Shaft seal structure for automobile

A technology for shaft seals and automobiles, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of seal failure and easy wear of packing, and achieve the effect of increasing sealing performance, smooth sliding, and avoiding pressure rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

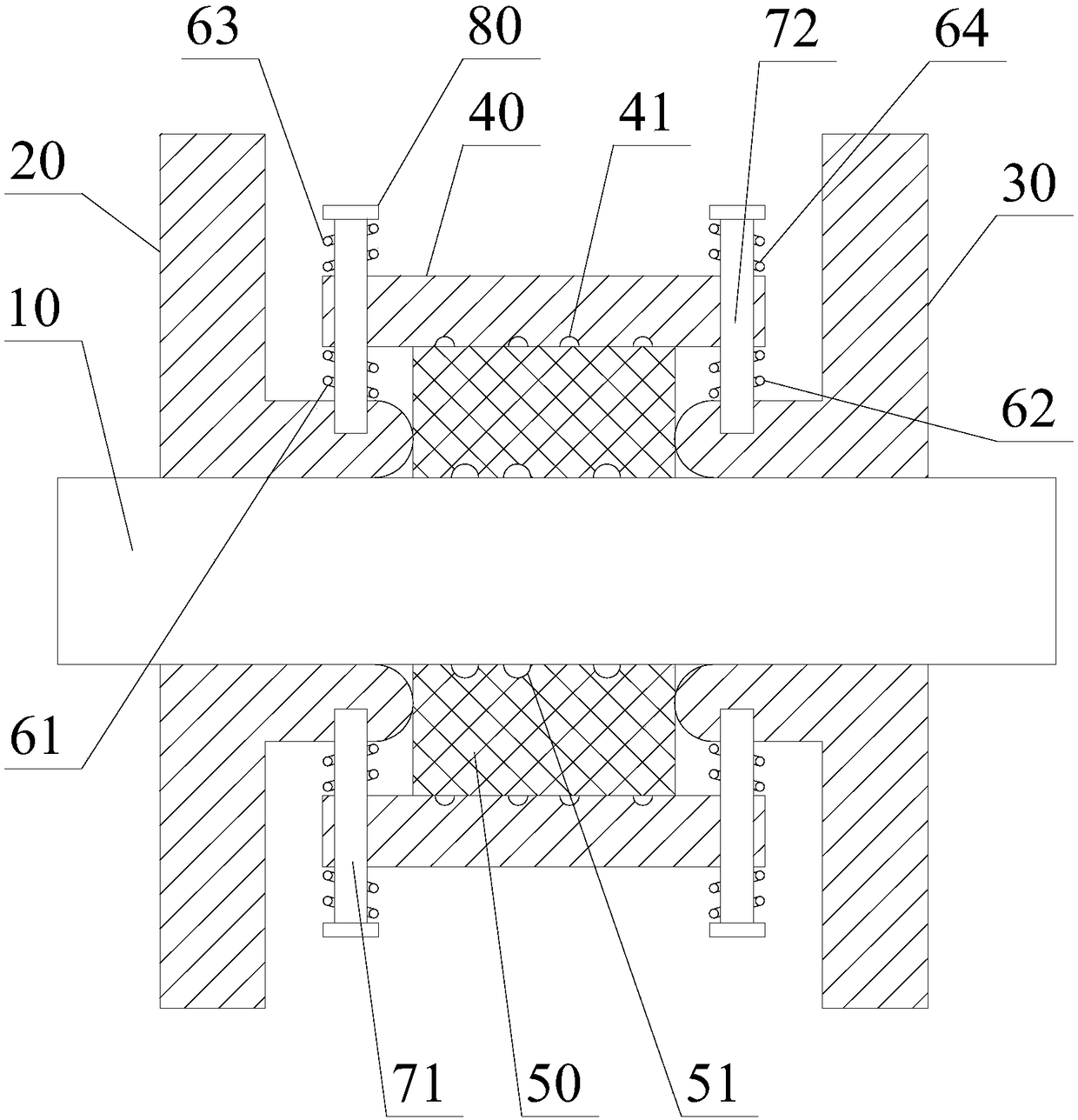

[0030] like figure 1 As shown, the shaft sealing structure for automobiles includes a rotating shaft 10, a left sealing cylinder 20, a right sealing cylinder 30, a middle sealing cylinder 40, a sealing cylinder 50, a first spring 61, a second spring 62, a third spring 63, a Four springs 64, the first fixing bolt 71, the second fixing bolt 72 and the nut 80;

[0031] The middle sealing cylinder 40 is sleeved on the rotating shaft 10, and there is an annular sealing space between the middle sealing cylinder 40 and the rotating shaft 10; the left sealing cylinder 20 and the right sealing cylinder 30 are both sleeved on the rotating shaft 10. On the rotating shaft 10, the left sealing cylinder 20 and the right sealing cylinder 30 are respectively located on the left side and the right side of the middle sealing cylinder 40; one end of the left sealing cylinder 20 and the right sealing cylinder 30 both extend into the In the sealed space; the sealed cylinder 50 is sleeved on the r...

Embodiment 2

[0037] like figure 1 As shown, this embodiment is based on Embodiment 1, and the inner surface of the middle sealing cylinder 40 is provided with a plurality of annular grooves 41 extending around the axis of the rotating shaft 10 .

[0038] An annular groove 41 is provided, and the sealing cylinder 50 is inserted into the annular groove 41 under the action of pressure to increase the sealing performance between the sealing cylinder 50 and the inner surface of the middle sealing cylinder 40 .

Embodiment 3

[0040] like figure 1 As shown, in this embodiment, on the basis of Embodiment 1 or 2, one end face of the left sealing cylinder 20 extending into the sealed space is a protruding arc surface;

[0041] One end surface of the right sealing cylinder 30 extending into the sealed space is a convex arc surface.

[0042] Both the left sealing cylinder 20 and the right sealing cylinder 30 have arc surfaces without sharp corners, so as to prevent the sealing cylinder 50 from breaking due to the sharp corners at the ends of the left sealing cylinder 20 and the right sealing cylinder 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com