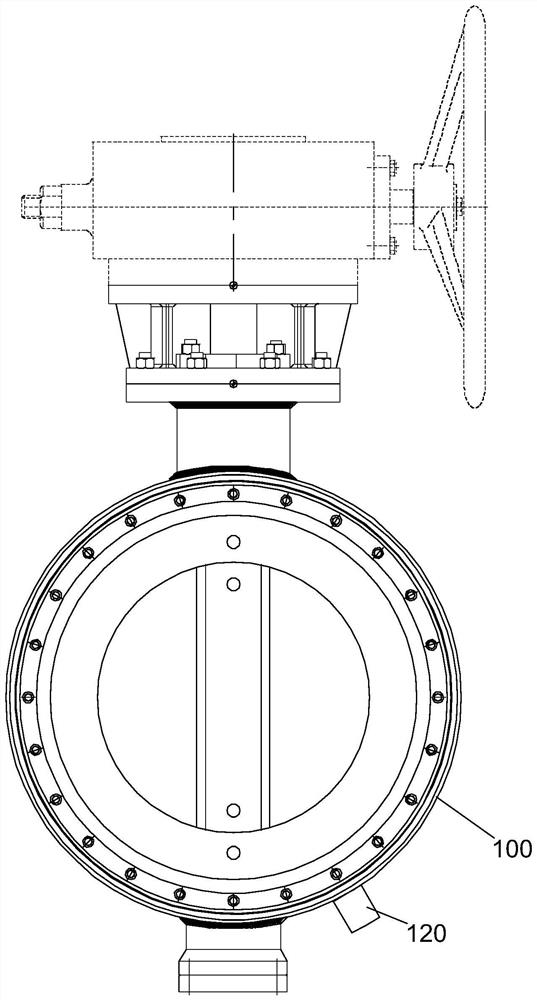

Single eccentric butterfly valve with double sealing pairs

PendingCN114526341ASame sealing effectImprove sealingInternal combustion piston enginesLift valveEngineeringButterfly valve

The invention provides a single eccentric butterfly valve with double sealing pairs, relates to the technical field of butterfly valves, and aims to solve the technical problem of poor sealing effect of the butterfly valve. The double-sealing-pair single-eccentric butterfly valve comprises a valve body, a valve rod and an executing mechanism, a valve cavity is formed in the valve body, the executing mechanism is arranged on the valve body, the power input end of the valve rod is connected with the output end of the executing mechanism, and the power output end of the valve rod extends into the valve cavity. The double-sealing-pair single eccentric butterfly valve further comprises two sets of sealing mechanisms which are arranged on the two opposite sides of the valve rod respectively, and each sealing mechanism comprises a butterfly plate, a valve seat and a limiting assembly. The butterfly plate is fixedly connected with the valve rod, the valve seat is arranged in the valve cavity in a sliding mode, the limiting assembly comprises a baffle ring and an elastic piece, the baffle ring is fixedly arranged on the inner wall of the valve cavity and located on the side, away from the valve rod, of the valve seat, and the elastic piece abuts against the baffle ring and the valve. The single eccentric butterfly valve with the double sealing pairs has a good sealing effect.

Owner:ZHONGHONG VALVE CO LTD

Tool assembly for assembly of manual-selected valve

ActiveCN113478428AEasy to assembleQuick installationWork holdersMetal-working hand toolsSteel ballMechanical engineering

The invention discloses a tool assembly for assembly of a manual-selected valve. The tool assembly comprises a positioning tool, an end cover mounting device and a constant-load pressurizing sealing device, the positioning tool fixes and positions the manual-selected valve by arranging a base, a bracket connecting sleeve, a pressing sleeve and the like; and the end cover mounting device is provided with a bearing plate, an end cover hanging frame, a long pressing bolt and the like to assist in mounting and fixing of a center shaft and an end cover, and the constant-load pressurizing sealing device is provided with a connecting plate, a base frame, a loading bolt and the like to achieve pressurization between a valve body and a sealing steel ball so as to improve the sealing performance. Compared with the prior art, the tool assembly has the beneficial effects that the valve is conveniently assembled through the arrangement of the positioning tool, the end cover and the center shaft are rapidly installed through the end cover mounting device, parts are protected in place in the mounting process, damage to the parts is avoided, pressurization sealing between the sealing steel ball and the valve body is conveniently and rapidly completed through the constant-load pressurizing sealing device, the sealing effect is improved, and the use stability of the parts is improved.

Owner:沈阳北方飞机维修有限公司

Flexing slot for plug valve insert

ActiveUS10890264B2Preferential deflectionImprove sealing propertiesPlug valvesMechanical engineeringPhysics

An insert adapted for use in a plug valve includes a single-piece body having an inner sidewall adapted to interface with a sidewall of a valve plug. First and second opposing apertures are each defined through the single-piece body for selective alignment with a flow bore of the valve plug. First and second opposing slots are each defined through the single-piece body at an angle to the first and second opposing apertures for allowing the body to flex in the direction of the first and second opposing apertures.

Owner:BLUECORE COMPLETIONS LLC

Functional modules for engines

ActiveCN104343582BSimple and compact constructionEffective guidanceCasingsExhaust gas recirculationEngineeringCooling medium

The invention relates to a functional module for an engine, wherein the functional module has a coolant inlet and a coolant outlet. It is known that multi-functional modules are very complex and configured as a link between the engine and a structure unit. The object of the invention is to realize a space-saving connection between the motor and a structural element. The functional module for the engine comprises the coolant inlet and the coolant outlet, and characterized by the fact that on one hand, the functional module can be connected with an engine housing, on the other hand, the functional module can be connected with the structural element, wherein the functional module forms a support function for the structural element and a channel function for the coolant inlet and the coolant outlet, wherein the coolant inlet and the coolant outlet are not directly in operative connection with the structural element. The functional module is advantageous in that the module is simple and compact, and the structural element can be arranged at the functional module and is not directly in operative connection with the functional module.

Owner:VOLKSWAGEN AG

Automobile rotation shaft movable sealing device

The invention discloses an automobile rotation shaft movable sealing device. The automobile rotation shaft movable sealing device comprises a rotation shaft, a left sealing barrel, a right sealing barrel, a middle sealing barrel, sealing filler, a first spring, a second spring, a first fixing bolt, a second fixing bolt and nuts. When the rotation shaft jumps, the rotation shaft exerts larger forceto the sealing filler on one side of the rotation shaft, the sealing filler conducts force to the middle sealing barrel at the time, and the middle sealing barrel overcomes the elastic force of the first spring and the second spring to slightly slide in the radial direction of the rotation shaft. Accordingly, it is guaranteed that the same sealing force is formed between the sealing filler on thetwo sides of the rotation shaft and the rotation shaft, and abrasion of the sealing filler due to jumping of the rotation shaft is avoided. In the normal state, the first fixing bolt and the second fixing bolt do not make contact with the middle sealing barrel. The nuts are used for avoiding large-range sliding of the middle sealing barrel. The first spring and the second spring are used for absorbing part of radial force generated during rotation shaft jumping, and the service life of the sealing filler is further improved.

Owner:重庆乐迪机车车辆配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com