Device and method for adjusting the working distance between a cylinder and at least one adjacent working element in a spinning preparation machine

A technology of working elements, equipment, applied in the field of spinning preparation machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

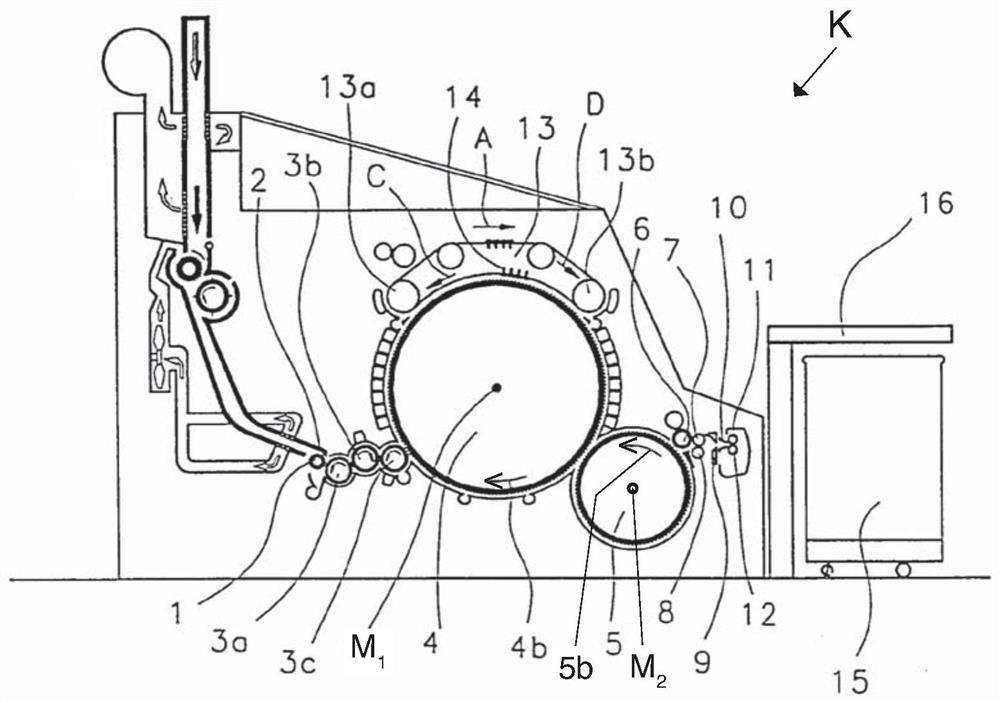

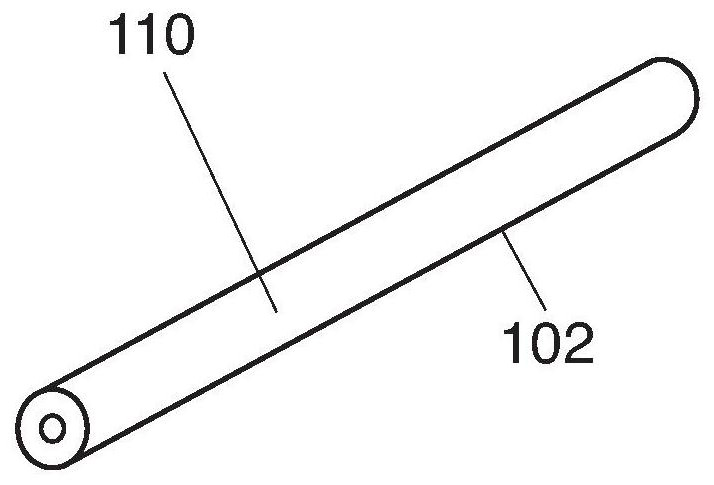

[0036] Refer below Figure 1 to Figure 8 A preferred embodiment of the device 100 according to the invention is described, which is intended for use on spinning preparation machines (eg carding or carding machines) for cotton, man-made fibers or the like. Identical features in the figures are each provided with the same reference numerals. It should be understood at this point that the figures are only shown simplified and in particular not to scale. The device 100 can be used to adjust the working distance between a clothing-clad cylinder (cylinder) and a working element arranged adjacent to the cylinder in a spinning preparation machine, as will be explained in more detail below.

[0037] The spinning preparation machine in which the device 100 according to the invention is used may be a card K, which is figure 1 Shown in side view. Such a card K comprises a feed roller 1, a feed table 2, licker-in rollers 3a, 3b, 3c, a cylinder 4 (=needle cylinder), working elements in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com