An active labyrinth seal structure

A labyrinth sealing and active technology, which is applied to the sealing of the engine, engine components, machines/engines, etc., can solve problems such as gas leakage, achieve the effect of enhancing the sealing effect and suppressing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

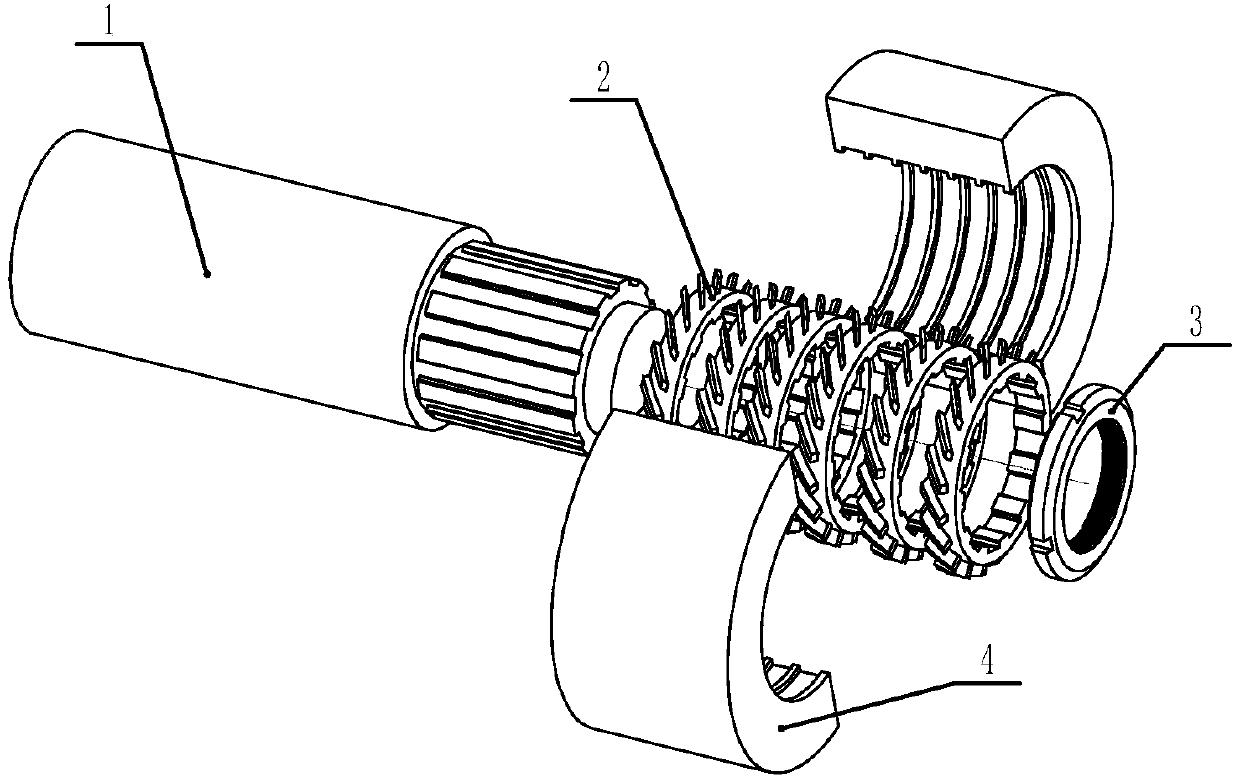

[0026] Such as figure 1 As shown, the present invention is an active labyrinth seal structure, including a rotor 1, a blade sealing ring 2, a semicircular sealing sheath 4, and a lock nut 3 at the shaft end. The blade seal ring 2 is fastened to the rotor 1 through a spline connection, and the number of blade seal rings is superimposed according to the need. The shaft end of the rotor 1 is fastened with a lock nut 3, and then two semicircular seal sheaths 4 are buckled on the blade seal. On the ring, the rectangular teeth on the sealing sheath 4 are used for crossing the blades. When the rotor 1 rotates, it drives the blade sealing ring to rotate, and the blades on the blade sealing ring 2 can form active directional airflow in the sealing channel.

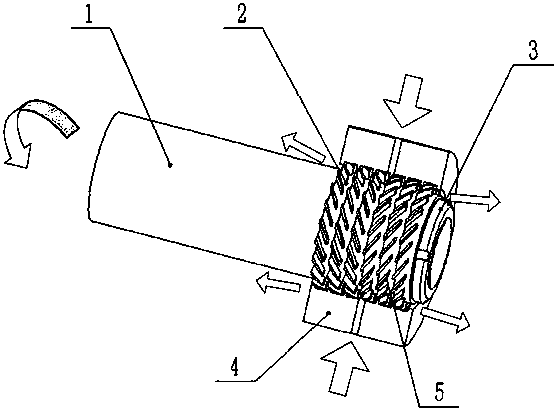

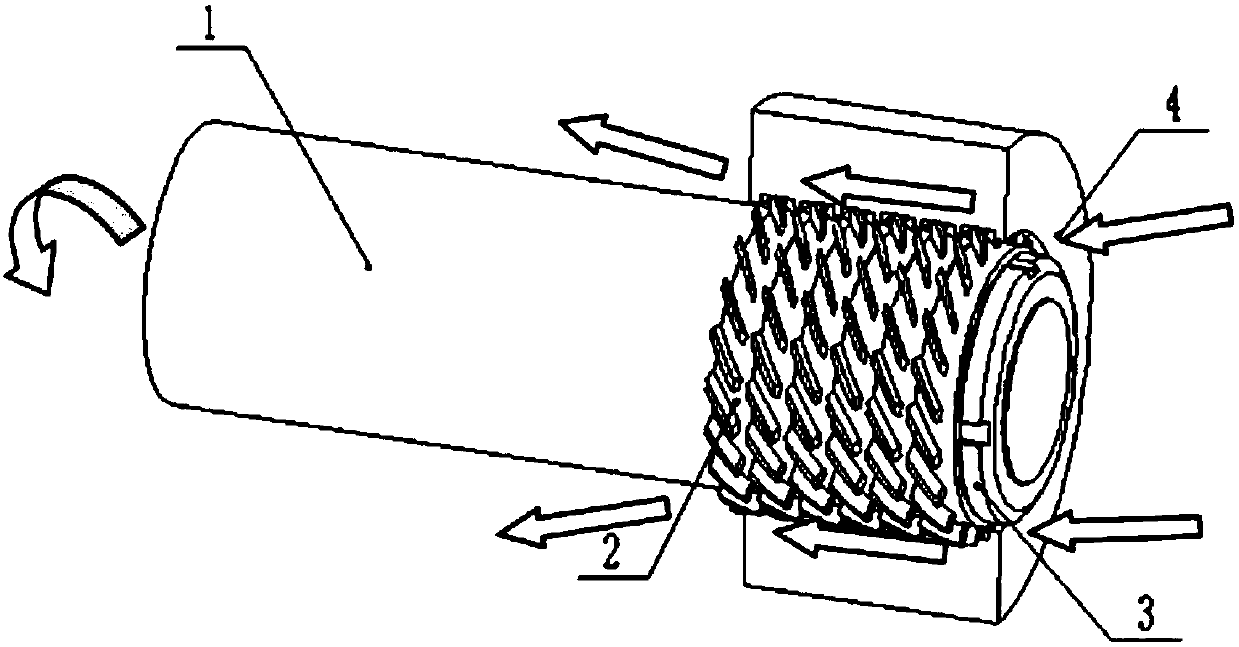

[0027] The left side of the seal is the high-pressure side, and the right side is the low-pressure side. Normally, the gas will flow from the high-pressure side to the low-pressure side, resulting in pressure loss on the high-press...

Embodiment 2

[0031] Such as Figure 4 , 5 As shown, the gas enters from the air inlet 41 on the sealing sheath 4, because the blade sealing ring 2 and the reverse blade sealing ring 5 have a separation effect on the gas entering the sealing gap, and the sealing effect is achieved. When the rotor rotates On the contrary, the positions of the vane sealing ring 2 and the reverse vane sealing ring 5 can be exchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com