Functional modules for engines

A technology of functional modules and engines, which is applied in the direction of engine cooling, combustion engines, engine components, etc., can solve problems such as complex multifunctional module structures, and achieve the effect of simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

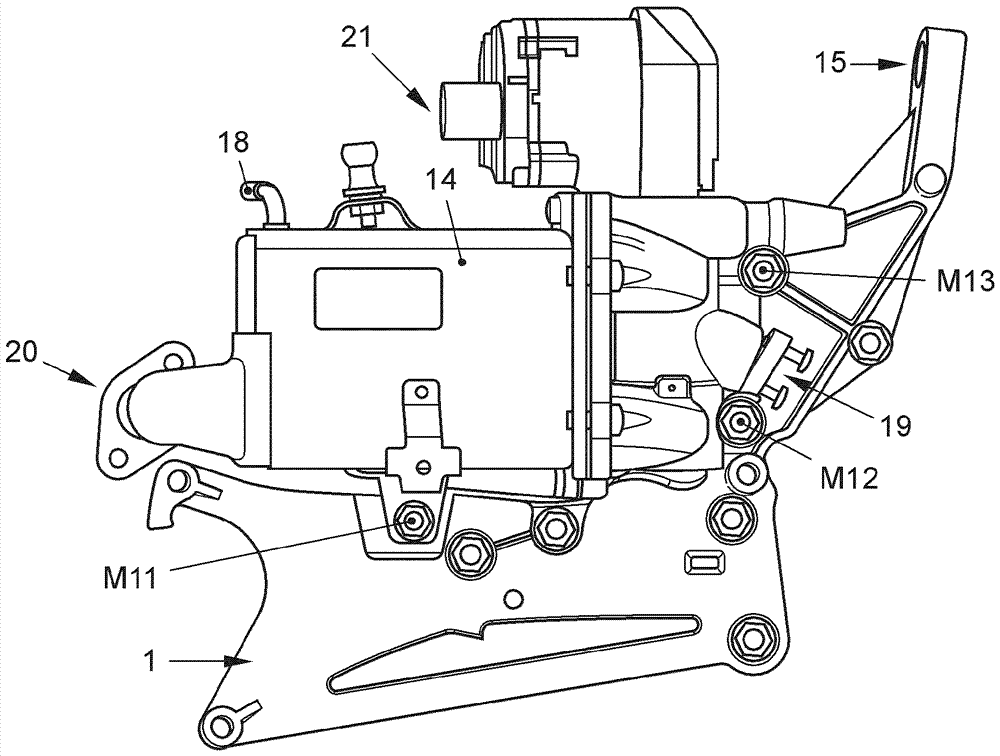

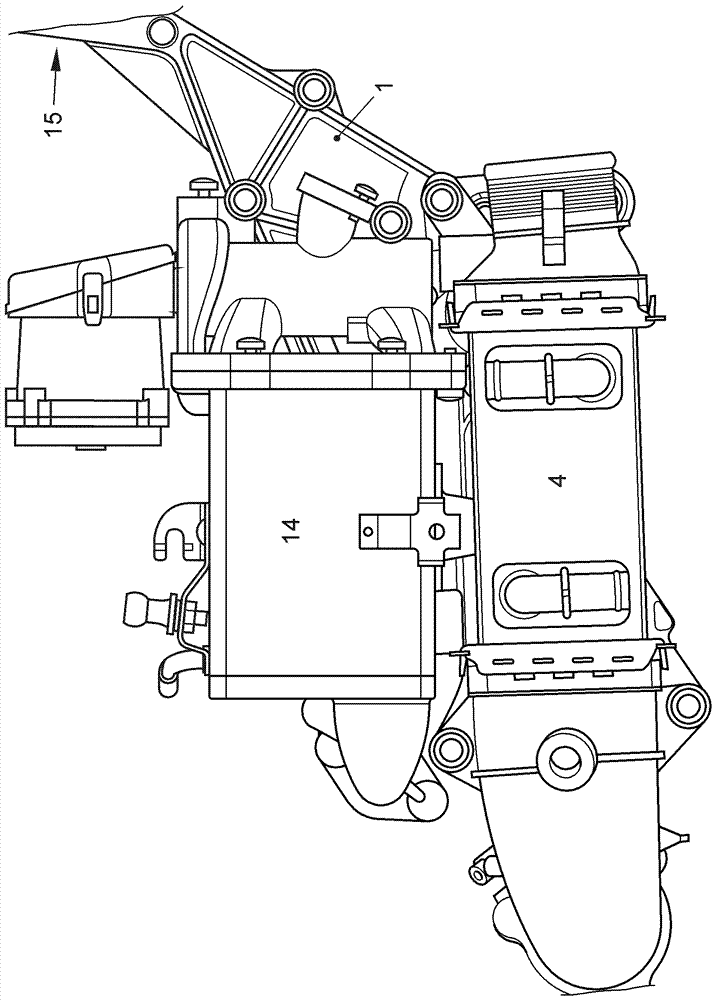

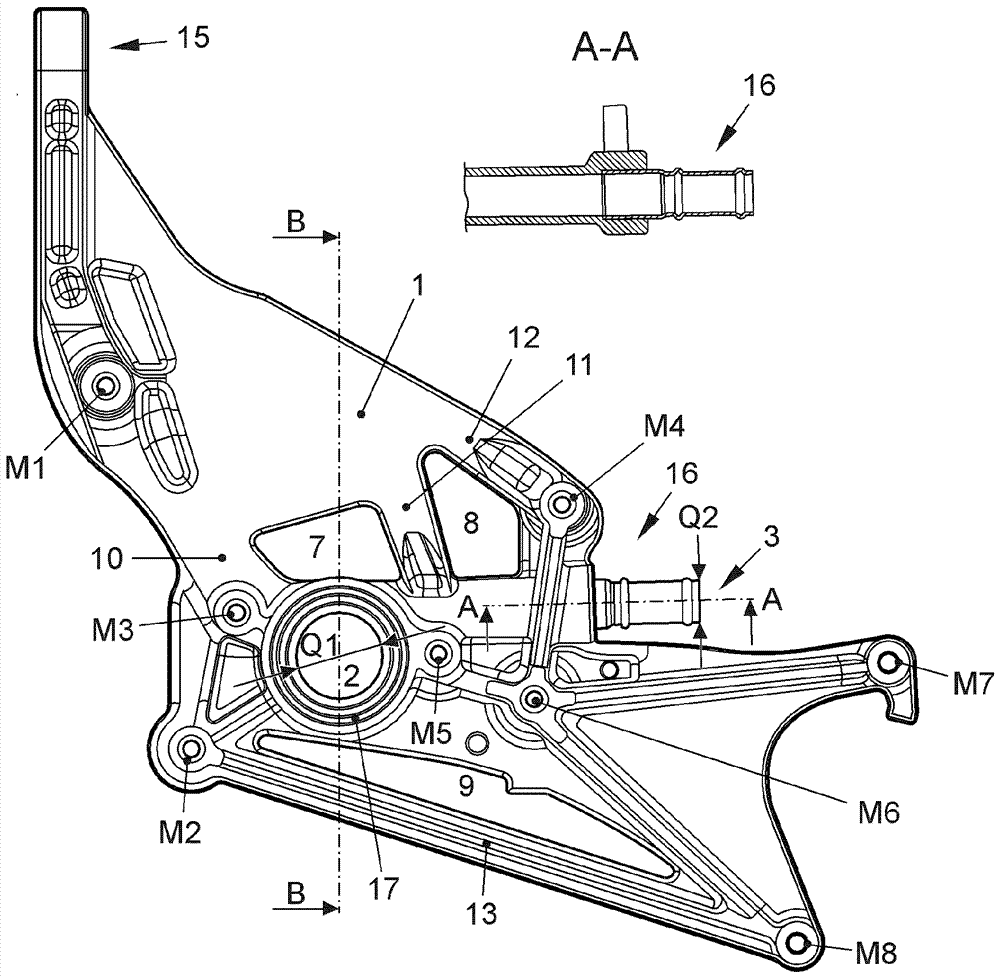

[0023] exist figure 1 The functional module 1 is shown in side view. The functional module 1 has openings 7 , 8 , 9 and supports 10 , 11 , 12 , 13 . The combination of openings and struts facilitates on the one hand and structurally more stable design of the functional module on the other hand.

[0024] The functional module 1 has a coolant inlet 2 and a coolant outlet 3 . The coolant outlet 3 is pressed in as a coolant pipe 16 and glued to the stop. As a result, no additional connection elements are required for the coolant outlet 3 in order to conduct the coolant liquid from the coolant inlet 2 to the coolant outlet 3 . The coolant inlet 2 is provided with a seal 17 . The coolant inlet 2 is connected to a not shown engine housing, preferably a cylinder head. The functional module 1 is connected to a motor, not shown here, via screw connection points M1 to M8 . The transport plate 15 is provided for the reliable handling and transport of the functional modules 1 during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com