Method for producing fiber reinforced plastic pressure container

The technology of a pressure vessel and a production method, which is applied in the production field of glass fiber reinforced plastic pressure vessels, can solve problems such as poor pressure bearing performance, and achieve the effects of high product qualification rate and high process productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

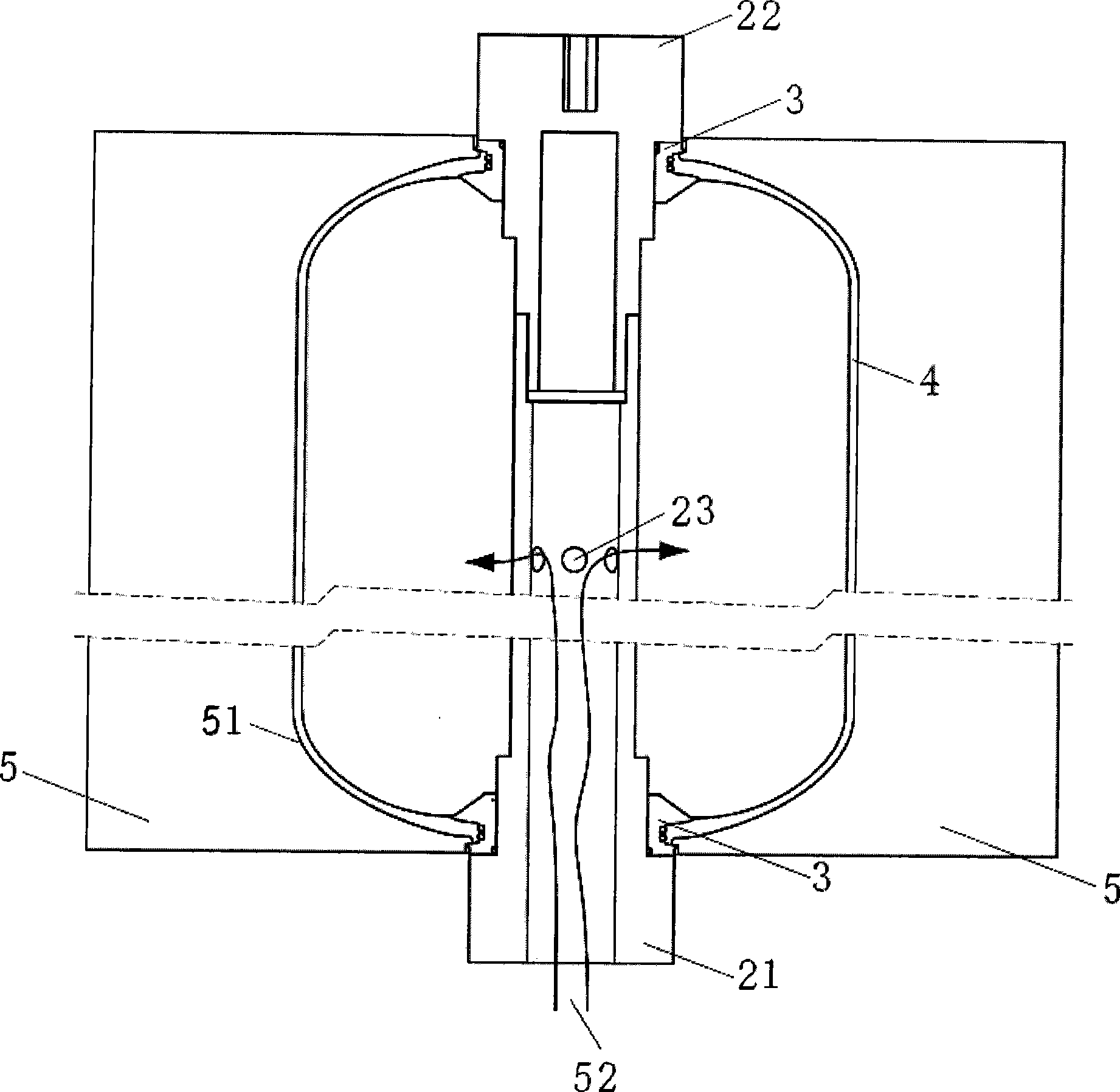

[0028] Such as Figure 3-4 As shown, the screw (ie, threaded joint) in the production method of the FRP pressure vessel of this embodiment is different from the general screw in the prior art. The outer middle part of the screw 3 has a sealing groove 31 for accommodating sealing components. The sealing part is made of elastic material, and it is placed in the sealing groove 31 corresponding to the screw port 3 before the neck of the inner tank is formed. Between the mouth and neck. The neck of the liner mouth compresses the sealing component into the sealing groove 31 on the screw 3, and because of the sealing property of the sealing component, a seal is formed between the inside and the outside of the pressure vessel.

[0029] Two main tools are applied in the present invention, one is a blow mold 5, and the other is a segmented blowing needle 2. Let's introduce it first.

[0030] The blow mold 5 includes two left and right cavities, and the inner contour 51 of the cavity ...

Embodiment 2

[0034] The screw port in Embodiment 2 is a common screw port in the prior art, so the steps of this embodiment are basically the same as those in Embodiment 1. The difference is that when the injection-molded preformed threaded interface 3 is respectively fixed on the uppermost blowing needle 22 and the lowermost blowing needle 21 , there is no need to attach a sealing member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com