Absorbent article and process for manufacturing the same

a technology of absorbent articles and manufacturing processes, applied in the field of absorbent articles, can solve the problems of reducing the cushioning property, affecting the soft feeling of skin, and affecting the effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

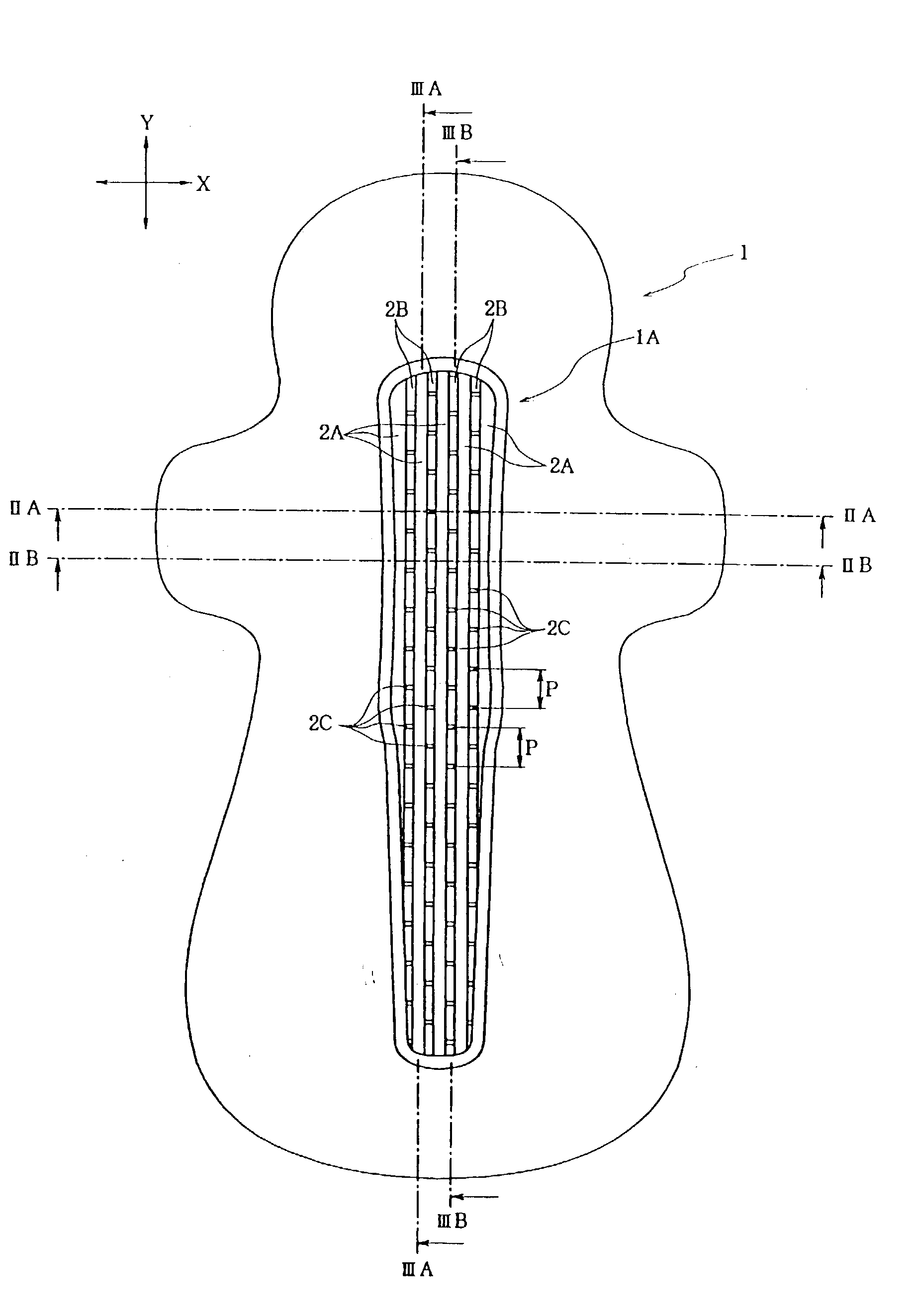

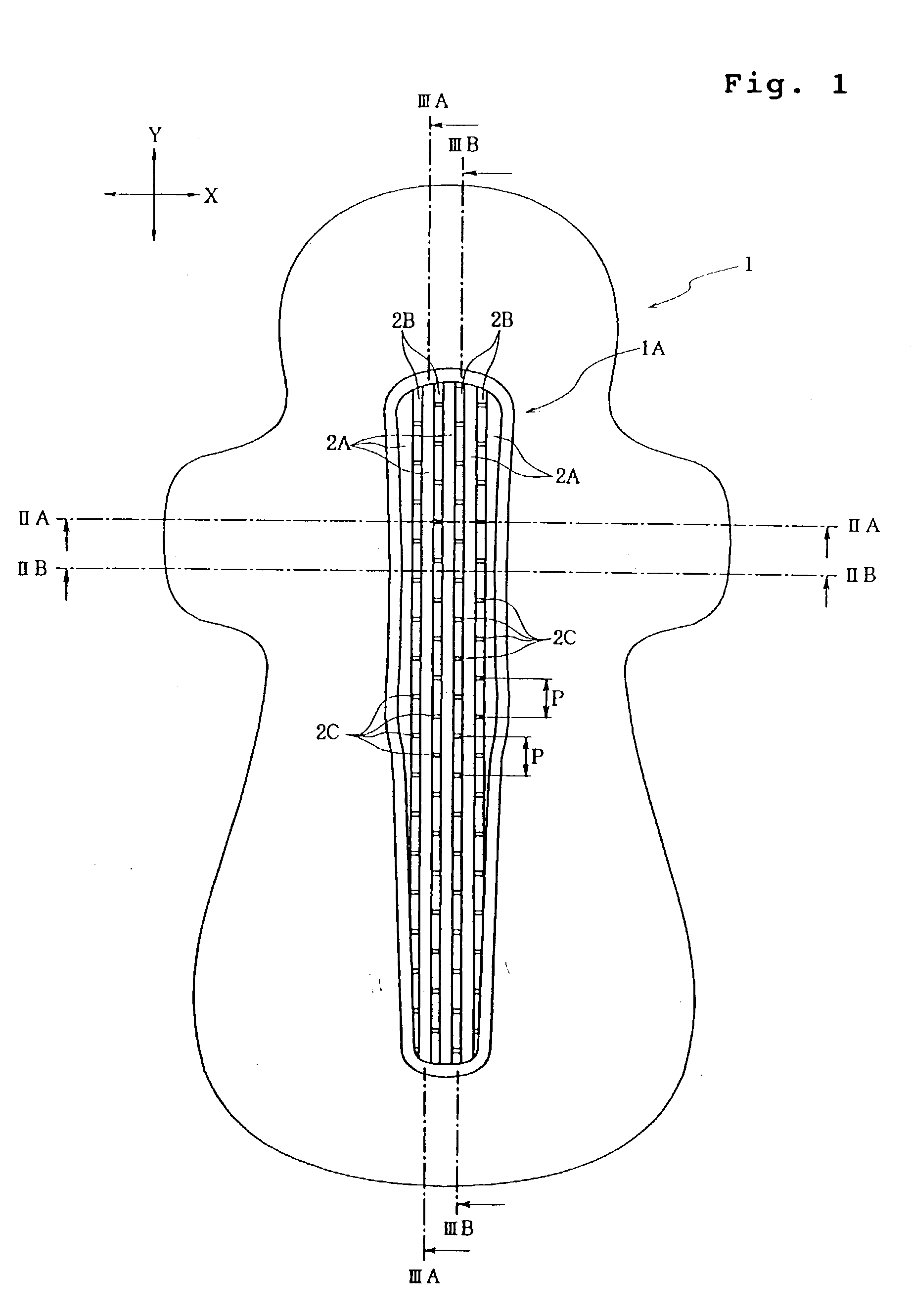

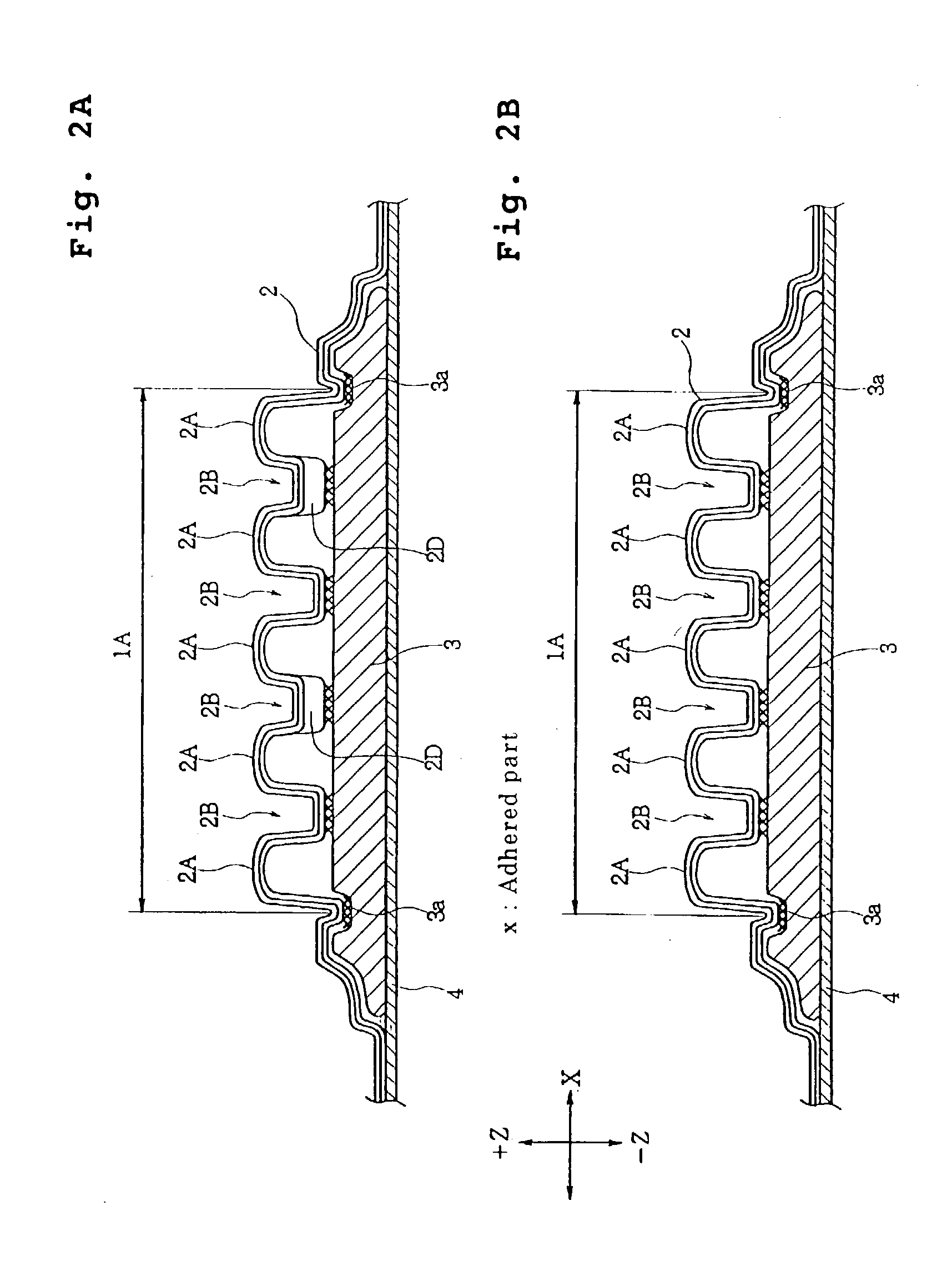

[0081] A sanitary napkin including a corrugated surface sheet (A) formed with connecting parts 2C and another sanitary napkin including a corrugated surface sheet (B) with no connecting part were prepared and subjected to evaluation tests. Details are described hereinbelow.

[0082] (Specification of a Compounded Sheet to be Used for Surface Sheets)

[0083] PE (polyethylene) / PET (polyethylene terephthalate) core-sheath type fibers having a fineness of 2.5 deniers and a fiber length of 51 mm were made into a sheet form by air-through method to prepare a nonwoven fabric having a basis weight of 30 g / m.sup.2, a CD strength of 190 g / inch and a thickness of 0.5 mm. Three sheets thereof were laminated to form a compounded sheet.

[0084] (Specification of the Corrugated Surface Sheet (A) Formed with Connecting Parts)

[0085] The multi-row mold 11 (See FIG. 5) where the height h1 of the convex rib 11a was 5 mm and the interval Win the transverse direction was 5 mm and the convex mold 12 (See FIG. 6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| elongation percentage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com