Static and dynamic composite sealing structure and method for rotary machine rotor

A composite sealing and rotating machinery technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of limited use and poor economical use, reduce temperature rise, avoid short circuit or corrosion, and improve sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

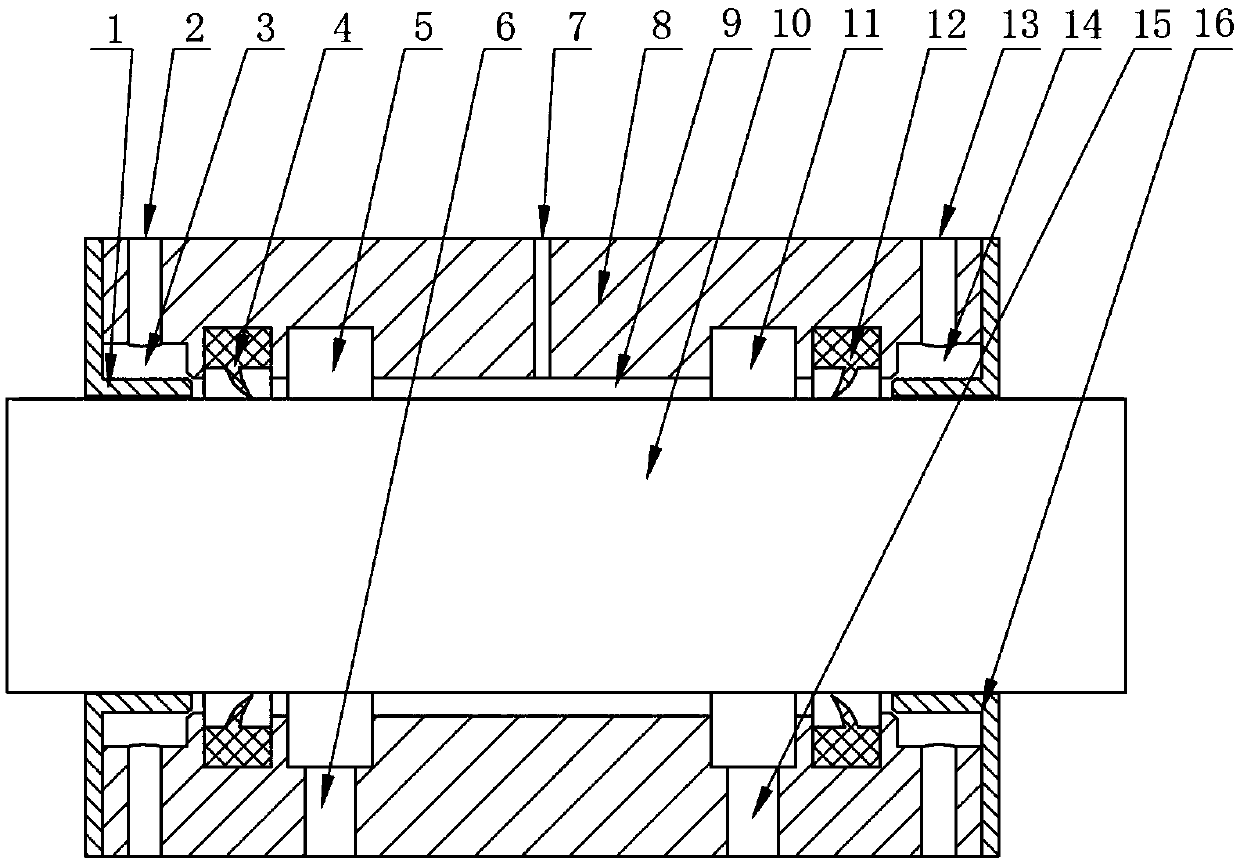

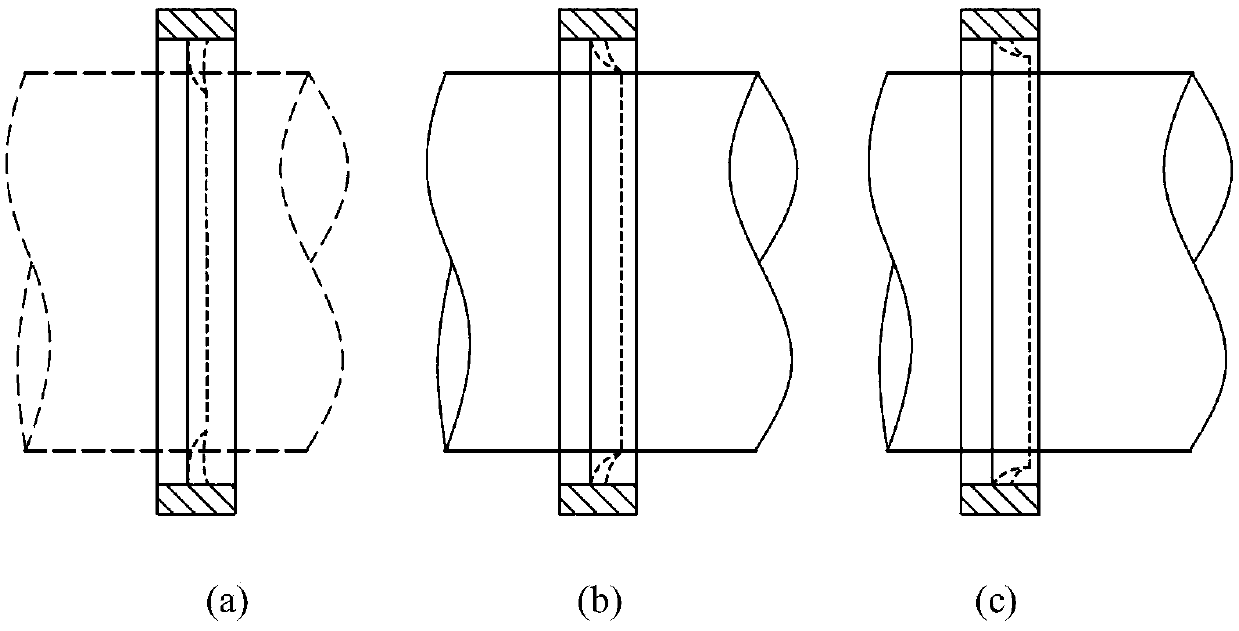

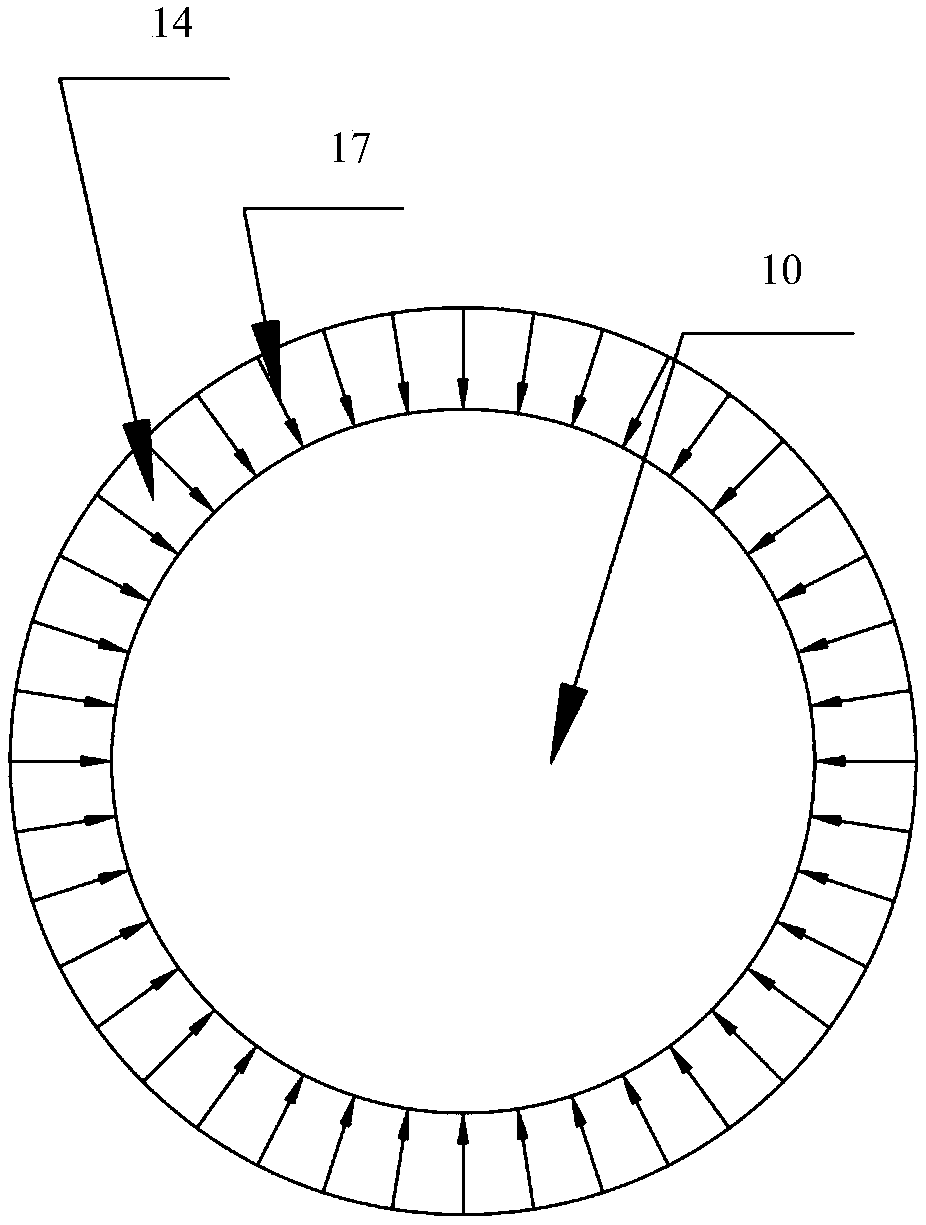

[0022] Such as figure 1 As shown, the two ends of the sliding bearing are provided with a left annular oil return groove 5 and a right annular oil return groove 11, and a left lip seal ring 4 and a right lip seal ring are arranged on the outer sides of the left annular oil return groove 5 and the right annular oil return groove 11 respectively. 12. On the outside of the left lip seal ring 4 and the right lip seal ring 12, there are left slit annular air pressure chamber 3, right slit annular air pressure chamber 14, left slit annular air pressure chamber 3, and right slit annular air pressure chamber 14 is connected with the external high-pressure air source by air inlet. Before the rotor is started, the left lip seal ring 4 and the right lip seal ring 12 are tightly attached to the rotor to prevent the lubricating fluid flowing out from the bearing gap from flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com